Академический Документы

Профессиональный Документы

Культура Документы

Back Up Rings

Загружено:

J.SIVIRAАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Back Up Rings

Загружено:

J.SIVIRAАвторское право:

Доступные форматы

Back-Up Rings

5700 Handbook

Parker O-Ring Handbook

Section VI

Back-Up Rings

6.1 Introduction ............................................................................................................................................. 6-2

6.2 Anti-Extrusion Device Design Hints ...................................................................................................... 6-2

6.3 Parbak Elastomer Back-Up Rings ......................................................................................................... 6-2

6.4 Other Back-Up Ring Materials ............................................................................................................... 6-3

6.4.1 Polytetrafluoroethylene (PTFE) Back-Up Rings .......................................................................... 6-3

6.4.2 Metal Non-Extrusion Rings........................................................................................................... 6-3

6.4.3 Leather Back-Up Rings ................................................................................................................. 6-3

6.5 Parbak Compound Information ............................................................................................................... 6-3

6.6 Parker Parbak 8-Series Dimensions ........................................................................................................ 6-3

Parbak is a registered trademark of Parker Hannifin Corporation.

6-1

Seals

Build With The Best!

Parker Hannifin Corporation O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 Fax: (859) 335-5128

www.parker.com/o-ring

Back-Up Rings

5700 Handbook

Parker O-Ring Handbook

Parbaks are contoured on one face to minimize distortion of

the O-ring when under pressure, yet the orientation of the

contoured face is immaterial to the proper function of the

part because it is flexible.

Back-Up Rings

Parbaks are quick and easy to assemble, minimizing assembly costs, and they cannot fall out of the O-ring groove.

Besides their advantages as antiextrusion devices, Parbak

rings help trap lubricant, preserving the O-ring.

The standard sizes are listed in Table 6-1. Refer to the

appropriate Design Chart for recommended groove width.

Special sizes are also made to order.

6.2 Anti-Extrusion Device Design Hints

6.1 Introduction

1.

Parbak back-up rings offered by Parker Seal help prevent

extrusion in high pressure service or compensate for loose

fitting parts. The use of loose fitting parts makes for cost

reduction in the machining of unit components.

The 90 durometer curve in Figure 3-2 may be used to find

the maximum recommended clearance at a given pressure

for temperatures up to 74C (165F) when standard Parbak

rings in Parkers N0300-90 nitrile compound are used to

protect an O-ring from extrusion. In using these curves, it

must be remembered that cylinders tend to expand when

pressurized. The clearance that the Parbak will see is the

clearance between the piston and the expanded cylinder.

The extrusion curves can be used in two different ways to

reap the benefits of Parbaks, depending on the application.

In low pressure seals, the curves will indicate wider permissible clearances than those given in the design charts.

Tolerances on these can be opened up until they permit

these larger clearances to occur, resulting in substantial

machining economies. When tolerances are increased, however, one must check to be sure that squeeze values cannot

become too high or too low.

In high pressure applications, the curves will indicate

whether adding a Parbak will permit the use of standard

catalog gland dimensions or whether the clearance will

need to be reduced further.

In double acting seal assemblies, a Parbak is required on

both sides of the O-ring. It is cheap insurance to use two

Parbaks even in single acting installations. At assembly, it

is too easy to place a single Parbak on the wrong side of the

O-ring. By specifying one on each side of the O-ring, there

will be one on the low pressure side, where it is needed, and

the extra Parbak does no harm.

Unlike many PTFE back-up rings, Parbak rings are continuous; i.e. they do not have a cut because they can be

stretched over the end of a piston to assemble. Hence they

contact the mating O-ring uniformly, and do not cause localized wear spots.

Parbak is a registered trademark of Parker Hannifin Corporation.

2.

3.

4.

5.

Wherever possible use two back-up rings, one on

each side of the O-ring.

If only one back-up ring is used, the O-ring should

be placed between it and the pressure.

Parbaks may be installed with the contoured face

either against the O-ring or against the side of the

groove, but reversal does no harm.

Parkers Parbaks will not collapse or cold flow if

used with proper groove designs.

Use groove widths given in the Static O-Ring Sealing and Dynamic O-Ring Sealing Sections.

6.3 Parbak Elastomer Back-Up Rings

Hard rubber back-up rings combine most of the best features of both leather and PTFE anti-extrusion devices.

Although no industrial or military standards have been

issued for rubber back-up rings, they have been in use for

a number of years. These are special devices designed to

satisfy a specific problem.

Parbaks in Parker Seal Groups standard nitrile compound,

N0300-90, are generally usable through a temperature

range of -55C to 120C (-65 to 250F).

Features of Parbak Rings

1. Elastic memory permits Parbak rings to be stretched

into place for assembly without preconditioning or

cutting.

2. Continuous construction prevents damage to the

O-ring seal.

3. Lubrication is enhanced by rubber which absorbs

system fluid and does not plate out on rubbing surfaces.

Parbak is a Parker standard rubber back-up ring of

contoured design. It is intended for use in dynamic and

static seal applications, in O-ring glands depicted in the

tables in the Static O-Ring Sealing and Dynamic O-Ring

Sealing Sections. When used in standard static glands, a

generous lead-in chamfer and lubrication are particularly

important to facilitate assembly. In some cases increased

gland depth may be appropriate.

