Академический Документы

Профессиональный Документы

Культура Документы

13 Jigging

Загружено:

Tapas Das0 оценок0% нашли этот документ полезным (0 голосов)

290 просмотров33 страницыjigging proccess

Оригинальное название

13.Jigging

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документjigging proccess

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

290 просмотров33 страницы13 Jigging

Загружено:

Tapas Dasjigging proccess

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 33

JIGGING

Govardhana | Dept of MME | NIT Warangal

Jigging

Jigging is a ore concentration carried out in any

fluid and depending for its effectiveness on

differences in specific gravity of granular mineral

practice

Jigging is one of the oldest methods for

concentrating minerals (3-10 mm) based on

differences in the density of the particles by the

pulsation of a stream of liquid (water), flowing

through the bed of materials

Jigging

The liquid pulsation causes stratification i.e. the

heavy particles to migrate through the bed to the

bottom of the bed and the light particles to rise to

the top

It consists of stratification of the particles into

layers of different specific gravities followed by

removal of the stratified layers

Application- recovery of gold, tin, tungsten and iron ore industries

Jigging

Each fraction can then be separately taken out

The main phenomenon of the particle separation in

jigging is by hindered settling

Mechanical device used for separating the materials using the jigging principle JIG

1.

2.

3.

Three effects can be distinguished as contributing to

the stratification in jigs they are

Hindered settling classification

Differential acceleration at beginning of fall

Consolidation trickling at end of fall

Contd...

On the pulsion stroke the bed is normally lifted as a mass,

then as the velocity decreases it tends to dilate

The bottom particles falling first until the whole bed is

loosened

On the suction stroke it then closes slowly again. The

frequency usually varying between 55 and 330 c/m

Fine particles tend to pass through the interstices after the

large ones have become immobile

The motion can be obtained either by using a fixed sieve jig,

and pulsating the water, or by employing a moving sieve, as in

the simple hand-jig

Contd...

Jigging process

Jigging process

Hindered settling

The essential difference in hindered settling

between jigs and classifiers is that in jigging the

solid-fluid mixture is so thick as to approximate a

loosely packed bed of solids with interstitial fluid

instead if a fluid carrying a great number of

suspended solid particles

Contd...

The thick solid-fluid mixture used in jigging cannot

be maintained for any length of time

It does not allow sufficient play for complete

rearrangement of the solids

After a longer time particles attain their terminal

velocities and will be moving at a rate dependent

on their specific gravity and size

Contd...

The material bed is a loosely packed mass with

interstitial water providing a very thick suspension

of high density , hindered-settling conditions

prevail, i.e. settling ratio of heavy to light minerals

is higher than that for free settling

The upward flow can be adjusted so that it overcomes

the downward velocity of the fine light particles and

carries them away, thus achieving separation

Contd...

The upward flow can be increased further so that only

large heavy particles settle

But it will not be possible to separate the small heavy

and large light particles of similar terminal velocity

Hindered settling has a marked effect on the separation

of coarse minerals, for which longer, slower strokes

should be used

Differential acceleration

During the accelerating period, the heavy particles have a

greater initial acceleration and speed than the lighter particles

The initial acceleration of the mineral grains is independent of

size and dependent only on the densities of the solid and the

fluid

It follows that if the duration of fall is short enough and the

repetition of fall frequent enough, the total distance travelled

by the particles will be affected more by the differential initial

acceleration than to their terminal velocity, means

stratification would take place on the basis of density alone

Contd...

In other words, to separate small heavy mineral

particles from large light particles a short jigging

cycle is necessary

Consolidation trickling

At the end of a pulsion stroke, as the bed begins to

compact, the larger particles interlock, allowing the

smaller grains to move downwards through the

interstices under the influence of gravity

The fine grains may not settle as rapidly during this

consolidation trickling phase as during the initial

acceleration or suspension

But if consolidation trickling can be made to last

long enough, the effect, especially in the recovery

of the fine heavy minerals, can be considerable

Contd...

