Академический Документы

Профессиональный Документы

Культура Документы

RC Slab Design-1-Way Coefficient Example

Загружено:

Mike0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров9 страницОригинальное название

RC slab design-1-way coefficient example.docx

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров9 страницRC Slab Design-1-Way Coefficient Example

Загружено:

MikeАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 9

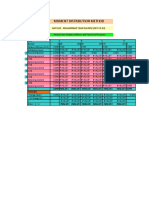

RC slab designIn accordance with EN1992-1-1:2004 incorporating corrigendum

January 2008 and the UK national annexTedds calculation version 1.0.11Library

item: Calc title Library item - Show active sketchSlab definition;Overall slab

depth;

h = 150 mmNumber of spans; Nspans =

3First support;

SimpleLast support;

cover to top reinforcement;

cnom_t = 20 mmNominal cover to bottom

reinforcement;

cnom_b = 20 mmLoadingCharacteristic

permanent action;

Gk = 5.0 kN/m2Characteristic variable

action;

Qk = 5.0 kN/m2Partial factor for

permanent action;

G = 1.35Partial factor for variable action;

Q = 1.50Quasi-permanent value of variable action;

SimpleNominal

2 = 0.30Design

ultimate load;

q = G Gk + Q Qk = 14.3

kN/m2Quasi-permanent load;

qSLS = 1.0 Gk + 2 Qk = 6.5

kN/m2Library item - Slab definition 1 wayConcrete propertiesConcrete strength

class;

C25/30Characteristic cylinder strength;

fck = 25 N/mm2Partial factor (Table 2.1N);

C =

1.50Compressive strength factor (cl. 3.1.6);

cc =

0.85Design compressive strength (cl. 3.1.6);

fcd = 14.2

N/mm2Mean axial tensile strength (Table 3.1);

fctm = 0.30

N/mm2 (fck / 1 N/mm2)2/3 = 2.6 N/mm2Maximum aggregate size;

20 mmReinforcement propertiesCharacteristic yield strength;

N/mm2Partial factor (Table 2.1N);

dg =

fyk = 500

S = 1.15Design yield strength (fig. 3.8);

fyd = fyk / S = 434.8 N/mm2Library item - Material propertiesConcrete cover

to reinforcementNominal cover to top reinforcement;

cnom_t = 20

mmNominal cover to bottom reinforcement;

cnom_b = 20

mmFire resistance period to top of slab;

Rtop = 60

minFire resistance period to bottom of slab;

Rbtm = 60

minAxis distance to top reinft (Table 5.8);

afi_t = 20

mmAxis distance to bottom reinft (Table 5.8);

afi_b = 20

mmMax bar diameter in top;

max_t = 10 mmMax bar diameter in

bottom;

max_b = 10 mmMin. top cover

requirement with regard to bond;

cmin,b_t = max_t = ;10; mmMin. btm

cover requirement with regard to bond;

cmin,b_b =

max_b = ;10; mmReinforcement fabrication;

Not subject to QA

systemCover allowance for deviation; cdev = 10 mmMin. required nominal

cover to top reinft;

cnom_t_min = max(afi_t - max_t / 2,

cmin,b_t + cdev) = 20.0 mmMin. required nominal cover to bottom reinft;

cnom_b_min = max(afi_b - max_b / 2, cmin,b_b + cdev) = 20.0 mmPASS -

There is sufficient cover to the top reinforcementPASS - There is sufficient cover

to the bottom reinforcementLibrary item - Cover 1 way T BBending design

checks = 1.0Redistribution ratio;

= 1.0Limiting value of K;

K = 0.598

- 0.18 2 - 0.21 = 0.208Reinforcement design at midspan of span 1

(cl.6.1)Length of span 1;

l1 = 3600 mmBending moment coefficient;

fmp1 = 0.0860Design bending moment;

Mp1 = fmp1 q

l12 = 15.9 kNm/mReinforcement provided;

10 mm dia. bars

at 250 mm centres;Area provided;

Asp1 = 314 mm2/mEffective depth to

tension reinforcement;

dp1 = h - cnom_b - p1 / 2 = 125.0 mmK

factor;

K = Mp1 / (b dp12 fck) = 0.041K < K'

- Compression reinforcement is not requiredLibrary item - K span 1Lever arm;

z = min(0.95 dp1, dp1 / 2 (1 + (1 - 3.53 K))) = 118.7 mmArea of

reinforcement required for bending;

Asp1_m = Mp1 / (fyd z) = 308

mm2/mMinimum area required;

Asp1_min = max(0.26 (fctm/fyk),

0.0013) b dp1 = 167 mm2/mArea of reinforcement required;

