Академический Документы

Профессиональный Документы

Культура Документы

Pile Foundations Part-1

Загружено:

mohanty_anantakumar6332Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pile Foundations Part-1

Загружено:

mohanty_anantakumar6332Авторское право:

Доступные форматы

CE 632

CE-632

Foundation Analysis and

Design

Pile Foundations

1

Foundation Analysis and Design: Dr. Amit Prashant

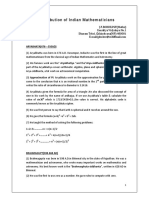

Indian Standards on Piles

IS 2911 : Part 1 : Sec 1 : 1979 Driven cast in-situ concrete piles

IS 2911 : Part 1 : Sec 2 : 1979 Bored cast-in-situ

cast in situ piles

IS 2911 : Part 1 : Sec 3 : 1979 Driven precast concrete piles

IS 2911 : Part 1 : Sec 4 : 1984 Bored precast concrete piles

IS 2911 : Part 2 : 1980 Timber piles

IS 2911 : Part 3 : 1980 Under reamed piles

IS 2911 : Part 4 : 1985 Load test on piles

IS 5121 : 1969 Safety code for piling and other deep foundations

IS 6426 : 1972 Specification for pile driving hammer

IS 6427 : 1972 Glossary of Terms Relating to Pile Driving Equipment

IS 6428 : 1972 Specification for pile frame

IS 9716 : 1981 Guide for lateral dynamic load test on piles

IS 14362 : 1996 Pile boring equipment - General requirements

IS 14593 : 1998 Bored cast-in-situ piles founded on rocks - Guidelines

IS 14893 : 2001 N

Non-Destructive

D t ti IIntegrity

t it T

Testing

ti off Pil

Piles (NDT) Guidelines

Foundation Analysis and Design: Dr. Amit Prashant

When is it needed

Top layers of soil are highly compressible for it to support

structural loads through shallow foundations

foundations.

Rock level is shallow enough for end bearing pile

foundations provide a more economical design

design.

Lateral forces are relatively prominent.

I presence off expansive

In

i and

d collapsible

ll

ibl soils

il att th

the site.

it

Offshore structures

Strong uplift forces on shallow foundations due to shallow

water table can be partly transmitted to Piles.

For structures near flowing water (Bridge abutments, etc.)

to avoid the problems due to erosion.

3

Foundation Analysis and Design: Dr. Amit Prashant

Types of Piles

Steel Piles

Pipe

piles

Rolled steel H-section

H section piles

Concrete Piles

Pre-cast

Piles

Cast

Cast-in-situ

in situ Piles

Bored-in-situ piles

Timber Piles

C

Composite

it Pil

Piles

4

Foundation Analysis and Design: Dr. Amit Prashant

Steel Piles: Facts

Usual length: 15 m 60 m

Usual Load: 300 kN 1200 kN

Advantage:

g

Relatively less hassle during installation and easy to achieve

cutoff level.

Hi h driving

High

d i i force

f

may be

b used

d for

f fast

f t installation

i t ll ti

Good to penetrate hard strata

Load carrying capacity is high

Disadvantage:

Relatively expensive

Noise pollution during installation

Corrosion

Bend in piles while driving

5

Foundation Analysis and Design: Dr. Amit Prashant

Concrete Piles: Facts

Pre-cast Piles:

Usuall llength:

U

h 10 m 45

4 m

Usual Load: 7500 kN 8500 kN

Cast-in-situ Piles:

Usual length: 5 m 15 m

Usual Load: 200 kN 500 kN

Advantage:

Relatively cheap

It can be easily combined with concrete superstructure

Corrosion resistant

It can bear hard driving

Disadvantage:

Difficult to transport

p

Difficult to achieve desired cutoff

6

Foundation Analysis and Design: Dr. Amit Prashant

Types of Piles Based on Their Function and Effect

of Installation

Pil b

Piles

based

d on th

their

i ffunction

ti

End Bearing Piles

F i ti Piles

Friction

Pil

Compaction Piles

Anchor Piles

Uplift Piles

Effect of Installation

Displacement

Di

l

t Pil

Piles

Non-displacement Piles

7

Foundation Analysis and Design: Dr. Amit Prashant

Displacement Piles

In loose cohesionless soils

Densifies the soil upto

p a distance of 3.5 times the p

pile diameter

(3.5D) which increases the soils resistance to shearing

The friction angle varies from the pile surface to the limit of

compacted soil

In dense cohesionless soils

The dilatancy effect decreases the friction angle within the zone of

p

p

pile ((3.5D approx.).

pp

)

influence of displacement

Displacement piles are not effective in dense sands due to above

reason.