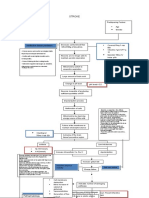

Ideal Jigging process

In the jig the pulsating water currents are caused by

a piston having a movement which is a harmonic

waveform

The vertical speed of flow through the bed is

proportional to the speed of the piston

When this speed is greatest, the speed of flow

through the bed is also greatest

The upward speed of flow increases after point A, the beginning of

the cycle

As the speed increases, the grains will be loosened and the bed will

be forced open, or dilated

At, say, point B, the grains are in the phase of hindered settling in

an upward flow, and since the speed of flow from B to C still

increases, the fine grains are pushed upwards by the flow

The chance of them being carried along with the top flow into the

tailings is then at its greatest

In the vicinity of D, first the coarser grains and later on the

remaining fine grains will fall back

Due to the combination of initial acceleration and hindered settling,

it is mainly the coarser grains that will lie at the bottom of the bed

At the point of transition between the pulsion and the suction

stroke, at point E, the bed will be compacted

Consolidation trickling can now occur to a limited extent

In a closely sized ore the heavy grains can now penetrate only

with difficulty through the bed and may be lost to the tailings

Severe compaction of the bed can be reduced by the addition

of hutch water, a constant volume of water, which creates a

constant upward flow through the bed

This flow, coupled with the varying flow caused by the piston,

is shown in Figure

Effect of hutch water on flow through bed

Thus suction is reduced by hutch-water addition, and is

reduced in duration; by adding a large quantity of water, the

suction may be entirely eliminated

The coarse ore then penetrates the bed more easily and the

horizontal transport of the feed over the jig is also improved

However, fines losses will increase, partly because of the

longer duration of the pulsion stroke, and partly because the

added water increases the speed of the top flow

TYPICAL HYDRAULIC JIGS

Fixed sieve Plunger Jigs [ Harz jig ]

It has fixed sieve

Jigging motion is obtained by a plunger P reciprocating in a

compartment C adjoining the sieve compartment

The bottom layer is removed through the gate A after passage

into the well or draw B

The upper layer (usually the tailing) is discharged at the end

away from the feed

Harz jigs are usually built of wood, but construction of

concrete has been reported

They are built of several compartments in series the tailing

from one compartment passing as feed into the next

compartments

The amplitude of jigging is greatest in the first cell and least in

the last

Rising water is added to compensate for excessive suction

either above or below the plunger

Variations in the relative use of pulsion and suction are

obtained by varying the amount of rising water

The length of stroke usually ranges from 0.5 to 8 cm

depending upon the fineness of the feed, long strokes being

used for coarse feed

Jigging cycles range form 0.2 to 0.6 sec (100 to 300 strokes

per minute )

Fixed-sieve Pulsator Jigs (Richards pulsator jig)

This jig has arated capacity 90 tons per day

Each of four compartments having a screen surface only 4 by

4 inch

Water is admitted through a rotating valve V at 150 to 200

strokes per minute

Water requirement is relatively large, power consumption is

low

Clean concentrates are easily obtained but clean tailings are

not the rule

Richards pulsator jig

Fixed-sieved, Air-pulse Jigs (Simon-Carves jig)

By this jigs and by using jigging principles to clean the coal

The jig is shaped like U tube with one side sealed and the

other opened

The sealed side alternately receives and exhausts compressed

air through a piston valve

This communicates pulsion and suction respectively to the

other side of U tube in which perforated plates carry the coal

and refuse

The complete machine consists of five cells

Feed enters at the right end of the machine at A

The clean coal leaves at the other end of the machine

at B

Tailings discharges by a gate under the feed chute to

the right of the machine at C

PNEUMATIC JIGS

Pneumatic jigs utilize stratification of particles in

air instead of in water

30 to 40 million tons coal was annually treated

Current models of pneumatic jigs use a shallow bed

of mineral and are surfaced with riffles in the

manner of shaking table (Pneumatic tables)

It uses art of wet gravity concentration

All pneumatic jigs or tables produce first a vertical

stratification of the particles in order of decreasing

specific gravity more or less modified by size

Pneumatic Jigs using no Horizontal Stratification

(Plumb jig)

It is a pulsator jig controlled by a rotary value and

using 400 to 500 pulsations per min of 10 to 30 lb

air

Capacity is 0.5 ton per sq.ft. per hour for the

coarsest feed down to a small fraction of this for

fine feed

This jig was used for concentration of sulphides

Вам также может понравиться

- History Taking in CVA (HOPI DR Chandra)Документ3 страницыHistory Taking in CVA (HOPI DR Chandra)AshbirZammeriОценок пока нет

- Concept Map CVAДокумент1 страницаConcept Map CVASuzette Rae Tate100% (2)

- Leaching of Nickel (Group B) 2Документ16 страницLeaching of Nickel (Group B) 2Thato MaamoeОценок пока нет

- Chemicals Zetag MSDS Beads Magnafloc 156 - 0510Документ7 страницChemicals Zetag MSDS Beads Magnafloc 156 - 0510PromagEnviro.com100% (1)

- Chainage Ground Level Rail Level Distance From Tunnel Axis To Rail LevelДокумент3 страницыChainage Ground Level Rail Level Distance From Tunnel Axis To Rail Levelnipun jainОценок пока нет

