Академический Документы

Профессиональный Документы

Культура Документы

Chain Link Fences and Gates

Загружено:

Nassim SabriИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chain Link Fences and Gates

Загружено:

Nassim SabriАвторское право:

Доступные форматы

ISSUED FOR

USE (IFU)

23-May-2011

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

TABLE OF CONTENTS

1.0

SCOPE ................................................................................................................................................ 3

2.0

DEFINITIONS...................................................................................................................................... 3

3.0

REFERENCES.................................................................................................................................... 3

4.0

5.0

6.0

3.1

SPECIFICATIONS .................................................................................................................... 3

3.2

ASTM INTERNATIONAL .......................................................................................................... 3

GENERAL REQUIREMENTS............................................................................................................. 4

4.1

SUBMITTALS............................................................................................................................ 4

4.2

PRODUCT DELIVERY, STORAGE AND PROTECTION ........................................................ 5

4.3

GROUNDING OF FENCING ..................................................................................................... 5

MATERIALS........................................................................................................................................ 5

5.1

GENERAL ................................................................................................................................. 5

5.2

GALVANIZED CHAIN-LINK FABRIC FENCE ......................................................................... 6

5.3

ALUMINUM-COATED CHAIN-LINK FABRIC FENCE ............................................................ 8

5.4

PVC-COATED CHAIN-LINK FENCE...................................................................................... 10

5.5

GATES .................................................................................................................................... 13

5.6

CONCRETE AND GROUT...................................................................................................... 14

EXECUTION...................................................................................................................................... 15

6.1

PREPARATION ...................................................................................................................... 15

6.2

INSTALLATION ...................................................................................................................... 16

ATTACHMENT 1: FENCE AND GATE DETAILS .................................................................................... 28

ATTACHMENT 2: PURPOSE CODE DEFINITIONS ................................................................................ 32

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 2 of 32

WEST QURNA I

1.0

SPECIFICATION CHAIN LINK FENCES

AND GATES

SCOPE

This specification covers the requirements for material and installation of chain link fences and

gates.

2.0

DEFINITIONS

The entities used in this specification are defined as follows:

Company: The entity issuing the contract for the work or their authorized agent.

Contractor: The entity contracted to perform the work for the Company.

Contract Documents: The documents that form the contract issued by the Company.

3.0

REFERENCES

The following publications form a part of this Specification. This specification requires

compliance with all governing laws and regulations, which are applicable at the installation site.

3.1

SPECIFICATIONS

IQWQ-FT-NSPDS-00-040101

Concrete Design & Construction

IQWQ-FT-ESPDS-00-160401

Grounding and Overvoltage Protection

3.2

ASTM INTERNATIONAL

Doc. No.

Date

Title

ASTM A36M

2008

Standard Specification for Carbon Structural Steel

2010

Standard Specification for Pipe, Steel, Black and Hot-Dipped ZincCoated Welded and Seamless

2007

Standard Specification for Metallic-Coated Carbon Steel Barbed Wire

2009

Standard Specification for Zinc (Hot-Dip Galvanized) Coating on Iron and

Steel Products

2009

Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel

Hardware

2010

Standard Specification for Carbon Steel Bolts and Studs, 60 000 PSI

Tensile Strength

2011

Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric

ASTM A53M

ASTM A121

ASTM A123M

ASTM A153M

ASTM A307

ASTM A392

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 3 of 32

WEST QURNA I

Doc. No.

ASTM A491

ASTM A500M

ASTM A641M

ASTM A809

ASTM A992

ASTM A1011

Date

Title

2010

Standard Specification for Aluminum-Coated Steel Chain-Link Fence

Fabric

2010

Standard Specification for Cold-Formed Welded and Seamless Carbon

Steel Structural Tubing in Rounds and Shapes

2009

Standard Specification for Zinc Coated (Galvanized) Carbon Steel Wire

2008

Standard Specification for Aluminum-Coated (Aluminized) Carbon Steel

Wire

2006

Standard Specification for Structural Steel Shapes

2010

ASTM C94M

ASTM F668

ASTM F934

ASTM F1043

4.0

SPECIFICATION CHAIN LINK FENCES

AND GATES

Standard Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon,

Structural, High-Strength Low-Alloy, High-Strength Low-Alloy with

Improved Formability, and Ultra-High Strength

2011

Standard Specification for Ready-Mixed Concrete

2007

Standard Specification for Polyvinyl Chloride (PVC) and Other Organic

Polymer-Coated Steel Chain-Link Fence Fabric

2008

Standard Specification for Standard Colors for Polymer-Coated Chain

Link Fence Materials

2011

Standard Specification for Strength and Protective Coatings on Steel

Industrial Fence Framework

GENERAL REQUIREMENTS

Unless specified otherwise in the Contract Documents, fencing materials shall comply with

Section 5.2, Galvanized Chain-Link Fabric Fence. Galvanized steel framework may be used with

galvanized PVC, coated aluminum, coated fabric; tension wire; and barbed wire.

4.1

SUBMITTALS

4.1.1

Contractor shall provide evidence of a minimum 2-year work history in chain

link fence installation.

4.1.2

Before the start of field installation, shop drawings of gates, bracing, and typical

fence details shall be submitted to the Company for approval.

4.1.3

A sample of approximately 15.2 cm (6 in) square fabric material, post section,

and typical accessories for Company approval, prior to start of installation.

4.1.4

Before the start of installation, material data for fabrics, post, rails, tension wire,

and rods showing compliance with this specification shall be submitted to the

Company. Mill certifications listing compliance with zinc coatings, weights,

Polyvinyl Chloride (PVC) coating types, and material lot source.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 4 of 32

WEST QURNA I

4.1.5

4.2

4.3

SPECIFICATION CHAIN LINK FENCES

AND GATES

Contractor shall provide a guarantee against defects for all materials, installation,

and workmanship for 1 year from the date of acceptance. Any defect in

installation or workmanship shall be repaired, and defective materials shall be

replaced during the guarantee period without cost to the Company.

PRODUCT DELIVERY, STORAGE, HANDLING AND PROTECTION

4.2.1

Contractor shall deliver materials with the manufacturer's tags and labels intact

and handle and store materials in accordance with the manufacturers instructions

so as to avoid damage

4.2.2

Materials shall be stored 100 to 300 mm (4 to 12 in) off the ground or slab by

using wood blocking or other approved materials. Standard dunnage sizes shall

be used.

4.2.3

Materials shall be stored in areas of the job site designated and approved by the

Company.

GROUNDING OF FENCING

Grounding of fencing around electrical equipment shall be in accordance with

specification IQWQ-FT-ESPDS-00-160401.

5.0

MATERIALS

5.1

GENERAL

5.1.1

Contractor shall install new, non rejected and undamaged, and properly coated

materials only.

5.1.2

The schedules of galvanized, aluminum-coated, and PVC-coated steel posts,

rails, brace rails, and gate frames shall be in accordance with Table 1 and Table

2.

5.1.3

The materials to be used for posts, rails, brace rails, and gate frames shall be in

accordance with Table 3.

5.1.4

The chain-link fabric shall meet the following requirements:

1) A minimum height of 2.44 m (8 ft), unless modified in Contract Documents,

and woven in one piece for widths up to a maximum of 3.66 m (12 ft).

2) A uniform 5.08 cm (+0.32 cm) [2 in (+1/8 in)] diamond mesh woven #9

finished gauge steel wire, with 1200 lb minimum breaking strength for

interior fence and #6 finished gauge steel wire for perimeter fencing.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 5 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

3) A selvage, twisted and barbed on one edge and knuckled on the other; with

barbs formed by cutting wire on a bias.

