Академический Документы

Профессиональный Документы

Культура Документы

Hybrid Cooling

Загружено:

Deepak JhaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hybrid Cooling

Загружено:

Deepak JhaАвторское право:

Доступные форматы

Hybrid Space Cooling

Introduction:

Ground Based Cooling System

Cooling by underground Earth Tubes:

Cooling tubes are long, underground metal or plastic pipes

through which air is down. The idea is that as the air travels

through the pipes, it given up some of its heat to the surrounding

soil, entering the house as cooler air. A cooling tube system uses

either an open or closed loop design.

In an open loop system, the outdoor air is drawn into the tubes

and transported directly to the inside of house. This provides

ventilation while optimistically cooling the houses interior.

MECHANICAL ENGINEERING DEPARTMENT

Page 1

Hybrid Space Cooling

In a closed loop system, interior air circulates through the earth

cooling tubes. A closed loop system is more efficient than open

loop design. It does not exchange air with the outside.

Closed Loop

Horizontal

Vertical

Why Ground Based Cooling?

Low Grade geothermal technology is

cost. Effective, environmentally

friendly method of providing cooling

as well as heating. Already widely

accepted around the world, this

technology continues to grow in

popularity. In the context of to days

diminishing fossil fuel reserves,

increasing electrical cost, air

pollution and global warming,

properly designed earth cooling

tubes offer a sustainable alternative to reduce or eliminate the

need for conventional compressor based air conditioning system.

They also provide the added benefit of control, filter, temperate

fresh air intake, which is especially valuable in tight, well

weatherized, efficient building envelopes.

MECHANICAL ENGINEERING DEPARTMENT

Page 2

Hybrid Space Cooling

Benefits of ground based cooling:

GBCS require less maintenance than combustion based

heating systems.

Heat pumps save carbon emissions.

GBCS are safe, silent, unobtrusive and out-of-sight: they

require no planning permission.

Heat pumps can also provide cooling in summer, as well as

heating in winter.

Ground source heat pumps are the only renewable energy

technology that can benefit from the thermal energy storage

properties of the ground to recycle heat from summer to

winter.

MECHANICAL ENGINEERING DEPARTMENT

Page 3

Hybrid Space Cooling

Heat in order to achieved desired heating or cooling. An

important design aspect of heat exchanger technology is

the selection of appropriate materials to conduct and

transfer heat and efficiently.

Copper has many desirable properties for thermally

efficient and durable head exchanges. First and foremost,

copper is an excellent conductor of heat. This means that

coppers high thermal conductivity allows heat to pass

through it quickly. Other desirable properties of copper in

heat exchangers include its corrosion resistance,

biofouling resistance, maximum allowable stress and

internal pressure,creep rupture strength, fatigue strength,

hardness, thermal expansion, specific heat, antimicrobial

properties, tensile strength, yield strength, high melting

strength, yield strength, high melting point, alloyability,

ease of fabrication.

Thermo Electric Cooling (TEC ):

Ground based cooling can be more effective by use of another eco

friendly cooling principle i.e. Thermo Electric Cooling (Peltier

Refrigeration).

MECHANICAL ENGINEERING DEPARTMENT

Page 4

Hybrid Space Cooling

Thermoelectirc Cooling

French watchmaker, Jean Charles Athanase Peltier, discovered

Thermoelectric cooling effect, also known as Peltier cooling effect,

in 1834. Peltier discovered that the passage of a current through a

junction formed by two dissimilar conductors caused a

temperature change. However, Peltire Failed to understand this

physics phenomenon, and his explanation was that the weak

current doesnt obey Ohms law. Peltier effect was made clear in

1838 by Emil Lenz, a member of the St. Petersburg Academy. Lenz

demonstrated that water could be frozen when placed on a

bismuth-antimony junction by passage of an electric current

through the junction. He also observed that if the current was

reversed the ice could ice could be melted. In 1909 and 1911

another scientist Alternkirch derived the basic theory of thermo

electrics. His work pointed out that thermo electric cooling

materials needed to have high Seebeck coefficients, good

electrical conductivity to minimize Joule heating, and low thermal

conductivity to reduce heat transfer from junctions to junctions.

MECHANICAL ENGINEERING DEPARTMENT

Page 5

Hybrid Space Cooling

Shortly after the development of practical semiconductors in

1950s, bismuth telluride began to be the primary material used

in the thermoelectric cooling. The passage of an electric current

through junctions of dissimilar metals causes a fall in temperature

at one junction and a rise at the other, the Peltier effect.