- Cerro Corona Testwork Report May09.2Документ4 страницыCerro Corona Testwork Report May09.2Freck Pedro OliveraОценок пока нет

- Kemix Electrowinning-Cell-Brochure 2018 Rev0Документ4 страницыKemix Electrowinning-Cell-Brochure 2018 Rev0evalenciaОценок пока нет

- Reichert Cone Concentrator SystemДокумент9 страницReichert Cone Concentrator Systemaneece786Оценок пока нет

- Chapt5 - Theory of Sedimentation PDFДокумент18 страницChapt5 - Theory of Sedimentation PDFNgoni Mukuku100% (1)

- Carbon StrippingДокумент13 страницCarbon StrippingFrankulloa31Оценок пока нет

- Dense Medium SeparationДокумент37 страницDense Medium SeparationFelipe Goes Ribeiro BrideОценок пока нет

- SART For Copper Control in Cyanide Heap LeachingДокумент13 страницSART For Copper Control in Cyanide Heap Leachingriturrieta878Оценок пока нет

- The Effect of External Gasislurry Contact On The Flotation of Fine ParticlesДокумент130 страницThe Effect of External Gasislurry Contact On The Flotation of Fine ParticlesOmid VandghorbanyОценок пока нет

- Beneficiation of Low Grade Graphite Ore Deposits of Tamilnadu (India)Документ10 страницBeneficiation of Low Grade Graphite Ore Deposits of Tamilnadu (India)sanjibkrjanaОценок пока нет

- Electrical Resistivity and ConductivityДокумент16 страницElectrical Resistivity and ConductivityPrince JunejaОценок пока нет

- Whole-Life Cost Analysis of Concrete Block Paving PDFДокумент9 страницWhole-Life Cost Analysis of Concrete Block Paving PDFSi ZhangОценок пока нет

- Comminution PDFДокумент10 страницComminution PDFKhana Rizki MaulanaОценок пока нет

- SedimentationДокумент38 страницSedimentationMilind BhaskarОценок пока нет

- Treatment of A Copper-Rich Gold Ore by C PDFДокумент11 страницTreatment of A Copper-Rich Gold Ore by C PDFGeorgi SavovОценок пока нет

- Mass Balance Calculations Around Mineral Processing Units Using Composition Analyses Within Particle-Size ClassesДокумент18 страницMass Balance Calculations Around Mineral Processing Units Using Composition Analyses Within Particle-Size ClassesRobby AnugrahОценок пока нет

- Mine Process Report PDFДокумент65 страницMine Process Report PDFKurabiy KahinОценок пока нет

- Celda Flash Site Skim Air Test Procedure With PhotosДокумент9 страницCelda Flash Site Skim Air Test Procedure With Photosealfaro6580Оценок пока нет

- Effect of The Bubble Size On The Dynamic Adsorption of Frothers and Collectors in FlotationДокумент9 страницEffect of The Bubble Size On The Dynamic Adsorption of Frothers and Collectors in FlotationJose Luis Barrientos RiosОценок пока нет

- Hydro MetallurgyДокумент51 страницаHydro MetallurgyMamamamajОценок пока нет

- Angle of Repose: Instructions (Read These Carefully or You Will Have To Redo Your Responses!)Документ6 страницAngle of Repose: Instructions (Read These Carefully or You Will Have To Redo Your Responses!)Rohit GadekarОценок пока нет

- Gravity Separation-Old Technique-New Methods PDFДокумент19 страницGravity Separation-Old Technique-New Methods PDFVinCent RoHerОценок пока нет

- Characterization of Single ParticleДокумент29 страницCharacterization of Single ParticlePiyush RajОценок пока нет

- MEng - Effect of Slurry Rheology On Gas Dispersion in A Pilot-Scale Mechanical Flotation CellДокумент7 страницMEng - Effect of Slurry Rheology On Gas Dispersion in A Pilot-Scale Mechanical Flotation Cellpmanquera89Оценок пока нет

- GPH 231Документ113 страницGPH 231Adwaitesh Aaradhya100% (2)

- Storage PDFДокумент12 страницStorage PDFanasabdullahОценок пока нет

- A Parametric Study of Froth Stability and Its EffectДокумент19 страницA Parametric Study of Froth Stability and Its EffectJuan OlivaresОценок пока нет

- Particle Size AnalysisДокумент27 страницParticle Size AnalysisPhan Nee100% (1)

- Flotation: Hydrophobicity and HydrophilicityДокумент19 страницFlotation: Hydrophobicity and HydrophilicitydiRkdARyLОценок пока нет