5.2

5.1.5

Tension truss rods shall be 10 mm (3/8 in.) diameter ASTM A36M steel with

truss tighteners for gate post, terminal post, brace post (pull post) and both sides

of corner posts. All fasteners and nuts shall be 10 mm (3/8 in) diameter, ASTM

A307. The compression brace bar, 4.13 cm (1 5/8 in) O.D. truss bar, shall have

0.79 cm (5/16 in) minimum diameter steel tension truss rods with adjustable

take-up, brace bands, tension bands, or corner connections for attaching the

braces and truss rods to the posts.

5.1.6

Stretcher bars shall be 6 mm x 20 mm (1/4 in x 3/4 in) ASTM A1011M, Grade

50, steel. Stretcher bars shall be in one piece, equal to the full fabric height, with

a minimum 0.48 cm x 1.91 cm (3/16 in x in) section and associated bands shall

be a minimum 0.318 cm x 1.91 cm (1/8 in x in) section, both in heavy pressed

steel or malleable iron.

5.1.7

The top rail shall be closed-seam or seamless top rail to form a continuous brace

from end to end of the fence and be securely fastened to the gate, terminal, end,

corner, and pull posts. Couplings shall be of outside sleeve type, approximately

17.78 cm (7 in) long, spaced approximately 6.10 m (20 ft) apart, and with one

coupling in five fitted with a heavy spring, to provide expansion and contraction

in top rail.

GALVANIZED CHAIN-LINK FABRIC FENCE

Steel shall be galvanized by hot dip after rolling, forming, or weaving of the fence

component. Galvanized fence materials shall be uniform and consistent and shall be in

accordance with the following requirements:

5.2.1

Chain-Link Fabric

Fabric shall consist of heavy galvanized chain link material, in accordance with

ASTM A392, Class 2 coating; 50 mm (2 in) diamond mesh 9-gauge steel wire (4

mm (0.148 in.) in diameter), with the top and bottom selvedges twisted and

barbed.

5.2.2

Posts, Rails, and Brace Rails

1) The dimensions and weights of posts, rails and brace rails shall be in

accordance with Table 1.

2) The materials of posts, rails and brace rails shall be in accordance with Table

3.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 6 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

3) The posts shall be closed-seam or seamless tubular posts, continuous with no

spliced sections, and equipped with a closed top unit, including a top rail

carrier and an apron securely fitted around the outside of the post.

4) End posts shall be complete with necessary fittings, continuous with no

spliced sections, include one compression brace bar and one truss rod with

adjustable take-up.

5) Corner and pull posts shall be complete with necessary fittings, including

two compression brace bars and two truss rods with adjustable take-up.

6) Galvanized coating shall meet the following requirements:

a) Pipe shall be in accordance with ASTM A 53M.

b) C-Section, Square, H-Beam and I-Beam shall be in accordance with

ASTM A 123M.

c) Tubing 1.5 oz zinc per ft2 (47.75 cm3/m2) of uncoated steel surface.

5.2.3

Tension Truss Rod

1) Tension truss rods shall be galvanized in accordance with ASTM A153M.

5.2.4

Tension Wire and Fabric Ties

1) Tension wire shall be a minimum 7-guage galvanized steel wire in

accordance with ASTM A641M with coating Class 5.

2) The tension wire shall be stretched near the bottom of the fence. If a top rail

is not used, the tension wire shall be stretched at the top also.

3) Fabric ties and hog rings shall be galvanized steel in accordance with ASTM

A641M with coating Class 1. See Table 4 for Schedule of Tie Wire.

5.2.5

Post Tops and Fittings

1) One post top shall be provided for each post, with openings to permit through

passage of top rail.

2) Post top material shall be pressed steel or malleable iron that is designed as a

watertight closure cap for tubular posts and shall be galvanized in accordance

with ASTM A153M.

3) Open-type posts such as C-Posts, H-Beams, and I-Beams do not require a

post top, unless the top rail is specified.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 7 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

4) Fence fittings such as end clamps, corner clamps, rail sleeves, barbed wire

arms, gate corners, etc. shall be pressed steel or malleable iron and shall be

galvanized in accordance with ASTM A153M.

5.2.6

Barbed Wire

1) Barbed wire shall consist of two strands of 12.5-gage, galvanized wire in

accordance with ASTM A121 Coating Type Z, Coating Class 3, with 14gage, 4-point round barbs spaced on 75 mm (3 in) centers.

2) The top 300 mm (1 ft) of the fence shall consist of three equally spaced rows

of barbed wire attached to 45-degree angle heavy-pressed galvanized arms

capable of withstanding, without failure 1112 N (250 lbs) downward pull at

the outmost end of the arm.

3) Barbed wires are to be high security-type, two-stranded, twisted steel wire,

each 0.25 cm (0.099 in) diameter; four point 14-gauge barbs, spaced not

more than 7.62 cm (3 in) apart.

4) Barbed wire extension arms are to be 45-degree (0.79 radius) angle post

mounted, fitted to carry three equally spaced rows of barbed wire; adding

approximately 300 mm (1 ft) to fence height.

5) Extension arms are to be constructed of malleable iron, pressed steel, or

aluminum, finished to match the fabric.

Note: Vertical barbed wire extension arms on gates add 300 mm (1 ft) to gate

frame height.

5.2.7

Appurtenances

1) Brace bands and tension bands shall fabricated from 3 mm by 22 mm (0.125

in by 0.875 in) galvanized steel with galvanized steel carriage bolts and nuts

galvanized in accordance with ASTM A153M.

2) Stretcher bars shall be galvanized in accordance with ASTM A153M.

3) Tighteners shall be galvanized in accordance with ASTM A153M.

5.3

ALUMINUM-COATED CHAIN-LINK FABRIC FENCE

If aluminum-coated fabric fence is specified in the contract documents, materials shall be

uniform and consistent and shall be in accordance with the following requirements:

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 8 of 32

WEST QURNA I

5.3.1

SPECIFICATION CHAIN LINK FENCES

AND GATES

Chain-Link Fabric

Fabric shall consist of aluminum-coated steel wire in accordance with ASTM

A491, Type I aluminum coating; 50 mm (2 in) diamond mesh 9-gauge steel wire

(4 mm (0.148 in.) in diameter), with the top and bottom selvedges twisted and

barbed. Clear paint shall be applied after the fabric is woven, to prevent

premature discoloration of wires and rusting of cut ends.

5.3.2

Posts, Rails, and Brace Rails

This section shall be as specified in Section 5.2.2.

5.3.3

Tension Truss Rod

This section shall be as specified in Section 5.2.3.

5.3.4

Tension Wire and Fabric Ties

1) Tension wire shall be a minimum 7-gage aluminum-coated steel wire in

accordance with ASTM A809.

2) The tension wire shall be stretched near the bottom of the fence. If a top rail

is not used, the tension wire shall be stretched at the top also.

3) Fabric ties and hog rings shall be aluminum-coated steel wire in accordance

with ASTM A809. See Table 4 for Schedule of Tie Wire.

5.3.5

Post Tops and Fittings

This section shall be as specified in Section 5.2.5.

5.3.6

Barbed Wire

1) Barbed wire shall consist of two strands of aluminum-coated 12.5-gage wire

with 14-gage, 4-point round aluminum barbs spaced on 75 mm (3 in) centers

in accordance with ASTM A121, Class 2.

2) The top 300 mm (1 ft) of the fence shall consist of three equally spaced rows

of barbed wire attached to 45-degree angle heavy-pressed galvanized arms

capable of withstanding, without failure 1112 N (250pounds) downward pull

at the outmost end of the arm.

3) Barbed wires are to be high security-type, two-stranded, twisted steel wire,

each 0.25 cm (0.099 in) diameter; four point 14-gauge barbs, spaced not

more than 7.62 cm (3 in) apart.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 9 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

4) Barbed wire extension arms are to be 45-degree (0.79 radius) angle post

mounted, fitted to carry three equally spaced rows of barbed wire; adding

approximately 300 mm (1 ft) to fence height.