Improvements in this method of cooling have been made possible

in recent years by the production of suitable semiconductors.

Applications are limited in size, owing to the high electric currents

required and practical uses are small cooling systems for military,

aerospace and laboratory use.

Operating Principle:

Thermoelectric coolers operate by the Peltier effect (Which

also goes by the more general name thermoelectric effect).

MECHANICAL ENGINEERING DEPARTMENT

Page 6

Hybrid Space Cooling

The device has two sides, and when DC current flows

through the device, it brings heat from one side to the

other, so that one gets cooler while the other gets hotter.

The hot side is attached to a heat sink so that it remains

at ambient temperature, while the cool side goes below

room temperature.

In some applications, multiple coolers can be cascaded

together for lower temperature.

Thermo Electric cooling is done by a device called peltier

which solar energy for its working.

BENEFITS OF USING TEC

No moving parts, so maintenance is required less frequently.

MECHANICAL ENGINEERING DEPARTMENT

Page 7

Hybrid Space Cooling

No chlorofluorocarbons.

Temperature control to within fractions of a degree can be

maintained.

Flexible shape (Form factor); in particular, they can have a

very small size.

Can be used in environments that are smaller or more

severe than conventional refrigeration.

Has a long life, with mean time between failures (MTBF)

exceeding 100,00 hours.

Is controllable via changing the input voltage/current.

Identification

Construction

MECHANICAL ENGINEERING DEPARTMENT

Page 8

Hybrid Space Cooling

Two unique semiconductors, one n-type and one p-tpye, are

used because they need to have different electron densities.

The semiconductors are placed thermally in parallel to each

other and electrically in series and joined with a thermally

conducting plate on each side.

When a voltage is applied to the free ends of the two

semiconductors there is a flow of DC current across the

junction of the semiconductors causing a

Temperature difference. The side with the cooling plate

absorbs heat which

is then moved to the other side of the device where the

heat sink is.

TECs are typically connected side by side and sandwiched

between two ceramic plates. The cooling ability of the total

unit is then proportional to the number of TECs in it.

MECHANICAL ENGINEERING DEPARTMENT

Page 9

Hybrid Space Cooling

Components:

Complete System is divided into three parts:

1. Isolated chamber

2. Cooling Tower

3. Foundation Unit

Isolated Chamber:

It is space where we want to maintain comfort temperature. It is

made by GI Sheet. Side walls of this chamber are properly

insulated. Peltier Device is placed at bottom of isolated chamber.

MECHANICAL ENGINEERING DEPARTMENT

Page 10

Hybrid Space Cooling

After circulation of Cooled air through earth tube, the air is

supplied to this chamber. A heat exchanger is placed to take away

the heat from hot surface of peltier.

Isolated chamber has following parts:

1.

2.

3.

4.

5.

Insulated cabin

Peltier Device

Heat Exchanger

Silica Gel

Digital Temperature Sensor

MECHANICAL ENGINEERING DEPARTMENT

Page 11

Hybrid Space Cooling

Materials Used:

Insulated with thermocol blocks.

Used copper pipe for heat exchanger.

M-seal.

Digital Thermometer 1 unit, temperature in degree

centigrade or faranite.

Peltier device.

Construction

1. First rectangular piece of thermacol is measured cut.

2. Then part thermacol is divided in four parts.

3. And from a hollow cuboid.

MECHANICAL ENGINEERING DEPARTMENT

Page 12

Hybrid Space Cooling

4. Now its cap is made with thermacol only such that insulator

can be inserted in it.

5. Now used container which is filled with soil.

6. Now two holes are made in thermocol compartment for

insertion of pipe in isolated chamber.

7. And container have two holes . One hole is on the top of the

container and another is at the bottom of container

8. We have inserted the pipe from top hole of the container and

fixed with the blower through the bottom hole.

9. The power is supplied to the blower and air is sucked

10.

Then it goes to the chamber which is to be cooled.

11.

Though it is the hybrid cooling system the another

method of cooling is cooling through the paltier effect

12.

We have two paltier devices fitted with insulation in the

chamber.

13.

The cooling phase of both the paltier is inside the

chamber and hot phases of paltier is brought little out of the

chamber.

14.

The paltier are connected to the battery of 12V which is

charged by the solar pannel of 12V also.

15.

The whole setup is kept on cast iron stand.

