Академический Документы

Профессиональный Документы

Культура Документы

BA067DEN Fieldcheck OM

Загружено:

Jabulani2010Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BA067DEN Fieldcheck OM

Загружено:

Jabulani2010Авторское право:

Доступные форматы

Operating Instructions

Proline Fieldcheck

Flow simulator

BA067D/06/en/04.04

50100085

Valid as of software version

V 1.02.XX

Proline Fieldcheck

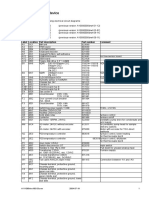

Table of contents

Table of contents

1

Safety instructions . . . . . . . . . . . . . . . . 4

1.1

1.2

1.3

1.4

Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Notes on operating Fieldcheck in an environment with

strong electromagnetic interference . . . . . . . . . . . . . 4

1.3.1 Radiated RF noise (EN 61326-1) . . . . . . . . . 4

Notes on safety conventions and icons . . . . . . . . . . . 5

Identification . . . . . . . . . . . . . . . . . . . . 6

2.1

Device designation . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Fieldcheck nameplate . . . . . . . . . . . . . . . . .

2.1.2 Simubox nameplate . . . . . . . . . . . . . . . . . . .

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE mark, Declaration of conformity . . . . . . . . . . . . .

Registered trademarks . . . . . . . . . . . . . . . . . . . . . . .

2.2

2.3

2.4

6

6

6

7

7

7

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting to Promag 10 . . . . . . . . . . . . . . . . . . . . 9

Connecting to Promag 50/53 compact version . . . 10

Connecting to Promag 50/53 remote version . . . . 11

Connecting to Promass 40/80/83 compact version 12

Connecting to Promass 80/83 remote version . . . . 13

Connecting to Prowirl 72 . . . . . . . . . . . . . . . . . . . 14

3.7.1 Prowirl 72 wiring diagram . . . . . . . . . . . . . 15

Assignment of Fieldcheck connections . . . . . . . . . . 16

Post-connection check . . . . . . . . . . . . . . . . . . . . . . 16

Operation . . . . . . . . . . . . . . . . . . . . . . 17

4.1

Display and operating elements . . . . . . . . . . . . . . .

4.1.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Display icons . . . . . . . . . . . . . . . . . . . . . . .

Brief operating instructions on the function matrix .

4.2.1 General notes . . . . . . . . . . . . . . . . . . . . . .

Communication . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 FieldTool operating program . . . . . . . . .

4.2

4.3

17

18

19

20

20

21

21

8.1.3

8.1.4

8.1.5

8.1.6

8.1.7

8.1.9

8.1.10

Power supply . . . . . . . . . . . . . . . . . . . . . . .

Performance characteristics . . . . . . . . . . . .

Operating conditions (Environment) . . . . . .

Mechanical construction . . . . . . . . . . . . . .

Display and user interface . . . . . . . . . . . . .

Accessories . . . . . . . . . . . . . . . . . . . . . . . .

Documentation . . . . . . . . . . . . . . . . . . . . .

25

25

25

26

26

26

26

Description of device functions General section . . . . . . . . . . . . . . . . . . 27

9.1

Notes on the description of device functions . . . . . . 27

9.1.1 Using the table of contents to locate a function

description . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.1.2 Using the graphic of the function matrix to

locate a function description . . . . . . . . . . . 27

Function matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Block USER INTERFACE . . . . . . . . . . . . . . . . . . . . 29

9.3.1 Group CONTROL . . . . . . . . . . . . . . . . . . . 29

Block BASIC FUNCTIONS . . . . . . . . . . . . . . . . . . . 31

9.4.1 Group SENSOR PARAMETER . . . . . . . . . . 32

9.4.2 Group OUTPUTS . . . . . . . . . . . . . . . . . . . . 33

9.4.3 Group PROCESS PARAMETER . . . . . . . . . 34

9.4.4 Group READ IN PARAMETERS . . . . . . . . . 35

Block SUPERVISION . . . . . . . . . . . . . . . . . . . . . . . 36

9.5.1 Group RESULTS . . . . . . . . . . . . . . . . . . . . 36

9.5.2 Group VERSION INFO . . . . . . . . . . . . . . . 38

9.2

9.3

9.4

9.5

10

Description of device functions Fieldcheck and electromagnetic

measuring devices . . . . . . . . . . . . . . . . 39

10.1

Block FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.1.1 Group SIMULATION . . . . . . . . . . . . . . . . . 40

10.1.2 Group VERIFICATION . . . . . . . . . . . . . . . 44

11

Description of device functions Fieldcheck and Coriolis measuring

systems . . . . . . . . . . . . . . . . . . . . . . . . 49

Commissioning. . . . . . . . . . . . . . . . . . 22

5.1

5.2

Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.1 Charging the battery . . . . . . . . . . . . . . . . . 22

11.1

Block FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . 49

11.1.1 Group SIMULATION . . . . . . . . . . . . . . . . . 50

11.1.2 Group VERIFICATION . . . . . . . . . . . . . . . 53

Maintenance. . . . . . . . . . . . . . . . . . . . 23

12

Accessories. . . . . . . . . . . . . . . . . . . . . 24

Description of device functions Fieldcheck and vortex measuring

systems . . . . . . . . . . . . . . . . . . . . . . . . 59

7.1

Software history . . . . . . . . . . . . . . . . . . . . . . . . . . 24

12.1

Technical data . . . . . . . . . . . . . . . . . . 25

Block FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . 59

12.1.1 Group SIMULATION . . . . . . . . . . . . . . . . . 60

12.1.2 Group VERIFICATION . . . . . . . . . . . . . . . 63

8.1

Technical data at a glance . . . . . . . . . . . . . . . . . . . 25

8.1.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Endress+Hauser

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Safety instructions

Proline Fieldcheck

Safety instructions

1.1

Designated use

The Fieldcheck flow simulation system may only be used for the simulation of sensor signals with a

flowmeter of the Proline equipment generation from Endress+Hauser. The device is normally

installed by service technicians who are familiar with the function and operating method of the

equipment. The manufacturer accepts no liability for damages resulting from incorrect use.

Warning!

Fieldcheck may not be used in hazardous areas without corresponding safety measures.

1.2

Operational safety

The manufacturer reserves the right to modify technical data without prior notice. Please contact

your E+H distributor for information on modifications or updates of these Operating Instructions.

The measuring system complies with the general safety requirements in accordance with EN

61010, the EMC requirements of EN 61326/A1 and NAMUR Recommendation NE 21.

1.3

Notes on operating Fieldcheck in an environment with

strong electromagnetic interference

1.3.1

Radiated RF noise (EN 61326-1)

To operate Fieldcheck with a Proline flowmeter in the simulation and verification mode, the

electronics and connection compartments must first be opened. In this mode, the radiated RF noise

will not exceed the industrial limits (EN 61326-1).

In a heavily disturbed (EMC) environment, you must expect that the operation of both Fieldcheck

and the flowmeter may be temporarily affected. We recommend that - when using Fieldcheck - you

take care to ensure effective ESD protection for the affected measuring point and the operator.

If necessary, the measuring equipment can be reset:

Via the local controls

By interrupting the voltage supply

By restarting Fieldcheck.

Endress+Hauser

Proline Fieldcheck

Safety instructions

1.4

Notes on safety conventions and icons

The devices are designed to meet state-of-the-art safety requirements, have been tested, and left the

factory in a condition in which they are safe to operate. The devices comply with the applicable

standards and regulations in accordance with EN 61010 Protection Measures for Electrical

Equipment for Measurement, Control, Regulation and Laboratory Procedures. They can, however,

be a source of danger if used incorrectly or for other than the designated use.

Consequently, always pay particular attention to the safety instructions indicated in these Operating

Instructions by the following icons:

#

"

!

Endress+Hauser

Warning!

Warning indicates an action or procedure which, if not performed correctly, can result in injury

or a safety hazard. Comply strictly with the instructions and proceed with care.

Caution!

Caution indicates an action or procedure which, if not performed correctly, can result in incorrect

operation or destruction of the device. Comply strictly with the instructions.