5) Extension arms are to be constructed of malleable iron, pressed steel, or

aluminum, finished to match the fabric.

Note: Vertical barbed wire extension arms on gates add 300 mm (1 ft) to gate

frame height.

5.3.7

Appurtenances

This section shall be as specified in Section 5.2.7.

5.4

PVC-COATED CHAIN-LINK FENCE

Fencing components shall be evenly PVC fused, free of blisters, have undispersed

pigments, stabilizers, or other discrete particles, and also have a minimum specific

gravity of 1.3. The bond between vinyl coating and metals shall be equal to or greater

than the cohesive strength of the vinyl. If PVC-coated fence is specified in the contract

documents, materials shall be uniform and consistent and shall be in accordance with the

following requirements:

5.4.1

Chain-Link Fabric

1) Fabric shall be in accordance with ASTM F668, 0.1778 mm (7 mils) of

thermally bonded PVC over 92 g/m2 (0.30 oz/ft2) zinc substrate; 50 mm (2

in) diamond mesh 9-gauge steel wire (4 mm (0.148 in.) in diameter), with the

top and bottom selvedges twisted and barbed.

2) Colors shall be in accordance with ASTM F934 (i.e., brown, green, or black)

and as specified in the Contract Documents.

5.4.2

Posts, Rails, and Brace Rails

1) This section shall be as specified in Section 5.2.2.

2) Posts, rails, and Brace Rails shall be primed to receive 0.25 to 0.38 mm (10to 15-mils) thermal fusion coating of PVC, in accordance with ASTM F1043.

3) Colors shall be in accordance with ASTM F934 (i.e., brown, green, or black)

and as specified in the Contract Documents.

5.4.3

Tension Truss Rod

1) Tension truss rods shall be galvanized in accordance with ASTM A153M.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 10 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

2) Tension truss rods shall be primed to receive 0.25 to 0.38 mm (10- to 15mils) thermal fusion coating of PVC, in accordance with ASTM F1043.

3) Colors shall be in accordance with ASTM F934 (i.e., brown, green, or black)

and as specified in the Contract Documents.

5.4.4

Tension Wire and Fabric Ties

1) Tension wire shall be a minimum 7-guage galvanized steel wire in

accordance with ASTM A641M.

2) Tension wire shall be primed to receive 0.25 to 0.38 mm (10- to 15-mils)

thermal fusion coating of PVC of same quality, color, and process as

specified for the fabric.

3) The tension wire shall be stretched near the bottom of the fence. If a top rail

is not used, the tension wire shall be stretched at the top also.

4) Fabric ties and hog rings shall be galvanized steel in accordance with ASTM

A641M with coating Class 1. See Table 4 for Schedule of Tie Wire.

5) Fabric ties and hog rings shall be primed to receive 0.25 to 0.38 mm (10- to

15-mils) thermal fusion coating of PVC in accordance with ASTM F1043.

Colors shall be in accordance with ASTM F934 (i.e., brown, green, or black)

and as specified in the Contract Documents.

5.4.5

Post Tops and Fittings

1) One post top shall be provided for each post, with openings to permit through

passage of top rail.

2) Post top material shall be pressed steel or malleable iron that is designed as a

watertight closure cap for tubular posts and shall be primed to receive 0.25 to

0.38 mm (10- to 15-mils) thermal fusion coating of PVC, in accordance with

ASTM F1043.

3) Open-type posts such as C-Posts, H-Beams, and I-Beams do not require a

post top, unless the top rail is specified.

4) Fence fittings such as end clamps, corner clamps, rail sleeves, barbed wire

arms, gate corners, etc. shall be pressed steel or malleable iron and shall be

primed to receive 0.25 to 0.38 mm (10- to 15-mils) thermal fusion coating of

PVC, in accordance with ASTM F1043.

5) Colors of post top and fittings shall be in accordance with ASTM F934 (i.e.,

brown, green, or black) and as specified in the Contract Documents.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 11 of 32

WEST QURNA I

5.4.6

SPECIFICATION CHAIN LINK FENCES

AND GATES

Barbed Wire

1) Barbed wire shall consist of two strands of 12.5-gage, galvanized wire in

accordance with ASTM A121 Coating Type Z, Coating Class 3, with 14gage, 4-point round aluminum barbs spaced on 75 mm (3 in) centers.

2) The top 300 mm (1 ft) of the fence shall consist of three equally spaced rows

of barbed wire attached to 45-degree angle heavy-pressed galvanized arms

capable of withstanding, without failure 1112 N (250pounds) downward pull

at the outmost end of the arm.

3) Barbed wire shall be primed to receive 0.25 to 0.38 mm (10- to 15-mils)

thermal fusion coating of PVC.

4) Colors shall be in accordance with ASTM F934 (i.e., brown, green, or black)

and as specified in the contract documents.

5) Barbed wires are to be high security-type, two-stranded, twisted steel wire,

each 0.25 cm (0.099 in) diameter; four point 14-gauge barbs, spaced not

more than 7.62 cm (3 in) apart.

6) Barbed wire extension arms are to be 45-degree (0.79 radius) angle post

mounted, fitted to carry three equally spaced rows of barbed wire; adding

approximately 300 mm (1 ft) to fence height.

7) Extension arms are to be constructed of malleable iron, pressed steel, or

aluminum, finished to match the fabric.

Note: Vertical barbed wire extension arms on gates add 300 mm (1 ft) to gate

frame height.

5.4.7

Appurtenances

1) Brace bands and tension bands shall fabricated from 3 mm by 22 mm (0.125

in by 0.875 in) galvanized steel with galvanized steel carriage bolts and nuts

galvanized in accordance with ASTM A153M.

2) Stretcher bars shall be galvanized in accordance with ASTM A153/A153M.

3) Tighteners shall be galvanized in accordance with ASTM A153/A153M.

4) All appurtenances shall be primed to receive 0.25 to 0.38 mm (10- to 15mils) thermal fusion coating of PVC in accordance with ASTM F1043.

Colors shall be in accordance with ASTM F934 (i.e., brown, green, or black)

and as specified in the Contract Documents.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 12 of 32

WEST QURNA I

5.5

SPECIFICATION CHAIN LINK FENCES

AND GATES

GATES

5.5.1

Gate materials such as fabric, bolts, nuts, stretcher bars, barbed wire, brace rail,

and truss rods and tighteners shall be consistent with fence materials.

5.5.2

Gates shall be manually or electrically operated as specified in the Contract

Documents.

5.5.3

Swing Gates

1) Swing gate frame shall be 483 mm (1.9 in) O.D. steel pipe or 508 mm (2 in)

square tube in accordance with Table 1 and Table 2.

2) Gate frame materials shall be in accordance with Table 3.

3) The frame shall be with gate corners riveted or bolted at corners. Have

corners welded on galvanized steel gates and fastened by specially designed

corner fittings on vinyl-coated gates. Coating shall protect external weld

surface liable to corrode.

4) Horizontal center rails or vertical center uprights, as appropriate, with

adjustable truss rods shall be used to hold gate frame rigidity and square.

a) Gate fabric shall be attached to gate frame by tension rods and hook bolts

on four sides, or vertical stretcher bars and associated bands with tie

wires at top and bottom edges

b) Hold frame rigidity without sag or twist by 0.95 cm (3/8 in) diameter

adjustable diagonal truss rods, horizontal center rails, or vertical center

uprights, as appropriate

5) Bottom hinge shall be pivot type.

6) Have gates completely equipped with:

a) Two hinges per gate leaf, non lift-off type, permitting 180-degrees (3.14

radius) gate opening.

b) A fork-type latch (single leaf) or center-drop bar (double leaf), both of

which can be operated or padlocked from either side.

c) A complete plunger bar catch (double leaves only).