6-2

Seals

Build With The Best!

Parker Hannifin Corporation O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 Fax: (859) 335-5128

www.parker.com/o-ring

Back-Up Rings

5700 Handbook

Parker O-Ring Handbook

6.4 Other Back-Up Ring Materials

6.4.1 Polytetrafluoroethylene (PTFE) Back-Up

Rings

Anti-extrusion rings made from tetrafluoroethylene are

impervious to oils and solvents. Acids and inorganic salts

have very little effect on PTFE resin. In addition to its good

chemical resistance, PTFE may be used over a wide temperature range, from below -73C to over 204C (-100F to

over 400F). Thus, PTFE back-up rings may be used with

most elastomeric O-ring seals. For installation, PTFE backup rings are supplied either scarf or spiral cut as shown in

Figure 6-1. These discontinuities may contribute to seal

damage due to biting and pinching. PTFE can also impair

seal lubrication by plating rubbing surfaces with PTFE

resin to which lubricating oil will not adhere.

6.4.2 Metal Non-Extrusion Rings

In most cases it will be impracticable and unnecessary

(under 1380 bar; 20,000 PSI) to design bolt and rivet seal

glands that are self-tightening, i.e., tending to reduce rather

than increase seal extrusion clearance as pressure increases.

Adequate gland volume should be allowed, in keeping with

assembly tolerances. Two designs that have been helpful in

alleviating extrusion of bolt and similar ultra high pressure

seals are shown in Figure 6-2.

6.4.3 Leather Back-Up Rings

ultra smooth, wax-like surface results. Because an O-ring

may wipe all lubrication from such a surface, reverse

stroking is dry and greatly reduces seal life. Parbaks of

N0300-90 and other rubber compounds solve this problem.

They do not leave a deposit on the metal surface, thus

lubrication remains.

The standard compound for Parbaks is N0300-90. Careful

engineering and research has produced N0300-90 which

has the best combination of characteristics for the majority

of back-up ring installations broad temperature range,

proper hardness, long sealing life, and resistance to a great

number of fluids. It is resistant to nearly all hydraulic fluids

except certain of the non-flammable types such as Skydrol.

It is also resistant to air and water.

The recommended temperature range for N0300-90 is from

-40C to 121C (-40F to 250F).

Functional tests have proven that millions of cycles can be

obtained with Parbaks, showing their tremendous superiority over the older types of back-up rings.

In addition to N0300-90, Parker Seal has developed other

compounds for installations requiring special characteristics. Present capabilities include service at continuous

temperatures as high as 204C (400F).

Additional assistance in specifing and using Parbak rings is

available upon request by calling your Parker Seal representative.

Leather has been a standard back-up ring material for many

years. Manufacturers of these rings have developed special

processing methods and impregnations for different types

of applications. Standard sizes have been established for

use with all standard O-rings. If there is any question

concerning the suitability of leather for the application,

consult the supplier. Leather back-up rings are manufactured as continuous rings and in most cases must be stretched

during installation. Less damage will be incurred to the

back-up rings if they are soaked in oil before installation.

After installation, a short exposure to heat will shrink the

leather rings back to size. Leather back-up rings should

never be cut to facilitate installation.

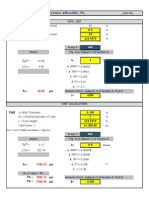

6.6 Parker Parbak 8-Series Dimensions

6.5 Parbak Compound Information

Table 6-1 provides Parker Parbak 8-Series Dimensions.

Developed primarily for service in petroleum base hydraulic fluids, at -40C to 121C (-40F to 250F), Parkers

standard Parbak compound N0300-90 provides the maximum benefits in back-up ring service. Compounds for use

in other fluids and for temperatures up to 204C (400F) are

available on request.

Parbaks will stretch up to 50%, and are quickly and easily

installed. Advantages of the contour design are obtained

regardless of how Parbaks are installed. They may be

installed with the concave face in either direction, toward

or away from the O-ring.

Some back-up ring materials tend to leave deposits in the

micro fine grooves of the surface on which they rub. An

Thin Metal Section Will Expand

Due to Pressure and Maintain

Metal-to-Metal Fit

7 to 10

Scarf Cut

Spiral

Figure 6-1: Typical Back-Up Rings

Parbak

Figure 6-2: Clearance Control for High Pressure Seals

6-3

Seals

Soft Metal AntiExtrusion Wedge Ring

Build With The Best!

Parker Hannifin Corporation O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 Fax: (859) 335-5128

www.parker.com/o-ring

Back-Up Rings

5700 Handbook

Parker O-Ring Handbook

Parker Parbak 8-Series Dimensions

T Ref.

A

A

I.D.

R

.010 R. Max.

Section W-W

Developed primarily for service in petroleum base hydraulic fluids, at 4C to 121C (-40F to 250F), Parker's

standard Parbak compound N0300-90, provides the maximum benefits in back-up ring service. Compounds for use

in other fluids and for temperatures up to 204C (400F) are

available on request.

Dash I.D.

No. (in.)

