Академический Документы

Профессиональный Документы

Культура Документы

United States Patent Tº: º ( (J /H+. A o

Загружено:

KrozeОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

United States Patent Tº: º ( (J /H+. A o

Загружено:

KrozeАвторское право:

Доступные форматы

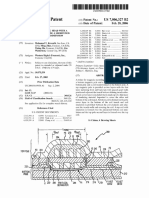

United States Patent t

[11] Patent Number:

[45] Date of Patent:

Dyhr

[54] CHOKE VALVE ESPECIALLY USED IN OIL

AND GAS WELLS

DK-2840 Holte, Denmark

[21] Appl. No.: 841,564

[22] Filed:

Mar. 20, 1986

[30]

Foreign Application Priority Data

Apr. 11, 1985 [DK] Denmark ............................. 1628/85

[51] Int. Cl* ............................................ F16K 31/122

[52] U.S. Cl. ........................................... 251/5; 251/4;

251/63.4

[58] Field of Search ................. 251/1.1, 4, 5, 62, 63.4;

137/68.1; 92/89; 175/48

[56]

References Cited

U.S. PATENT DOCUMENTS

2,124,015 7/1938 Stone et al. .......................... 251/1.1

3,599,713 8/1971 Jenkins ............................... 137/68.1

3,646,607 2/1972 Dower .................................... 251/5

3,821,726 6/1974 Chang et al. .......................... 175/48

3,868,826 3/1975 Landers ...

251/1.1

4,085,765 4/1978 Nelson .....

... 137/68.1

4,300,748 11/1981 Kreeley ................................... 251/5

4,310,058 1/1982 Bourgoyne, Jr. ..................... 175/48

4,378,849 4/1983 Wilks ....................

..., 251/1.1

4,508,311 4/1985 Just et al. ............................. 251/1.2

ABSTRACT

A choke valve specially used for regulating the flow

volume and with it the back pressure of liquids or gas

while drilling through shallow gas bearing formations

from an off-shore drilling platform. The valve com

prises a flexible cylindrical valve element (8) positioned

in the valve housing (1) flow passage and where the

valve is so designed that the valve elements (8) flow

area can be reduced by a radial reduction of the valve

element. The flow area of the valve element (8) is equal

to or larger than the remaining flow area of the valve.

The valve has devices (10;22) for constricting the end of

the valve element (8) being nearest to the outlet opening

(3) of the valve. The valve element (8) is so long that it

is possible to compensate for the wear to which the end

is exposed by sliding the valve element against the con

stricting devices (10;22) or by moving the latter along

the valve element as the wear proceeds. Only the valve

element (8) is exposed to wear and no other parts of the

valve being positioned within the wearing zone. The

valve element (8) in its withdrawn position has its total

diameter free allowing a full flow through the valve.

Accordingly the valve do not disturb the flow under

normal condition and is not exposed to any wear. At a

gas kick the well can be controlled during a long period

as it is possible to compensate the wear on the valve

element during operation.

Primary ExaminerA. Michael Chambers

10 Claims, 16 Drawing Figures

Assistant ExaminerJohn C. Fox

*zil. TIT %

{{j

/H+. HA

*s--

KL

#N.

Dec. 1, 1987

Attorney, Agent, or FirmThomas R. Morrison

[57]

[76] Inventor: Einar Dyhr, Skodsborgvej 160,

4,709,900

U.S. Patent Dec. 1, 1987

Sheet 1 of 12

|-- =|

TH ||

|-|| |

Y.

4,709,900

Fig. A

U.S. Patent Dec. 1, 1987

Sheet 2 of 12

Fig. 2

4,709,900

U.S. Patent Dec. 1, 1987

Sheet 3 of 12

2 t -

#

i;

4,709,900

Fig. 6

U.S. Patent Dec. 1 1987

4,709,900

|-2

U.S. Patent Dec. 1, 1987

Sheets of 12

4,709,900

V

IX T

W aft

X

3/

3|||XI.

X

X

X

X

ZN

22

B. T.

32 W.

X

X

X

X

X

NZ--?

25

27

27

26

Fig. 8

26

U.S. Patent

4,709,900

Sheet 6 of 12

Dec. 1, 1987

6,7CIAVS

* <--

/ *

|

|

/

Lil

Li-CD

$2/

O

,

-,o oz

U.S. Patent Dec. 1, 1987

Sheet 7 of 12

4,709,900

U.S. Patent

Dec. 1, 1987

Sheet 8 of 12

C

4,709,900

S.