Asp1_req =

max(Asp1_m, Asp1_min) = 308 mm2/mAscp1_req = 0 mm2/mPASS - Area of

tension reinforcement provided is adequate (0.979)Library item - As no comp

reinf span 1Check reinforcement spacings = if(_rcs.Method1==Directly,

(fyk / S) min((Asp1_m/Asp1), 1.0) getvar(rq,1.0),(fyk / S)

min((Asp1_m/Asp1), 1.0) getvar(qSLS,1 kN/m2) / getvar(q,1 kN/m2)) =

194.2 N/mm2Reinforcement service stress;

s = (fyk / S)

min((Asp1_m/Asp1), 1.0) qSLS / q = ;194.2; N/mm2smax_p1 = if( s<=160

N/mm2, 300 mm, if(s<=200 N/mm2, 300 mm - 50 mm (s - 160 N/mm2) /

40 N/mm2, if(s<=240 N/mm2, 250 mm - 50 mm (s - 200 N/mm2) / 40

N/mm2, if(s<=280 N/mm2, 200 mm - 50 mm (s - 240 N/mm2) / 40

N/mm2, if(s<=320 N/mm2, 150 mm - 50 mm (s - 280 N/mm2) / 40

N/mm2, 100 mm - 50 mm (s - 320 N/mm2) / 40 N/mm2))))) = 257.3

mmMaximum allowable spacing (Table 7.3N);

mmActual bar spacing;

smax_p1 = 257

sp1 = 250 mmPASS - The reinforcement

spacing is acceptableLibrary item - Spacing span 1Reinforcement design at

midspan of span 2 (cl.6.1)Length of span 2;

mmBending moment coefficient;

l2 = 3600

fmp2 = 0.0630Design bending moment;

Mp2 = fmp2 q l22 = 11.6 kNm/mReinforcement provided; 8 mm dia. bars at

200 mm centres;Area provided;

Asp2 = 251 mm2/mEffective depth to

tension reinforcement;

dp2 = h - cnom_b - p2 / 2 = 126.0 mmK

factor;

K = Mp2 / (b dp22 fck) = 0.029K < K'

- Compression reinforcement is not requiredLibrary item - K span 2Lever arm;

z = min(0.95 dp2, dp2 / 2 (1 + (1 - 3.53 K))) = 119.7 mmArea of

reinforcement required for bending;

Asp2_m = Mp2 / (fyd z) = 224

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Crjgr2 Section 2Документ2 страницыCrjgr2 Section 2MikeОценок пока нет

- XXXXX BHДокумент2 страницыXXXXX BHMikeОценок пока нет

- Crjgr4 Section 4Документ2 страницыCrjgr4 Section 4MikeОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 2 Way Slab OkДокумент4 страницы2 Way Slab OkMikeОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Crjgr3 Section 3Документ2 страницыCrjgr3 Section 3MikeОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- AGS SI Input Excel Sheet Version 2.0Документ6 411 страницAGS SI Input Excel Sheet Version 2.0MikeОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- SIP Assessment Visit For Civil Engineering May 2017 Semester Total Students: 3Документ3 страницыSIP Assessment Visit For Civil Engineering May 2017 Semester Total Students: 3MikeОценок пока нет

- Table 1 2Документ2 страницыTable 1 2MikeОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Crjgr1 Section 1Документ2 страницыCrjgr1 Section 1MikeОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Company List For Sept 2017Документ193 страницыCompany List For Sept 2017MikeОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Evaluation Booklet SIT IDB3037 HC SV Ver2Документ10 страницEvaluation Booklet SIT IDB3037 HC SV Ver2Mike100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Purpose of RC Shear ReinforcementДокумент4 страницыPurpose of RC Shear ReinforcementMikeОценок пока нет

- Structural Steel JIS G 3466Документ1 страницаStructural Steel JIS G 3466MikeОценок пока нет

- Company List For Sept 2017Документ193 страницыCompany List For Sept 2017MikeОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- BRC CertДокумент1 страницаBRC CertMikeОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- STAAD - Foundation User's ManualДокумент490 страницSTAAD - Foundation User's ManualKang'ethe Geoffrey100% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Chinas High-Speed Rail Diplomacy Riding PDFДокумент20 страницChinas High-Speed Rail Diplomacy Riding PDFMikeОценок пока нет

- Rules of Thumb For Steel StructuresДокумент5 страницRules of Thumb For Steel StructuresLincs lincoln100% (1)

- BucklingДокумент16 страницBucklingMikeОценок пока нет

- Family Day ItineraryДокумент1 страницаFamily Day ItineraryMikeОценок пока нет

- Beam FormulaДокумент29 страницBeam FormulaMikeОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- BMP 2017Документ11 страницBMP 2017MikeОценок пока нет

- S 239 Content Beam DesignДокумент53 страницыS 239 Content Beam DesignkapilОценок пока нет

- ME482/582 Optimal DesignДокумент2 страницыME482/582 Optimal DesignMikeОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- C&S Isssuance TypeДокумент1 страницаC&S Isssuance TypeMikeОценок пока нет

- Designers' Guide To Eurocode 2: Design of Concrete StructuresДокумент242 страницыDesigners' Guide To Eurocode 2: Design of Concrete StructuresEmina LjubijankicОценок пока нет

- Moment Distribution Spread SheetДокумент1 страницаMoment Distribution Spread SheetSajid Nazir86% (7)