004

005

006

007

008

.096

.127

.140

.171

.202

009

010

011

012

013

.234

.265

.327

.390

.455

014

015

016

017

018

.518

.580

.643

.705

.768

019

020

021

022

023

.830

.893

.955

1.018

1.080

024

025

026

027

028

Tol.

R

T

A

.010 (Ref.) (in.)

.005

.087

.049

.045

Tol.

W

(in.)

.003

.053

Tol.

.003

Parbaks will stretch up to 50%, and are quickly and easily

installed. Advantages of the contour design are obtained

regardless of how Parbaks are installed they may be

installed with the concave face in either direction, toward

or away from the O-ring.

Dash I.D.

No. (in.)

Tol.

R

T

A

.010 (Ref.) (in.)

041

042

043

044

045

3.018

3.268

3.518

3.768

4.018

.240

.024

.024

.027

.027

046

047

048

049

050

4.268

4.518

4.768

5.018

5.268

102

103

104

105

106

.077

.109

.140

.171

.202

.009

.010

.010

107

108

109

110

111

.234

.265

.327

.390

.452

1.143

1.205

1.268

1.330

1.393

.010

.011

.011

.011

.013

112

113

114

115

116

.515

.577

.640

.702

.765

.005

.007

.009

.009

.009

029

030

031

032

033

1.518

1.643

1.768

1.893

2.018

.013

.013

.015

.015

.018

117

118

119

120

121

.831

.893

.956

1.018

1.081

.100

034

035

036

037

038

2.143

2.268

2.393

2.518

2.643

1.143

1.206

1.268

1.331

1.393

.010

.012

.018

.200

122

123

124

125

126

039

040

2.768

2.893

.200

.200

127

128

1.456

1.518

.005

.007

.009

.087

.049

.045

.003

.053

.003

W

(in.)

.003

.053

.087

.049

.030

.030

.030

.037

.037

.087

.049

.053

.005

.129

.053

.086

.129

.053

.012

.045

Tol.

.045

.003

.086

Tol.

.003

.003

Notes: 1. Parbak sizes are designed to correspond with the Parker 2-xxx, 3-xxx and AS568A series O-ring with which they are used.

2. Complete call-out consists of the digit 8, the dash number for the size wanted and the rubber material.

Example: N0300-90 8-009.

Table 6-1: Parker Parbak 8-Series Dimensions

6-4

Seals

Build With The Best!

Parker Hannifin Corporation O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 Fax: (859) 335-5128

www.parker.com/o-ring

Back-Up Rings

5700 Handbook

Parker O-Ring Handbook

Parker Parbak 8-Series Dimensions Continued

Dash I.D.

No. (in.)

Tol.

R

T

A

.010 (Ref.) (in.)

.015

.129

.053

.045

Tol.

W

(in.)

.003

.086

Tol.

129

130

131

1.581

1.643

1.706

.003

132

133

134

135

136

1.768

1.831

1.893

1.956

2.018

137

138

139

140

141

2.081

2.143

2.206

2.268

2.331

142

143

144

145

146

2.393

2.456

2.518

2.581

2.643

147

148

149

150

151

2.706

2.768

2.831

2.893

3.018

.022

152

153

154

155

156

3.268

3.518

3.768

4.018

4.268

.024

.024

.028

.028

.030

157

158

159

160

161

4.518

4.768

5.018

5.268

5.518

.030

.030

.035

162

163

164

165

166

5.768

6.018

6.268

6.518

6.768

167

168

169

170

171

7.018

7.268

7.518

7.768

8.018

.040

.045

172

173

174

175

176

8.268

8.518

8.768

9.018

9.268

.050

177

178

9.518

9.768

.055

.055

.129

.053

.045

.086

.003

201

202

203

204

205

.202

.265

.327

.390

.455

.005

.174

.050

.040

.118

.004

.015

.015

.017

.017

.017

.017

.020

.020

.022

.024

.035

.040

.045

.050

.055

.005

.174

.050

.040

.003

.118

.004

Dash I.D.

No. (in.)

Tol.

R

T

A

.010 (Ref.) (in.)

206

207

208

209

210

.518

.580

.643

.705

.766

.005

.007

.009

.009

.010

211

212

213

214

215

.828

.891

.953

1.016

1.078

.010

.010

216

217

218

219

220

1.141

1.203

1.266

1.334

1.397

.012

221

222

223

224

225

1.459

1.522

1.647

1.772

1.897

.012

.015

.015

.015

.018

226

227

228

229

230

2.022

2.147

2.272

2.397

2.522

.018

.018

.020

.020

.020

231

232

233

234

235

2.631

2.756

2.881

3.006

3.131

.020

.024

236

237

238

239

240

3.256

3.381

3.506

3.631

3.756

241

242

243

244

245

3.881

4.006

4.131

4.256

4.381

246

247

248

249

250

4.506

4.631

4.768

4.893

5.018

251

252

253

254

255

5.143

5.268

5.393

5.518

5.643

256

257

258

259

260

5.768

5.893

6.018

6.268

6.518

.035

.040

.040

261

6.768

.040

Tol.

W

(in.)

Tol.

.174

.050

.040

.003

.118

.004

.174

.050

.040

.003

.118

.004

.024

.028

.028

.030

.030

.035

Notes: 1. Parbak sizes are designed to correspond with the Parker 2-xxx, 3-xxx and AS568A series O-ring with which they are used.