S)

Ll

CU

cr)

H's 3 &

T

E=

| |CD||

Hri?

U.S. Patent

Dec. 1, 1987

614

?r

Sheet 9 of 12

4,709,900

U.S. Patent

De 1, 1987

Sheet 10 of 12

s

s

i;

8,

4,709,900

U.S. Patent Dec. 1, 1987

.

Sheet 11 of 12

Fig 14

4,709,900

U.S. Patent Dec. 1, 1987

Sheet 12 of 12

4,709,900

4,709,900

CHOKE WALVE ESPECIALLY USED IN OIL AND

GAS WELLS

The invention concerns a choke valve especially used

in regulating back pressure in oil and gas wells while

drilling through shallow gas bearing formations from an

off-shore drilling platform and constituting a flexible

cylindrical valve element positioned in the valve hous

ing flow passage and where the valve is so designed that

the valve element flow through area can be reduced by

a radial reduction of the valve element. In addition the

10

2

escape of the gas along the outside of the casing to the

surface.

If this happens the rig is in danger.

In the case of a jack-up which is supported by the sea

bed the outflowing gas can erode the sea bed enough to

cause the rig to turn over.

For floating platforms there is danger of capsizing

when the gas aerates the water around the rig.

There have been many such accidents in the drilling

industry and it is an established procedure not to close

the BOP valves during this phase of the drilling. The

standard rule for off-shore drilling is to close the diver

tor valve and divert the gas over board. But even with

this procedure the shallow gas kick still causes disasters.

One of the most common reasons for shallow gas

blow-out is drilling with too small a trip margin. It takes

only very little swabing effect to cause the gas to enter

the well bore. On the other hand drilling with too large

a margin will easily cause a surge pressure to lose dril

ling mud to the formation with subsequent loss of hy

drostatic pressure.

The shallow gas will then move to the surface in a

few seconds taking the drilling crew by surprise. When

the first gas bubble has surfaced part of the mud column

is displaced with the resulting loss of hydrostatic pres

sure. Unless a balancing hydrostatic pressure is estab

lished by replacing the lost mud or by increasing the

mud weight or by applying backpressure on the well

invention concerns a procedure to control a so called

shallow gas kick.

Drilling off-shore is done from platforms. As plat 15

forms can be used the so called jack-up rig which is a

platform supported by legs standing on the sea bed, or

the so called semi-submersibles which is a floating plat

form or a drill ship which is a conventional ship rigged 20

with drilling equipment.

Briefly described an off-shore well is made by drilling

a section of the hole, then lining the section with casing,

then drilling a smaller hole which then is lined with

casing etc. The casing is cemented in the formation. 25

During the drilling, mud is circulated through the drill

pipe up through the angles with the purpose of remov

ing the cuttings as well as imposing a hydrostatic pres

sure equal to that which exists in the geological forma head the well will flow out of control.

tion outside.

30 After having taken a kick it is a normal procedure to

This is all a well known procedure and if a so called close

divertor and start both mud pumps pumping

gas or oil influx is taken from hydro cup and deposits into thethehole.

increasing the hydrostatic head the gas

due to an unbalance in the hydrostatic head then the rig flow into the By

well

bore will hopefully stop.

personal have certain well established procedures and

But

what

happens

if the well in unloading mud faster

equipment to counter the problem.

35 than it can be pumped into it? Dependent on the rate of

If on the other hand the gas kick is taken in the upper unloading it can be impossible to re-establish a balanc

geological formation then the situation can become ing hydrostatic pressure.

very serious.

Having the divertor closed on the well flowing out

During the 25 years or so where the industry have over

the side one can only hope that the formation will

been drilling off-shore there have been no real satisfac breach itself or deplete before any damage is done to the

tory solution to control shallow gas kicks.

divertor lines. But there is no guarantee that the flowing

The risk of drilling through shallow gas sands has sand and gas will not come through the divertor lines or

been reduced by the use of high resolution seismics. that the gas does not contain H2S which is a very poi

Where the presence of so called bright-spots indicate sonous gas. On top of that it is very likely that the well

the presence of shallow gas. This knowledge, however, 45 gas will ignite. To prevent this the engines must be shut

does not always keep the oil company from drilling a down further complicating the control process.