In cohesive soils

Soil is remolded near the displacement piles (2.0 D approx.) leading

to a decreased value of shearing resistance.

Pore

Pore-pressure

pressure is generated during installation causing lower

effective stress and consequently lower shearing resistance.

Excess pore-pressure dissipates over the time and soil regains its

g

strength.

Example: Driven concrete piles, Timber or Steel piles

8

Foundation Analysis and Design: Dr. Amit Prashant

Non--displacement Piles

Non

Due to no displacement during installation, there is no heave in

the ground.

g

Cast in-situ piles may be cased or uncased (by removing

casing as concreting progresses). They may be provided with

reinforcement

i f

t if economical

i l with

ith th

their

i reduced

d

d di

diameter.

t

Enlarged bottom ends (three times pile diameter) may be

provided in cohesive soils leading to much larger point bearing

capacity.

Soil on the sides mayy soften due to contact with wet concrete

or during boring itself. This may lead to loss of its shear

strength.

Concreting

C

ti under

d water

t may b

be challenging

h ll

i and

d may resulting

lti

in waisting or necking of concrete in squeezing ground.

Example: Bored cast in-situ or pre-cast piles

9

Foundation Analysis and Design: Dr. Amit Prashant

Load Transfer Mechanism of Piles

With the increasing load on a pile initially the resistance is offered by side friction

and when the side resistance is fully mobilized to the shear strength of soil, the

rest of load is supported

pp

by

yp

pile end. At certain load the soil at the p

pile end fails,

usually in punching shear, which is defined as the ultimate load capacity of pile.

10

Foundation Analysis and Design: Dr. Amit Prashant

Load Transfer Mechanism of Piles

The frictional resistance

per unit area at any

depth

Qz

qsz =

S .z

S = perimeter of pile

Ultimate skin friction

resistance of pile

Qsu

Ultimate point load

Q pu = q pu . Ap

z

Qs

q pu = bearing capacity of soil

Ap = bearing area of pile

Ultimate load capacity

in compression

Ultimate load capacity

in tension

Qu = Q pu + Qsu

Qu = Qsu

Qupp

Qus

Qu

11

Foundation Analysis and Design: Dr. Amit Prashant

Point Load capacity

p

y of Pile: General Bearing

g

Capacity approach

Ultimate bearing capacity of soil considering general bearing

capacity equation. Shape, inclination, and depth factors are

included in bearing capacity factors

q pu = cN c* + qN q* + 0.5 DN*

Since pile diameter is relatively small, third term may be dropped

out

q pu = cN c* + qN q*

Hence Pile load capacity

Q pu = q pu . Ap = cN c* + qN q* . Ap

12

Foundation Analysis and Design: Dr. Amit Prashant

Point Load capacity

p

y of Pile: Meyerhofs

y

((1976))

Method

Granular soils:

Point bearing capacity of pile increases with depth in sands and

reaches its maximum at an embedment ratio L/D = (L/D)cr.

Therefore, the point load capacity of pile is

Q pu = Ap .q.N q* < Ap .qul

qul = 0.5Pa N q* tan

Pa = Atmospheric

p

ppressure

(L/D)cr value typically ranges from 15D for loose to medium sand to

20D for dense sands.

Correlation of limiting point resistance with SPT value

qul = 0.4 ( N )

L

4 Pa ( N )

D

N value shall be taken as an average for a zone ranging from 10D

above to 4D below the pile point.

Saturated Clays:

Q pu = N c* .cu . Ap = 9.cu . Ap

13

Foundation Analysis and Design: Dr. Amit Prashant

Point Load capacity

p

y of Pile: Vesics ((1977)) Method

Pile point bearing capacity based on the theory of expansion of cavities

Q pu = Ap .qup = Ap . c.N c* + o N*

1 + 2Ko

3

o =

Mean effective normal stress at pile end

N* =

f ( I rr )

I rr =

I r = rigidity index =

N c* =

Ir

1 + Ir

avg vol strain at pile end

Reduced rigidity index of soil

Gs

Es

=

( c + q tan ) 2 (1 + s )( c + q tan )

I

+

+

ln

1

( rr ) + 1

3

2

Type of soil

Ir

Sand

75-150

Silt

50-75

Clay

150-250

Baldi

B

ldi ett al.

l (1981):

(1981)

For mechanical

cone resistance

Ir =

3

q f qc

For electric cone

resistance

Ir =

11.7

7

q f qc

14

Foundation Analysis and Design: Dr. Amit Prashant

Point Load capacity of Pile: Janbus

Janbu s (1976) Method

Q pu = Ap c.N c* + q.N q*

N = tan + 1 + tan 2

*

q

) (e

2

2 tan

60o 90o

Clay

Sand

N c* = N q* 1 cot

15

Foundation Analysis and Design: Dr. Amit Prashant

Point Load capacity of Pile:

Coyle and Costellos (1981)

Method for Granular Soils

Q pu = Ap .q.N q*

L

ratio

N is a function of

D

L is length of pile below G.L.

