Академический Документы

Профессиональный Документы

Культура Документы

057

Загружено:

Dipti BhanjaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

057

Загружено:

Dipti BhanjaАвторское право:

Доступные форматы

-----------------------------------------------------------------------------------------------------4 18000 83 057----------------------Rev 00

(A)

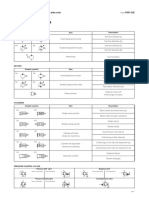

LUBE OIL TEMPERATURE CONTROL

[Scheme enclosed at sheet no.-5]

(Fig.-1)

INTRODUCTION :

The controller serves to maintain the temperature of lubricating oil supplied to each of

the TG bearings constantly at 45 C, irrespective of the load and the coolant

temperature. The controller is realized as a part of MAXDNA system.

DESCRIPTION:

A three-way valve MAV41 AA001 is installed in the bearing oil line, which enables a

part flow of oil to bypass the oil coolers and thus regulates the flow of oil through the

oil coolers. The flow of cooling water through oil coolers is kept constant. The cooling

water passing through the oil cooler in the counter-current mode absorbs the heat

from the hot oil in the cooler.

The oil temperature is measured after the three way-regulating valve by two

resistance thermometer (MAV42CT011, MAV42CT016).

Maximum of the twomeasured value is fed back to the controller. In case one measurement is faulty, it is

isolated and other one is used for control.

The controller operates the three-way

valve in such a way that the lube oil temperature to bearings always remains

constant.

Manual control of the valve is also possible from the operator workstation. A control

display is provided for controller ON / OFF and for manual operation of the valve.

The valve lift in percent and the control deviation is also indicated on the operator

station.

---------------------------------------------------------------------------------------------------SHEET NO. 02 OF 08------------------CIE, BHEL, HARDWAR

-----------------------------------------------------------------------------------------------------4 18000 83 057----------------------Rev 00

(B)

WARM-UP CONTROL

[Scheme enclosed at sheet no.-6]

(Fig.-2)

INTRODUCTION:

The warm-up controller has the task to ensure warming- up of the steam pipes and

the drain valves MAL11AA011 and MAL12AA011 after the emergency stop valves in

such a way that overstressing of the valve body is avoided. Temp margin from

sensor MAA10CT001 calculated by TSC is used for opening the drain valves as part of

warm-up controller.

The controller is realized as a part of MAX DNA system.

DESCRIPTION :

The upper temperature margin of Admission Area, as calculated within the TSC

(Turbine stress Controller) is fed to the warm-up controller. The output of this

controller controls both the two drain valves simultaneously.

The controller issues commands for opening / closing of the valves. The drain valve

MAL11AA011, after ESV1 (LHS) acts as the guiding valve. The feedback position

signals of both the drain valves are compared with each other and in case, any valve

has opened more than the other valve, it is blocked for opening and the other valve is

blocked for closing till the deviation is within certain limits. If any position transmitter

is detected to be faulty, the blocking signal is disabled.

Manual control of these valves is also possible from the operator workstation. Control

displays are provided for controller ON/OFF and for manual operation of the valves.

Manual commands override the blocking. Commands from SGC also override blocking.

The actual positions of both the valves and the control deviation are indicated on the

operator station.

---------------------------------------------------------------------------------------------------SHEET NO. 03 OF 08------------------CIE, BHEL, HARDWAR

-----------------------------------------------------------------------------------------------------4 18000 83 057----------------------Rev 00

(C)

CONTROL FLUID TEMP. CONTROL

[Scheme enclosed at sheet no.-7]

(Fig.-3)

INTRODUCTION:

The control loop serves to maintain a constant temperature (50C) of control fluid

required for the operation of the turbine, irrespective of the load and the coolant

temperature. The controller is realized as a part of MAX DNA based system.

DESCRIPTION:

The three-way valve MAX41AA041 is installed in the control fluid line, which enables a

part flow of fluid to bypass the fluid coolers and thus regulates the flow of control fluid

through the fluid coolers. The flow of cooling water through fluid coolers is kept

constant. The cooling water passing through the fluid cooler in the counter-current

mode absorbs the heat from the control fluid.