particular location. The reason for this can be, that the

In the process of controlling the well the gas will

signals are too weak to be absolutely sure of shallow most likely increase in velocity carrying more sand

gas, or because the target zones are so important that along from the formation. This flow is extremely abra

the goal overshadows the risk of encountering shallow 50 sive and can cut the divertor lines in minutes. If this

gas.

happens then the rig is in extreme danger and the per

The reason can be that the use of high resolution sonnel must be evacuated. At this point the BOPs if they

seismic is prohibitively expensive or because neighbour are installed would have to be closed stopping the gas

ing wells have shown only normal pressure formations. flow and buying time for mixing of heavy mud and

The casing depth can be changed to suit the actual 55 repairing the divertor lines.

formation, but very little can be done to improve the

Since there is no way to know whether the formation

strength of the 20" casing strength against vertical frac around the casing will withstand the pressure there is no

ture from the abnormal pressure zones or a too high alternative but to try.

hydrostatic pressure imposed from the surface.

If the gas does not come up around the casing then

It is well known that shallow gas is most dangerous in the well can be killed by using a conventional kill proce

the upper section of the hole which constitutes 20 dure. But if conversely the gas does come around the

casing before the 13? casings.

casing then the BOPs must be opened again and the

The reason for this is that the conductor pipe and the process of diversion must be continued. In the latter

20" casing shoe (geological formation around the end of case one can only hope that the gas will stop flowing

the casing) is unable to contain a pressure gradient 65 around the casing. If this does not happen the rig must

which exceeds 0.550.60 psi per foot. Pressure which be prepared for abandonment. In the case of a floating

exceeds this will most likely cause the formation to rig the procedure will be to cut the pipe and move the

fracture around the cement and will result in subsequent . rig away by pulling on the anchor lines. In this case the

4,709,900

equipment damaged would be limited to the subside

cylindrical valve element into the passage of the valve

as abrasion proceeds, the length of the valve element

the rig will have to be abandoned.

ment can be made substantially longer than its wall

BOP and the well head. In case of a jack-up there is

only a very slight chance to move the rig. In most cases

As previously described the uncoming gas rises to the

surface very quickly displaces the drilling mud in the

annulus. Since closing the BOP is not recommended

then there is only the alternative left to pump drilling

mud into the well with maximum pumping capacity.

While pumping, the gas will continue to enter the well

bore until unbalancing hydrostatic head is established.

As is often the case the incoming gas displaces a

larger volume of drilling mud than can be replaced by

the mud pumps. As an example will a two barrel gas

influx at 1500' and 9 ppg mud expand to 100 barrel at the

surface.

If such a kick is allowed to expand to the surface then

it in theory will vacate 275 of the 20" annulus causing

a 128 psi pressure drop in the hydrostatic head. Because

of this reduction more gas will enter the well bore and

if the incomming mud from the mud pumps continue to

be less than the displaced mud then the hydrostatic

will determine the life of the valve. As the valve ele

10

15

20

pressure will be reduced to a point where the incoming

mud will be ejected with the gas no matter how heavy

it it. To kill the well at this point is then impossible.

The logical way to limit the gas expansion as it rises

to the surface is to increase the surface pressure. In a

normal kill procedure this is done by opening the high

pressure choke valve enclosing the BOPs. Then adjust

25

thickness, the valve can be given a substantially longer

life than the well-known devices. Besides, except from

the valve element, the interior parts of the valve are not

essentially exposed to wear.

As regards the bending of the flexible tubular valve

element's end into the flow passage, then this can be

carried out in different ways. For instance, the valve

element can be exposed to radial forces. By way of

example a series of pistons may be placed longitudinally

within the valve housing and so arranged that they can

be pressed against the valve element as its end is

abraded. Another possibility is to constrict the end of

the valve element by means of a steel wire or a chain

wrapped around it or by using clamping jaws. An em

bodiment is described in which between a cylindrical

wall and the valve element is placed one or more flexi

ble bodies, divided into one or more chambers which

can be filled with liquid or gas and arranged so that the

pressure in the individual chamers can be regulated

individually to exert a radical pressure on the valve

element in order to keep the orifice of the latter con

stricted as abrasion proceeds. Thus the end of the valve

element is kept constricted by directing the pressure

along the element as its end is worn.