Specification:

ISOLATED COMPARTMENT:

Isolated compartment outer Dimensions:

MECHANICAL ENGINEERING DEPARTMENT

Page 13

Hybrid Space Cooling

Height 23cm

Width 21cm

Length 27cm

Isolated Compartment Inner Dimensions:

Height 18cm

Width 15cm

Length 21cm

Insulation thickness (Thermocol)

2.5cm

Peltier Heating and Cooling Area:4*4 cm2

Cooling Tower

Cooling tower is used to cool the water which got heated by

taking heat from the hot surface of cooling tower. Here, to show

the concept of cooling tower we used a cooler. Water becomes

cooler when it circulates through the wall where evaporative

cooling takes place.

MECHANICAL ENGINEERING DEPARTMENT

Page 14

Hybrid Space Cooling

Cooling has following parts:

1. Cooling Fan

2. Centrifugal Pump

3. Water Supply Unit

Specification

Foundation Unit

Foundation Unit is the main component of to show the

concept of Ground Based Cooling System. Basically it is a

container. This container is filled with the soil.

Atmospheric air is passed through the soil by earth tubes

with the help of blower. The soil will at lower temperature

compared to the atmospheric air. So, The air releases its

heat to soil and become cooler. This cooler air is supplied

to the isolated chamber through carrier tubes.

MECHANICAL ENGINEERING DEPARTMENT

Page 15

Hybrid Space Cooling

MECHANICAL ENGINEERING DEPARTMENT

Page 16

Hybrid Space Cooling

Foundation unit has following parts:

Soil container

Earth tube

Carrier Tube

Blower

MECHANICAL ENGINEERING DEPARTMENT

Page 17

Hybrid Space Cooling

SOIL CONTAINER

Soil container is made up of aluminium.

Stand specification:

LENGTH 35 CM

HEIGHT - 70 CM

WIDTH - 35 CM

Construction:

Stand is made up of cast iron bar.

Cutting is done by grinding machine.

Arc welding is used to join bar.

CONTAINER

Specification:Length 66cm

Width - 51cm

Height - 69cm

TUBES SPECIFICATION

MECHANICAL ENGINEERING DEPARTMENT

Page 18

Hybrid Space Cooling

EARTH TUBE SPECIFICATION:Diameter 1 cm

Height

- 50 cm

Blower

Blower will take hot air form the atmosphere and

supply it to soil chamber by earth tube.

Specification:3

Discharge : 2-3 m /min

Power : 600 watt

Speed : 16000 rpm

MECHANICAL ENGINEERING DEPARTMENT

Page 19

Hybrid Space Cooling

Power supply unit for peltier:

Peltier device is operated at 72 watt, 12 volts and 6

ampere. Battery is used to supply the power to peltier.

Solar plate is used for charging the battery.

Solar Plate

12 Volt/25 ampere

Collector Area

MECHANICAL ENGINEERING DEPARTMENT

Page 20

101*40

cm 2

Hybrid Space Cooling

Battery

MM MODEL 12V 7.2 Ah

L = 151 mm

WT = 2.45

W = 65 mm

H = 94.8 mm

MECHANICAL ENGINEERING DEPARTMENT

Page 21

Hybrid Space Cooling

MECHANICAL ENGINEERING DEPARTMENT

Page 22

Hybrid Space Cooling

FLOW DIAGRAM

Working Principle:

Hybrid space cooling works on the combination of

Ground based cooling and Thermo electric cooling

(Pleltier effect). We observe that if atmospheric air is pass

through a tube (good heat conductor) which is placed

beneath the earth surface then air transferred its heat to

soil which is kept beneath the earth surface. As we know

that the temperature of earth is maintained to low in

summer season below 7 ft. This low temperature takes

heat from the warmer air and temperature of air get

decrease. The flow of air is attained by the help of blower.

MECHANICAL ENGINEERING DEPARTMENT

Page 23

Hybrid Space Cooling

Now this low temperature air goes to the space to

the space where we want to cool environment. Here

ground based cooling system is coupled with

thermoelectric cooling device i.e. peltier. One surface of

peltier is colder. Air will flow on the colder surface and

become cooler. The combination of ground based cooling

and thermoelectric cooling will give comfort environment

of 24-26 c in the space in hot summer condition when

the outside temperature is 35-40 c.

Other surface of the peltier will get heated to

remove this heat we circulates water. Water will absorb

heat form hot surface and it will flow through the cooling

tower. In the cooling tower evaporative cooling takes

place with water so water again become ready to take

heat from the hot surface of peltier.