2. Complete call-out consists of the digit 8, the dash number for the size wanted and the rubber material.

Example: N0300-90 8-009.

Table 6-1: Parker Parbak 8-Series Dimensions

6-5

Seals

Build With The Best!

Parker Hannifin Corporation O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 Fax: (859) 335-5128

www.parker.com/o-ring

Back-Up Rings

5700 Handbook

Parker O-Ring Handbook

Parker Parbak 8-Series Dimensions Continued

Dash I.D.

No. (in.)

Tol.

R

T

A

.010 (Ref.) (in.)

Tol.

W

(in.)

.003

.118

Tol.

Dash I.D.

No. (in.)

Tol.

R

T

A

.010 (Ref.) (in.)

341

342

343

344

345

3.523

3.648

3.773

3.898

4.028

.024

.028

4.153

4.278

4.403

4.528

4.653

.028

.030

.050

.055

346

347

348

349

350

.055

.055

.055

.055

.065

351

352

353

354

355

4.778

4.903

5.028

5.153

5.278

11.518

12.018

13.018

14.018

15.018

5.403

5.528

5.653

5.778

5.903

.037

.065

356

357

358

359

360

282 15.989

283 16.989

284 17.989

.075

.080

.085

.450

.513

.575

.638

.700

.005

.005

.007

.009

.009

6.028

6.278

6.528

6.778

7.028

.037

.040

309

310

311

312

313

361

362

363

364

365

.763

.825

.888

.950

1.013

.010

7.278

7.528

7.778

8.028

8.278

.045

314

315

316

317

318

366

367

368

369

370

319

320

321

322

323

1.075

1.138

1.200

1.263

1.316

.010

.012

.012

.012

.012

371

372

373

374

375

8.528

8.778

9.028

9.278

9.528

324

325

326

327

328

1.388

1.513

1.638

1.763

1.888

.012

.015

376

377

378

379

380

9.778

10.028

10.528

11.028

11.528

.055

.060

.060

.065

329

330

331

332

333

2.013

2.138

2.268

2.393

2.518

.018

381

382

383

384

385

12.028

13.028

14.028

15.028

16.008

.065

.065

.070

.070

.075

334

335

336

337

338

2.643

2.768

2.893

3.018

3.143

.020

.020

.020

.024

386

387

388

389

390

17.008

18.008

19.006

20.006

21.006

.080

.085

.090

.095

.095

339

340

3.273

3.398

391

392

393

394

395

22.006

22.993

23.993

24.993

25.993

.100

.105

.110

.115

.120

262

263

264

265

266

7.018

7.268

7.518

7.768

8.018

.040

.045

267

268

269

270

271

8.268

8.518

8.768

9.018

9.268

.050

272 9.518

273 9.768

274 10.018

275 10.518

276 11.018

277

278

279

280

281

.174

.050

.040

.004

.045

.174

.050

.040

.003

.118

.004

.262

.076

.060

.004

.183

.005

.015

.018

.020

.024

.262

.076

.060

.004

.183

.005

Tol.

W

(in.)

Tol.

.262

.076

.060

.004

.183

.005

.262

.076

.060

.004

.183

.005

.030

.037

.037

.037

.040

.045

.050

.050

.055

Notes: 1. Parbak sizes are designed to correspond with the Parker 2-xxx, 3-xxx and AS568A series O-ring with which they are used.

2. Complete call-out consists of the digit 8, the dash number for the size wanted and the rubber material.

Example: N0300-90 8-009.

Table 6-1: Parker Parbak 8-Series Dimensions

6-6

Seals

Build With The Best!

Parker Hannifin Corporation O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 Fax: (859) 335-5128

www.parker.com/o-ring

Back-Up Rings

5700 Handbook

Parker O-Ring Handbook

Parker Parbak 8-Series Dimensions Continued

Dash I.D.

No. (in.)

425

426

427

428

429

4.551

4.676

4.801

4.926

5.051

430

431

432

433

434

Tol.

R

T

A

.010 (Ref.) (in.)

.033

.344

.117

.096

Tol.

W

(in.)

Tol.

.005

.236

.006

Dash I.D.

No. (in.)

Tol.

R

T

A

.010 (Ref.) (in.)

451

452

453

454

455

11.024

11.524

12.024

12.524

13.024

5.176

5.301

5.426

5.551

5.676

456

457

458

459

460

13.524

14.024

14.524

15.024

15.524

.070

435

436

437

438

439

5.801

5.926

6.051

6.274

6.524

461

462

463

464

465

16.004

16.504

17.004

17.504

18.004

.075

.075

.080

.085

.085

440

441

442

443

444

6.774

7.024

7.274

7.524

7.774

466

467

468

469

470

18.504

19.004

19.504

20.004

21.004

.085

.090

.090

.095

.095

471

472

473

474

475

22.004

23.004

24.004

25.004

26.004

.100

.105

.110

.115

.120

.033

.037

.037

.040

.040

.045

445 8.024

446 8.524

447 9.024

448 9.524

449 10.024

.045

.055

450 10.524

.060

.055

.344

.117

.096

.005

.236

.060

Tol.