*

q

16

Foundation Analysis and Design: Dr. Amit Prashant

Point Load Capacity

y of Pile resting

g on Rock

Goodman (1980):

Q pu = Ap .qu ( N + 1)

N = tan 2 ( 45 + 2 )

qu = unconfined compression strength of rock

= effective friction angle of rock

To consider the influence of distributed fractures in rock

which

hi h are not reflected

fl

db

by the

h compression

i tests on smallll

samples, the compression strength for design is taken as

( qu )design =

( qu )lab

5

17

Foundation Analysis and Design: Dr. Amit Prashant

Frictional Resistance of Pile: In Sand

The frictional resistance of pile may be

computed as

Qsu = S .L. f sz

f sz = K . v .tan f sL

The unit frictional resistance increases with

the depth and reaches its maximum at the

depth of approximately 15D to 20D, as shown

in the adjacent figure.

K v

Soil-Pile

S

il Pil iinterface

t f

ffriction

i ti angle

l varies

i ffrom

0.5' to 0.8.Earth pressure coefficient

depends on both soil type and pile installation.

18

Foundation Analysis and Design: Dr. Amit Prashant

Frictional Resistance of

Pile: In Sand

Bhushan ((1982)) suggested

gg

that the

value of K and K.tan for large

displacement piles can be

computed as

Coyle and

C t ll

Castello

(1981)

K = 0.50 + 0.008Dr

K .tan

t = 0.18

0 18 + 0.0065

0 0065Dr

Coyle and Castello (1981) proposed

that ultimate skin frictional resistance

of pile can be computed as

Qsu = ( f s )av .S .L

= K . v .tan

tan .S .L

Avg effective overburden

19

Foundation Analysis and Design: Dr. Amit Prashant

Frictional Resistance of Pile: In Sand

Zeitlen and Paikowski (1982) suggested

that limiting fs is automatically accounted

for by the decrease in with effective

confining pressure which may be used to

compute K and .

v

= o 5.5log

o

Failure

Envelope

Effective vertical stress at the depth of interest

Effective confining

g stress during

g triaxial test

Friction angle obtained through triaxial testing at some confining pressure o.

Typical values of K from a number of pile tests:

20

Foundation Analysis and Design: Dr. Amit Prashant

Frictional Resistance of Pile In Clays: -method

Proposed by Tomlinson (1971):

f s = .cu

Empirical adhesion factor

21

Foundation Analysis and Design: Dr. Amit Prashant

Frictional Resistance

of Pile In Clays:

-method

Randolph and

Murphy (1985)

Randolph and Murphy (1985):

Qsu = .cu .S .L

Sladen (1992):

f s = .cu = h .tan

and

h = K o , NC v

correction factor for soil disturbance on sides

With the above relationships, can be determined as a

function of effective overburden and undrained shear

strength

t

th

n

= C1. v cu

C1 and n are constants depending on soil

properties and type of pile installation

22

Foundation Analysis and Design: Dr. Amit Prashant

Frictional Resistance of

Pile In Clays: -method

Proposed by Vijayvergiya and Focht (1972):

( f s )av = ( v + 2cu )

M

Mean

undrained

d i d shear

h

strength

t

th

varies with the length of embedded pile

Ultimate skin friction resistance of pile

Qsu = ( f s )av .S .L

Value of v and cu are computed as

weighted average over the embedded

depth of pile

This method usually overpredicts the

capacity of piles with embedded

length less than 15 m.

23

Foundation Analysis and Design: Dr. Amit Prashant

Frictional Resistance of Pile In Clays: -method

In saturated clays displacement piles induce excess pore pressure near

pile surface during

p

g installation which eventually

y dissipates

p

within a month

or so. Hence, the frictional resistance of pile may be estimated on the

basis of effective stress parameters of clay in a remolded state.

f s = . v = K tan R . v

Effective friction angle of remolded clay at certain depth

Earth pressure coefficient may be estimated as the earth pressure at rest:

K = (1 sin R )

For Normally Consolidated Clay

K = (1 sin R ) OCR

For Over Consolidated Clay

Total frictional resistance of pile:

Qsu = f s .S .L

24

Foundation Analysis and Design: Dr. Amit Prashant

IS:2911 Pile Load Capacity in Cohesionless Soils

25

Foundation Analysis and Design: Dr. Amit Prashant

IS:2911

S 9 Pile

e Load

oad Capac

Capacity

ty in Co

Cohesionless

es o ess So

Soils

s

26

Foundation Analysis and Design: Dr. Amit Prashant

For

Driven

Piles

For

Bored

Piles

27

Foundation Analysis and Design: Dr. Amit Prashant

IS:2911

S 9 Pile

e Load

oad Capac

Capacity

ty in Co

Cohesionless

es o ess So

Soils

s

28

Foundation Analysis and Design: Dr. Amit Prashant

IS:2911

S 9 Pile

e Load

oad Capac

Capacity

ty in Co

Cohesionless

es o ess So

Soils

s

Soil movement

Bored P

Pile

Driven Con

nical Pile

e

Driv

ven Circu

ular Pile

It seems logical that K value shall be close to the coefficient of earth

pressure at rest Ko as described in earlier methods. However,, type

p

yp of

installation has a major impact on how the earth pressure may vary from

Ko, as shown in the figure below.

29

Foundation Analysis and Design: Dr. Amit Prashant

IS:2911 Pile Load Capacity in Cohesionless Soils

IS code recommends K-value to be chosen between 1 and 2 for

driven piles and 1 and 1.5 for bored piles. However, it is advisable

to estimate this value based on the type of construction and fair

estimation of the disturbance to soil around pile

pile. Typical values of

ratio between K and Ko are listed below.

30

Foundation Analysis and Design: Dr. Amit Prashant

IS:2911 Pile Load Capacity in Cohesive Soils

For v cu 1 = 0.5 v cu

For v cu < 1 = 0.5 v cu

0.25

0.5

, but >/ 1

, but </ 0.5 and >/ 1

31

Foundation Analysis and Design: Dr. Amit Prashant

IS:2911 Pile Load Capacity in Cohesive Soils

32

Foundation Analysis and Design: Dr. Amit Prashant

Meyerhofs

y

Formula for Driven Piles based on SPT value

For Sand:

For L/D > 10

A limiting value of 1000 t/m2 for point bearing and 6 t/m2 is suggested

For NonNon-plastic silt and fine sand:

For Clays:

33

Foundation Analysis and Design: Dr. Amit Prashant

IS:2911 Pile Load Capacity in NonNon-Cohesive

Soils Based on CPT data

The ultimate point

bearing capacity:

34

Foundation Analysis and Design: Dr. Amit Prashant

IS:2911 Pile Load Capacity in NonNon-Cohesive

Soils Based on CPT data

The ultimate skin friction resistance:

Correlation of SPT and CPT:

35

Foundation Analysis and Design: Dr. Amit Prashant

Pile Load Capacity:

p

y Other Correlations with

SPT value

36

Foundation Analysis and Design: Dr. Amit Prashant

Point Load Capacity of Pile: Correlation with CPT

data by LCPC Method

q pu = ( qc )eq .kb

Get the average qc value

f a zone 1.5D

for

1 D above

b

to

1.5D below the pile tip.

Equivalent avg

avg.

cone resistance

Empirical bearing

capacity factor

Eliminate the qc values

that are higher than

1.3(qc)avg or lower than

0 7(qc)avg.

0.7(q

Compute the (qc )eq as

g of the

an average

remaining qc values.

Briaud and Miran (1991):

kb = 0.6 for clay and silt

kb = 0.375 for sand and gravel

37

Foundation Analysis and Design: Dr. Amit Prashant

Pile Load Capacity:

Correlation with CPT by

Dutch Method

Compute the average qc value for

a zone yD below the pile tip for y

varying from 0.7 to 4. Define qc1

as the minimum value of above

(qc)avg.

Average the value of qc for a zone

pile tip,

p, and g

get

of 8D above the p

qc2. Ignore sharp peaks during

averaging.