ObservationTIME

12:11PM

TEMPERATURE(in degree

celcious )

37.0

12:21PM

33.4

12:31PM

30.2

12:39PM

28.3

12:45PM

26.8

MECHANICAL ENGINEERING DEPARTMENT

Page 24

Hybrid Space Cooling

Our observation shows that temperature drops take

place from 37.00C to 26.80C.

It takes 34 minutes to achieve this temperature in

the isolated cooling chamber.

ANALYSIS:Blower:- V= 2626V

P= 600W

Battery:- P= VI

V= 12V

I= 7.2Ah

P= 12*7.2

P = 86.4W

Two Peltier:Power = 90W + 90W

= 180W

Two Fan :V = 12V

I = 0.15Ah

MECHANICAL ENGINEERING DEPARTMENT

Page 25

Hybrid Space Cooling

Power = 12*0.15*2 = 3.6W

Total Input Power:P = Power used in blower + Power used

in peltier +

power used in fan

= 600 + 180 + 3.6

= 783.6W

Total Output:mC p

Q=

* T

m = Density * Volume

= 1.2 * 2.3

= 2.76 Kg/min

Then,

Q = [2.76 * 1.008 * (37-26.8)] / 60

= 0.47 KJ/sec = 0.47KW

= 470W

Now,

COP = Desired Effect / Work Input

= 470 / 783.6 = 59.9 %

MECHANICAL ENGINEERING DEPARTMENT

Page 26

Hybrid Space Cooling

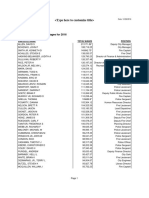

Cost Analysis:

Peltier Device

: Rs. 1600

Solar Plate

: Rs. 1,500

Battery

: Rs. 900

Temperature sensor : Rs. 550

Tubes

: Rs. 1,800

Blower

: Rs. 3,000

Container

: Rs. 550

Wheels

: Rs. 400

Stand

: Rs. 580

Machining cost

:

Rs. 1,000

Labour Charge

:

Rs. 300

Total Estimate:

RS.

12,180

APPLICATION:

Hybrid space cooling system can be used for space

cooling in industries, commercial buildings, and domestic

purpose.

Themoelectric Cooling has many applications like,

USB Powered beverage cooler

MECHANICAL ENGINEERING DEPARTMENT

Page 27

Hybrid Space Cooling

Consumer Products: portable coolers, cooling

electronic components and small instruments.

ADVANTAGES:

1. Eco Friendly

2. Required very less maintenance.

3. Low running cost.

4. Application in Remote Areas.

5. Can be used for cooling in summer and heating in

winter season.

6. Compared to conventional cooling it is more

effective.

7. GBCS have few moving parts so they are highly

reliable.

LIMITATIONS

High installation cost.

Dependent on topographical conditions of site.

Disturbances to land during installations.

CONLUSIONS

The increasing cost of fossil fuels led to a rapid use of

alternative heating and cooling systems, which can

take on a wide range of different formats.

It is estimated that the heat pump heating and

cooling system, already widely used in commercial

MECHANICAL ENGINEERING DEPARTMENT

Page 28

Hybrid Space Cooling

building due to advantages of increased efficiency

and reduced heating and fuel costs.

REFERENCES:

Refrigeration and Air conditioning by C P Arora.

Themoelectric Cooler basics..TEC Micro

system

International Journal of Sustainable Construction

Engineering and Technology (Energy Efficient

Green Building Based on Geo Cooling System)

American Journal of Engineering Research

(Experimental Investigation of Geothermal Air

Conditioning)

Google

Wikipedia

MECHANICAL ENGINEERING DEPARTMENT

Page 29

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- CSE Main Paper2Документ11 страницCSE Main Paper2Deepak JhaОценок пока нет

- Answer Keys:: Email: Info@engineeringolympiad - inДокумент11 страницAnswer Keys:: Email: Info@engineeringolympiad - inDeepak JhaОценок пока нет

- SQL TutorialДокумент13 страницSQL TutorialDeepak JhaОценок пока нет

- Sandeep Baliyan: Create A Post..Документ30 страницSandeep Baliyan: Create A Post..Deepak JhaОценок пока нет

- Modern History Notes On Advent of European in India: SSC CGL Tier I 2017 Online Test Series - Get NowДокумент6 страницModern History Notes On Advent of European in India: SSC CGL Tier I 2017 Online Test Series - Get NowDeepak JhaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- CS-6777 Liu AbsДокумент103 страницыCS-6777 Liu AbsILLA PAVAN KUMAR (PA2013003013042)Оценок пока нет