Note!

Note indicates an action or procedure which, if not performed correctly, can have an indirect

effect on operation or trigger an unexpected response on the part of the device.

Identification

Proline Fieldcheck

Identification

2.1

Device designation

The Fieldcheck flow simulation system consists of the following components:

The Fieldcheck flow simulator itself

The Simubox for correct connection to the respective measuring device

2.1.1

Fieldcheck nameplate

ENDRESS+HAUSER

FIELD CHECK

1

Order Code:

Ser.No.:

50098801

12345678901

0C(+32F)<Tamb<+60C(+140F)

F06-DXC10xxx-18-00-xx-xx-000

Fig. 1:

1

2

Nameplate specifications for the Fieldcheck flow simulator (example)

Order code/serial number

Permitted ambient temperature range

2.1.2

Simubox nameplate

ENDRESS+HAUSER

SIMUBOX - MID

1

2

Order Code:

Ser.No.:

50097102

12345678901

4

F06-DXC10xxx-18-00-xx-xx-001

Fig. 2:

1

2

Nameplate specifications for the Simubox (example)

Order code

Serial number

Endress+Hauser

Proline Fieldcheck

Identification

2.2

Scope of delivery

The equipment supplied with Fieldcheck comprises the following components:

The Fieldcheck flow simulator with battery pack

A connecting cable for the service interface

A connecting cable for the Simubox

Two connecting cables for current and frequency output

An "RS 232" connecting cable for connecting the Fieldcheck to a computer (9-pin COM interface)

A line adapter

A softcase

Operating Instructions

The Simuboxes for the respective flow measuring systems are available via separate order numbers.

2.3

CE mark, Declaration of conformity

The devices are designed to meet state-of-the-art safety requirements, have been tested, and left the

factory in a condition in which they are safe to operate. The devices comply with the applicable

standards and regulations in accordance with EN 61010 Protection Measures for Electrical

Equipment for Measurement, Control, Regulation and Laboratory Procedures.

The measuring system described in these Operating Instructions thus complies with the statutory

requirements of the EC Directives. Endress+Hauser confirms successful testing of the device by

affixing the CE mark.

2.4

Registered trademarks

FieldTool, Fieldcheck

Registration-pending or registered trademarks of Endress+Hauser Flowtec AG, Reinach,

Switzerland

Endress+Hauser

Wiring

Proline Fieldcheck

Wiring

Warning!

When connecting Ex-certified devices, see the notes and diagrams in the Ex-specific supplement to

these Operating Instructions of the relevant measuring device. Fieldcheck may not be used in

hazardous areas. Please do not hesitate to contact your E+H representative if you have any

questions.

3.1

Overview

Fieldcheck is connected to the following transmitter connections:

Via the Simubox to the transmitter amplifier

To the transmitter service plug

To the current or frequency output.

For correct synchronisation with the measuring device we recommend that you abide by the

following procedure.

1.

Start the device to be tested.

2.

First connect the cables to the flowmeter ( Page 9 to Page 14).

3.

Next, connect the cables to the front of Fieldcheck ( Page 16).

! Note!

Fieldcheck does not need an external power supply during operation. Power is provided by internal

storage batteries. Make sure that the storage batteries are fully charged before beginning a

simulation.

Endress+Hauser

Proline Fieldcheck

Wiring

3.2

"

Connecting to Promag 10

Caution!

Connect the ground terminals on the cables to the uninsulated housing components or to the

ground terminals in the cover of the connection compartment.

1.

Remove cover of the electronics compartment (c).

2.

Remove the local display (d) from the connection compartment cover.

3.

Press the side latches (e) and fold down the connection compartment cover.

4.

Pull the sensor signal cable plug out of the amplifier socket (f).

5.

Insert Simubox cable plug into the amplifier socket (f).

6.

Connect Fieldcheck to current and pulse output (g) of the transmitter.

! Note!

The configuration of the outputs is dependent on the product type and the product version of

the tested transmitter. To find out which terminal pairs are assigned to the outputs, see the

Wiring chapter of the flowmeter Operating Instructions.

7.

Connect FieldCheck to the service plug (h).

1

h

f

c

Esc

d

e

b

a

F06-DXC10xxx-04-00-xx-xx-007

Fig. 3:

a

b

c

d

e

f

g

h

Endress+Hauser

Connecting Fieldcheck to Promag 5X (compact version)

Fieldcheck flow simulator

Simubox

Electronics compartment cover

Local display

Latches

Amplifier socket

Terminals for current/pulse output

Service plug-in jack

Wiring

Proline Fieldcheck

3.3

"

Connecting to Promag 50/53 compact version

Caution!

Connect the ground terminals on the cables to the uninsulated housing components or to the

ground terminals in the cover of the connection compartment.

1.

Remove cover of the electronics compartment (e).

2.

Pull local display (f) down.

3.

Pull the sensor signal cable plug out of the amplifier socket (g).

4.

Insert Simubox cable plug into the amplifier socket (g).

5.

Remove the cover of the connection compartment (h) from the transmitter housing.

6.

Connect Fieldcheck to the current and frequency outputs of the transmitter (terminal pairs

22/23, 24/25 or 26/27).

! Note!

The configuration of the outputs is dependent on the product type and the product version of

the tested transmitter. To find out which terminal pairs are assigned to the outputs, see the

Wiring chapter of the flowmeter Operating Instructions.

7.

Connect Fieldcheck to the service plug (i).

h

e

27

26

25

24

23

22

21

20

N (L-) 2

L1 (L+) 1

F06-DXC10xxx-04-00-xx-xx-000

Fig. 4:

a

b

c

d

e

f

g

h

I

10

Connecting Fieldcheck to Promag 5X (compact version)

Fieldcheck flow simulator

Simubox

Stainless steel transmitter

Aluminium transmitter

Electronics compartment cover

Local display

Amplifier socket

Connection compartment cover

Service plug

Endress+Hauser

Proline Fieldcheck

Wiring

3.4

"

Connecting to Promag 50/53 remote version

Caution!

Connect the ground terminals on the cables to the uninsulated housing components or to the

ground terminals in the cover of the connection compartment.

1.

Remove the cover of the connection compartment (d).

2.

Completely remove the terminal block (e, terminal nos. 4-8, 36+37) from the base.

" Caution!

If the terminal block is not removed, a correct simulation/verification is not guaranteed.

3.

Insert Simubox cable plug into the amplifier socket (g).

4.

Connect Fieldcheck to the current and frequency outputs of the transmitter (terminal pairs

22/23, 24/25 or 26/27).

! Note!

The configuration of the outputs is dependent on the product type and the product version of

the tested transmitter. To find out which terminal pairs are assigned to the outputs, see the

Wiring chapter of the flowmeter Operating Instructions.

5.

Connect Fieldcheck to the service plug (f).

c

f e

1

20 21 22 23 24 25 26 27

6 5 7 8 4 37 36

42 41

b

d

F06-DXC10xxx-04-00-xx-xx-001

Fig. 5:

a

b

c

d

e

f

g

Endress+Hauser

Connecting Fieldcheck to Promag 5X (remote version)

Fieldcheck flow simulator

Simubox

Transmitter wall-mount housing

Connection compartment cover

Terminal block

Service plug

Amplifier socket

11

Wiring

Proline Fieldcheck

3.5

"

Connecting to Promass 40/80/83 compact version

Caution!

Connect the ground terminals on the cables to the uninsulated housing components or to the

ground terminals in the cover of the connection compartment.

1.

Remove cover of the electronics compartment (e).

2.

Remove local display.

3.

Disconnect the excitation current cable from the excitation current socket (f).

# Warning!

The excitation current cable must be disconnected as otherwise the measuring tube could

vibrate in the resonance frequency and become damaged!

4.

Pull the sensor signal cable plug out of the amplifier socket (g).

5.

Insert Simubox cable plug into the amplifier socket (g).

6.

Remove the cover of the connection compartment (h) from the transmitter housing.

7.

