Академический Документы

Профессиональный Документы

Культура Документы

Design capacity checks for Busia water treatment works

Загружено:

n_zeinounОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design capacity checks for Busia water treatment works

Загружено:

n_zeinounАвторское право:

Доступные форматы

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

Feasibility Report - Busia

APPENDIX A.2.1

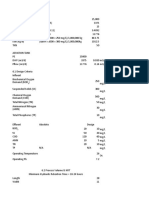

DESIGN CAPACITY CHECK FOR EXISTING FILTERS

The surface loading rate is the most important parameter in the design of filters. The

recommended surface loading rate for rapid sand filters is 4-6m 3/m2/hr. The adequacy of the

existing filters will be checked by checking the surface loading rate on the filters when the

treatment works is operating at full capacity. The existing filters will be deemed adequate if the

surface loading rate does not exceed 6m3/m2/hr when the treatment works operates at full

design capacity.

Existing Filters:

- Nr of filters provided, n

- Effective Sand Area of filters

nr

Length, L

Width, W

1.85

Design Calculations and Checks:

Surface Area of each filter, A (= L x W)

7.4

m2

Total Surface Area of filtration (= A x n)

22.2

m2

Treatment Works Design Capacity, Q

2700

m3/d

0.031

m3/s

2700

22.2

m3/d

m2

Surface Loading Rate on Filters when

Operating at Design Capacity (= Q / A)

Water Design

Manual (MWI)

Recommended Surface Loading Rate for Filters

121.62

m3/m2/d

5.1

m3/m2/hr

Thus the existing filters ARE NOT ADEQU for a design capacity of

m3/m2/hr

2700 m3/d

1 of 12

Feasibility Report - Busia

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

2 of 12

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

Feasibility Report - Busia

APPENDIX A.2.2

DESIGN CAPACITY CHECK FOR EXISTING FLOCCULATION CHAMBERS

The Phase II flocculation basin takes the flow for 1 sedimentation tank tank while the Phase I

flocculation basin takes the flow for 2nr sedimentation tanks. The 3nr sedimentation tanks are all of

similar size hence the total flow is proportioned equally between them

Phase I Floculation chambers

Nr of Flocculation Chamber =

Total Volume of water to be treated, Q =

2700

m3/d

112.5

m3/hr

75

m3/hr

0.0208

m3/s

Recommended inlet velocity in floculation chambers =

0.6000

m/s

Recommended outlet velocity in floculation chambers =

0.2000

m/s

Flow into Flocculation Chamber (=Q x 2/3)

Assuming average velocity in the chambers is =

0.4

m/s

Calculating headloss from equation for discharge through orifice

Q CD 2 gh

Where

Q = Discharge (m3/s)

CD = 0.6200

h = Headloss (m)

Chamber

Length

Breadth

Depth

Volume

1

2

1.1

1.1

1.1

1.1

3.15

3.13

3.812

3.787

1.1

1.1

3.11

3.767

Area of

Orifice

Required

0.052

0.052

0.052

Headloss

0.021

0.021

0.021

11.366

Detention Time =

Total Volume

Discharge into Chamber

545.55

Sec

9.09

min

Velocity Gradient in Flocculation Chamber

P

C

where

G = Velocity Gradient (s-1)

Q = Design flow in basin (m3/s)

h = Headloss (m)

= Density of Water (Kg/m3)

3 of 12

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

Feasibility Report - Busia

g = Graviational Constant

= Absolute viscosity of water

C = Volume of fluid in chamber (m3)

Chamber

1

G

23.73

Check

OK!

23.81

OK!

No Velocity Gradient Required

Recommended range of G is 20s-1 - 75s-1

Thus the flocculation chambers

are adequate

for design capacity of

1800 m3/d

Phase II Floculation chambers

Nr of Flocculation Chamber =

Total Volume of water to be treated, Q =

2700

m3/d

112.5

m3/hr

Flow into Flocculation Chamber (=Q x 1/3)

37.5

m3/hr

0.0104

m3/s

Recommended inlet velocity in floculation chambers =

0.6000

m/s

Recommended outlet velocity in floculation chambers =

0.2000

m/s

Assuming average velocity in the chambers is =

0.4

m/s

Calculating headloss from equation for discharge through orifice

Q CD 2 gh

Where

Q = Discharge (m3/s)

CD = 0.6200

h = Headloss (m)