W

(in.)

Tol.

.344

.117

.096

.005

.236

.006

.344

.117

.096

.005

.236

.006

.060

.070

.006

Notes: 1. Parbak sizes are designed to correspond with the Parker 2-xxx, 3-xxx and AS568A series O-ring with which they are used.

2. Complete call-out consists of the digit 8, the dash number for the size wanted and the rubber material.

Example: N0300-90 8-009.

Table 6-1: Parker Parbak 8-Series Dimensions

6-7

Seals

Build With The Best!

Parker Hannifin Corporation O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 Fax: (859) 335-5128

www.parker.com/o-ring

Back-Up Rings

5700 Handbook

Parker O-Ring Handbook

Back-Up Rings Cross Reference

This cross reference chart is to be utilized when considering the use of Parkers Parbak back-up rings as a retrofit for a

PTFE or leather back-up. Keep in mind, there is not a military specification that pertains to Parkers Parbak series backup rings. This chart is intended as a retrofit guideline only.

Parker

N0300-90

Parker

Parbak

Size No.*1

8-004

8-005

8-006

8-007

8-008

8-009

8-010

8-011

8-012

8-013

MIL-R-5521 MIL-R-8791 MIL-R-8791 MIL-R-5521

Parker

Leather

PTFE

PTFE

Leather

N0300-90

AN62441

AN62461

MS275951

MS287742

Dash No.

AN6246-1

AN6246-2

AN6246-3

-004

-005

-006

-007

-008

AN6246-4

AN6246-5

AN6246-6

AN6246-7

-009

-010

-011

-012

-013

MS287823

MS287833

MS358031

Dash No.

MS28782-1

MS28782-2

MS28782-3

-6

-7

-8

MS28782-4

MS28782-5

MS28782-6

MS28782-7

-9

-10

-11

-12

Parker

Parbak

Size No.*1

MIL-R-5521 MIL-R-8791 MIL-R-8791 MIL-R-5521

Leather

PTFE

PTFE

Leather

MS275951

MS287742

Dash No.

AN62441

AN62461

8-130

8-131

8-132

8-133

8-134

-130

-131

-132

-133

-134

8-135

8-136

8-137

8-138

8-139

-135

-136

-137

-138

-139

MS287823

MS287833

MS358031

Dash No.

8-014

8-015

8-016

8-017

8-018

-014

-015

-016

-017

-018

8-140

8-141

8-142

8-143

8-144

-140

-141

-142

-143

-144

8-019

8-020

8-021

8-022

8-023

-019

-020

-021

-022

-023

8-145

8-146

8-147

8-148

8-149

-145

-146

-147

-148

-149

8-024

8-025

8-026

8-027

8-028

-024

-025

-026

-027

-028

8-210

8-211

8-212

8-213

8-214

AN6246-15

AN6246-16

AN6246-17

AN6246-18

AN6246-19

-210

-211

-212

-213

-214

MS28782-15

MS28782-16

MS28782-17

MS28782-18

MS28782-19

-210

-211

-212

-213

-214

8-110

8-111

8-112

8-113

8-114

AN6246-8

AN6246-9

AN6246-10

AN6246-11

AN6246-12

-110

-111

-112

-113

-114

MS28782-8

MS28782-9

MS28782-10

MS28782-11

MS28782-12

-110

-111

-112

-113

-114

8-215

8-216

8-217

8-218

8-219

AN6246-20

AN6246-21

AN6246-22

AN6246-23

AN6246-24

-215

-216

-217

-218

-219

MS28782-20

MS28782-21

MS28782-22

MS28782-23

MS28782-24

-215

-216

-217

-218

-219

8-115

8-116

8-117

8-118

8-119

AN6246-13

AN6246-14

-115

-116

-117

-118

-119

MS28782-13

MS28782-14

-115

-116

8-220

8-221

8-222

8-223

8-224

AN6246-25

AN6246-26

AN6246-27

AN6244-1

AN6244-2

-220

-221

-222

-223

-224

MS28782-25

MS28782-26

MS28782-27

MS28783-1

MS28783-2

-220

-221

-222

-223

-224

8-120

8-121

8-122

8-123

8-124

-120

-121

-122

-123

-124

8-225

8-226

8-227

8-228

8-229

AN6244-3

AN6244-4

AN6244-5

AN6244-6

AN6244-7

-225

-226

-227

-228

-229

MS28783-3

MS28783-4

MS28783-5

MS28783-6

MS28783-7

-225

-226

-227

-228

-229

8-125

8-126

8-127

8-128

8-129

-125

-126

-127

-128

-129

8-230

8-231

8-232

8-233

8-234

AN6244-8

AN6244-9

AN6244-10

AN6244-11

AN6244-12

-230

-231

-232

-233

-234

MS28783-8

MS28783-9

MS28783-10

MS28783-11

MS28783-12

-230

-231

-232

-233

-234

*Add Parker compound number N0300-90 to complete the call out. Example: N0300-90 8-009.

Note: These corresponding part numbers do not have identical dimensions, but they are intended for use with O-rings of the same

dimensions. Parbak sizes with no corresponding military part number are not shown.