Connect Fieldcheck to the current and frequency outputs of the transmitter (terminal pairs

22/23, 24/25 or 26/27).

! Note!

The configuration of the outputs is dependent on the product type and the product version of

the tested transmitter. To find out which terminal pairs are assigned to the outputs, see the

Wiring chapter of the flowmeter Operating Instructions.

8.

Connect Fieldcheck to the service plug (i).

h

e

e

g

27

26

25

24

23

22

21

20

N (L-) 2

L1 (L+) 1

F06-DXC10xxx-04-00-xx-xx-004

Fig. 6:

a

b

c

d

e

f

g

h

i

12

Connecting Fieldcheck to Promass 8x (compact version)

Fieldcheck flow simulator

Simubox

Stainless steel transmitter

Aluminium transmitter

Electronics compartment cover

Exciting current socket

Amplifier socket

Connection compartment cover

Service plug

Endress+Hauser

Proline Fieldcheck

Wiring

3.6

"

Connecting to Promass 80/83 remote version

Caution!

Connect the ground terminals on the cables to the uninsulated housing components or to the

ground terminals in the cover of the connection compartment.

1.

Remove the cover of the connection compartment (d).

2.

Remove excitation current cable (h, terminal pair 41/42).

# Warning!

The excitation current cable must be removed as otherwise the measuring tube could vibrate

in the resonance frequency and become damaged!

3.

Completely remove the terminal block (e, terminals 4-12) from the base.

" Caution!

If the terminal block is not removed, a correct simulation/verification is not guaranteed.

4.

Insert Simubox cable plug into the amplifier socket (g).

5.

Connect Fieldcheck to the current and frequency outputs of the transmitter (terminal pairs

22/23, 24/25 or 26/27).

! Note!

The configuration of the outputs is dependent on the product type and the product version of

the tested transmitter. To find out which terminal pairs are assigned to the outputs, see the

Wiring chapter of the flowmeter Operating Instructions.

6.

Connect Fieldcheck to the service plug (f).

e h

c

1 2

20 21 22 23 24 25 26 27

4 5 6 7 8 9 10 11 12

41 42

b

d

F06-DXC10xxx-04-00-xx-xx-005

Fig. 7:

a

b

c

d

e

f

g

h

Endress+Hauser

Connecting Fieldcheck to Promass 8X (remote version)

Fieldcheck flow simulator

Simubox

Transmitter wall-mount housing

Connection compartment cover

Terminals for sensor signal cable

Service plug

Amplifier socket

Terminals for excitation current cable

13

Wiring

Proline Fieldcheck

3.7

"

Connecting to Prowirl 72

Caution!

Connect the ground terminals on the cables to the uninsulated housing components or to the

ground terminals in the cover of the connection compartment.

1.

Remove cover of the electronics compartment (c).

2.

Remove the local display module (d) from the retainer rails (e).

3.

Fit the local display module (d) with its left side onto the right retainer rail (e) (this secures the

local display module).

(Continued on next page)

g

i

k

b

F06-DXC10xxx-04-00-xx-xx-006

Fig. 8:

a

b

c

d

e

f

g

h

i

j

k

14

Connecting Fieldcheck to Prowirl 72

Fieldcheck

Simubox

Electronics compartment cover

Local display module

Local display module retainer rails

Fixing screw for cover of connection compartment

Connection compartment cover

Terminals for current output/power supply and pulse output (optional)

Plastic cover

Amplifier socket

Service plug

Endress+Hauser

Proline Fieldcheck

Wiring

4.

Loosen the fixing screw (f) of the cover of the connection compartment (g) and fold down the

cover.

5.

Connect Fieldcheck to the current output/power supply and to the pulse output if available.

The terminals can be disconnected for this.

" Caution!

The current output can only be tested for accuracy during the verification if it is connected

to the current input of Fieldcheck.

The pulse output is connected to the frequency input of Fieldcheck.

6.

Fold up the plastic cover (i).

7.

Disconnect the signal cable plug from the amplifier socket (j).

8.

Insert Simubox cable plug into the amplifier socket (j).

9.

Connect Fieldcheck to the service plug (k).

3.7.1

Prowirl 72 wiring diagram

B

A

+ -

1 2

+ -

3 4

F06-72xxxxxx-04-00-00-xx-000

Fig. 9:

A=

B=

C=

Endress+Hauser

Assignment of terminals

Power supply/current output

Pulse/status output

Ground terminal (only relevant for remote version)

15

Wiring

Proline Fieldcheck

3.8

Assignment of Fieldcheck connections

SRV

SIM

DC

F06-DXC10xxx-04-00-xx-xx-003

Fig. 10:

1

2

3

4

5

3.9

Fieldcheck connection diagram on the front panel

Connection to the frequency output of the device

Connection to the current output of the device

Connection to the internal service interface of the device

Connection to the Simubox

Connection to the plug power unit

Post-connection check

Fieldcheck can only complete the start-up procedure correctly if the simulation box and the

service cable are correctly connected.

Current and frequency outputs which are incorrectly connected or mixed up result in an incorrect

verification result.

16

Endress+Hauser

Proline Fieldcheck

Operation

Operation

4.1

Display and operating elements

The local display enables you to read all important variables of the simulation and configure the

device using the function matrix.

+7.000 dm3/m

+7.012 dm3/m

5%

MP1

Esc

4

F06-DXC10xxx-07-xx-xx-xx-000

Fig. 11:

1

2

3

Endress+Hauser

Display and operating elements

Liquid crystal display

The backlit, liquid crystal display shows measured values, dialog texts, fault messages and information messages.

The HOME position (operating mode) is the name given to the display during normal measuring operation.

Optical operating elements for "Touch Control"

Plus/minus keys

Enter numerical values, select parameters

Select different blocks, groups and function groups within the function matrix

The following functions are activated by pressing the +/- keys (X) simultaneously:

Exit the function matrix step by step HOME position

Press the +/- keys longer than 3 seconds Direct return to the HOME position

Cancel data entry

Enter key

HOME position Enter the function matrix

Save numerical values entered or altered settings

17

Operation

Proline Fieldcheck

4.1.1

Display

The display area consists of three to four lines; this is where measured values are displayed, and/or

status variables (sequence information of a verification.

4

+7.000 dm3/m

+7.012 dm3/m

I = 17,12 mA

F = 783 Hz

F06-DXC10xxx-07-xx-xx-xx-001

Fig. 12:

1

2

3

4

5

6

18

Typical display for normal operating mode (HOME position)

Main line: shows simulation values, e.g. volume flow in [dm3/s]

Additional line: shows up-to-date measured values of the tested measuring device]

Information line: shows the current variables for current and frequency if the corresponding outputs of the device

are connected to Fieldcheck. This is only possible in the SIMULATION operating mode

Information icons field: icons representing additional information on the measured values are shown in this field.

See figure for a full list of the icons and their meanings.

Measured values field: the current measured values appear in this field.

Unit of measurement field: the units of measure and time defined for the flow values appear in this field.

Endress+Hauser

Proline Fieldcheck

Operation

4.1.2

Display icons

The icons which appear in the field on the left make it easier to read and recognise error messages

locally.

10

F06-DXC10xxx-07-xx-xx-xx-002

Fig. 13:

1

2

3

4

5

6

7

8

9

10

Endress+Hauser

Fieldcheck display icons

DC power supply

Charging status: battery fully charged

Charging status: battery 2/3 charged

Charging status: battery 1/3 charged (flashing in HOME position)

Simulation continuous"

Simulation step"

Simulation profile"

Verification

Measured volume flow

Measured mass flow

19

Operation

Proline Fieldcheck

4.2

Brief operating instructions on the function matrix

Note!

See the general notes on Page 20.

Description of functions Section 9 to Section 12

1.

HOME position F Enter the function matrix

2.

Select a block (e.g. USER INTERFACE)

3.

Select a group (e.g. CONTROL)

4.

Select a function group (e.g. BASIC CONFIGURATION)

5.

Select a function (e.g. LANGUAGE)

Change parameter / enter numerical values:

P Select or enter release code, parameters, numerical values

F Save your entries

6.