Calculate

qp

Atmospheric

p

Pressure

qc1 + qc 2 )

(

=

k 150. p

2

kb = 1.0 for OCR = 1

kb = 0.67 for OCR = 2 to 4

38

Foundation Analysis and Design: Dr. Amit Prashant

Pile Load Capacity: Correlation with CPT by Dutch

Method

q p = R1 R2

( qc1 + qc 2 ) k 150. p

2

R1 = Reduction factor as function of cu

R2 = 1 ffor electrical

l t i l cone penetrometer

t

t

R2 = 0.6 for mechanicsl cone penetrometer

39

Foundation Analysis and Design: Dr. Amit Prashant

Pile Load

Capacity:

Correlation

with CPT data

in Sand by

Dutch Method

Electric Cone

Mechanical Cone

Frictional cone

resistance

40

Foundation Analysis and Design: Dr. Amit Prashant

Pile Load Capacity: Correlation with CPT data in

Clays by Dutch Method

Frictional cone

resistance

41

Foundation Analysis and Design: Dr. Amit Prashant

Allowable Pile Capacity

Factor of Safety shall be used by giving due consideration to the

following points

Reliability of soil parameters used for calculation

Mode of transfer of load to soil

Importance of structure

Allowable total and differential settlement tolerated by structure

Factor of Safety as per IS 2911:

42

Вам также может понравиться

- LECTURE - FoundationsДокумент6 страницLECTURE - FoundationsFazelah YakubОценок пока нет

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionОт EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionОценок пока нет

- CE 632 Shallow Foundations Part-1Документ39 страницCE 632 Shallow Foundations Part-1Abdul KabasyОценок пока нет

- Elasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyОт EverandElasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyОценок пока нет

- CE 632 Pile Foundations Part-1Документ42 страницыCE 632 Pile Foundations Part-1Shailesh GuptaОценок пока нет

- Lesson 09-Chapter 9 Deep Foundations - Part 1 A (Piles)Документ59 страницLesson 09-Chapter 9 Deep Foundations - Part 1 A (Piles)vipkolonОценок пока нет

- Df05 Pile DesignДокумент31 страницаDf05 Pile DesignAbdul KabasyОценок пока нет

- Uplift Capacity of Piles 6Документ3 страницыUplift Capacity of Piles 6nhoniepogiОценок пока нет

- Piled Raft FoundationsДокумент3 страницыPiled Raft FoundationsNadim527Оценок пока нет

- Deep FoundationsДокумент52 страницыDeep FoundationsAlfredo A LopezОценок пока нет

- UC2013 Book LRДокумент272 страницыUC2013 Book LREric OwusuОценок пока нет

- Scia Engineer Fact Sheet: Surface Load GeneratorsДокумент2 страницыScia Engineer Fact Sheet: Surface Load Generatorsadnandj100% (1)

- Lecture 5 Slabs and Flat Slabs PHG N Rev13 15 Oct 16Документ40 страницLecture 5 Slabs and Flat Slabs PHG N Rev13 15 Oct 16josОценок пока нет

- Ensoft, Inc.: A Program For The Analysis & Design of Piles and Drilled Shafts Under Lateral LoadsДокумент2 страницыEnsoft, Inc.: A Program For The Analysis & Design of Piles and Drilled Shafts Under Lateral LoadsviralisursОценок пока нет

- Design Examples: Concentrically Loaded Lipped Channel ColumnДокумент25 страницDesign Examples: Concentrically Loaded Lipped Channel ColumnmrnaeemОценок пока нет

- Stapile 3Документ29 страницStapile 3jesusgameboyОценок пока нет

- Basic Concepts PDFДокумент27 страницBasic Concepts PDFMoonzeОценок пока нет

- OPILE Help File PDFДокумент148 страницOPILE Help File PDFTherar AlbaghdadiОценок пока нет

- CombiwallДокумент20 страницCombiwallPeyman MznОценок пока нет

- Braced Cuts (Excavations)Документ6 страницBraced Cuts (Excavations)Rajeev KusugalОценок пока нет

- Design Considerations For Offshore Piles PDFДокумент1 страницаDesign Considerations For Offshore Piles PDFarkadjyothiprakashОценок пока нет

- Cost-Effective Piled-Raft Foundation For High-Rise BuildingДокумент8 страницCost-Effective Piled-Raft Foundation For High-Rise Buildingxheurtaux100% (1)

- 325 UniPile Version 5 - User and Examples ManualДокумент98 страниц325 UniPile Version 5 - User and Examples ManualFernando SmithОценок пока нет

- AMCRPS - PHB - 9thedition - Web PDFДокумент448 страницAMCRPS - PHB - 9thedition - Web PDFThaungMyintОценок пока нет

- Stability Calculation of Retaining Wall at Sandtrap (ECEQ)Документ11 страницStability Calculation of Retaining Wall at Sandtrap (ECEQ)Septian AnggoroОценок пока нет

- Sheet Pile Wall IntroductionДокумент19 страницSheet Pile Wall IntroductionSâu HeoОценок пока нет

- Slope Stabilization in Highways by Subsurface Horizontal DrainsДокумент18 страницSlope Stabilization in Highways by Subsurface Horizontal DrainsShamih Sikthy100% (2)