By another embodiment, the flexible cylindrical

valve element has two terminal surfaces facing the

valve's inlet and outlet orifice respectively, and it has an

essentially radial supporting surface at one end of the

element and has a valve seat intended for co-operating

with the other end of the element, and where the sup

porting surface and the valve seat are designed so that

they can be moved axially against each other thus bend

ing the end of the valve element causing a radial con

striction of the passage of the valve; it also has devices

for adjustable displacement of the supporting surface

ing the choke valves to establish the desired back pres 30

sure. As it already has been established that in the top

section of the hole it is dangerous to close the BOPs and

as all wells are drilled without BOPs on the 36 casing

and some wells drilled without BOPs on the 20" casing

. . and as high pressure choke valves do not have a large 35

enough choking diameter for venting shallow gas then

it is not possible to increase surface pressure using the

s conventional equipment.

s. If one could apply a back pressure on the surface then

the gas expansion would be limited causing a smaller

and the valve seat towards one another. The desired

hydrostatic pressure drop in the bottom of the hole.

This could make it possible for the mud pumps to end diameter of the valve element can be kept constant,

keep up with the mud displacement and by pumping even if the flowing liquid or gas abrades the valve ele

heavy mud into the well bore could make it possible to ment heavily. This is obtained by displacing the valve

regain the balancing head. While it is important to refill 45 element and the valve seat axially in proportion to each

the well with drilling mud it is equally important not to other until the back pressure wanted is achieved. As the

bent part of the valve element is worn down, the valve

break down the formation at the casing shoe.

It is a purpose of the invention to design a choke element and valve seat are moved further towards each

valve that can regulate the back pressure at the well other to keep a constant back pressure resulting in more

head while flowing shallow gas even when the choking 50 of the valve element being bent inwards thus keeping a

process requires hours of flowing highly abrasive gas/ constant inner diameter or passage. This process can go

sand/mud mixture without wearing the valve below its on until all of the bendable part of the valve element is

operating specifications. This is extremely important as worn out. The length of the bendable part of the valve

it is impossible to perform any repair work during the element is merely a function of the safety margin de

choking process.

55 sired.

According to the invention this problem is solved by

By a suitable embodiment of the valve its seat is de

a valve indicated in the introduction, viz. by designing signed conically with its sloping surface facing the

it so that the flow passage of the valve element is equal valve element and the passage of the valve. Thus the

to or larger than the remaining flow passage of the end of the valve element will be bent against the conical

valve, that the valve has devices for constricting the 60 valve seat and into the passage.

end of the valve element nearest to the outlet orifice of

The valve seat may be shaped in many different ways,

the valve, that the inner parts of the valve except for the e.g. it may consist of a series of segments, however, it is

valve element are not essentially exposed to abrasion, suitable to give it an annular form.

and that the valve element is so long that there will be

In principle it is secondary if the valve seat is moved

compensated for the abrasion, to which the end is ex 65 against the valve element or reversely, however, it is

posed, by pushing the valve element against the con most suitable to move the valve seat against the valve

stricting devices or by moving the latter as the abrasion element. For a certain embodiment of the valve the

proceeds. By bending the outermost end of the flexible supporting surface of the valve element is firmly con

4,709,900

5

nected with the valve housing, while the valve seat is

axially movable.

The mutual axial displacement of the valve element

and the valve seat may be designed in many different

ways; by way of example it can be carried out by means

of bolts which are tightened or using cables or chains.

However, a suitable embodiment of the valve is charac

terized by the device for the mutual, axial displacement

of the supporting surface and the valve seat being a

hydraulic driving unit.

An embodiment of the valve includes a hydraulic

driving unit comprising at least two hydraulic cylinders

placed on either side of the valve housing, with one end

attached to the housing and the other one to the valve

seat. Placing the hydraulic cylinders symmetrically in

10

circulation. In the case where the well continues to flow

In a further embodiment of the choke valve, the valve

the choke pressure will be kept at the maximum allow

able to avoid complete depletion of the well and to

allow heavy mud to be mixed and pumped into the well

15 bore.

proportion to the housing will neutralize an offset pull.

In addition the movement of the hydraulic cylinders is

easily controlled.

It is principally secondary if the cylinder jacket is

attached to the valve seat and the cylinder piston to the 20

valve housing, however, it is most suitable to attach the

jacket to the valve housing and the cylinder piston to

the valve seat.

6

annulus and discharge lines as well as special combina

tion control gadget included in this invention and capa

ble of displaying not only the floater armature but also

the degree of wear on the flexible insert.

The console can also be preprogrammed to open the

choke in case the back pressure exceeds a pre-calculated

maximum fracture pressure.