Exit the function matrix:

Press Esc key (X) longer than 3 seconds HOME position

Repeatedly press Esc key (X) Return step by step to HOME position

F06-x3xxxxxx-19-xx-xx-xx-000

Fig. 14:

4.2.1

Selecting functions and configuring parameters (function matrix)

General notes

The function matrix comprises a multiplicity of functions which, for the sake of clarity, are arranged

on a number of menu levels (blocks, groups and function groups).

20

Endress+Hauser

Proline Fieldcheck

Operation

Comply with the following instructions when configuring functions:

You select functions as described on Page 20.

Note!

A detailed description of all the functions as well as a detailed overview of the function matrix are

provided in Sections 9 to 12.

4.3

Communication

Operation via a personal computer using the FieldTool operating software.

4.3.1

FieldTool operating program

FieldTool is a universal service and configuration software package designed for the Proline

measuring devices. The connection is made with a commercial serial cable (9-pole DSUB, 0Modem) to the underside of Fieldcheck.

FieldTool offers the user the following fields of application:

Configuring the equipment functions.

Archiving the verification data.

Printout of a verification certificate with all measuring results and I/O parameters.

You can find more information on FieldTool in the following E+H document:

System Information: SI 031D/06/en FieldTool"

Endress+Hauser

21

Commissioning

Proline Fieldcheck

Commissioning

5.1

Function check

Make sure that Fieldcheck is correctly connected to the measuring device that is to be simulated

( Page 8 ff.). The measuring device must be working free of errors in order for a simulation or

verification to be started.

5.2

Commissioning

Fieldcheck is powered via an adapter or via the storage battery included in the delivery. Before the

simulation, make sure that the storage batteries are fully charged. To ensure correct commissioning

you are advised to abide by the processes as they are described on Page 8 ff.

Fieldcheck switches itself on automatically as soon as one of the connecting cables is inserted.

Fieldcheck performs a number of self-tests after power-on. As this procedure progresses, diverse

messages which have to be acknowledged appear on the local display.

You know that Fieldcheck is ready for operation when the HOME position appears on the display.

If batteries are being used, the charge status of the battery pack also appears (Page 19 ff.).

5.2.1

Charging the battery

The battery is charged automatically as soon as the power unit or the car-adapter cable is connected

to Fieldcheck. The charging time is less than 3 hours if there is no simulation in progress. When the

battery is fully charged it is switched to conservation charging. The charging time is considerably

longer during a simulation.

The charge status is displayed in the HOME position via the charge status icon (Page 19 ff.).

22

Endress+Hauser

Proline Fieldcheck

Maintenance

Maintenance

Fieldcheck requires no special maintenance.

"

Caution!

To prevent a low discharge of the battery in case of not using Fieldcheck for a longer period it is

recommended to charge the device every quarter of a year.

Exterior cleaning

When cleaning the exterior of measuring devices, always use cleaning agents that do not attack the

surface of the housing.

Endress+Hauser

23

Accessories

Proline Fieldcheck

Accessories

Various accessories can be supplied for Fieldcheck and they can be ordered separately from

Endress+Hauser. The E+H service organisation can provide detailed information on the order code

of your choice.

Accessory

Description

Order code

FieldTool

Configuration and service software for flowmeters in the

field:

Commissioning, maintenance analysis

Configuring flowmeters

Service functions

Visualisation of process data

Troubleshooting

Controlling the Fieldcheck tester/simulator

DXS10 - * * * * *

Contact your E+H representative for more information.

Simubox MID for FieldCheck

Serves communication between FieldCheck and

electromagnetic flowmeters.

50097102

Simubox Coriolis for FieldCheck

Serves communication between FieldCheck and Coriolis

mass flowmeters.

50097101

Plug-in power unit 85260 VAC

Power unit for charging the battery and the operation of

FieldCheck at the mains

50095659

Car adapter 12 VDC

Adapter for connecting to the car battery.

50095660

NiMH AccuPack

Additional battery

50095661

Softcase

Practical storage bag

50095662

Simubox/FieldCheck connecting cable For connecting the Simubox to FieldCheck

50095663

Proline measuring device/FieldCheck

interface cable

For connecting FieldCheck to the internal service

interface of the flowmeter

50097100

FieldCheckcurrent or frequency

output measuring cable

For connecting FieldCheck to the current or frequency

output of the flowmeter

50095664

FC/Tooling interface cable

For connecting FieldCheck to the Tooling computer

50098800

7.1

24

Software history

Software version / date

Changes to software

Changes to documentation

V 1.00.00

V 1.00.01/11.2001

Device release

V 1.00.02/08.2002

Software adaptation

V 1.01.00/07.2003

Software extension for Coriolis flow

measuring systems

Operating Instructions

V 1.02.00/04.2004

Software extension for Prowirl 72

Operating Instructions

Endress+Hauser

Proline Fieldcheck

Technical data

Technical data

8.1

Technical data at a glance

8.1.1

Input

Measured variable

Current input, frequency input

Measuring range

0...25 mA, 0...15000 Hz

8.1.2

Output

Output signal

Electromagnetic: simulation voltage

Coriolis: 2 phase-shifted sinusoidal signals

Galvanic isolation

Yes

8.1.3

Power supply

Electrical connections

Input for power unit: 100-240 V AC (47-63 Hz) Prim., 12 V DC (2.5 A) Sec.

Supply voltage

12 V DC, internal battery 7.2 V, 3800 mAh

Power consumption

140 mA

Charging current: max. 2A (max. 350 mA for simultaneous operation)

8.1.4

Performance characteristics

Reference operating

conditions

+22 C 2K

Max. measured error for

outputs

Electromagnetic measuring device

Voltage 0.2 % of full scale (0.150 ... 20 mV)

Coriolis measuring device:

Phase difference 0.2 % of full scale

Max. measured error for

inputs

Current

5 A (0 ... 25 mA)

Frequency

< 0.5 Hz (0 ...15 kHz)

8.1.5

Operating conditions (Environment)

Ambient temperature range

0 ... 60C

Electromagnetic compatibility

(EMC)

In accordance with EN 61326/A1 and NAMUR Recommendation NE 21

Endress+Hauser

25

Technical data

Proline Fieldcheck

8.1.6

Design, dimensions

Mechanical construction

Fieldcheck

270 x 130 x 60 mm (length x width x height)

Simubox (without cable)

120 x 60 x 30 mm (L x W x H)

Softcase

400 x 180 x 300 mm (L x W x H)

Weight

1.6 kg

8.1.7

Display and user interface

Display elements

Liquid crystal display: illuminated,

for presenting different measured value and status variables

Operating elements

Local operation with three optical keys (O, S, F)

Computer interface

FieldTool

Permanent storage of verification data

Printing of certificates

CE mark

The measuring system is in conformity with the statutory requirements of the EC Directives.

Endress+Hauser confirms successful testing of the device by affixing the CE mark.

Other standards and

guidelines

EN 60529:

Degrees of protection by housing (IP code)

EN 61010:

Protection Measures for Electrical Equipment for Measurement, Control, Regulation and Laboratory

Procedures

EN 61326/A1 (IEC 1326):

Electromagnetic compatibility (EMC requirements)

8.1.8

Ordering information

The E+H service organisation can provide detailed ordering information and information on the

order codes on request.

8.1.9

Accessories

Various accessories can be supplied for Fieldcheck and they can be ordered separately from

Endress+Hauser (see Page 24). The E+H service organisation can provide detailed information

on the order codes of your choice.

8.1.10

Documentation

System Information SI 030D/06/en

Technical Information TI 059D/06/en

26

Endress+Hauser

Proline Fieldcheck

Description of device functions - General section

Description of device functions - General

section

9.1

Notes on the description of device functions

The description of device functions is split into the following sections:

Description of device functions - General section ( Page 27 ff.)

This introduces you to the function matrix and provides you with an overview of the device

functions and a description of the device functions which apply to all applications.

Description of device functions - Fieldcheck and electromagnetic measuring devices

( Page 39 ff.)