1. Continuous back-up ring.

2. Single turn, scarf cut.

3. Double turn.

Table 6-2: Back-Up Rings Cross Reference

6-8

Seals

Build With The Best!

Parker Hannifin Corporation O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 Fax: (859) 335-5128

www.parker.com/o-ring

Back-Up Rings

5700 Handbook

Parker O-Ring Handbook

Back-Up Rings Cross Reference Continued

Parker

N0300-90

Parker

MIL-R-5521 MIL-R-8791 MIL-R-8791 MIL-R-5521

N0300-90

Leather

PTFE

PTFE

Leather

MIL-R-5521 MIL-R-8791 MIL-R-8791 MIL-R-5521

Leather

PTFE

PTFE

Leather

Parker

Parbak

Size No.*1

AN62441

AN62461

MS275951

MS287742

Dash No.

MS287823

MS287833

MS358031

Dash No.

Parker

Parbak

Size No.*1

AN62441

AN62461

MS275951

MS287742

Dash No.

MS287823

MS287833

MS358031

Dash No.

8-235

8-236

8-237

8-238

8-239

AN6244-13

AN6244-14

AN6244-15

AN6244-16

AN6244-17

-235

-236

-237

-238

-239

MS28783-13

MS28783-14

MS28783-15

MS28783-16

MS28783-17

-235

-236

-237

-238

-239

8-336

8-337

8-338

8-339

8-340

AN6246-39

AN6246-40

AN6246-41

AN6246-42

AN6246-43

-336

-337

-338

-339

-340

MS28782-39

MS28782-40

MS28782-41

MS28782-42

MS28782-43

-336

-337

-338

-339

-340

8-240

8-241

8-242

8-243

8-244

AN6244-18

AN6244-19

AN6244-20

AN6244-21

AN6244-22

-240

-241

-242

-243

-244

MS28783-18

MS28783-19

MS28783-20

MS28783-21

MS28783-22

-240

-241

-242

-243

-244

8-341

8-342

8-343

8-344

8-345

AN6246-44

AN6246-45

AN6246-46

AN6246-47

AN6246-48

-341

-342

-343

-344

-345

MS28782-44

MS28782-45

MS28782-46

MS28782-47

MS28782-48

-341

-342

-343

-344

-345

8-245

8-246

8-247

8-248

8-249

AN6244-23

AN6244-24

AN6244-25

AN6244-26

AN6244-27

-245

-246

-247

MS28783-23

MS28783-24

MS28783-25

-245

-246

-247

8-346

8-347

8-348

8-349

8-425

AN6246-49

AN6246-50

AN6246-51

AN6246-52

AN6246-88

-346

-347

-348

-349

-425

MS28782-49

MS28782-50

MS28782-51

MS28782-52

MS28782-88

-346

-347

-348

-349

-425

8-250

8-251

8-252

8-253

8-254

AN6244-28

AN6244-29

AN6244-30

AN6244-31

AN6244-32

8-426

8-427

8-428

8-429

8-430

AN6246-53

AN6246-54

AN6246-55

AN6246-56

AN6246-57

-426

-427

-428

-429

-430

MS28782-53

MS28782-54

MS28782-55

MS28782-56

MS28782-57

-426

-427

-428

-429

-430

8-255

8-256

8-257

8-258

8-259

AN6244-33

AN6244-34

AN6244-35

AN6244-36

AN6244-37

8-431

8-432

8-433

8-434

8-435

AN6246-58

AN6246-59

AN6246-60

AN6246-61

AN6246-62

-431

-432

-433

-434

-435

MS28782-58

MS28782-59

MS28782-60

MS28782-61

MS28782-62

-431

-432

-433

-434

-435

8-260

8-261

8-262

8-263

8-264

AN6244-38

AN6244-39

AN6244-40

AN6244-41

AN6244-42

8-436

8-437

8-438

8-439

8-440

AN6246-63

AN6246-64

AN6246-65

AN6246-66

AN6246-67

-436

-437

-438

-439

-440

MS28782-63

MS28782-64

MS28782-65

MS28782-66

MS28782-67

-436

-437

-438

-439

-440

8-265

8-266

8-267

8-268

8-269

AN6244-43

AN6244-44

AN6244-45

AN6244-46

AN6244-47

8-441

8-442

8-443

8-444

8-445

AN6246-68

AN6246-69

AN6246-70

AN6246-71

AN6246-72

-441

-442

-443

-444

-445

MS28782-68

MS28782-69

MS28782-70

MS28782-71

MS28782-72

-441

-442

-443

-444

-445

8-270

8-271

8-272

8-273

8-274

AN6244-48

AN6244-49

AN6244-50

AN6244-51

AN6244-52

8-446

8-447

8-448

8-449

8-450

AN6246-73

AN6246-74

AN6246-75

AN6246-76

AN6246-77

-446

-447

-448

-449

-450

MS28782-73

MS28782-74

MS28782-75

MS28782-76

MS28782-77

-446

-447

-448

-449

-450

8-325

8-326

8-327

8-328

8-329

AN6246-28

AN6246-29

AN6246-30

AN6246-31

AN6246-32

-325

-326

-327

-328

-329

MS28782-28

MS28782-29

MS28782-30

MS28782-31

MS28782-32

-325

-326

-327

-328

-329

8-451

8-452

8-453

8-454

8-455

AN6246-78

AN6246-79

AN6246-80

AN6246-81

AN6246-82

-451

-452

-453

-454

-455

MS28782-78

MS28782-79

MS28782-80

MS28782-81

MS28782-82

-451

-452

-453

-454

-455

8-330

8-331

8-332

8-333

8-334

AN6246-33

AN6246-34

AN6246-35

AN6246-36

AN6246-37

-330

-331

-332

-333

-334

MS28782-33

MS28782-34

MS28782-35

MS28782-36

MS28782-37

-330

-331

-332

-333

-334

8-456

8-457

8-458

8-459

8-460

AN6246-83

AN6246-84