7) Gates shall be provided with padlocking device, center rest, and semiautomatic catch to secure gate in open position.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 13 of 32

WEST QURNA I

5.5.4

SPECIFICATION CHAIN LINK FENCES

AND GATES

Slide Gates

1) Slide gates shall be in accordance with Attachment 1 and the vertical

clearance required.

2) Designs for special gates shall be submitted to Company for approval.

5.5.5

Size of gateposts shall be in accordance with Table 1 and Table 2.

5.5.6

Gatepost materials shall be in accordance with Table 3 with coating materials as

determined as follows:

1) Galvanized chain-link fence

a) Pipe shall be in accordance with ASTM A 53M.

b) C-Section, Square, H-Beam and I-Beam shall be in accordance with

ASTM A 123M.

2) Aluminum-coated chain-link fence

a) This section shall be as specified in Section 5.5.6.1.

3) PVC-coated chain-link fence

a) This section shall be as specified in Section 5.5.6.1.

b) Gateposts shall be primed to receive 0.25 to 0.38 mm (10- to 15-mils)

thermal fusion coating of PVC, in accordance with ASTM F1043.

c) Colors shall be in accordance with ASTM F934 (i.e., brown, green, or

black) and as specified in the Contract Documents.

5.6

CONCRETE AND GROUT

5.6.1

Concrete

1) Concrete shall have a minimum 28-day compressive strength of 20 MPa

(3000 PSI). Refer to Specification IQWQ-FTH-NSPDS-00-040101.

2) Aggregate size shall be 25 mm (1 in) maximum.

3) Slump shall be 75 mm (3 in) maximum, and entrained air shall be between 2

percent and 4 percent.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 14 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

4) Concrete mix design shall be in accordance with ASTM C94M.

5.6.2

Grout

Contractor shall use nonshrink Portland cement grout, approved by the Company,

to grout in the posts into solid rock.

6.0

EXECUTION

6.1

PREPARATION

6.1.1

Contractor shall perform clearing and grubbing to a width of 600 mm (2 ft)

minimum on each side of the fence line as necessary to permit a proper fence

installation.

6.1.2

Contractor shall not commence work until unsatisfactory conditions have been

corrected

6.1.3

A reasonably smooth profile at the fence line shall be provided. There shall be no

space between the bottom of the fence and the finished ground line.

6.1.4

Unless otherwise specified the Contract Documents, where the fence crosses

features such as streams and drainage ditches and where conforming the fence to

the ground contour is impractical, the fence shall span the depression. The space

below the bottom of the fence shall be closed with extra fence fabric or barbed

wire as specified in the Contract Documents. If extra length fence posts are

required at such locations, the extra length posts shall be furnished and installed

in lieu of standard length posts, together with any intermediate posts, stakes,

braces, extra fabric, or wire as may be required.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 15 of 32

WEST QURNA I

6.2

SPECIFICATION CHAIN LINK FENCES

AND GATES

INSTALLATION

6.2.1

Post Spacing

1) Line posts and brace posts shall be set at 3 m (10 ft) maximum intervals.

2) Posts shall be evenly spaced.

3) Corner or slope posts shall be installed where changes in horizontal

alignment or grade alignment are greater than a 30-degree.

4) Locate pull posts in line positions at equal distance, spacing in a maximum

90 m (300 ft) intervals or where changes in horizontal alignment or grade

alignment occur.

6.2.2

Foundation Bases and Post Hole Preparation

Assure rigid, secure fence installation where bases are set in wet conditions.

Unless otherwise specified in Contract Documents, the foundation bases and post

hole preparation shall be in accordance with the following requirements.

1) Concrete Base

a) Line, corner, pull, terminal and gate posts shall be set vertically in

cylindrical concrete foundations in accordance with Table 5.

b) Post holes shall be hand-augured or drilled.

c) Soil from the excavations shall be spread uniformly adjacent to the fence

line or as directed by the Company.

d) Crown concrete base tops by 5.08 cm (2 in) to shed water.

2) Grout Base

a) Grout base shall be applied to foundations with solid rock conditions.

b) Contractor shall drill a base hole in solid rock 1 in. larger in diameter

than the largest dimension of post section to be set to the depth specified

in Table 5.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 16 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

3) Combined Base for Solid Rock with Soil Overburden

a) Unless penetration into solid rock reaches minimum depth first as

specified in Table 5, Contractor shall use the combined bases with grout

base and concrete base to full depth specified in Table 5.

b) The grout base and concrete base shall be in accordance with paragraphs

2 and 1 above, respectively.

4) Base in Masonry Walls

a) Galvanized pipe socket/sleeves shall be used for posts setting in masonry

walls.

b) The length of galvanized pipe socket/sleeve shall be 1.1m (42 in) for line

posts and 1.3 m (48 in) for all other posts embedded into the masonry

walls.

c) Contractor shall set post bases into embedded galvanized pipe

socket/sleeves with the inside and outside surface liable to corrode

painted with bituminous paint or gout into place with appropriate fastsetting cement and caulk with lead wool.

i)

Bituminous paints shall be black asphalt paint, VALSPAR coatings,

or the equivalent

ii) Lead wool caulking shall be string-shredded, pure metallic lead wool

5) Base with Angle Bar Anchors

Where posts are set with angle bar anchors, Contractor shall submit the

design of angle bar anchor system to the Company for approval.

6.2.3

Post Setting

1) Loose and foreign materials shall be removed from the sides and bottoms of

the holes.

2) Posts shall be centered and aligned in the holes. Set posts vertical to within

20.32 cm (8 in), inside 3.05 m (10 ft), true to line and grade in concrete

bases, pipe sleeves, or sockets in masonry walls or with angle bar anchors.

3) If posts are placed in the solid rock holes, nonshrink Portland cement grout,

approved by the Company, shall be used to grout in the posts.

4) The soil shall be moistened before placing the concrete.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 17 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

5) The concrete shall be placed in a continuous pour into the hole around the

posts and tamp to consolidate.

6) The post shall be checked for vertical and horizontal alignment, and secured

to permit proper curing of the concrete.

7) Except for gateposts, the exposed surface of the concrete foundation shall be

set 50 mm (2 in 50 mm) above surrounding grade with a smooth 13 mm

(0.5in) crown, sloping away from the post.

8) Footings for gateposts shall extend to the underside of the bottom of the

hinge.

9) Unless the concrete has reached 75 percent minimum of its design strength,

before placing components such as fabric, rails, tension wire, and gates, the

concrete shall have cured 7 days minimum.

10) Concrete surfaces for gatepost footings shall be kept moist for 7 days

minimum after placement, or cured with membrane-curing material or other

Company-approved method.

6.2.4

Rails and Bracing

1) Fence shall be installed with a top rail and bottom tension wire unless

otherwise specified in the Contract Documents.

2) If it is necessary for a top rail to be omitted, a top tension wire shall be

installed.

3) Top rails shall be continuous through post caps or extension arms, bending to

the radius for wired runs.

4) The size and spacing of fabric tie wire shall be in accordance with Table 4.

5) Tension wires shall be installed parallel to the line of fabric by weaving 6gage minimum wire of the appropriate type through the fabric and tying the

wire to each post.

a) Bottom

i)

Contractor shall install one continuous length of tension wire that

passes through the bottom mesh of fence fabric between pull posts

and tied to pull posts before stretching the fabric.

b) Top

i)

19-May-2011, Rev. 0

Contractor shall install one continuous length of tension wire

between pull posts, secured to pull posts and connected to line posts

IQWQ-FT-NSPDS-00-777714

Page 18 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

within 6 in. (15.24 cm) of the top of the fence fabric to tension wire

with hog rings at 24 in. (60.96 cm) intervals

6) Top rail and tension wire shall be installed before installing the chain link

fabric.

7) A manufacturers standard expansion/contraction coupling shall be provided

every 30 m (100 feet) on straight runs and installed 600 mm (2 feet)

maximum from a line post.