This provides you with a description of the device functions which only apply to the simulation

and verification of electromagnetic flow measurement systems.

Description of device functions - Fieldcheck and Coriolis measuring systems

( Page 49 ff.)

This provides you with a description of the device functions which only apply to the simulation

and verification of Coriolis mass flow measuring systems.

Description of device functions - Fieldcheck and vortex measuring systems

( Page 59 ff.)

This provides you with a description of the device functions which only apply to the simulation

and verification of vortex measuring systems.

There are various ways of locating the description of a function of your choice in the manual:

9.1.1

Using the table of contents to locate a function description

The designations of all the cells in the function matrix are listed in the table of contents. You can

use these unambiguous designations (such as USER INTERFACE, INPUTS, OUTPUTS, etc.) to

choose whichever functions are applicable to a particular set of conditions. The page references

show you exactly where to find the detailed descriptions of the functions in question. The table of

contents can be found on Page 3.

9.1.2

Using the graphic of the function matrix to locate a function

description

This step-by-step, top-down approach starts with the blocks, the highest level, and works down

through the matrix to the description of the function you need:

Endress+Hauser

1.

All blocks available, and their related groups are illustrated on Page 28. Select the block (or the

group within the block) which you need for your application and use the page reference to

locate the information corresponding to the next level.

2.

The page in question contains a graphic illustration of the block with all its subordinate groups,

function groups and functions.Select the function which you need for your application and use

the page reference to locate the detailed function description.

27

Description of device functions - General section

9.2

Proline Fieldcheck

Function matrix

BLOCKS

FUNCTION

Proline Promag: Page 39 ff.

Proline Promass: Page 49 ff.

Proline Vortex: Page 59 ff.

GROUPS

SIMULATION

Electromagnetic measuring devices (Proline

Promag)

Page 40 ff.

Coriolis measuring devices (Proline Promass)

Page 50 ff.

Vortex measuring devices (Proline Prowirl)

Page 60 ff.

Electromagnetic measuring devices (Proline

Promag)

Page 44 ff.

Coriolis measuring devices (Proline Promass)

Page 53 ff.

Vortex measuring devices (Proline Prowirl)

Page 63 ff.

CONTROL

Page 29 ff.

Sensor data

Page 32 ff.

OUTPUTS

Page 33 ff.

PROCESS PARAMETER

Page 34

READ IN PARAMETERS

Page 35

RESULTS

Page 36 ff.

VERSION INFO

Page 38 ff.

USER INTERFACE

FUNCTIONS

VERIFICATION

BASIC FUNCTIONS

SUPERVISION

28

Endress+Hauser

Proline Fieldcheck

Description of device functions - General section

9.3

Block

USER

INTERFACE

Group

Block USER INTERFACE

Function group

CONTROL

Function

LANGUAGE

P. 29

CONTRAST

LCD

P. 29

FORMAT TIME

TIME

P. 29

P. 30

P. 29

9.3.1

BACK LIGHT

P. 29

FORMAT

DATE

P. 29

DATE

P. 29

Group CONTROL

Function description

USER INTERFACE CONTROL

LANGUAGE

Use this function to select the language for all texts, parameters and messages shown on

the local display.

Options:

ENGLISH

DEUTSCH

CONTRAST LCD

Use this function to optimise display contrast to suit

local operating conditions.

User input:

10...100%

Factory setting:

50%

BACK LIGHT

Options:

ON(AUTOMATIC)

OFF

Factory setting:

ON(AUTOMATIC)

Note!

If the ON(AUTOMATIC) setting is selected, the lighting of the display is automatically

switched off if the equipment is not used for 10 minutes.

FORMAT DATE

Use this function to select a date format.

Options:

DD.MM.YYYY

MM/DD/YYYY

Factory setting:

DD.MM.YYYY

DATE

Use this function to enter the date.

User input:

DD.MM.YYYY (MM/DD/YYYY)

FORMAT TIME

Options:

24H

12H (AM/PM)

Factory setting:

24H

Endress+Hauser

29

Description of device functions - General section

Proline Fieldcheck

Function description

USER INTERFACE CONTROL

TIME

Use this function to enter the time.

User input:

HH:MM

30

Endress+Hauser

Proline Fieldcheck

Description of device functions - General section

9.4

Block

Group

BASIC

FUNCTIONS

SENSOR

PARAMETER

P. 32

Block BASIC FUNCTIONS

Function group

Function

K-FACTOR

POS/NEG

P. 32

OUTPUTS

OUTPUT

P. 33

P. 33

OPERATION

MODE

P. 33

VALUE FHIGH

P. 34

Endress+Hauser

DENSITY

VALUE

P. 34

P. 32

FLOW

DIRECTION

P. 32

SERIAL

NUMBER

P. 32

ASSIGN

P. 33

CURRENT

RANGE

P. 33

VALUE 0_4 mA

P. 33

ASSIGN

P. 33

START VALUE

FREQUENCY

P. 33

END

FREQUENCY

P. 33

PULSE VALUE

P. 34

OUTPUT

SIGNAL

P. 34

STANDARD

DENSITY

P. 34

OPERATING

DENSITY

P. 34

REFERENCE

DENSITY

P. 34

VALUE 20 mA

P. 33

VALUE FLOW

P. 33

APPLICATION

P. 34

TYPE UNIT

MEAS.

P. 34

READ IN

PARAMETERS

P. 35

P. 32

NOMINAL

DIAMETER

TAG NAME.

P. 32

PROCESS

PARAMETER

P. 34

ZERO POINT

READ IN

PARAMETERS

P. 35

31

Description of device functions - General section

9.4.1

Proline Fieldcheck

Group SENSOR PARAMETER

Use this function group to display the characteristic data of the connected sensor, such as calibration

factor, nominal diameter, serial number, etc.

Function description

BASIC FUNCTIONS SENSOR PARAMETER

K-FACTOR

POSITIVE/NEGATIVE

Use this function to view the positive/negative K factor

ZERO POINT

Use this function to view the zero-point correction value for the sensor.

Note!

This function is not displayed when testing vortex measuring devices.

NOMINAL DIAMETER

Use this function to view the nominal diameter of the sensor.

DIRECTION OF FLOW

Use this function to view the set mounting direction of the sensor.

Note!

This function is not displayed when testing vortex measuring devices.

32

SERIAL NUMBER

Use this function to view the serial number of the connected measuring device.

TAG NAME

Use this function to view the device tag name of the connected measuring device.

Endress+Hauser

Proline Fieldcheck

Description of device functions - General section

9.4.2

Group OUTPUTS

Use this function group to view the configuration and settings of the current and frequency outputs.

Function description

BASIC FUNCTION OUTPUTS

OUTPUT

Use this function to select the output

Options:

CURR. OUTPUT

FREQUENCY OUTPUT

ASSIGN

Use this function to view the physical measured variable which is assigned to the current

output of the measuring device (e.g. volume flow, mass flow, temperature)

Note!

This function is only available if CURRENT OUTPUT was selected in the OUTPUT

function.

CURRENT RANGE

Use this function to view the set current range in the measuring device.

Note!

This function is only available if CURRENT OUTPUT was selected in the OUTPUT

function.

VALUE 0_4 mA

Use this function to view the flow value, which is assigned to the 0_4 mA current in the

measuring device.

Note!

This function is only available if CURRENT OUTPUT was selected in the OUTPUT

function.

VALUE 20 mA

Use this function to view the flow value, which is assigned to the 20 mA current in the

measuring device.

Note!

This function is only available if CURRENT OUTPUT was selected in the OUTPUT

function.

OPERATION MODE

Use this function to view the set operating mode of the frequency output in the

measuring device.

Note!

This function is only available if FREQUENCY OUTPUT was selected in the OUTPUT

function.

ASSIGN

Use this function to view the physical measured variable which is assigned to the

frequency output of the measuring device (e.g. volume flow, mass flow, temperature)

Note!

This function is only available if FREQUENCY OUTPUT was selected in the OUTPUT

function.

START FREQUENCY

Use this function to view the set start frequency in the measuring device.