AN6246-85

AN6246-86

AN6246-87

-456

-457

-458

-459

-460

MS28782-83

MS28782-84

MS28782-85

MS28782-86

MS28782-87

-456

-457

-458

-459

-460

8-335

AN6246-38

-335

MS28782-38

-335

*Add Parker compound number N0300-90 to complete the call out. Example: N0300-90 8-009.

Note: These corresponding part numbers do not have identical dimensions, but they are intended for use with O-rings of the same

dimensions. Parbak sizes with no corresponding military part number are not shown.

1. Continuous back-up ring.

2. Single turn, scarf cut.

3. Double turn.

Table 6-2: Back-Up Rings Cross Reference (Continued)

6-9

Seals

Build With The Best!

Parker Hannifin Corporation O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 Fax: (859) 335-5128

www.parker.com/o-ring

Back-Up Rings

5700 Handbook

Parker O-Ring Handbook

Comparison of Parbak vs. PTFE and Leather Back-Up

Parker Parbaks

PTFE Back-Up Rings

Leather Back-Up Rings

Continuous ring.

Spiral or scarf-cut for most applications.

This discontinuity is often a cause of leaks

or damage to the O-ring.

Continuous ring.

Easiest and quickest to assemble in either

piston or cylinder groove.

Moderately simple to assemble. Scarf or

spiral cut can be opened, for assembling

over piston or doubled over itself for

assembly into cylinder groove.

Difficult to assemble over piston. Must be

soaked in oil, stretched, then pounded into

place. Less difficult to assemble into

cylinder groove.

Good resistance to extrusion. Standard

material satisfactory up to (121C) 250F.

Other compounds available for temperatures as high as (204C) 400F.

Tends to soften and extrude at temperatures around (149C) 300F.

Tends to harden and crack at high

temperature.

Does not cause overly smooth rubbing

surface. Maintains lubrication.

Deposits on rubbing surface making it

extremely smooth. The O-ring then wipes

the surface dry.

Does not cause overly smooth rubbing

surface. Maintains lubrication.

Good resistance to radiation. Can be

made in compound having even better

resistance when required.

Fair resistance to radiation.

No information available.

Continuous ring with no loose particles

or sections.

Thin sections of spiral may become lodged

under O-ring causing leakage.

Loose leather fibers may become lodged

under O-ring causing leakage.

No scarf cut to open. Coefficient of thermal

expansion comparable to O-ring material.

Low temperature shrinkage may open up

Continuous ring.

scarf cut, causing low temperature leakage.

Continuous ring, no scarf cut.

High temperature expansion may overlap

scarf cut causing damage to O-ring.

Continuous ring, no scarf cut.

Absorbs slight amount of oil, aiding

lubrication.

Almost completely non-absorbent, will not

hold enough oil to aid lubrication.

Tends to absorb moisture, increasing

possibility of corrosion.

Resists cold flow and tendency to extrude

under high pressure.

Will cold flow and extrude at room

temperature and high pressure.

Resists cold flow and tendency to extrude

under high pressure.

Uniform dimensions.

Uniform dimensions.

Variable dimensions.

Table 6-3: Comparison of Parbak vs. PTFE and Leather Back-Up

6-10

Seals

Build With The Best!

Parker Hannifin Corporation O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 Fax: (859) 335-5128

www.parker.com/o-ring

Вам также может понравиться

- Metering Pumps - The Lowdown On TurndownДокумент7 страницMetering Pumps - The Lowdown On TurndownJ.SIVIRAОценок пока нет

- HAT Horiz Vessel VolДокумент1 страницаHAT Horiz Vessel VolJ.SIVIRAОценок пока нет

- EMINENT - Quick Release HooksДокумент17 страницEMINENT - Quick Release HooksJ.SIVIRAОценок пока нет

- Ug 28Документ3 страницыUg 28J.SIVIRA100% (1)

- UHX CalcsДокумент5 страницUHX CalcsJ.SIVIRA100% (2)

- Api 682 Update PDFДокумент5 страницApi 682 Update PDFJ.SIVIRAОценок пока нет

- Extreme Fiber Elongation Calcs - J.SДокумент1 страницаExtreme Fiber Elongation Calcs - J.SJ.SIVIRA100% (1)

- Semi Elliptical Head Specs PDFДокумент2 страницыSemi Elliptical Head Specs PDFJ.SIVIRAОценок пока нет

- Seal Chamber Pressure PDFДокумент10 страницSeal Chamber Pressure PDFJ.SIVIRA50% (2)