When the heavy kill mud has entered up into the

annulus thus increasing the hydrostatic pressure the

surface backpressure can be reduced to avoid loss of

If the kick has been detected too late then the rig

personnel must continue pumping into the well with

maximum pump capacity while still applying maximum

allowable back pressure to the choke. At the same time

the rig crew will mix kill mud to a pre-calculated den

sity.

The flow from gas bearing sand can be extremely

abrasive and since such parameters as bottom hole pres

sure, fracture gradient, gas volume, sand and water

contents etc. are unknown quantities it is impossible to

predetermine how long the well will keep blowing. It

be therefore important that the surface equipment is

designed to continue the choking process for long peri

housing comprises an interior cylindrical wall, forming 25

the passage, and an outer cylindrical jacket concentric

with said wall, and the hydraulic driving unit is posi

tioned in the space between the two walls. Thus the

choke valve can be placed as a unit within the well bore, ods under the most abrasive conditions.

and in addition the hydraulic driving unit lies protected. 30 The valve element can be made out of rubber com

To prevent dirt being accumulated in the valve dur pound which on one hand has the ability to withstand

ing its production, shipment and storage its inlet and the abrasive flow and on the other hand has the flexibil

outlet orifices be covered by a protective membrane ity it takes to close the valve. As the gas and sand flow

which is torn at a certain pressure.

under a prolonged choking process whereof the flexible

To preserve the elastic properties of the valve ele 35 material which is exposed in the choking orifice the

ment the passage between the two protective mem back pressure will decrease. This will cause the opera

branes may be filled with a preservative. Thus the tor to push the valve seat further against the valve ele

choke valve will always be ready to work, regardless of ment thus bringing more flexible material into the chok

& the fact that it has not been working for a rather long ing orifice, with subsequent decrease of the orifice. This

period.

40 will increase the back pressure. Unveven wear on the

Another embodiment of the protective membrane inside of the flexible element such as channeling has

allowing an undisturbed flow through the valve when it little or no effect on the efficiency of the choke. The

is not in use, is characteristic by the fact that it is de valve seat and other vital metal parts are protected

signed as a tubular, preferably flexible envelope posi against wear by the valve element.

tioned within the valve element and stretching along 45 The elastic valve element has cast grooves stretching

the entire length of the valve and having flanges at its concentrically and longitudinally on its outside thus

ends intended for clamping it to the entire valve, viz. at dividing it into segments which during a prolonged

its inlet and outlet respectively. Beyond its not being wear help to keep the choke opening clear. The worn

disturbing the flow when it is in its passive position, it segments will be carried away by the flowing medium.

can also be tested and even all the way down to the 50 The valve element can be eroded continuously over

closed position by making the protective envelope flexi the total stroke of the hydraulic cylinders and protects

ble enough. As distinct from the above embodiment, against prolonged flows from the well.

The choke valve does not eliminate all the risk in

this protective membrane must not be burst to open, but

be worn open at the moment when you start throttling volved with drilling throug shallow gas zones. But it is

the valve.

55 an important alternative to the procedures available

The wear-compensating, variable constriction of the to-day and furthermore the investment only represents

throttle valve, of which the full flow diameter is up to a fraction of the potential loss associated with the full

20", is operated hydraulically. The choke valve is capa scale blow-out.

ble of controlling a flow of heavily abrasive liquids or

If attempts to stop the flow with the last kill-mud has

gasfrom when the flow is free and until it is totally failed then the process enters in its second phase. At that

stopped.

time it is necessary for the personnel to have sufficient

In case of a blow out in the top hole section of the time to mix a new batch of kill-mud, prepare to set a

well bore the divertor and the mud return lines are

cement plug or to wait for a new delivery of barite or

closed. The gas can now only flow through the choke. cement. While this is going on sea water is pumped into

The choke control console is installed on the drill floor 65 the well bore at full capacity. At this point in time the

and is either connected to the BOP accumulator unit or

well is most likely blowing gas mixed with sand and

to a separate hydraulic pumping unit. The console con water and it is safe to assume that the 20"/5" annulus is

tains pressure gadets for measuring the pressure in the aerated to such a degree that the hydrostatic pressure

4,709,900

7

on the 20" casing shoe is only a fraction of the original

pressure.