Note!

This function is only available if FREQUENCY OUTPUT was selected in the OUTPUT

function.

END FREQUENCY

Use this function to view the set end frequency in the measuring device.

Note!

This function is only available if FREQUENCY OUTPUT was selected in the OUTPUT

function.

VALUE f-LOW

Use this function to view the flow value, which is assigned to the start frequency in the

measuring device.

Note!

This function is only available if FREQUENCY OUTPUT was selected in the OUTPUT

function.

Endress+Hauser

33

Description of device functions - General section

Proline Fieldcheck

Function description

BASIC FUNCTION OUTPUTS

VALUE f-HIGH

Use this function to view the flow value, which is assigned to the end frequency in the

measuring device.

Note!

This function is only available if FREQUENCY OUTPUT was selected in the OUTPUT

(6900) function.

PULSE VALUE

Use this function to view the set pulse value in the measuring device.

Note!

This function is only available if FREQUENCY OUTPUT was selected in the OUTPUT

(6900) function and the operating mode in the measuring device is set to PULSE.

OUTPUT SIGNAL

9.4.3

Use this function to view the output signal settings (ACTIVE/PASSIVE,

POSITIVE/NEGATIVE).

Group PROCESS PARAMETER

Function description

BASIC FUNCTION PROCESS PARAMETER

DENSITY VALUE

Note!

This function only appears if a Promag 53-type electromagnetic flow measurement system

is being tested.

Use this function to view the density factor entered in the measuring device. With this

value, the volume flow is converted to a mass flow during simulation.

STANDARD DENSITY

Note!

This function only appears if a Coriolis flow measurement system is tested.

Use this function to view the standard density entered in the measuring device. With this

value, the mass flow is converted to the corrected volume flow during simulation.

OPERATING DENSITY

Note!

This function only appears if a vortex flow measurement system is tested.

Use this function to view the density at process conditions entered in the measuring

device. With this value, the volume flow is converted to a mass flow or corrected volume

flow during simulation.

REFERENCE DENSITY

Note!

This function only appears if a vortex flow measurement system is tested.

Use this function to view the density at reference conditions entered in the measuring

device. With this value, the volume flow is converted to a mass flow or corrected volume

flow during simulation.

APPLICATION

Note!

This function only appears if a vortex flow measurement system is tested.

Use this function to view the set application (liquid or gas/steam) in the measuring device.

TYPE UNIT

MEASURAND

Note!

This function only appears if a vortex flow measurement system is tested.

Use this function to view the set unit type (volume flow, calculated mass flow or calculated

corrected volume flow) in the measuring device.

34

Endress+Hauser

Proline Fieldcheck

Description of device functions - General section

9.4.4

Group READ IN PARAMETERS

Function description

BASIC FUNCTION READ IN PARAMETERS

READ IN PARAMETERS

Use this function to transfer the complete data record from the measuring device to

Fieldcheck, if, for example, you have changed parameters in the connected measuring

device,

Options:

START

CANCEL

Endress+Hauser

35

Description of device functions - General section

9.5

Block SUPERVISION

Block

Group

Function group

SUPERVISION

RESULTS

Proline Fieldcheck

Function

RESULTS VER.

MID

P. 36

RESULTS VER.

COR.

P. 37

P. 38

SERIAL

NUMBER

P. 38

CALIBRATION

DATE

P. 38

TYPE

HW VERSION

SW VERSION

P. 38

P. 38

P. 38

SERIAL

NUMBER

P. 38

P. 36

STORAGE

LOC. VER.

P. 36

INFO

STORAGE

LOC.

P. 36

DELETE

STORAGE

P. 37

STORAGE

LOCATION

P. 37

HW VERSION

SW VERSION

P. 38

VERSION INFO

FIELDCHECK

P. 38

P. 38

SIMUBOX

P. 38

RESULTS VER.

VOR.

P. 37

CALIBRATION

DATE

P. 38

MANUFACT./

TEST DATE

P. 38

9.5.1

Group RESULTS

Function description

SUPERVISION RESULTS

STORAGE LOCATION

VERIFICATION

Use this function to define the storage location of the verification to be displayed.

User input:

1...20

INFO STORAGE

LOCATION

Use this function to view information about the measuring device and the verification

saved in the storage location.

Display:

Main line: measuring device type

Additional line: serial number

Information line: date of verification

RESULTS

VERIFICATION

MAGMETER

Use this function to recall the results of the verification. The result (PASSED, FAILED) is

displayed in the information line.

If the results of a linearity check are recalled, the list of deviation values also appears when

confirming the selection.

Options:

FINAL RESULT

ZERO POINT (with list of deviation values)

AMPLIFIER (with list of deviation values)

CURRENT OUTPUT (with list of deviation values)

FREQ. OUT. (with list of deviation values)

PULSE MEASUREMENT (with list of deviation values)

SENSOR

36

Endress+Hauser

Proline Fieldcheck

Description of device functions - General section

Function description

SUPERVISION RESULTS

RESULTS

VERIFICATION

CORIOLIS

Use this function to recall the results of the verification. The result (PASSED, FAILED) is

displayed in the information line.

If the results of a linearity check are recalled, the list of deviation values also appears when

confirming the selection.

Options:

FINAL RESULT

ZERO POINT (with list of deviation values)

AMPLIFIER (with list of deviation values)

DENSITY (with list of deviation values)

TEMPERATURE (with list of deviation values)

CURRENT OUTPUT (with list of deviation values)

FREQUENCY OUTPUT (with list of deviation values)

PULSE MEASUREMENT (with list of deviation values)

SENSOR

RESULTSVERIFICATI

ON VORTEX

Use this function to recall the results of the verification. The result (PASSED, FAILED) is

displayed in the information line.

If the results of a linearity check are recalled, the list of deviation values also appears when

confirming the selection.

Options:

FINAL RESULT

ZERO POINT (with measured value for the current output)

AMPLIFIER (with list of deviation values)

CURRENT OUTPUT (with list of deviation values)

PULSE MEASUREMENT (with list of deviation values)

SENSOR

DELETE STORAGE

Use this function to delete the content of the memory.

Options:

NO

STORAGE LOCATION

ALL

STORAGE LOCATION

Endress+Hauser

Use this function to specify the storage location whose contents should be deleted. User

input :1...20. This function does not appear unless the STORAGE LOCATION parameter

was selected in the DELETE STORAGE function.

37

Description of device functions - General section

9.5.2

Proline Fieldcheck

Group VERSION INFO

Function group FIELDCHECK

Function description

SUPERVISION VERSION INFO FIELDCHECK

HW VERSION

Use this function to view the hardware version number of Fieldcheck.

SW VERSION

Use this function to view the software version number of Fieldcheck.

SERIAL NUMBER

Use this function to view the manufacturer serial number of Fieldcheck.

CALIBRATION DATE

Use this function to view the last calibration date of Fieldcheck.

Function group SIMUBOX

Function description

SUPERVISION VERSION-INFO SIMUBOX

38

TYPE

Use this function to view the measuring principle of the Simubox

HW VERSION

Use this function to view the hardware version number of the Simubox.

SW VERSION

Use this function to view the software version number of the Simubox.

SERIAL NUMBER

Use this function to view the manufacturer serial number of the Simubox.

CALIBRATION DATE

Use this function to view the last calibration date of the Simubox -(electromagnetic and

Coriolis Simuboxes).

MANUFACTURING/TE

ST DATE

Use this function to view the date of manufacture of the Simubox (vortex and ultrasonic

Simuboxes).

or

Use this function to view the last test date (vortex and ultrasonic Simuboxes ).