Chamber

Length

Breadth

Depth

Volume

0.925

0.925

3.19

2.729

Area of

Orifice

Required

0.026

0.925

0.925

3.17

2.711

0.026

0.021

3

4

0.925

0.925

0.925

0.925

3.16

3.15

2.702

2.697

0.026

0.021

Headloss

0.021

10.840

Detention Time =

Total Volume

Discharge into Chamber

1040.63

Sec

17.34

min

Velocity Gradient in Flocculation Chamber

P

C

where

P Q. .h.g

G = Velocity Gradient (s-1)

4 of 12

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

Feasibility Report - Busia

Q = Design flow in basin (m3/s)

h = Headloss (m)

= Density of Water (Kg/m3)

g = Graviational Constant

= Absolute viscosity of water

C = Volume of fluid in chamber (m3)

5 of 12

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

Feasibility Report - Busia

Chamber

Check

28.05

OK!

2

3

28.14

28.19

OK!

OK!

No Velocity Gradient Required

Recommended range of G is 20s-1 - 75s-1

Thus the flocculation chambers are adequate for design capacity of

900 m3/d

6 of 12

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

Feasibility Report - Busia

APPENDIX A.2.3

DESIGN CAPACITY CHECK FOR EXISTING SEDIMENTATION TANKS

The surface overflow rate is the most important design parameter for horizontal flow sedimentation

tanks. The recommended surface overflow rate for horizontal flow sedimentation tanks is 1.0m 3/m2/hr.

The adequacy of the existing sedimentation tanks will be checked by determining the surface overflow

rate on the sedimentation tanks when the treatment works is operating at full capacity. The existing

sedimentation tanks will be deemed adequate if the surface overflow rate does not exceed 1.0m 3/m2/hr

when the treatment works operates at full design capacity.

Existing Sedimentation Tanks:

- Nr of sedimentation tanks provided, n

nr

- Dimensions of sedimentation tanks

Length, L

Width, W

9.5

4

m

m

Surface Area of each sedimentation tank, A (= L x W)

38

m2

Total Surface Area of sedimentation tanks (= A x n)

114.0

m2

Treatment Works Design Capacity, Q

2700

m3/d

0.031

m3/s

2700

114.0

m3/d

m2

23.68

m3/m2/d

0.99

m3/m2/hr

1.0

m3/m2/hr

Design Calculations and Checks:

Surface Overflow Rate on Sedimentation Tanks when

Operating at Design Capacity (= Q / A)

Water Design

Manual (MWI)

Recommended Surface Loading Rate for Horizontal Flow

Sedimentation Tanks

Thus the existing sedimentation tanks ARE ADEQUATE

for a design capacity of

2700 m3/d

7 of 12

Feasibility Report - Busia

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

8 of 12

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

Feasibility Report - Busia

APPENDIX A.2.4

DESIGN CAPACITY CHECK FOR EXISTING CLEAR WATER TANK

The clear water reservoir is used to provide the necessary chlorine contact time for treated water prior to

distribution of treated water to consumers. It is recommended that a minimum of 30 minutes chlorine contact

time should be provided for treated water.

Existing Clear Water Reservoir:

- Nr of clear water reservoirs provided, n

nr

- Capacity of clear water reservoirs

175

m3

- Total Storage Capacty provided for clear water,

175

m3

2700

m3/d

1.875

m3/min

175

1.875

m3

m3/min

93.33

minutes

30

minutes

Design Calculations and Checks:

Treatment Works Design Capacity, Q

Chlorine contact time provided by existing clear

water reservoir (= C / Q)

Water Design

Manual (MWI)

Recommended minimum chlorine contact time

Thus the existing clear water reservoir

IS ADEQUATE

for a treatment works design capacity of 2700 m3/d

9 of 12

Feasibility Report - Busia

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

10 of 12

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

Feasibility Report - Busia

APPENDIX A.2.5

DESIGN CAPACITY CHECK FOR EXISTING BACKWASH TANK

The backwash tank should have a capacity equal to the volume of water required to backwash at least one filter at a time.

The backwash rate for a filter is dependent on the filter media characteristics, mainly the effective size of the filter medium

grain. It is recommended that a filter be backwashed at the appropriate rate for a duration of at least 10 minutes.