Based on this assumption the backpressure is in

creased to substitute. In theory if the well is flowing

100% gas then the backpressure could be increased to

8

FIG. 13 shows a hydraulic steering system for steer

ing the movement of the valve seat,

FIG. 14 shows a control and scale unit to the hydrau

lic steering system, and

reflect the maximum allowable pressure on the 20"

casing shoe. Since there is no exact way to determine

the actual hydrostatic pressure on the casing shoe it is

necessary to make an estimate based on the visual judge

ment of the gas/water/sand mix which flows from the 10

well.

Flowing gas mixed with sand will wear down any

existing divertor lines in a few minutes. By using this

choke valve combined with Densit lined housing spit

tings and piping the choking process can go on for a 15

long time.

The choke valve can be installed in combination with

the existing divertor. This system, however, does nor

mally not allow a smooth flow from the well head to the

oil bore line. This can cause successive wear in places as 20

well as blocked up lines with subsequent uncontrolled

increase in backpressure. Another installation mode is

to install the choke on a special mud flow cross under

the existing divertor system. This system will then only

be installed when drilling the particular section of the 25

hole. As a new feature the flow can be diverted on the

sea floor. This is done by installing the mud cross and

choke on the subseawei head. The well head is then

controlled through the rise of kill line. The rised choke

line can be used to monitor the annulus pressure and the

control parts on the upper marine riser package can be

used to operate the valve. As an additional feature the

inside of all pipings and fittings can be coated with

30

Densit (trade mark).

The embodiments of the invention are diagrammati 35

.... cally illustrated in the accompanying drawings, in

*... which:

* FIG. 1 is an axial cut-away of the choke valve ac

*.cording to the invention,

FIG. 2 is a cross section of the choke valve according

FIG. 3 is a longitudinal section as in FIG. 1, but here

the valve is shown working,

FIG. 4 shows the choke valve of FIG. 1 locked at

45

directly from its end,

FIG. 5 shows a typical surface arrangement of an

off-shore oil or gas well while drilling in the upper

to FIG. 1,

Strata,

FIG. 6 is a horizontal section of the arrangement

shown in FIG. 5,

50

FIG. 7 shows another embodiment of the choke

valve according to the invention,

FIGS. 8A and 8B show schematically a jack-up dril

ling rig and a semi-submercible platform, respectively

where both platforms have drilled into a shallow gas

bearing formation which communicates to deeper gas

sand through a fault,

FIG. 9 shows pressure/depth diagram showing the

pressure steps used in a typical kill procedure with

emphasis on use of this divertor choke,

FIG. 10 shows the choke valve mounted on an exist

ing divertor system,

and semi-submercibles.

wall 7 houses a flexible tubular valve element 8 with a

flat first end resting against a support 9, which is firmly

combined with the interior part 6 of the valve housing,

and another conical end which co-operates with a valve

seat 10 or with a contracting piston. The interior and

the exterior surfaces of these are flush with the exterior

and interior side of the tubular valve element 8 when

the valve is fully open is as it appears from FIG. 1.

The valve seat 10 is equipped with radially protrud

ing flaps 11, e.g. four such wings passing through axial

slits 12 in the wall 7, and with a corresponding number

of hydraulic driving units 13 are positioned in the annu

lar space between the walls 5 and 7. The cylinder 14 of

the driving unit is supported by the intermediate part of

the valve housing and its piston is connected to the

corresponding flap 11 by the piston rod 16.

In the position shown in FIG. 1 the pressure medium

via hoses not shown can be carried to the piston on the

side with the piston rod and by this cause the valve seat

10 to move to the left on the drawing. As the tubular

valve element is firmly supported by the support 9, the

displacement of the valve seat will squeeze the right end

of the tubular element 8 to take up the position shown in

FIG. 3, where the flow passage through the valve is

totally closed. However, the valve seat 10 is adjustable

to any position between those shown on the drawing, so

that the passage remains more or less open and thus

controls the liquid flow as wanted.

The constricted zone formed by the inwards bent end

of the valve element 8 is exposed to a considerable

abrasion, but this wear will be compensated for by grad

ually displacing the valve seat 10 axially against the

valve element 8. Therefore, such an adjustment for

55

FIG. 12 shows the choke valve and mud cross 65

mounted on a subsea well head with the lower marine

riser packet mounted on top. This is used on drill ships

ing comprises a cylindrical jacket 1 with an inlet and an

outlet joint 2, 3 fitted with flanges which, as it appears

from FIG. 1, can be covered by protected membranes 4

as long as the valve has not been in operation. In the

embodiment shown the valve housing comprises three

parts, viz. an exterior jacket 5 firmly combined with the

outlet joint 3, an interior part 6 firmly combined with

the inlet joint 2 and an intermediate part which forms a

cylindrical wall 7 defining the flow passage between the

two joining ends 2, 3 and which is build integral with 1.