8) End clamps shall be used for attaching the top rail or tension wire and braces

to the brace terminal and gateposts.

9) Corner clamps shall be used for attaching top rails or tension wire and braces

to corner posts.

10) Bracing

a) One brace assembly shall be used for each terminal or gatepost.

b) Two brace assemblies shall be used for each corner or pull post.

c) Unless otherwise specified in the Contract Documents, the brace rail

shall be positioned 300 mm (12 in) below the top tension wire.

d) Braces shall extend from a line post to the related gate, corner, pull, or

terminal post

6.2.5

Fabric

1) The chain link fence fabric shall be installed with the posts enclosed.

2) The fabric shall be stretched tautly, and fastened securely to the posts.

3) The fabric shall be cut and attached to each span independently at all

terminal/gate and corner/pull posts.

4) The fabric shall be attached to the terminal/gate posts as follows:

a) For square terminal/gate posts, stretcher bars shall be used with specially

designed fabric clips spaced at 375 mm (15 in) maximum intervals to

fasten fabric to the posts.

b) For pipe terminal/gate posts, stretcher bars shall be used with fabric

bands spaced at 375 mm (15 in) maximum intervals to fasten fabric to

the posts.

c) For open-type terminal/gate posts such as C-Posts, H-Beams and IBeams, Contractor shall weave fabric into loops and stamp into the

posts.

5) The fabric shall be attached to the corner/pull posts as follows:

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 19 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

a) For square corner/pull posts, stretcher bars shall be used with specially

designed fabric clips spaced at 300 mm (12 in) maximum intervals to

fasten fabric to the posts.

b) For pipe corner/pull posts, stretcher bars shall be used with fabric bands

spaced at 300 mm (12 in) maximum intervals to fasten fabric to the

posts.

c) For open-type corner/pull posts such as C-Posts, H-Beams and I-Beams,

Contractor shall fasten fabric by integrally weaving 6-gage minimum

wire of appropriate type through the fabric and tying the wire to the

posts.

6) Contractor shall fasten fabric to top rails or top tension wires, bottom rails or

bottom tension wires, intermediate brace rails, and line posts in accordance

with Table 4.

7) Contractor shall install fabric on the side of posts away from the area being

protected except on curved layouts where fabric shall be installed on the side

of the post on the outside of the curve.

8) Contractor shall install individual barriers at depressed openings to maintain

a secure, impenetrable perimeter at the areas where the fence runs through

drainage ways, ditches, and etc.

6.2.6

Barbed Wire

1) Contractor shall:

a) Install three taut rows of barbed wire, supported on 45-degree (0.79

radius) angle extension arms, which are inclined upward and outward

from area being protected.

b) Incline 45-degree (0.79 radius) extension arms toward the area being

protected, where outward inclination would infringe on property of

others.

c) Install vertical barbed wire extension arms on the gates.

2) Barbed wire on gates shall match wire installed on the line fence.

3) To accommodate barbed wire, the end members of gates shall be extended

300 mm (1 ft) above the horizontal section of the gate frame.

4) Three strands of barbed wire shall be installed.

5) Strands shall be spaced uniformly and attached to frame with bands, clips, or

eyebolts.

6) Extension arms on all posts shall be inclined at approximately 45 degrees

toward or away from the property enclosed.

7) The strands of barbed wire shall be stretched to remove sag and be anchored

firmly to extension arms.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 20 of 32

WEST QURNA I

6.2.7

SPECIFICATION CHAIN LINK FENCES

AND GATES

Gates

1) Gates shall be installed in accordance with the locations, type, and size

specified in the Contract Documents.

2) Gates shall be braced and trussed to prevent sagging, buckling, and weaving.

3) Gates shall be covered with same type of fabric as the fence.

4) Vertical members of a gate shall carry the top three strands of barbed wire.

5) Fixed end ratchet bands shall be provided for fastening the barbed wire.

6) Hardware

a) Gates shall be provided with necessary fittings and hardware.

b) Latches provided for use with padlocks and hinges shall allow swing

gates to swing 180 degrees.

c) Plunger bars shall have top, bottom, and middle locking points; the

middle point shall be arranged for padlocking.

d) Gates shall have keepers that engage automatically when the gate is

swung open and that require manual release.

7) Gates shall be installed plumb, level, and secure for the full opening without

interference. Install bottom rail of gate to swing clear of finished grade for

full 180-degree (3.14 radius) swing.

8) Match gate frame top rails to height of fence top rail.

9) Ground items shall be set in concrete in accordance with gate manufacturers

recommendations.

10) Equipment shall be installed, lubricated, and adjusted to ensure smooth

operation.

6.2.8

Miscellaneous Installation

1) Tie Wires

a) Tie wires shall be U-shaped and shall conform to the diameters of pipe.

b) The tie wires shall clasp the pipe and fabric firmly with ends twisted two

full turns minimum.

c) The ends of exposed wires shall be bent to minimize hazards to persons

or clothing.

d) Sharp burrs shall be repaired using methods and techniques

recommended by the manufacturer.

2) Nuts for fasteners on tension bands and hardware bolts shall be installed on

the side of the fence opposite the fabric. Contractor shall install nuts for

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 21 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

stretcher bands and hardware bolts on sides of posts facing the area being

protected.

3) The ends of bolts, once secure and checked for smooth operation, shall be

peened to prevent removal of nuts.

4) Coatings damaged in the field shall be repaired using methods and

techniques recommended by the manufacturer.

5) Parts and attachments shall be inspected for defects.

6.2.9

Quality Assurance

1) Quality control shall be provided for all furnished materials, installations,

and workmanship, including those items or installations furnished by

Contractors subcontractors or vendors.

2) The Company reserves the right to make inspections at any time during the

receipt and installation of fencing materials.

3) The physical locations of features such as fence lines, gates, and terminal

posts shall be in accordance with the Contract Documents.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 22 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

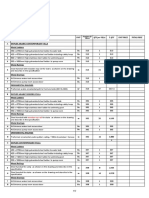

Table 1: Schedule for Galvanized Steel Post, Rail, Brace Rail, and Gate Frame

Component

Dimensions

Shape

kg/m (lb/ft)

4.763 cm x 4.128 cm

(1.875 in x 1.625 in)

C-Post

3.482

(2.34)

4.763 cm x 4.128 cm

(1.875 in x 1.625 in)

H-Beam

4.048

(2.72)

6.033 cm O.D.

(2.375 in O.D.)

Pipe

5.432

(3.65)

5.715 cm x 4.326 cm

(2.250 in x 1.703 in)

C-Post

4.063

(2.73)

5.715 cm x 4.763 cm

(2.250 in x 1.875 in)

H-Beam

6.102

(4.10)

6.033 cm O.D.

(2.375 in O.D.)

Pipe

5.432

(3.65)

6.350 cm x 6.350 cm

(2.500 in x 2.500 in)

Square

7.590

(5.10)

8.890 cm x 8.890 cm

(3.500 in x 3.500 in)

**C-Post

7.649

(5.14)

7.303 cm O.D.

(2.875 in O.D.)

Pipe

8.617

(5.79)

6.350 cm x 6.350 cm

(2.500 in x 2.500 in)

Square

7.590

(5.10)

8.890 cm x 8.890 cm

(3.500 in x 3.500 in)

C-Post

7.590

(5.10)

7.3035 cm O.D.

(2.875 in O.D.)

Pipe

8.617

(5.79)

7.620 cm x 7.620 cm

(3.000 in x 3.000 in)

I-Beam

9.670

(6.50)

10.160 cm O.D.

(4.000 in. O.D.)

Pipe

13.557

(9.11)

8.890 cm x 8.890 cm

(3.000 in x 3.000 in)

Square

13.543

(9.10)

Line Post

Max. 2.44 m (8 ft) fabric

height

Over 2.44 m (8 ft) fabric

height

Terminal, Corner, and Pull

Posts

Note: ** Denotes maximum 3.658 m (12 ft) fabric height.