- Calculation of Wind Load On Building Side Walls - Eurocode 1Документ7 страницCalculation of Wind Load On Building Side Walls - Eurocode 1Jun Hao OngОценок пока нет

- Bearing Capacity2Документ34 страницыBearing Capacity2Shepherd NhangaОценок пока нет

- Verification Examples enДокумент143 страницыVerification Examples enmagiОценок пока нет

- BreakwatДокумент4 страницыBreakwatberrougОценок пока нет

- Python Advance Course Via Astronomy Street: Sérgio Sousa (CAUP)Документ6 страницPython Advance Course Via Astronomy Street: Sérgio Sousa (CAUP)Dr. Shubhankar BhowmickОценок пока нет

- Foundation Design BuildingДокумент37 страницFoundation Design BuildingJuan Fernando ChavezОценок пока нет

- Wall Presure AnalysisДокумент6 страницWall Presure Analysisbuffyto5377Оценок пока нет

- Study of Piled Raft Foundation With Consideration To Soil Structure InteractionДокумент4 страницыStudy of Piled Raft Foundation With Consideration To Soil Structure InteractionGRD JournalsОценок пока нет

- Load Design ChartДокумент12 страницLoad Design ChartLuis Ugalde MirandaОценок пока нет

- Formulae: Two-Way Shear With Negligible Moment TransferДокумент7 страницFormulae: Two-Way Shear With Negligible Moment TransferKory EstesОценок пока нет

- Ref 5 Cowi - 8459785Документ69 страницRef 5 Cowi - 8459785DuckОценок пока нет

- Laterally Loaded Piles - FinalДокумент360 страницLaterally Loaded Piles - Finalcjcute91100% (1)

- Tutorial 1 - Axial Pile AnalysisДокумент11 страницTutorial 1 - Axial Pile AnalysisRaghvendra ShrivastavaОценок пока нет

- BM EC7 - Pad Foundations ManuallyДокумент4 страницыBM EC7 - Pad Foundations ManuallyNeil WilsnachОценок пока нет

- Assessment of Wind Loading On The Claddings of High-Rise Buildings by R. P. LAM and L. C. H. LAMДокумент14 страницAssessment of Wind Loading On The Claddings of High-Rise Buildings by R. P. LAM and L. C. H. LAMgulilero_yoОценок пока нет

- Sluis Et - Al. (2014) - Modelling of A Pile Row in A 2D Plane Strain FE-AnalysisДокумент7 страницSluis Et - Al. (2014) - Modelling of A Pile Row in A 2D Plane Strain FE-AnalysisViet Anh PhamОценок пока нет

- Beams On Elastic Foundation 2Документ8 страницBeams On Elastic Foundation 2Mauricio Gomes de BarrosОценок пока нет

- GR L Weap 2010 Whats New 2010Документ6 страницGR L Weap 2010 Whats New 2010Nguyen Quoc VuОценок пока нет

- Smith - Retaining Walls and Geotechnical Design To Eurocode 7Документ92 страницыSmith - Retaining Walls and Geotechnical Design To Eurocode 7Davor KirinОценок пока нет

- USBR - Design of Embankement DamДокумент2 страницыUSBR - Design of Embankement Dampggopal_85Оценок пока нет

- Behavior of Cantilever and Counterfort R PDFДокумент15 страницBehavior of Cantilever and Counterfort R PDFKhalid AljanabiОценок пока нет

- Pile Design PDFДокумент14 страницPile Design PDFhiren_22286Оценок пока нет

- Anchored Retaining WallsДокумент13 страницAnchored Retaining Wallsobp213100% (2)

- Structural Design OffshoreДокумент27 страницStructural Design OffshoreantofirdausОценок пока нет

- Chapter 9: Pile Foundations: Civil Engineering Department: Foundation Engineering (ECIV 4052)Документ18 страницChapter 9: Pile Foundations: Civil Engineering Department: Foundation Engineering (ECIV 4052)Niamul IslamОценок пока нет

- Lesson 09-Chapter 9 Deep Foundations - Part 4 (Shafts)Документ56 страницLesson 09-Chapter 9 Deep Foundations - Part 4 (Shafts)mrnaeem100% (1)

- Sound: Wall de IgnДокумент36 страницSound: Wall de IgnHundeejireenyaОценок пока нет

- CE 632 Retaining Wall Design Part-1Документ27 страницCE 632 Retaining Wall Design Part-1rodjendanОценок пока нет

- Pile FoundationДокумент38 страницPile FoundationChowdhury PriodeepОценок пока нет

- Bearing N Settlement 3Документ13 страницBearing N Settlement 3U4rayОценок пока нет