- Classification in Mineral ProcessingДокумент3 страницыClassification in Mineral ProcessingNyasha Makwarimba0% (1)

- Presentation On Type of Sample and Sampler in Geotechnical Engineering 1234Документ15 страницPresentation On Type of Sample and Sampler in Geotechnical Engineering 1234Indranil Banerjee0% (1)

- Selective Nickel ElectrowinningДокумент36 страницSelective Nickel ElectrowinningmehdituranОценок пока нет

- Electrowinning of Metals: Mineral Processing CourseДокумент13 страницElectrowinning of Metals: Mineral Processing CourseAdham ElbrawyОценок пока нет

- Belt Filter Cloth Brochure - SaferДокумент11 страницBelt Filter Cloth Brochure - Saferrajeevup2004Оценок пока нет

- Rheology of Slurry A ReviewДокумент15 страницRheology of Slurry A ReviewIJRASETPublicationsОценок пока нет

- P1 (Intro) & P2Документ38 страницP1 (Intro) & P2Khana Rizki MaulanaОценок пока нет

- Spiral Brochure 3-2007Документ8 страницSpiral Brochure 3-2007MikeWalsheОценок пока нет

- Zaldivar Agglomeration DrumДокумент1 страницаZaldivar Agglomeration DrumKroya Hun100% (1)

- Understanding Impurities in Copper ElectrometallurgyДокумент61 страницаUnderstanding Impurities in Copper ElectrometallurgyJoselinn LoaezaОценок пока нет

- Circulating Load RatioДокумент2 страницыCirculating Load RatioAraf AhmadОценок пока нет

- Comminution Ore TestingДокумент35 страницComminution Ore TestingHarrison Antonio Mira NiloОценок пока нет

- SedimentationДокумент41 страницаSedimentationGailОценок пока нет

- Robin Grayson Gold Recovery Method14Документ1 страницаRobin Grayson Gold Recovery Method14JavierMamaniVelasquezОценок пока нет

- Centrifugal Separation and SievingДокумент5 страницCentrifugal Separation and SievingVincent NguyenОценок пока нет

- Hand Panning: Vincent T. Cui Mete 128: Mineral Processing LaboratoryДокумент3 страницыHand Panning: Vincent T. Cui Mete 128: Mineral Processing LaboratoryVincent Tayanes Cui100% (1)

- CHE 321 Unit Operation 1 (3 Units) : 1: Drying, Conveying 2: Sedimentation, ClarificationДокумент32 страницыCHE 321 Unit Operation 1 (3 Units) : 1: Drying, Conveying 2: Sedimentation, ClarificationGlory UsoroОценок пока нет

- SedimentationДокумент3 страницыSedimentationEldee BalolongОценок пока нет

- FlotationДокумент7 страницFlotationArif HışırОценок пока нет

- Leaching 1 2Документ32 страницыLeaching 1 2hartatiprasetyoОценок пока нет

- Gravity ConcentrationДокумент21 страницаGravity ConcentrationLucia Ines Ochoa CorreaОценок пока нет

- Written ReportДокумент16 страницWritten ReportJamel Cayabyab50% (2)

- Igneous Rock TexturesДокумент5 страницIgneous Rock Texturesapi-3808551Оценок пока нет

- Lecture 1 - Origin of HydrocarbonsДокумент19 страницLecture 1 - Origin of Hydrocarbonshasan sabahОценок пока нет

- The Principles of Gravity Concentration-RevisiДокумент27 страницThe Principles of Gravity Concentration-Revisinadya zulfaniОценок пока нет

- Beneficiation of CoalДокумент24 страницыBeneficiation of CoalPARTHA SARATHI PANDAОценок пока нет

- Jose Bene Assgnmnt 1Документ9 страницJose Bene Assgnmnt 1RODGERSОценок пока нет

- AFPT-Lecture 28-1Документ22 страницыAFPT-Lecture 28-1Tapas DasОценок пока нет

- ElectrometalurgiaДокумент24 страницыElectrometalurgiaEmmanuel BocheОценок пока нет

- 01 CFF Fracture NNДокумент97 страниц01 CFF Fracture NNTapas DasОценок пока нет

- Introduction PDFДокумент15 страницIntroduction PDFTapas DasОценок пока нет

- Phase Diagram/ Equilibrium DiagramДокумент12 страницPhase Diagram/ Equilibrium DiagramTapas DasОценок пока нет

- L2 BondsДокумент10 страницL2 BondsTapas DasОценок пока нет

- 2 SamplingДокумент24 страницы2 SamplingTapas DasОценок пока нет

- Fourier Series AssignmentДокумент3 страницыFourier Series AssignmentTapas Das0% (1)