Gate Posts, Single Leaf Width

Max. 1.829 m

(6 ft)

1.829 m to 3.658 m

(6 ft to 12 ft)

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 23 of 32

WEST QURNA I

Component

SPECIFICATION CHAIN LINK FENCES

AND GATES

Dimensions

Shape

kg/m (lb/ft)

10.160 cm x 10.160 cm

(4.000 in x 4.000 in)

H-Beam

17.203

(11.56)

3.658 m to 5.486 m

(12 ft to 18 ft)

16.828 cm O.D.

(6.625 in O.D.)

Pipe

28.230

(18.97)

5.486 m to 7.01 m

(18 ft to 23 ft)

21.908 cm O.D.

(8.625 in O.D.)

Pipe

36.758

(24.70)

7.010 m to 9.144 m

(23 ft to 30 ft)

27.305 cm O.D.

(10.750 in O.D.)

Pipe

46.431

(31.20)

4.128 cm x 3.175 cm

(1.625 in x 1.250 in)

C-Section

2.010

(1.35)

4.216 cm O.D.

(1.660 in O.D.)

Pipe

3.378

(2.27)

3.810 cm x 3.810 cm

(1.500 in x 1.500 in)

I-Beam

3.378

(2.27)

Brace Rail

4.216 cm O.D.

(1.660 in O.D.)

Pipe

3.378

(2.27)

Swing Gate Frame

5.080 cm x 5.080 cm

(2.000 in x 2.000 in)

Square

4.048

(2.72)

4.826 cm O.D.

(1.900 in O.D.)

Pipe

4.048

(2.72)

Top and Bottom Rails

Table 2: Schedule for PVC-Coated Steel Post, Rail, Brace Rail, and Gate Frame

Component

Dimensions

Shape

kg/m (lb/ft)

Max. 2.44 m (8 ft) fabric height

4.763 cm x 4.128 cm

(1.875 in x 1.625 in)

C-Post

3.482

(2.34)

Over 2.44 m (8 ft) fabric height

5.715 cm x 4.326 cm

(2.250 in x 1.703 in)

C-Post

4.063

(2.73)

6.350 cm x 6.350 cm

(2.500 in x 2.500 in)

Square

7.590

(5.10)

6.350 cm x 6.350 cm

(2.500 in x 2.500 in)

Square

7.590

(5.10)

Line Post

Terminal, Corner, and Pull

Posts

Gate Posts, single leaf width

Max. 1.829 m

(6 ft)

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 24 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

1.829 m to 3.658 m

(6 ft to 12 ft)

10.160 cm O.D.

(4.000 in O.D.)

Pipe

13.557

(9.11)

3.658 m to 5.486 m

(12 ft to 18 ft)

16.828 cm O.D.

(6.625 in O.D.)

Pipe

28.230

(18.97)

5.486 m to 7.01 m

(18 ft to 23 ft)

21.908 cm O.D.

(8.625 in O.D.)

Pipe

36.758

(24.70)

7.010 m to 9.144 m

(23 ft to 30 ft)

27.305 cm O.D.

(10.750 in O.D.)

Pipe

46.431

(31.20)

Top and Bottom Rail

4.128 cm O.D.

(1.625 in O.D.)

Pipe

2.009

(1.35)

Brace Rail

4.216 cm O.D.

(1.660 in O.D.)

Pipe

3.378

(2.27)

Swing Gate Frame

5.080 cm x 5.080 cm

(2.000 in x 2.000 in)

Square

4.048

(2.72)

Table 3: ASTM Standards for Post, Rail, Brace Rail, and Gate Frame Materials

Shape

ASTM Standard

Pipe

A53M

Schedule 40

C-Post, C-Section

A1011M, Grade 50

Square

A500M, Grade B

H Beam

A992

I-Beam

A36

Note: C-Post and C-Section shall be roll formed.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 25 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

Table 4: Schedule of Tie Wire

Component

Size and Material

Fabric Tie Wire Spacing

Open Section: H-Beam,

I-Beam, C -Post

6 gauge steel

300 mm (12 in.) on centers

Pipe, Square

9 gauge steel

380 mm (15 in.) on centers

Rails and Brace Rails

9 gauge steel

380 mm (15 in.) on centers

9 gauge aluminum

610 mm (24 in.) on centers

13 gauge steel

610 mm (24 in.) on centers

Line Post

(Double Wrap)

Tension Wire

9 gauge hog ring

380 mm (15 in.) on centers

11 gauge hog ring

610 mm (24 in.) on centers

Note: Tie wire and hog ring coatings to match fabric finish.

Table 5: Schedule of Post Foundation Size and Depth

Concrete Base

Fence

Component

Line Post

Grout Base

Combined Base

Solid Rock with Soil

Overburden

< 35.56 cm (14 in.) in

solid rock, and full depth

of 106.68 cm (42 in.)

below finished grade

< 50.8 cm (20 in.) in

solid rock, and full depth

of 121.92 cm (48 in.)

below finished grade

Foundation

Diameter

25 cm (10)

Foundation

Depth

1.1 m (42)

Solid Rock Without

Soil Overburden

35.56 cm

(14 in.) Min.

Corner, Pull, and

Terminal Posts

30 cm (12)

Min.

1.2 m (48)

50.80 cm

(20 in.) Min.

Gatepost: Single

Leaf Width

Max. 1.829 m

(6 ft)

30 cm (12)

Min.

1.2 m (48)

50.80 cm

(20 in.) Min.

1.829 m to 3.658

m

(6 ft to 12 ft)

30 cm (12)

Min.

1.2 m (48)

50.80 cm

(20 in.) Min.

3.658 m 5.486

m (12 ft 18 ft)

45 cm (18)

1.2 m (48)

50.80 cm

(20 in.) Min.

19-May-2011, Rev. 0

< 50.8 cm (20 in.) in

solid rock, and full depth

of 121.92 cm (48 in.)

below finished grade

< 50.8 cm (20 in.) in

solid rock, and full depth

of 121.92 cm (48 in.)

below finished grade

< 50.8 cm (20 in.) in

solid rock, and full depth

of 121.92 cm (48 in.)

below finished grade

IQWQ-FT-NSPDS-00-777714

Page 26 of 32

WEST QURNA I

Larger than 5.486

m (18 ft)

19-May-2011, Rev. 0

SPECIFICATION CHAIN LINK FENCES

AND GATES

60 cm (24)

1.5 m (60)

50.80 cm

(20 in.) Min.

< 50.8 cm (20 in.) in

solid rock, and full depth

of 121.92 cm (48 in.)

below finished grade

IQWQ-FT-NSPDS-00-777714

Page 27 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

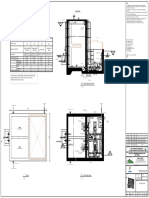

ATTACHMENT 1: FENCE AND GATE DETAILS

Figure 1: Fences and Gates

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 28 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

Figure 2: Fences and Overhead Sliding Gates with Roller and Guide

Assembly

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 29 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

Figure 3: Fences and Overhead Sliding Gates with Upper Track Assembly

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 30 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

Figure 4: Guard Rails

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 31 of 32

WEST QURNA I

SPECIFICATION CHAIN LINK FENCES

AND GATES

ATTACHMENT 2: PURPOSE CODE DEFINITIONS

Code

Description

[A]

Assigned to paragraphs that require approval from the Companys Engineer before the work

may proceed or the design is finalized.

[C]

Assigned to paragraphs containing specifications whose primary purpose is reduced costs.

Reduced cost in this context refers to initial investment cost and does not include Life-Cycle

cost considerations. Life-Cycle cost considerations are captured under reliability,

maintainability, or operability purpose codes.