- CH (3) H Design of Pile FoundationsДокумент8 страницCH (3) H Design of Pile FoundationsSasha NewmanОценок пока нет

- Design and Testing of Bored Pile Foundation To The 2 Penang Bridge, MalaysiaДокумент43 страницыDesign and Testing of Bored Pile Foundation To The 2 Penang Bridge, MalaysiaOsama EL HakimОценок пока нет

- Types of DikshaДокумент22 страницыTypes of Dikshamohanty_anantakumar6332100% (1)

- Indian Heritage Time CapsuleДокумент9 страницIndian Heritage Time Capsulemohanty_anantakumar6332Оценок пока нет

- The Sangha GeetaДокумент97 страницThe Sangha Geetamohanty_anantakumar6332Оценок пока нет

- A Letter From Albert Einstein To His DaughterДокумент2 страницыA Letter From Albert Einstein To His DaughterMJ Ferma100% (3)

- A Letter From Albert Einstein To His DaughterДокумент2 страницыA Letter From Albert Einstein To His DaughterMJ Ferma100% (3)

- Sat-Chakra-Nirupana: (By Purnananda Swami)Документ17 страницSat-Chakra-Nirupana: (By Purnananda Swami)murali900Оценок пока нет

- Types of DikshaДокумент22 страницыTypes of Dikshamohanty_anantakumar6332100% (1)

- Haskel TosuiДокумент185 страницHaskel Tosuirhvenkat100% (3)

- Gaytri Sampoorn Puja VidhiДокумент123 страницыGaytri Sampoorn Puja VidhiAnurag Chand75% (8)

- Presidential Address To The Symposium On Ancient Indian Scientific KnowledgeДокумент6 страницPresidential Address To The Symposium On Ancient Indian Scientific Knowledgemohanty_anantakumar6332Оценок пока нет

- Scientists of Ancient IndiaДокумент9 страницScientists of Ancient IndiaViseshОценок пока нет

- Contribution of Indian Mathematicians: ARYABHATA (476-550AD)Документ4 страницыContribution of Indian Mathematicians: ARYABHATA (476-550AD)Raja .SОценок пока нет

- Staad Manual 1Документ13 страницStaad Manual 1mohanty_anantakumar6332Оценок пока нет

- Ancientindianscience 110613015342 Phpapp01Документ46 страницAncientindianscience 110613015342 Phpapp01mohanty_anantakumar6332Оценок пока нет

- Life Story ThakurДокумент6 страницLife Story Thakurmohanty_anantakumar6332Оценок пока нет

- Nick Trost - Mental Card MiraclesДокумент19 страницNick Trost - Mental Card MiraclesOmar Banna91% (11)

- A NirvanaДокумент222 страницыA Nirvanamohanty_anantakumar6332Оценок пока нет

- Gayatri Worship 1Документ123 страницыGayatri Worship 1mohanty_anantakumar6332Оценок пока нет

- MagicДокумент123 страницыMagicsumandak2003100% (1)

- Vastu For House EbookДокумент30 страницVastu For House EbookpankgargОценок пока нет

- RekhaganitaVOL II DLIДокумент259 страницRekhaganitaVOL II DLImohanty_anantakumar6332Оценок пока нет

- Arch DesignДокумент16 страницArch DesignATHULОценок пока нет

- RekhaganitaVOL II DLIДокумент259 страницRekhaganitaVOL II DLImohanty_anantakumar6332Оценок пока нет

- Biryanis 3 Method of Preparation Vegetable BriyaniДокумент1 страницаBiryanis 3 Method of Preparation Vegetable Briyanimohanty_anantakumar6332Оценок пока нет

- 2013seismic Behaviour of Flat Slab Framed Structure With and Without Masonry Infill WallДокумент5 страниц2013seismic Behaviour of Flat Slab Framed Structure With and Without Masonry Infill WallBasil Baby-PisharathuОценок пока нет

- VbfdsaДокумент20 страницVbfdsazaidОценок пока нет

- 63200Документ306 страниц63200olonamsaa86% (7)

- Pipe Rack CalculationДокумент51 страницаPipe Rack Calculationbalumagesh1979100% (2)

- Building Digest 116Документ8 страницBuilding Digest 116mohanty_anantakumar6332Оценок пока нет

- Svetasvatara UP TNS CompleteДокумент65 страницSvetasvatara UP TNS Completemohanty_anantakumar6332Оценок пока нет

- ISRM SM, DiscontinuitesДокумент50 страницISRM SM, DiscontinuitesGustavo GouveiaОценок пока нет