The control fluid temperature is measured after the three way-regulating valve by two

RTD (MAX41CT011A, MAX41CT006). Maximum of the two-measured value is fed back

to the controller. In case one measurement is faulty, it is isolated and other one is

used for control. The controller operates the three-way valve in such a way that the

control fluid temperature remains constant.

Manual control of the valve is possible from the operator workstation. A control

display is provided for controller ON/OFF and for manual operation of the valve.

The valve lift in percent and the control deviation is indicated on the operator station.

---------------------------------------------------------------------------------------------------SHEET NO. 04 OF 08------------------CIE, BHEL, HARDWAR

Вам также может понравиться

- APC EEC WorkshopДокумент35 страницAPC EEC WorkshopLalatendu PattanayakОценок пока нет

- Ci Fex300 Fex500 en eДокумент80 страницCi Fex300 Fex500 en eDipti BhanjaОценок пока нет

- Annexure To Income Tax CircularДокумент6 страницAnnexure To Income Tax CircularDipti BhanjaОценок пока нет

- GFK 1779MДокумент124 страницыGFK 1779MDipti BhanjaОценок пока нет

- ./administrator P@$sw0rd&Документ1 страница./administrator P@$sw0rd&Dipti BhanjaОценок пока нет

- Ci Fex300 Fex500 en eДокумент80 страницCi Fex300 Fex500 en eDipti BhanjaОценок пока нет

- Heat Rate PDFДокумент9 страницHeat Rate PDFDipti BhanjaОценок пока нет

- Turbine EfficiencyДокумент10 страницTurbine EfficiencyDipti BhanjaОценок пока нет

- Unity Pro Language PDFДокумент722 страницыUnity Pro Language PDFDipti BhanjaОценок пока нет

- TG Building Equipment Unit 4Документ3 страницыTG Building Equipment Unit 4Dipti BhanjaОценок пока нет

- Heat RateДокумент9 страницHeat RateDipti BhanjaОценок пока нет

- Quickstart Tutorial V70 PDFДокумент75 страницQuickstart Tutorial V70 PDFDipti BhanjaОценок пока нет

- Bee Code - CogenerationДокумент56 страницBee Code - Cogenerationszumny0% (1)

- Directional Change ValveДокумент93 страницыDirectional Change ValveDipti BhanjaОценок пока нет

- Aux Steam SystemДокумент14 страницAux Steam SystemDipti BhanjaОценок пока нет

- Servalve OperationДокумент4 страницыServalve OperationDipti BhanjaОценок пока нет

- Relief Valves PDFДокумент10 страницRelief Valves PDFDipti BhanjaОценок пока нет

- Pilot Operated Check ValveДокумент1 страницаPilot Operated Check ValveDipti BhanjaОценок пока нет

- Auxiliary Power Cosumption PDFДокумент44 страницыAuxiliary Power Cosumption PDFDipti BhanjaОценок пока нет

- Symbols PDFДокумент2 страницыSymbols PDFKuttappa I GОценок пока нет

- Mole Ratio AirДокумент1 страницаMole Ratio AirDipti BhanjaОценок пока нет

- APHДокумент17 страницAPHDipti BhanjaОценок пока нет

- TG Building Equipment Unit 4Документ3 страницыTG Building Equipment Unit 4Dipti BhanjaОценок пока нет

- Refrigeration and Air Conditioning StudДокумент16 страницRefrigeration and Air Conditioning StudDipti BhanjaОценок пока нет

- Paper-4 REG - Set A - 20.04.2017Документ17 страницPaper-4 REG - Set A - 20.04.2017Dipti BhanjaОценок пока нет

- HeatEnginesVol 1 Chapter 11 RS PDFДокумент48 страницHeatEnginesVol 1 Chapter 11 RS PDFDipti BhanjaОценок пока нет

- Paper-4 SUP - Set A20.04.2017Документ16 страницPaper-4 SUP - Set A20.04.2017Dipti BhanjaОценок пока нет

- SCAPHДокумент2 страницыSCAPHDipti BhanjaОценок пока нет

- Bee Code - CogenerationДокумент56 страницBee Code - Cogenerationszumny0% (1)