[E]

Assigned to paragraphs containing specifications whose primary purpose is driven by

environmental considerations. Environmental considerations typically include specifications

intended to protect against emissions/leakage to the air, water, and/or soil. Deviations from the

specifications contained in such paragraphs require formal review and approval according to

local environmental policy.

[I]

Assigned to paragraphs that provide only clarifying information such as Scope statements,

definitions of terms, etc.

[M]

Assigned to paragraphs containing specifications whose primary purpose is to provide for

maintainability of equipment or systems. Maintainability provisions are those that facilitate the

performance of maintenance on equipment/systems either during downtimes or during onstream operations.

[O]

Assigned to paragraphs containing specifications whose primary purpose is to assure

operability of equipment or systems. Operability is the ability of the equipment/system to

perform satisfactorily even though conditions are off-design, such as during start-ups, process

swings, subcomponent malfunction, etc.

[R]

Assigned to paragraphs containing specifications whose primary purpose is to improve or

assure the reliability of equipment or systems. Reliability is a measure of the ability of

equipment/systems to operate without malfunction or failure between planned maintenance

interventions.

[S]

Assigned to paragraphs containing specifications whose primary purpose is avoidance of

personnel or operational safety incidents. Any deviation from the specifications contained in

such designated paragraphs requires formal review and approval according to local safety

policy.

Personnel Safety:

Refers to the avoidance of recordable personnel injuriese.g., burns,

cuts, abrasions, inhalation, or exposure to dangerous substances, etc.,

that could result in medical treatment, restricted work, lost-time incidents,

or fatalities.

Operational

Safety:

Refers to the prevention and control of process releases, fires,

explosions, etc.

19-May-2011, Rev. 0

IQWQ-FT-NSPDS-00-777714

Page 32 of 32

Вам также может понравиться

- Blockwork DetailsДокумент5 страницBlockwork DetailsrthomsanОценок пока нет

- Building Rebar InspectionДокумент41 страницаBuilding Rebar Inspectionjackcan501Оценок пока нет

- Revised BOQ 1Документ154 страницыRevised BOQ 1mkpqОценок пока нет

- KEC International Limited: Pile FoundationДокумент49 страницKEC International Limited: Pile FoundationDinesh Kumar100% (1)

- Sample EstimateДокумент13 страницSample Estimateart freakОценок пока нет

- Schedule of Qua Tities FOR Civil & Structural WorksДокумент12 страницSchedule of Qua Tities FOR Civil & Structural WorksMohammed Younus AhmedОценок пока нет

- Schedule of Quantity For Industrial BuildingДокумент4 страницыSchedule of Quantity For Industrial BuildingShashankSinghОценок пока нет

- Astm A 159 - 83 R01Документ5 страницAstm A 159 - 83 R01Er WidodoОценок пока нет

- ACI Beam DesignДокумент8 страницACI Beam DesignsujatОценок пока нет

- Concrete WorksДокумент28 страницConcrete WorksMohammad SayeedОценок пока нет

- Civil SpecificationsДокумент86 страницCivil Specificationstiruyam@gmail.comОценок пока нет

- Chain-Link Fence and Gate: Installation InstructionsДокумент11 страницChain-Link Fence and Gate: Installation InstructionsLloyd R. Ponce100% (4)

- C 1063 - 03 QzewnjmДокумент9 страницC 1063 - 03 QzewnjmGarcia ManuelОценок пока нет

- Chain Link Fence and Gates 32-31-13Документ14 страницChain Link Fence and Gates 32-31-13melvinkorahОценок пока нет

- 07a BoQДокумент15 страниц07a BoQDean KoortzenОценок пока нет

- Structural Drawings 2Документ9 страницStructural Drawings 2Makenson MuscadinОценок пока нет

- RET. WALL OriginalДокумент15 страницRET. WALL OriginalSupun Aravinda JayawardhaneОценок пока нет

- R5 - Design of R C Slabs - 2015!01!28Документ41 страницаR5 - Design of R C Slabs - 2015!01!28Udaysingh Patil100% (1)

- Development and Splice Length Calculation For Aci-318 08Документ1 страницаDevelopment and Splice Length Calculation For Aci-318 08dantevarias100% (1)

- Akzonobel Uae Paints LLC': Item Description QtyДокумент8 страницAkzonobel Uae Paints LLC': Item Description Qtyimtz2013Оценок пока нет

- Build 139 36 Design Right Free Standing Timber DecksДокумент3 страницыBuild 139 36 Design Right Free Standing Timber Deckssuejack2020Оценок пока нет

- Eranda EstimateДокумент129 страницEranda EstimateGayan Indunil JayasundaraОценок пока нет

- EPS Construction ManualДокумент97 страницEPS Construction ManualMarius IonitaОценок пока нет

- Fire-Pump Room - Rev.cДокумент1 страницаFire-Pump Room - Rev.cwael72Оценок пока нет

- Piles Table of Contents - Chapter 23Документ46 страницPiles Table of Contents - Chapter 23HumayunKabirОценок пока нет

- Civil Works MtoДокумент28 страницCivil Works MtoNassim SabriОценок пока нет

- 15 TMSS 02 R0Документ0 страниц15 TMSS 02 R0renjithas2005Оценок пока нет

- Div. 05 - BOQ - (Metal Works)Документ2 страницыDiv. 05 - BOQ - (Metal Works)Akber HassanОценок пока нет

- Grouted RiprapДокумент2 страницыGrouted Riprapflmm09100% (1)

- False Form WKДокумент12 страницFalse Form WKRonald Cario SeguinОценок пока нет

- West Qurna 1 - Weekly Progress Report # 122Документ31 страницаWest Qurna 1 - Weekly Progress Report # 122Nassim SabriОценок пока нет

- MIMO (eRAN12.1 01)Документ98 страницMIMO (eRAN12.1 01)CosminD100% (2)

- Standing Sawtooth Staircase Analysis Design and DetailingДокумент8 страницStanding Sawtooth Staircase Analysis Design and DetailingMahesh SОценок пока нет

- Construction and Design of MultistoreyДокумент37 страницConstruction and Design of MultistoreyFawadОценок пока нет

- Western India Group - PresentationДокумент32 страницыWestern India Group - PresentationZamir MujawarОценок пока нет

- HMMWV HawkeyeДокумент2 страницыHMMWV HawkeyeVictor PileggiОценок пока нет

- Steelwork Framing C2Документ26 страницSteelwork Framing C2Luwalhati TomilasОценок пока нет

- Foreman False Ceiling and Dry Wall Installation PDFДокумент53 страницыForeman False Ceiling and Dry Wall Installation PDFFazil YousufОценок пока нет

- Civil Estimate of One Storey 60x30 RC SchoolДокумент24 страницыCivil Estimate of One Storey 60x30 RC Schoolritesh patel67% (6)

- Introduction To StructuralДокумент46 страницIntroduction To Structuraljaman hossainОценок пока нет

- Debonairs Pizza Generic Costing V0615 Full Delevry Store 150 SA MetersДокумент1 страницаDebonairs Pizza Generic Costing V0615 Full Delevry Store 150 SA MetersMpange Anthony MusabailaОценок пока нет

- Yas MZ Acm ST C40 B1 DT 06003 (A)Документ1 страницаYas MZ Acm ST C40 B1 DT 06003 (A)hemanthsridharaОценок пока нет

- Description QTY Unit Rate Amount (N: K) Item NoДокумент3 страницыDescription QTY Unit Rate Amount (N: K) Item NoDamola PopoolaОценок пока нет

- Labourer Histograms GraphДокумент1 страницаLabourer Histograms Graphcrk document JayanathОценок пока нет

- Punching CheckДокумент2 страницыPunching CheckJule LobresОценок пока нет

- Construction Estimator TemplateДокумент12 страницConstruction Estimator TemplateChujja ChuОценок пока нет