- Hot Work Tool Steel: Z Similar SteelsДокумент2 страницыHot Work Tool Steel: Z Similar SteelsMikeОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Analysis and Design of Flat Slab by Using Etabs Software: 1.1 GeneralДокумент8 страницAnalysis and Design of Flat Slab by Using Etabs Software: 1.1 GeneralMikeОценок пока нет

- MS 1525 2007 Prev PDFДокумент7 страницMS 1525 2007 Prev PDFguy69oiОценок пока нет

- Catabolism of Proteins and Amino AcidsДокумент63 страницыCatabolism of Proteins and Amino Acidsflairtique shopОценок пока нет

- ww16 Sludge 2 WB PDFДокумент114 страницww16 Sludge 2 WB PDFmohamedbadawyОценок пока нет

- Understanding Valves and Their Role in Mechanical IntegrityДокумент13 страницUnderstanding Valves and Their Role in Mechanical Integritydhanu_lagwankarОценок пока нет

- Cell Disruption Techquines: By: Ritika SharmaДокумент20 страницCell Disruption Techquines: By: Ritika SharmaArup ChakrabortyОценок пока нет

- ISO 5817-1992 Arc-Welded Joints in Steel - Guidance On QualiДокумент17 страницISO 5817-1992 Arc-Welded Joints in Steel - Guidance On QualiThaiminh VoОценок пока нет

- 113 12 Phe BrochureДокумент4 страницы113 12 Phe BrochureolivaresjhonОценок пока нет

- Bomba Jockey GrundfosДокумент49 страницBomba Jockey GrundfosharlyganОценок пока нет

- Quantitative JДокумент4 страницыQuantitative Jryan caballerobatuangОценок пока нет

- LS 100 BrochureДокумент2 страницыLS 100 BrochureLun DingОценок пока нет

- CMK 13 PDFДокумент228 страницCMK 13 PDFSonja DragovicОценок пока нет

- Kalina Cycle - Wikipedia, The Free EncyclopediaДокумент3 страницыKalina Cycle - Wikipedia, The Free Encyclopediawilliam4132Оценок пока нет

- Mat Foundation PhilippinesДокумент7 страницMat Foundation PhilippinesAly Arquillano JrОценок пока нет

- Basic Mechanical Engineering Books For ReferanceДокумент3 страницыBasic Mechanical Engineering Books For ReferanceAbhimechОценок пока нет

- 12th Chemistry Cbse Board Paper 2008 To 12 (Solved)Документ285 страниц12th Chemistry Cbse Board Paper 2008 To 12 (Solved)jaisabhi01570% (27)

- Worksheet14 HybridДокумент5 страницWorksheet14 HybridRAGINI AGARWALОценок пока нет

- Answers Bahan Pelajar Bintang Carbon Compound: Quiz 1 1 (A)Документ5 страницAnswers Bahan Pelajar Bintang Carbon Compound: Quiz 1 1 (A)airinОценок пока нет

- 2.presentazione Funaro IMA-BASF SpainДокумент62 страницы2.presentazione Funaro IMA-BASF SpainPaqui Miranda GualdaОценок пока нет

- Chapter 7Документ36 страницChapter 7ajayОценок пока нет

- HCL PDFДокумент13 страницHCL PDFjoycepeterОценок пока нет

- Is SP 23 1982 PDFДокумент151 страницаIs SP 23 1982 PDFMano MaddulaОценок пока нет

- Building and Environment: A. Franco, R. Fernández-Cañero, L. Pérez-Urrestarazu, D.L. ValeraДокумент9 страницBuilding and Environment: A. Franco, R. Fernández-Cañero, L. Pérez-Urrestarazu, D.L. Valerafrank_luna_43Оценок пока нет

- Ee65 - Design of Electrical Machines (2 Marks Questions and Answers) - Unit - IДокумент18 страницEe65 - Design of Electrical Machines (2 Marks Questions and Answers) - Unit - Iashok kumarОценок пока нет

- Shield Water Heater LiteratureДокумент4 страницыShield Water Heater LiteratureJohn MoreОценок пока нет

- Theory of The Stability of Lyophobic ColloidsДокумент6 страницTheory of The Stability of Lyophobic Colloidsivan celyОценок пока нет

- GIR Courses For First Year-1 2019-2020 NIT TrichyДокумент23 страницыGIR Courses For First Year-1 2019-2020 NIT TrichyGirish ThiyagarajanОценок пока нет

- Aga TableДокумент35 страницAga TableilublessingОценок пока нет

- Project On Refractive Index of Different LiquidsДокумент5 страницProject On Refractive Index of Different LiquidsPRABHU JENAОценок пока нет

- Vivek Vinayakumar: Work Experience SkillsДокумент1 страницаVivek Vinayakumar: Work Experience SkillsVivek VinayakumarОценок пока нет

- Literature Review On Pervious Concrete Literature Review On Pervious ConcreteДокумент23 страницыLiterature Review On Pervious Concrete Literature Review On Pervious ConcreteVivek KumarОценок пока нет

- Corbel Pier 1Документ3 страницыCorbel Pier 1Phani PitchikaОценок пока нет