Existing Backwash Tank:

- Nr of backwash tanks provided, n

nr

- Capacity of existing backwash tanks

50

m3

- Total existing storage capacty for backwash water, C

50

m3

Length, L

Width, W

1.85

7.4

m2

0.5

mm

25

m3/m2/hr

minutes

Design Calculations and Checks:

Existing filters: 3nr, each of dimension

Area of one filter, A ( =L x W )

Efffective sand size in filter

Water Design

Manual (MWI)

Recommended back wash rate for a filter with effective

sand size 0.5mm, R

Recommended backwash time, T

10

Backwash Water Volume required for one filter

(=RxAxT)

30.83

m3

Capacity of backwash tank provided

50

m3

Thus the existing backwash tank IS ADEQUATE

to backwash one filter at a time

11 of 12

Feasibility Report - Busia

Nzoia Cluster Feasibility Study

Phase II Towns Kakamega, Busia and Nambale

12 of 12

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- 2012-08 SEAOC Solar PV Wind Document Final PDFДокумент38 страниц2012-08 SEAOC Solar PV Wind Document Final PDFfdfdfddОценок пока нет

- Thrust Block Calculation PDFДокумент2 страницыThrust Block Calculation PDFRaju ShresthaОценок пока нет

- ABB Electromagnetic FlowmetersДокумент48 страницABB Electromagnetic Flowmetersn_zeinounОценок пока нет

- WAFLER 2010 Anaerobic Baffled Reactor - 0Документ20 страницWAFLER 2010 Anaerobic Baffled Reactor - 0Muzdalifah Nur JОценок пока нет

- Thrust Block Sizing 13feb14Документ1 страницаThrust Block Sizing 13feb14n_zeinounОценок пока нет

- Airrex Diesel HeaterДокумент4 страницыAirrex Diesel Heatern_zeinounОценок пока нет

- ORF1Документ25 страницORF1Mokez JittasopawadeeОценок пока нет

- Thrust Block SizingДокумент1 страницаThrust Block Sizingn_zeinounОценок пока нет

- Thrust Block Sizing 13feb14Документ1 страницаThrust Block Sizing 13feb14n_zeinounОценок пока нет

- BORDA Dewats HandbookДокумент161 страницаBORDA Dewats HandbookJizzlmanizzlОценок пока нет

- AnoxKaldnesBrochure2016Документ6 страницAnoxKaldnesBrochure2016n_zeinounОценок пока нет

- Selection and Sizing of Air Release Valves PDFДокумент22 страницыSelection and Sizing of Air Release Valves PDFMilenko TulencicОценок пока нет

- Bilogical Treatment of Dairy Industry Wastewater and Its Comparison With Other Techniques-Libre PDFДокумент14 страницBilogical Treatment of Dairy Industry Wastewater and Its Comparison With Other Techniques-Libre PDFwiicho91Оценок пока нет

- Deterministic shallow foundation design using SPT dataДокумент4 страницыDeterministic shallow foundation design using SPT dataZahira HeloОценок пока нет

- SBR Design CalculationsДокумент26 страницSBR Design Calculationsn_zeinoun78% (9)

- Activated Sludge ModelДокумент30 страницActivated Sludge Modelvikas2504Оценок пока нет

- Napoleon B36 Ascent 36 Direct Vent Gas Fireplace Manual PDFДокумент144 страницыNapoleon B36 Ascent 36 Direct Vent Gas Fireplace Manual PDFn_zeinounОценок пока нет

- SBR Design CalculationsДокумент9 страницSBR Design Calculationsn_zeinounОценок пока нет

- 02 - Biological WWTP II - Moving Bed Biofilm ReactorДокумент45 страниц02 - Biological WWTP II - Moving Bed Biofilm ReactorAquasoul CoОценок пока нет

- 00 HVAC CalcДокумент52 страницы00 HVAC Calcibson045001256Оценок пока нет

- MC608 Manual PDFДокумент68 страницMC608 Manual PDFn_zeinounОценок пока нет

- WAFLER 2010 Anaerobic Baffled Reactor - 0Документ20 страницWAFLER 2010 Anaerobic Baffled Reactor - 0Muzdalifah Nur JОценок пока нет

- IBC Seismic For Abu DhabiДокумент9 страницIBC Seismic For Abu Dhabin_zeinounОценок пока нет

- MC608 ManualДокумент12 страницMC608 Manualn_zeinounОценок пока нет

- SENSOR MUT2200EL - Electromagnetic flowmeter for all applicationsДокумент12 страницSENSOR MUT2200EL - Electromagnetic flowmeter for all applicationsn_zeinoun100% (1)

- Specifications WWTP Parshall FlumeДокумент572 страницыSpecifications WWTP Parshall Flumen_zeinounОценок пока нет

- MC608 ManualДокумент12 страницMC608 Manualn_zeinounОценок пока нет

- 00 HVAC CalcДокумент52 страницы00 HVAC Calcibson045001256Оценок пока нет

- Activated Sludge ModelДокумент30 страницActivated Sludge Modelvikas2504Оценок пока нет