Endress+Hauser

Proline Fieldcheck

Block

Description of device functions - Fieldcheck and electromagnetic measuring devices

10

Description of device functions - Fieldcheck and

electromagnetic measuring devices

10.1

Block FUNCTION

Group

Function group

SIMULATION

FUNCTION

P. 40

Function

CONFIGURATI

ON

P. 40

OPERATION

MODE

P. 40

SIMUL. TIME 2

P. 42

OPERATION

SIMUL SIGNAL

P. 41

FLOW 1

P. 41

PROFILE TIME

1

PROFILE TIME

2

P. 42

P. 42

DEV.FREQU.O

UTPUT

P. 46

FLOW 2

P. 41

SIMUL. TIME 1

P. 41

SIMULATE

P. 43

VERIFICATION

OUTPUTS

P. 44

P. 43

OUTPUTS

P. 45

P. 45

LIMIT VALUES

P. 46

DEVIATION

FLOW

P. 46

DEV.CURR.OU

TPUT

P. 46

FLOW 100%

P. 47

MEAS. POINT

1/2

P. 47

VERIFICATION

P. 48

VERIFICATE

P. 48

PARAMETER

P. 47

OPERATION

P. 48

Endress+Hauser

STORAGE

LOCATION

P. 48

39

Description of device functions - Fieldcheck and electromagnetic measuring devices

10.1.1

Proline Fieldcheck

Group SIMULATION

Function group CONFIGURATION

Function description

FUNCTION SIMULATION CONFIGURATION

OPERATION MODE

Use this function to select the operation mode for the simulation.

There are two freely adjustable flow signals of -12.5 m/s to + 12.5 m/s and the assigned

duration of simulation is 1 second to 999 seconds.

Options:

CONTINUOUS

The flow behaviour in the process has low dynamics.

Q1

STOP

START

F06-DXC10xxx-05-xx-xx-xx-000

Q1 = Simulation value 1

STEP

The flow rates in the process are very dynamic and change very quickly. This operation

mode is also suitable for the simulation of flows outside the tolerance limits (Error

simulation). Here very dynamic or disrupted conditions can also be simulated.

T1

Q1

Q2

T2

STOP

START

t

F06-DXC10xxx-05-xx-xx-xx-001

Q1 = Simulation value 1, Q2 = Simulation value 2, T1 = Duration of simulation 1,

T2 = Duration of simulation 2

PROFILE

For the depiction of real sequences in the course of a process or of a filling procedure.

The controlled rise or fall in one flow value to the next can be depicted.

T1

T3

T2

T4

Q2

Q1

START

STOP

t

F06-DXC10xxx-05-xx-xx-xx-002.eps

Q1 = Simulation value 1, Q2 = Simulation value 2, T1 = Duration of simulation 1,

T2 = Duration of simulation 2, T3 = Profile time 1, T4 = Profile time 2

Factory setting:

CONTINUOUS

40

Endress+Hauser

Proline Fieldcheck

Description of device functions - Fieldcheck and electromagnetic measuring devices

Function description

FUNCTION SIMULATION CONFIGURATION

SIMULATION SIGNAL

Use this function to select which measurement is to be simulated.

Options:

VOLUME FLOW

MASS FLOW

Note!

"Calculated mass flow" simulation is only possible with "Promag 53" type devices.

The value stored in the function DENSITY VALUE (DENSITY PARAMETER function

group of the device) is used for the calculation.

If a current input is available in the device and the density is assigned to it, mass flow

simulation is not possible

Factory setting:

VOLUME FLOW

FLOW 1

Use this function to enter the flow value which is to be simulated.

User input:

0.000...999999 (6-digit floating-point number, with sign)

Note!

The unit of the connected measuring device is adopted. The corresponding flow velocity

must lie within the value range - 12.5 m/s to + 12.5 m/s.

Unit:

The unit configured in the measuring device is adopted

Factory setting:

0.000

FLOW 2

Use this function to enter the second flow value which is to be simulated.

Note!

This function is only available if the STEP or PROFILE setting was selected in the

OPERATION MODE function.

More information is provided in the OPERATION MODE function.

User input:

0.000...999999 (6-digit floating-point number, with sign)

Note!

The unit of the connected measuring device is adopted. The corresponding flow velocity

must lie within the value range - 12.5 m/s to + 12.5 m/s.

Unit:

The unit configured in the measuring device is adopted

Factory setting:

0.000

DURATION OF

SIMULATION 1

Use this function to enter the duration of simulation signal 1 (flow).

Note!

This function is only available if the STEP or PROFILE setting was selected in the

OPERATION MODE function.

More information is provided in the OPERATION MODE function.

User input:

1 ... 999 (max. 3-digit number )

Unit:

s ( seconds )

Factory setting:

10

Endress+Hauser

41

Description of device functions - Fieldcheck and electromagnetic measuring devices

Proline Fieldcheck

Function description

FUNCTION SIMULATION CONFIGURATION

DURATION OF

SIMULATION 2

Use this function to enter the duration of simulation signal 2 (flow).

Note!

This function is only available if the STEP or PROFILE setting was selected in the

OPERATION MODE function.

More information is provided in the OPERATION MODE function.

User input:

1 ... 999 (max. 3-digit number )

Unit:

s ( seconds )

Factory setting:

10

PROFILE TIME 1

Use this function to enter the period of time for the change from simulation signal 1 to

simulation signal 2.

Note!

This function is only available if the PROFILE setting was selected in the OPERATION

MODE function.

More information is provided in the OPERATION MODE function.

User input:

1 ... 99 (max. 2-digit number)

Unit:

s ( seconds )

Factory setting:

5

PROFILE TIME 2

Use this function to enter the period of time for the change from simulation signal 2 to

simulation signal 1.

Note!

This function is only available if the PROFILE setting was selected in the OPERATION

MODE function.

More information is provided in the OPERATION MODE function.

User input:

1 ... 99 (max. 2-digit number)

Unit:

s ( seconds )

Factory setting:

5

42

Endress+Hauser

Proline Fieldcheck

Description of device functions - Fieldcheck and electromagnetic measuring devices

Function group OPERATION

Function description

FUNCTION SIMULATION OPERATION

SIMULATE

Use this function to control the simulation.

Options:

START

STOP

Factory setting:

START

Display during the simulation:

Main line

Symbol of the selected operating mode and the simulated value (with unit).

Additional line

The measured value sent back by the measuring device.

Information line

In the SIMULATION operating mode, the current values of the current and frequency

output of the tested device are displayed (multimeter function). Pulses are displayed as

frequency if there is more than 1 pulse/second at the frequency input of Fieldcheck.

In the STOP status the simulation signal value 0 is always given. Affected settings for

the simulation, however, are maintained.

Endress+Hauser

43

Description of device functions - Fieldcheck and electromagnetic measuring devices

10.1.2

Proline Fieldcheck

Group VERIFICATION

In the VERIFICATION group, a measuring device can be checked for the following characteristic

values.

Functionality and deviation in the flow measurement (based on the set point preset by Fieldcheck)

Functionality and deviation of the current and frequency outputs if these outputs are available in

the measuring device. The specified set points correspond in the gradation to the measuring

points when determining flow.

Data bus outputs such as PROFIBUS or FOUNDATION FIELDBUS cannot be directly checked by

Fieldcheck.

Static and dynamic characteristic values of the magnetic field and electrodes.

Verification of the transmitter

Checking the linearity of the amplifier:

Simulated flow at four measuring points which are determined via the 100% full scale value (can be

selected for a presumed fluid velocity between 4 m/s and 8 m/s).

Checking a current output:

Each current output can be verified in the configuration in the measuring device (CURRENT

RANGE function (0-20 mA, 4-20 mA) in the same gradation (5% ... 100%) as the amplifier. For this

purpose, the current output must be directly connected to the current input of the Fieldcheck. If

more than one current output is available, verification takes place in several, menu-guided steps.

Checking a frequency output

(FREQUENCY operating mode, (not for "Promag 10" type devices):

Each frequency output can be verified in the configuration in the measuring device (START VALUE

FREQUENCY, END VALUE FREQUENCY, OUTPUT SIGNAL functions) in the same gradation ( 5%

... 100% ) as the amplifier. For this purpose, the frequency output must be directly connected to the

frequency input of the Fieldcheck. If more than one frequency output is available, verification takes

place in several, menu-guided steps.

A frequency output cannot be checked on "Promag 10" type devices.