- Datum Compressor Cut PDFДокумент1 страницаDatum Compressor Cut PDFJ.SIVIRAОценок пока нет

- Tank Heat LossДокумент25 страницTank Heat Lossdanmaltais100% (3)

- UHX CalcsДокумент5 страницUHX CalcsJ.SIVIRA100% (2)

- Centrifugal PumpsДокумент82 страницыCentrifugal PumpsMd KalamuddinОценок пока нет

- Volume of (Any) EllipsoidДокумент3 страницыVolume of (Any) EllipsoidJ.SIVIRAОценок пока нет

- Pump AlignmentДокумент69 страницPump AlignmentJ.SIVIRA100% (1)

- Taller Comercio C.A. - Punto Fijo, Venezuela : General IndexДокумент1 страницаTaller Comercio C.A. - Punto Fijo, Venezuela : General IndexJ.SIVIRAОценок пока нет

- Propane Gas and Liquefied GasДокумент10 страницPropane Gas and Liquefied GasJ.SIVIRAОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- New Approach For The Measurement of Damping Properties of Materials Using The Oberst BeamДокумент6 страницNew Approach For The Measurement of Damping Properties of Materials Using The Oberst BeamMatnSambuОценок пока нет

- DBMS-LM Kavi With MinipjtДокумент56 страницDBMS-LM Kavi With Minipjtkavi_mithuОценок пока нет

- Role of Technology in AdvertisementtДокумент29 страницRole of Technology in AdvertisementtShalini ChatterjeeОценок пока нет

- Cat 15Документ2 страницыCat 15Gustavo Vargas0% (1)

- Switch v7LAB StudentДокумент206 страницSwitch v7LAB Studentkcf4scribdОценок пока нет

- Manual qf1200Документ24 страницыManual qf1200Guilherme MiyashiroОценок пока нет

- Rescue Boat Lsa 5.1Документ4 страницыRescue Boat Lsa 5.1Celal BozdoganОценок пока нет

- Case Study Analysis of Apex Corporation PDFДокумент2 страницыCase Study Analysis of Apex Corporation PDFAJОценок пока нет

- Electra BrochureДокумент10 страницElectra BrochureVërshim KastratiОценок пока нет

- Career Development PlanДокумент5 страницCareer Development Planapi-317247630Оценок пока нет

- 4 - 5.1 - Fluid Action On Surfaces (Plane Surface)Документ16 страниц4 - 5.1 - Fluid Action On Surfaces (Plane Surface)Jacky CagampanОценок пока нет

- Vertical Gas Smoker Fumador de Gas Vertical: Owner'S Manual / Manual Del PropietarioДокумент46 страницVertical Gas Smoker Fumador de Gas Vertical: Owner'S Manual / Manual Del PropietarioJason KarpinskiОценок пока нет

- 08L76 HR3 A21Документ6 страниц08L76 HR3 A21liebofreakОценок пока нет

- Paranormal Activity 3Документ5 страницParanormal Activity 3alexОценок пока нет

- ABB - AppNotes - 2.2 - 1HC0138868 EN AAДокумент8 страницABB - AppNotes - 2.2 - 1HC0138868 EN AADeoudrafОценок пока нет

- Cardox-Blockage Removal SystemДокумент5 страницCardox-Blockage Removal SystemNaelОценок пока нет

- Biochemical Oxygen DemandДокумент18 страницBiochemical Oxygen DemandUnputdownable Bishwarup100% (1)

- IB JIO Technical Previous Year PaperДокумент62 страницыIB JIO Technical Previous Year PaperHello HoneyyОценок пока нет

- Eminence Deltalite II 2515Документ1 страницаEminence Deltalite II 2515Suto BandОценок пока нет

- QA/QC Filling INDEX: North Gas Compression Plants (NGCP) Pipelines Index File Name File #Документ3 страницыQA/QC Filling INDEX: North Gas Compression Plants (NGCP) Pipelines Index File Name File #deva017Оценок пока нет

- PQ070XF02SZH: Features Outline DimensionsДокумент4 страницыPQ070XF02SZH: Features Outline DimensionsJulio Cesar CastilloОценок пока нет

- Catalogo de Oleohidraulica AGVДокумент73 страницыCatalogo de Oleohidraulica AGVadjime3Оценок пока нет

- CVДокумент2 страницыCVAkash JainОценок пока нет

- HOF - To PrasannaДокумент3 страницыHOF - To PrasannahishamndtОценок пока нет

- Driving Goods VehiclesДокумент336 страницDriving Goods VehiclesAsmawi AkhirОценок пока нет

- CRMДокумент15 страницCRMPradeep ChintadaОценок пока нет

- Parts List: 8108.010 MagnumДокумент16 страницParts List: 8108.010 MagnumRoque LlamoccaОценок пока нет

- Haas Axis Lubrication Oil - Conversion - AD0629Документ12 страницHaas Axis Lubrication Oil - Conversion - AD0629Jhonny PérezОценок пока нет

- Hitman Contracts PC ManualДокумент14 страницHitman Contracts PC ManualChernoll MendoncaОценок пока нет

- Dilg-Mbcrpp Isf Q2 2023Документ2 страницыDilg-Mbcrpp Isf Q2 2023Mallari GabrielОценок пока нет