- 02 - Biological WWTP II - Moving Bed Biofilm ReactorДокумент45 страниц02 - Biological WWTP II - Moving Bed Biofilm ReactorAquasoul CoОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- LV 2000LowVolumeДокумент2 страницыLV 2000LowVolumeDian MiauОценок пока нет

- Photography March 2016Документ32 страницыPhotography March 2016ArtdataОценок пока нет

- Performance of HT & LT Catalyst: Amit Kumar Jha MT (Chemical) # 0247/7161Документ25 страницPerformance of HT & LT Catalyst: Amit Kumar Jha MT (Chemical) # 0247/7161sb1984_hithaldiaОценок пока нет

- Ion Exchange ChromatographyДокумент3 страницыIon Exchange ChromatographysherfudeenОценок пока нет

- Manual Fundamental Hydraulic SystmsДокумент131 страницаManual Fundamental Hydraulic Systmssawmag123100% (3)

- Machining Processes SyllabusДокумент2 страницыMachining Processes SyllabusshailkhanОценок пока нет

- Orientation of Students to Science TopicsДокумент115 страницOrientation of Students to Science TopicsShaynie Mhe Amar AntonioОценок пока нет

- 2A The Structure of The Atom-AnswerДокумент6 страниц2A The Structure of The Atom-AnswerSiti Nursahidah0% (1)

- Lightning Protection System Analysis of High Voltage 70 KV Transmission Line in Area With High Lightning Density, Study Case Sutt 70 KV MalangДокумент8 страницLightning Protection System Analysis of High Voltage 70 KV Transmission Line in Area With High Lightning Density, Study Case Sutt 70 KV MalangGdeKomangFmoОценок пока нет

- Determine COP of a Heat Pump/Refrigeration MachineДокумент2 страницыDetermine COP of a Heat Pump/Refrigeration MachineJeremy Tay0% (2)

- Lap Reoprt 1Документ9 страницLap Reoprt 1api-350815927Оценок пока нет

- Simple Lifting Machines MyДокумент14 страницSimple Lifting Machines MyAkash SinghОценок пока нет

- Plate Tectonic UnitДокумент95 страницPlate Tectonic Unitapi-227272561Оценок пока нет

- GE6251 Basic Civil and Mechanical Engineering Regulation 2013 Lecture NotesДокумент112 страницGE6251 Basic Civil and Mechanical Engineering Regulation 2013 Lecture NotesSasi Dharan100% (1)

- 1711710238363Документ93 страницы1711710238363srashmiiiscОценок пока нет

- Surveying Lecture 1Документ39 страницSurveying Lecture 1Ruel Torres50% (4)

- Research Paper in MicrowavesДокумент10 страницResearch Paper in MicrowavesManoling PanopioОценок пока нет

- CLMD4A Science8Документ39 страницCLMD4A Science8GreyОценок пока нет

- Refractory Degradation in Glass Tank Melters. A Survey of Testing MethodsДокумент5 страницRefractory Degradation in Glass Tank Melters. A Survey of Testing MethodsRizqi Ahmad FauzanОценок пока нет

- Sual Power Station: Philippines' Largest Coal-Fired PlantДокумент7 страницSual Power Station: Philippines' Largest Coal-Fired PlantscaffmasterОценок пока нет

- Sandwich Panel Anchors - Precast ConcreteДокумент40 страницSandwich Panel Anchors - Precast ConcreteCorbean AlexandruОценок пока нет

- Test 1Документ12 страницTest 1Harminder SanghaОценок пока нет

- Bulk and Suspenshion Polynerization of MMA Into PMMAДокумент5 страницBulk and Suspenshion Polynerization of MMA Into PMMADavid Meza CarbajalОценок пока нет

- An Inexpensive BRDF Model For Physically-Based RenderingДокумент14 страницAn Inexpensive BRDF Model For Physically-Based RenderingKmilo VinaTea ChavezОценок пока нет

- Military RadarДокумент20 страницMilitary Radarrakesh100% (2)

- Gases Tutorial 2Документ4 страницыGases Tutorial 2Idil WarsameОценок пока нет

- L&T Project ReportДокумент48 страницL&T Project Reportdeepakarora201188Оценок пока нет

- Lesson Plan For Demo Class RumanaДокумент2 страницыLesson Plan For Demo Class RumanaRumana PathanОценок пока нет

- Bernoulli's PrincipleДокумент15 страницBernoulli's PrincipleDedy KristiantoОценок пока нет

- Important Link For Class XII - 1Документ3 страницыImportant Link For Class XII - 1Utsaw SagarОценок пока нет