- Beam Column Connection To BS5950Документ6 страницBeam Column Connection To BS5950MEPОценок пока нет

- Mitra InstituteДокумент8 страницMitra InstituteVMBUILDERS MANJERIОценок пока нет

- Building-Estimation Excel SheetДокумент3 страницыBuilding-Estimation Excel Sheetsadam mohamedОценок пока нет

- Documentation Schedule - Drum Filling SystemДокумент7 страницDocumentation Schedule - Drum Filling SystemRanjithОценок пока нет

- Tutorial 2Документ9 страницTutorial 2Sam NagpalОценок пока нет

- Lecture 17 - Design of Reinforced Concrete Beams For Shear: November 1, 2001 CVEN 444Документ35 страницLecture 17 - Design of Reinforced Concrete Beams For Shear: November 1, 2001 CVEN 444Ram RamisettiОценок пока нет

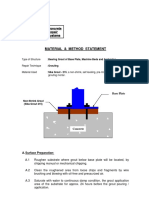

- Material & Method Statement: Concrete Repair SystemsДокумент3 страницыMaterial & Method Statement: Concrete Repair SystemsJuris DixonОценок пока нет

- Foundations High MastДокумент6 страницFoundations High MastPriya Ranjan SinghОценок пока нет

- IGS Paper Q 291Документ4 страницыIGS Paper Q 291RoshanRSVОценок пока нет

- Calculation Thickness of Tube : Design DataДокумент2 страницыCalculation Thickness of Tube : Design DataMohammad HamdaniОценок пока нет

- BOQ SampleДокумент5 страницBOQ SampleSumit yadavОценок пока нет

- Suncast Gazebo - Suncast 10' X 10' GazeboДокумент47 страницSuncast Gazebo - Suncast 10' X 10' GazeboHuh84100% (3)

- RC Two Way Slab Design ACI318 05 PDFДокумент6 страницRC Two Way Slab Design ACI318 05 PDFSafi Zabihullah SafiОценок пока нет

- Fundamentals of Civil EngineeringДокумент161 страницаFundamentals of Civil EngineeringAmyОценок пока нет

- Tech Spec Civil (Non - DSR - Items) - Vol 3Документ99 страницTech Spec Civil (Non - DSR - Items) - Vol 3Varunn Vel100% (1)

- Bridge Proper SL Item of Work Cl. No. of Unit Qty No. Mort & H'S Specification 1 2 3 4 5Документ8 страницBridge Proper SL Item of Work Cl. No. of Unit Qty No. Mort & H'S Specification 1 2 3 4 5Hoque joynulОценок пока нет

- Improving Bearing Capacity of SoilДокумент3 страницыImproving Bearing Capacity of SoilJustin MusopoleОценок пока нет

- Chain Link Fences and Gates Part 1 - General 1.1 DescriptionДокумент5 страницChain Link Fences and Gates Part 1 - General 1.1 Descriptionm_a_nada67% (3)

- QCS 2010 Section 4 Part 8 Steel PilesДокумент6 страницQCS 2010 Section 4 Part 8 Steel Pilesbryanpastor106Оценок пока нет

- Table of Contents PageДокумент15 страницTable of Contents PageEr Nizar AhamedОценок пока нет

- Iqwq-Ce1092-Cpzzz-00-0003 - 0 - Civil Work Construction Procedure PDFДокумент12 страницIqwq-Ce1092-Cpzzz-00-0003 - 0 - Civil Work Construction Procedure PDFNassim SabriОценок пока нет

- Grade of Re-Bar Must Be 60 ASTM A615/A615M: O RO CO PДокумент1 страницаGrade of Re-Bar Must Be 60 ASTM A615/A615M: O RO CO PNassim SabriОценок пока нет

- Ce-C 0195Документ3 страницыCe-C 0195Nassim SabriОценок пока нет

- SXQДокумент5 страницSXQNassim SabriОценок пока нет

- Readiness For Project AWQ 317Документ1 страницаReadiness For Project AWQ 317Nassim SabriОценок пока нет

- Audit For Lab A Q: This Audit Was Carried On As Per The ( (Astm Standard D 3740 - 10) )Документ1 страницаAudit For Lab A Q: This Audit Was Carried On As Per The ( (Astm Standard D 3740 - 10) )Nassim SabriОценок пока нет

- Site Civil Tests Lab LocationsДокумент1 страницаSite Civil Tests Lab LocationsNassim SabriОценок пока нет

- GF-C Fan Belt Drive: Local Add On Manual Operation InstructionsДокумент32 страницыGF-C Fan Belt Drive: Local Add On Manual Operation InstructionsFaysbuk KotoОценок пока нет

- Manual de Diseño Bunker para Acelerador LinealДокумент184 страницыManual de Diseño Bunker para Acelerador LinealJulian José Ollarvez Abreu67% (3)

- 12jun27 FC Perfect Stores Add Zing To HUL's Sales Growth - tcm114 289918 PDFДокумент1 страница12jun27 FC Perfect Stores Add Zing To HUL's Sales Growth - tcm114 289918 PDFSantosh SinghОценок пока нет

- Disawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Документ8 страницDisawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Mohamed HassanainОценок пока нет

- Domyancic State OfficialДокумент1 страницаDomyancic State Officialapi-300790110Оценок пока нет

- How To Check The Lms For MR PostingДокумент7 страницHow To Check The Lms For MR PostingMica FloresОценок пока нет

- LH T6540Документ54 страницыLH T6540raja1701Оценок пока нет

- The Great Eggscape: Corey Kelvin Group 73 Nizam Umayr PatriciaДокумент7 страницThe Great Eggscape: Corey Kelvin Group 73 Nizam Umayr PatriciaLegendaryNОценок пока нет

- GEA 2H Cross Flow FillsДокумент2 страницыGEA 2H Cross Flow FillsvijaysupriyaОценок пока нет

- LPBF48100 M(说明书)Документ8 страницLPBF48100 M(说明书)Pawrij SuriyaaroonrojОценок пока нет

- 14 ComputoДокумент549 страниц14 ComputoEver Henry FloresОценок пока нет

- TCH Assignment Success Rate (%)Документ7 страницTCH Assignment Success Rate (%)AbebeОценок пока нет

- RCDC Getting StartedДокумент13 страницRCDC Getting StartedEr Suresh Kumar100% (2)

- FTTX GPONДокумент25 страницFTTX GPONAlirezaОценок пока нет

- Unit 1Документ20 страницUnit 1S APОценок пока нет

- Erection of Transformer and ReactorДокумент90 страницErection of Transformer and Reactorumamaheshwarrao100% (1)

- Lean Case Study Part IДокумент6 страницLean Case Study Part IAnonymous QI9xEjrbplОценок пока нет

- Shindengen: Stepping Motor Driver IcsДокумент2 страницыShindengen: Stepping Motor Driver IcsEngin UzunОценок пока нет

- Rec Erc 78 08Документ22 страницыRec Erc 78 08Jerry PellerОценок пока нет

- WI - C.4.1 Set Up Site Documentation V1.1aДокумент5 страницWI - C.4.1 Set Up Site Documentation V1.1ayoen_anОценок пока нет

- Trent University Academic Plan (2012-2015)Документ94 страницыTrent University Academic Plan (2012-2015)Peterborough ExaminerОценок пока нет

- Design and Construction of A Yagi-Uda Antenna For The 433 MHZ BandДокумент4 страницыDesign and Construction of A Yagi-Uda Antenna For The 433 MHZ BandognianovОценок пока нет

- Position Paper ExampleДокумент3 страницыPosition Paper ExampleRamy Joy MorquianosОценок пока нет

- MOVsДокумент21 страницаMOVsCons Agbon Monreal Jr.Оценок пока нет

- Banana Peel ScriptДокумент4 страницыBanana Peel ScriptALoma JaneОценок пока нет