- TablingДокумент24 страницыTablingTapas DasОценок пока нет

- Sedimentation and Elutration PDFДокумент14 страницSedimentation and Elutration PDFTapas Das50% (4)

- TP - Properties of FluidsДокумент52 страницыTP - Properties of FluidsTapas DasОценок пока нет

- 3.sieve AnalysisДокумент24 страницы3.sieve AnalysisTapas DasОценок пока нет

- Clinical Pathway - Stroke Without Thrombolytic TherapyДокумент4 страницыClinical Pathway - Stroke Without Thrombolytic TherapysiusiuwidyantoОценок пока нет

- Filtri CavaliДокумент11 страницFiltri CavaliandreaОценок пока нет

- NP3 Recalls5Документ9 страницNP3 Recalls5AhrisJeannine EscuadroОценок пока нет

- Prof TestДокумент13 страницProf TestOlive NОценок пока нет

- Cerebrovascular AccidentДокумент34 страницыCerebrovascular AccidentCellanie Janson50% (8)

- Chapter 026 CoagulationДокумент7 страницChapter 026 Coagulationthubtendrolma100% (3)

- DantroleneДокумент10 страницDantroleneJason TiongОценок пока нет

- Midterm Exam: The Following Are Related To The Different Lobes of The CerebrumДокумент13 страницMidterm Exam: The Following Are Related To The Different Lobes of The CerebrumasdfasdfsadfsaОценок пока нет

- Dosing Pump BTB4Документ54 страницыDosing Pump BTB4Ci ReОценок пока нет

- 10 1161@jaha 115 003158 PDFДокумент9 страниц10 1161@jaha 115 003158 PDFnabila noorОценок пока нет

- Cardiovascular SystemДокумент5 страницCardiovascular SystemDrexel DalaygonОценок пока нет

- Stroke Syndromes (Etiology & Clinical Features)Документ40 страницStroke Syndromes (Etiology & Clinical Features)nisha_m_patel2006Оценок пока нет

- List of Medical and Nursing Abbreviations, Acronyms, Terms 1 - NurseslabsДокумент25 страницList of Medical and Nursing Abbreviations, Acronyms, Terms 1 - NurseslabsbeingfiredОценок пока нет

- Soalan LatihanДокумент7 страницSoalan LatihanNur Afiq NoorhishamОценок пока нет

- Management of Spasticity in Stroke: Bipin B BhaktaДокумент10 страницManagement of Spasticity in Stroke: Bipin B BhaktaCHANDAN RAIОценок пока нет

- Body Weight Support Treadmill TrainingДокумент23 страницыBody Weight Support Treadmill Trainingvidyasagar pagillaОценок пока нет

- Apostila R2Документ469 страницApostila R2Lucas TheotonioОценок пока нет

- The Star News January 28, 2016Документ36 страницThe Star News January 28, 2016The Star NewsОценок пока нет

- Health9 - q1 - Mod4 - Effects of Environmental Issues - v3Документ22 страницыHealth9 - q1 - Mod4 - Effects of Environmental Issues - v3HARLEY L. TAN89% (9)

- Lacunar SyndromeДокумент12 страницLacunar SyndromeRoxana Maria RaduОценок пока нет

- Implementation and Analysis of A Free Water Protocol in Acute Trauma and Stroke PatientsДокумент9 страницImplementation and Analysis of A Free Water Protocol in Acute Trauma and Stroke PatientsDewie DeblongОценок пока нет

- 100 Case Reviews in Neurosurgery 1St Edition Rahul Jandial Full ChapterДокумент51 страница100 Case Reviews in Neurosurgery 1St Edition Rahul Jandial Full Chapterseth.hilton498100% (16)

- Management of Diabetes and Hyperglycemia in Hospitals: S C S S. B, M F. M, A A, E P. S, R G. S, I B. H, D H W CДокумент39 страницManagement of Diabetes and Hyperglycemia in Hospitals: S C S S. B, M F. M, A A, E P. S, R G. S, I B. H, D H W CMarshell TendeanОценок пока нет

- Σκορ ΛιονηДокумент38 страницΣκορ ΛιονηΑντώνιος ΧατζηγεωργίουОценок пока нет

- Crossed AphasiaДокумент5 страницCrossed AphasiaBeny RiliantoОценок пока нет

- Content ServerДокумент19 страницContent ServerSitti Rosdiana YahyaОценок пока нет

- Finals Case 1 VDДокумент28 страницFinals Case 1 VDMae Arra Lecobu-anОценок пока нет

- Takaful Smart Plus BrochureДокумент27 страницTakaful Smart Plus BrochureSubang Jaya Youth ClubОценок пока нет