- Heat RateДокумент9 страницHeat RateDipti BhanjaОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Ny-Damecaax500 Brochure Juli-2019Документ8 страницNy-Damecaax500 Brochure Juli-2019Shavin FernandoОценок пока нет

- S Energy SN 72 Cell Series Solar Panel Datasheet V 01Документ2 страницыS Energy SN 72 Cell Series Solar Panel Datasheet V 01infercomОценок пока нет

- Motionless Electromagnetic GeneratorДокумент8 страницMotionless Electromagnetic Generatorraja100% (1)

- 02 WholeДокумент344 страницы02 WholeedithgclemonsОценок пока нет

- HANA OverviewДокумент69 страницHANA OverviewSelva KumarОценок пока нет

- PassivityДокумент15 страницPassivitySmarties AcademyОценок пока нет

- ST7201-Finite Element MethodДокумент14 страницST7201-Finite Element MethodVishal RanganathanОценок пока нет

- Dynamic Force AnalysisДокумент13 страницDynamic Force AnalysisJakesОценок пока нет

- Atmel 2565 Using The Twi Module As I2c Slave - Applicationnote - Avr311Документ14 страницAtmel 2565 Using The Twi Module As I2c Slave - Applicationnote - Avr311m3y54mОценок пока нет

- Chord Tone Improvisation Part IДокумент38 страницChord Tone Improvisation Part I2018 01097Оценок пока нет

- Tech Specs - TC 5540 PDFДокумент2 страницыTech Specs - TC 5540 PDFziaarkiplanОценок пока нет

- Pneumatic Conveying of Bulk Solids PDFДокумент231 страницаPneumatic Conveying of Bulk Solids PDFCarloLopez100% (2)

- Redox TitrationДокумент5 страницRedox TitrationchristinaОценок пока нет

- Famous MathematicianДокумент116 страницFamous MathematicianAngelyn MontibolaОценок пока нет

- Biomechanic of Foot PDFДокумент8 страницBiomechanic of Foot PDFMichealowen BabygoalОценок пока нет

- Ug CR RPTSTDДокумент1 014 страницUg CR RPTSTDViji BanuОценок пока нет

- Lecture 8cДокумент29 страницLecture 8cs_paraisoОценок пока нет

- Lab 3.1 - Configuring and Verifying Standard ACLsДокумент9 страницLab 3.1 - Configuring and Verifying Standard ACLsRas Abel BekeleОценок пока нет

- Slip Rings: SRI085 V100 - XX - XX - Xxx1XxДокумент3 страницыSlip Rings: SRI085 V100 - XX - XX - Xxx1XxMatheus Henrique MattiaОценок пока нет

- C191HM Powermeter and Harmonic Manager CommunicationsДокумент30 страницC191HM Powermeter and Harmonic Manager CommunicationsRoberto GarridoОценок пока нет

- Spare Parts List: Hydraulic BreakerДокумент28 страницSpare Parts List: Hydraulic BreakerTeknik MakinaОценок пока нет

- TMT Boron CoatingДокумент6 страницTMT Boron Coatingcvolkan1100% (2)

- Chapter One PDFДокумент74 страницыChapter One PDFAdelu BelleteОценок пока нет

- Activating The Standard BI ReportДокумент17 страницActivating The Standard BI ReportlearnsapbwОценок пока нет

- Exploring Music ContentsДокумент370 страницExploring Music ContentsRoby SamboraОценок пока нет

- Fisher Paykel SmartLoad Dryer DEGX1, DGGX1 Service ManualДокумент70 страницFisher Paykel SmartLoad Dryer DEGX1, DGGX1 Service Manualjandre61100% (2)

- Degree of ComparisonДокумент23 страницыDegree of Comparisonesalisa23Оценок пока нет

- Chapter 1 IntroductionДокумент49 страницChapter 1 IntroductionGemex4fshОценок пока нет

- KVS - Regional Office, JAIPUR - Session 2021-22Документ24 страницыKVS - Regional Office, JAIPUR - Session 2021-22ABDUL RAHMAN 11BОценок пока нет

- Tribology Module 01 NotesДокумент19 страницTribology Module 01 NotesVinayaka G P89% (9)