- Retail Banking Black BookДокумент95 страницRetail Banking Black Bookomprakash shindeОценок пока нет

- Types of Water Pump and Applications in Power Plant.Документ6 страницTypes of Water Pump and Applications in Power Plant.abbas bilalОценок пока нет

- HFE0106 TraskPart2Документ5 страницHFE0106 TraskPart2arunkr1Оценок пока нет

- Colorfastness of Zippers To Light: Standard Test Method ForДокумент2 страницыColorfastness of Zippers To Light: Standard Test Method ForShaker QaidiОценок пока нет

- A Review of Service Quality ModelsДокумент8 страницA Review of Service Quality ModelsJimmiJini100% (1)

- Manual E07ei1Документ57 страницManual E07ei1EiriHouseОценок пока нет

- Conservation Assignment 02Документ16 страницConservation Assignment 02RAJU VENKATAОценок пока нет

- Acc116 Dec 2022 - Q - Test 1Документ6 страницAcc116 Dec 2022 - Q - Test 12022825274100% (1)

- BARUДокумент53 страницыBARUhueuaОценок пока нет

- Komunikasi Sebagai Piranti Kebijakan Bi: Materi SESMABI Mei 2020Документ26 страницKomunikasi Sebagai Piranti Kebijakan Bi: Materi SESMABI Mei 2020syahriniОценок пока нет

- Lab Report SBK Sem 3 (Priscilla Tuyang)Документ6 страницLab Report SBK Sem 3 (Priscilla Tuyang)Priscilla Tuyang100% (1)

- Iaea Tecdoc 1092Документ287 страницIaea Tecdoc 1092Andres AracenaОценок пока нет

- 2016 W-2 Gross Wages CityДокумент16 страниц2016 W-2 Gross Wages CityportsmouthheraldОценок пока нет

- HSCC SRH 0705 PDFДокумент1 страницаHSCC SRH 0705 PDFBhawna KapoorОценок пока нет

- Ducted Split ACsДокумент31 страницаDucted Split ACsHammadZaman100% (1)

- Babe Ruth Saves BaseballДокумент49 страницBabe Ruth Saves BaseballYijun PengОценок пока нет

- Dwnload Full Beckers World of The Cell 9th Edition Hardin Solutions Manual PDFДокумент35 страницDwnload Full Beckers World of The Cell 9th Edition Hardin Solutions Manual PDFgebbielean1237100% (12)

- Aakriti 1Документ92 страницыAakriti 1raghav bansalОценок пока нет

- Ritesh Agarwal: Presented By: Bhavik Patel (Iu1981810008) ABHISHEK SHARMA (IU1981810001) VISHAL RATHI (IU1981810064)Документ19 страницRitesh Agarwal: Presented By: Bhavik Patel (Iu1981810008) ABHISHEK SHARMA (IU1981810001) VISHAL RATHI (IU1981810064)Abhi SharmaОценок пока нет

- Who Trs 993 Web FinalДокумент284 страницыWho Trs 993 Web FinalAnonymous 6OPLC9UОценок пока нет

- SABRE MK-3 CFT Gel SpecДокумент1 страницаSABRE MK-3 CFT Gel Specseregio12Оценок пока нет

- Battery Guide - 2021Документ27 страницBattery Guide - 2021Mario LaurieОценок пока нет

- Google Tools: Reggie Luther Tracsoft, Inc. 706-568-4133Документ23 страницыGoogle Tools: Reggie Luther Tracsoft, Inc. 706-568-4133nbaghrechaОценок пока нет

- Eurocode 3: Design of Steel Structures "ReadyДокумент26 страницEurocode 3: Design of Steel Structures "Readywazydotnet80% (10)

- Elpodereso Case AnalysisДокумент3 страницыElpodereso Case AnalysisUsama17100% (2)

- Analytical Chem Lab #3Документ4 страницыAnalytical Chem Lab #3kent galangОценок пока нет

- Wwii TictactoeДокумент2 страницыWwii Tictactoeapi-557780348Оценок пока нет

- Project Management TY BSC ITДокумент57 страницProject Management TY BSC ITdarshan130275% (12)

- CAA Safety Plan 2011 To 2013Документ46 страницCAA Safety Plan 2011 To 2013cookie01543Оценок пока нет