Checking a frequency output (PULSE operating mode):

Each pulse output available can be verified in the configuration in the measuring device (PULSE

VALUE, PULSE WIDTH, OUTPUT SIGNAL functions). For this purpose, the flow specified by

Fieldcheck must trigger at least one pulse within 30 s. Otherwise, 0 PULSE is specified. In this

instance, the output is not completely tested in its components.

Verification of the sensor

Coil current test:

For testing the sensor (for the electromagnetic measuring principle) the rise time of the coil current

and further magnetic field-relevant characteristic variables are determined and compared with the

corresponding set points. Exceeding the limit values leads to a FAILED message in the results

presentation.

"

44

Achtung!

Electrode integrity test (not for "Promag 10" type devices):

When testing the sensor the electrode integrity test is carried out at the end of the verification. For

this the measuring tube must be filled and the sensor signal cable must be inserted into the

measuring amplifier socket. A corresponding message appears in the display and you are given the

option to CONTINUE or CANCEL.

Endress+Hauser

Proline Fieldcheck

Description of device functions - Fieldcheck and electromagnetic measuring devices

Evaluation of the results

During verification, the current verification test section is displayed in the 'HOME position'.The

results can be shown on the display once verification is complete. They can be filed in Fieldcheck

under a storage location number of your choice (up to max. 20) together with the measuring device

serial no. and the measuring device tag name.

Via a connection with the FieldTool software, a protocol of the results can later be printed out and

the data from the verification can be stored in an archive file system.

Function group OUTPUTS

During verification, the function and accuracy of a current output and a frequency output can be

checked. Fieldcheck determines the current and frequency outputs available in the measuring

device.

Function description

FUNCTION VERIFICATION OUTPUTS

OUTPUTS

Use this function to display the outputs determined in the flowmeter on the local display

with the related terminals and to select the outputs to be tested. The outputs selected

are displayed inversely.

1. Use the Pkeys to select the outputs which should be tested during the verification

process.

2. Confirm the option selected with the F key.

Note!

It is not possible to select two outputs of the same type.

Start the verification process in the VERIFICATE function ( Page 48).

Two outputs of the same type are tested in two separate runs. After the 1st run, the

message MORE OUTPUTS TO BE TESTED? appears on the display.

If you want to test other outputs, Fieldcheck returns to the output selection area.

1. Select the output to be tested.

Note!

Having selected an output, make sure that the related terminal pair of the flowmeter

is connected to the -Fieldcheck input before the verification process is started.

The following combinations of current and frequency outputs are possible for PROline

Promag:

I

I+I

I+F

I+I+F

I+F+F

I+P (only Promag 10)

Note!

Fieldbus interfaces cannot be tested.

With this software-version current outputs run in passive mode cannot be tested.

Endress+Hauser

45

Description of device functions - Fieldcheck and electromagnetic measuring devices

Proline Fieldcheck

Function group LIMIT VALUES

You can specify the limit values for measured variables in this function group. If the deviation of a

verification step (see OPERATION, P. 38) lies within the configured limit values the result is

PASSED; if it lies outside of this range the result is FAILED. For a quick and unambiguous

identification, the FAILED results are presented inversely on the display.

Note!

For a frequency output operated in the pulse mode the fixed error limit is: 1 pulse 0.1% of the

pulse set number.

Function description

FUNCTION VERIFICATION LIMIT VALUES

DEVIATION FLOW

User input:

0.50 ... 10.0

Unit:

%

Factory setting:

0.5

DEVIATION CURRENT

OUTPUT

This function is only available if a current output was selected in the OUTPUTS function

( Page 45).

User input:

0.02...10.0

Unit:

mA

Factory setting:

0.05

DEVIATION

FREQUENCY OUTPUT

This function is only available if a frequency output was selected in the OUTPUTS

function ( Page 45).

Note!

This function is not available on "Promag 10" type devices.

User input:

1.0...10.0

Unit:

Hz

Factory setting:

2.00

46

Endress+Hauser

Proline Fieldcheck

Description of device functions - Fieldcheck and electromagnetic measuring devices

Function group PARAMETER

Verification of the amplifier takes place along four measuring points MP1...MP4. Use this function

group to enter the full scale value (100%) of the verification flow and the two selectable measuring

points MP2 and MP3 (in % of the full scale value).

Note!

The value of MP1 is predetermined (5% of the full scale value MP4).

Function description

FUNCTION VERIFICATION PARAMETER

FLOW 100%

Use this function to enter the full scale value of the verification flow.

User input:

max 6-digit floating point number (without sign)

Note!

Only values between 4 and 8 m/s are permissible. The input limits MIN and MAX are

displayed beyond the input line.

Unit:

The unit configured in the measuring device is adopted

Factory setting:

according 6m/s

MEASURING POINT

2/3

Use this function to enter the measuring points MP2 and MP3 (in % of the full scale

value).

User input:

MP2: integer between 10 and 90

MP3: integer between 15 and 95

Note!

The value of MP2 must be less than the value of MP3.

Both values are stored permanently.

Unit:

%

Factory setting:

MP2: 10 %

MP3: 50%

Endress+Hauser

47

Description of device functions - Fieldcheck and electromagnetic measuring devices

Proline Fieldcheck

Function group OPERATION

Use this function group to verify the measuring point.

Function description

FUNCTION VERIFICATION OPERATION

VERIFICATION

Use this function to define the scope of the verification.

Note!

A verification of the current and frequency outputs of the transmitter can only be

achieved with the TRANSMITTER or TRANSM. + SENSOR option.

If SENSOR or TRANSM. + SENSOR is selected, the electrode integrity test is carried out

at the end of the verification ( Page 44).

Options:

TRANSMITTER

SENSOR

TRANSM. + SENSOR

Factory setting:

TRANSMITTER

VERIFICATE

Use this function to control the verification. After completion of the verification, the

question STORE DATA? appears in this function.

Options:

START

The verification is started and the message VERIFICATION ACTIVE appears on the

display.At the end of the verification, the message RESULT: PASSED/FAILED - STORE

DATA? appears on the display.

STOP

Via the STOP option the active verification can be aborted.

STORE DATA?

The results of the verification can be saved using the STORE DATA? option.

Factory setting:

START

STORAGE LOCATION

Use this function to define where the results of the verification are to be stored.

User input:

1...20

Factory setting:

First available storage location

Note!

If there is no storage location available or the selected storage location is occupied, a

corresponding warning is given before saving (Overwrite storage location? Y/N).

48

Endress+Hauser

Proline Fieldcheck

Block

Description of device functions - Fieldcheck and Coriolis measuring systems

11

Description of device functions - Fieldcheck and

Coriolis measuring systems

11.1

Block FUNCTION

Group

Function group

SIMULATION

FUNCTION

P. 50

Function

CONFIGURATI

ON

P. 50

OPERATION

MODE

P. 50

SIMUL SIGNAL

P. 50

FLOW 1

P. 51

TYPE UNIT

FLOW

P. 54

OUTPUTS

FLOW 2

P. 51

SIMUL. TIME 1

P. 51

DEVIATION

CURRENT

OUTPUT

P. 56

DEVIATION

FREQU.

OUTPUT

P. 56

SIMUL. TIME 2

P. 51

OPERATION

SIMULATE

P. 52

VERIFICATION

P. 53

P. 52

APPLICAT./OU

FLOW RANGE

TP.

P. 54

P. 54

P. 55

LIMIT VALUES

P. 56

DEVIATION

FLOW

P. 56

DEVIATION

DENSITY

P. 56

DEVIATION

TEMPERATURE

P. 56

PARAMETER

FLOW 100%

P. 57

MEAS. POINT

1/2

P. 57

VERIFICATION

P. 58

VERIFICATE

P. 58

P. 57

OPERATION

P. 58

Endress+Hauser

STORAGE

LOCATION

P. 58

49

Description of device functions - Fieldcheck and Coriolis measuring systems

11.1.1

Proline Fieldcheck

Group SIMULATION

Function group CONFIGURATION

Function description

FUNCTION SIMULATION CONFIGURATION

OPERATION MODE

Use this function to select the operation mode for the simulation.