- Woliso Town WSS DesignДокумент87 страницWoliso Town WSS DesignAbdulbasit Aba Biya100% (1)

- 8414 PDFДокумент20 страниц8414 PDFPushpendra ChouhanОценок пока нет

- Separating Mixtures: Sedimentation and DecantationДокумент16 страницSeparating Mixtures: Sedimentation and DecantationChloeОценок пока нет

- Classification Procedures For Expansive Soils: Geotechnical Engineering January 2000Документ7 страницClassification Procedures For Expansive Soils: Geotechnical Engineering January 2000tpgggkОценок пока нет

- 4.1 4851 - Namas Wind Farm Prelimi GI - MORev01Документ44 страницы4.1 4851 - Namas Wind Farm Prelimi GI - MORev01migusagoОценок пока нет

- Probabilistic Seismic Hazard Assessment of NepalДокумент23 страницыProbabilistic Seismic Hazard Assessment of NepalSarrows PrazzapatiОценок пока нет

- English TestsДокумент9 страницEnglish TestsJohn ThiakoulisОценок пока нет

- Armitage & Anderson (2013)Документ6 страницArmitage & Anderson (2013)Olivier Delalande de MaineОценок пока нет

- Nico Berger (2014) : Analysis of A Possible Meteorite Impact in The Prims River Area (Nalbach, Saarland, Germany) .Документ2 страницыNico Berger (2014) : Analysis of A Possible Meteorite Impact in The Prims River Area (Nalbach, Saarland, Germany) .MuellerPrimsОценок пока нет

- Advance Retrofitting Techniques For Reinforced Concrete StructuresДокумент13 страницAdvance Retrofitting Techniques For Reinforced Concrete StructuresSoumya GoraiОценок пока нет

- Miracle Boy Survivor of The Haiti EarthquakeДокумент2 страницыMiracle Boy Survivor of The Haiti EarthquakeCristian Gordillo CОценок пока нет

- Prehistory of The PhilippinesДокумент29 страницPrehistory of The PhilippinesmhyckОценок пока нет

- Design and Simulation of An All Terrain Mobile Robot: 3810 Engineering ProjectДокумент90 страницDesign and Simulation of An All Terrain Mobile Robot: 3810 Engineering ProjectSunil BailyОценок пока нет

- Bray-EQ Fault Rupture-CUEE2009Документ9 страницBray-EQ Fault Rupture-CUEE2009Gilmar BastidasОценок пока нет

- History of Life On EarthДокумент9 страницHistory of Life On EarthblablaОценок пока нет

- 644296ee86310talwa G-4 For Iron-Manganese ProposalДокумент25 страниц644296ee86310talwa G-4 For Iron-Manganese Proposalamit kumar guptaОценок пока нет

- Chapter 12 Earthquakes PDFДокумент26 страницChapter 12 Earthquakes PDFKaye Macauba CentinoОценок пока нет

- Haywood Junior Exploration On Juggernaut TSX-V JUGRДокумент2 страницыHaywood Junior Exploration On Juggernaut TSX-V JUGRJames HudsonОценок пока нет

- Heavy Metals in Soils From The Horticultural Areas of Sârca and Huşi (Romania)Документ6 страницHeavy Metals in Soils From The Horticultural Areas of Sârca and Huşi (Romania)Eugen TătaruОценок пока нет

- Geotecnical FormulasДокумент13 страницGeotecnical FormulasArnel Tan100% (1)

- Horizontal Directional Drilling GuidelinesДокумент82 страницыHorizontal Directional Drilling GuidelinesDwi Hermawan86% (7)

- Fragment ExercisesДокумент8 страницFragment ExercisesSaood AlsuwaidiОценок пока нет

- MING5501 - 2 - Structural Mapping Principles - 1Документ59 страницMING5501 - 2 - Structural Mapping Principles - 1Roseanna DaleОценок пока нет

- Calcareous and Ultramafic MetДокумент13 страницCalcareous and Ultramafic MetFelichi Dacumos BalajadiaОценок пока нет

- FeasibilityДокумент474 страницыFeasibilityM Alim Ur RahmanОценок пока нет

- The Global Flood of Noah - Bert ThompsonДокумент64 страницыThe Global Flood of Noah - Bert ThompsonHAdrian87Оценок пока нет

- Identification Phase StudyДокумент38 страницIdentification Phase Studyricardov2009100% (1)

- ALS Minerals Service Schedule USDДокумент44 страницыALS Minerals Service Schedule USDGAUCHEX697355Оценок пока нет

- Mining Rights (EP, MPSA, FTAA)Документ16 страницMining Rights (EP, MPSA, FTAA)Neil Rivera100% (1)