Internally and along an essential part of its length the

wear can be carried out until the valve seat 10 has

FIG. 11 shows the choke valve mounted on a double

outlet mud cross under the existing divertor system,

FIG. 15 shows a hydraulic system for the valve illus

trated in FIG. 7.

The choke valve illustrated in FIG. 14 of the draw

reached its outermost position, i.e. only limited by the

length of each of the hydraulic cylinders stroke.

The flexibility of the tubular valve element 8 can be

improved by axial grooves distributed over its inner

surface and its outside can have circumferential weak

ening grooves, which indicate clear constriction

zones as the abrasion proceeds and results in a succes

sive sacrifice of the material of the valve element.

FIG. 5 shows a typical surface arrangement of an

offshore oil or gas well drilling mounted with the choke

valve 17 described above. In case it is necessary to air

the well because of an inflow of gas from the strata

drilled a divertor 18 is closed. By this the pressure in the

well 19 increases until the protective membrane 4 of the

choke valve is torn and the drilling liquid flows through

the choke valve and the divertor 20. After that the

4,709,900

9

drilling operator can adjust the end diameter of the

valve element 8 by exerting pressure on the valve seat

10 by means of the hydraulic driving unit 13 and with it

regulate the back pressure in the well to a beforehand

calculated maximum pressure which is read from the

manometer 21. The dotted line in FIG. 6 indicates an

alternative mounting of two choke valves, one on either

side of the well.

In FIG. 7 of the drawing there is shown another

embodiment of the choke valve according to the inven 10

tion. The reference numbers employed for certain parts

correspond to the same parts in FIG. 1. Between the

valve housing 1 and the valve element 8 there is posi

tioned a flexible element 22 stretching over the total or

nearly the total length of the valve element. That flexi 15

ble element is divided into a series of separate chambers

23 into which a liquid or gas can be led under pressure.

By adjusting the pressures in the individual chambers 23

you can obtain that the valve element 8 takes up the

shape shown in the figure, consequently a gradual con 20

striction towards the outlet end of the valve. As this end

of the valve element is worn-down, the pressure in the

outermost chamber at this end is reduced, whereas the

pressure is increased in the next chamber to constrict

the worn-down end of the valve element and so on.

FIG. 8A shows quite schematically a drilling plat

form 24 of the socalled jack-up type, i.e. a drilling plat

. . form supported by legs standing on the sea bed 25. It is

illustrated that while drilling a shallow gas zone 26 is

, hit. In this case it will not involve any especially critical

situation, as you will not hit the shallow gas zone until

after establishing the 20" casing 27. In this case the

casing 28 will be able to resist the forces occurring

25

30

when the well bore is closed with the usual BOPs.

FIG. 8B shows a far more critical situation, viz.

35

where, from a semi-submersible drilling platform 29,

while establishing the 20" casing 27, the shallow gas

zone 26 is penetrated. Here, due to geological displace

... ments, the strata, is placed higher. With the known

technique you are powerless here and can only hope for

good luck. As mentioned earlier, a closing of the well

bore will entail a great risk of breaking the casing 28 and

the surrounding geological formation, so that gas under

high pressure will leak up through the formation. Irre

spective of it being about a jack-up 24 or a semi-subm 45

ersible rig 29 it is equally hazardous. As to the jack-up

24 the ground under the legs will be eroded so much

that the platform may turn over. As regards the semi

submersible platform 29 the water will be aerated so

50

that the platform looses its buoyancy.

Utilizing the present invention you can throttle the

drilling under conditions so well controlled that there is

a possibility of reestablishing the back pressure thus

regaining control of the drilling.

FIG. 9 of the drawing illustrates the pressure condi 55

tions of a drilling which penetrates a gas-bearing sand

stratuma so-called shallow gas zone 26. The horizon

tal axis indicates the pressure in psi and the vertical axis

the level in feet. The drill floor 30 (FIGS. 8A, 8B) is

found on level + 100 above the water surface 31 on 60

level 0 as starting point. The seabed 25 is found on level

250'. On level 3000' the drilling penetrates a shal

low gas zone 26.

The extreme point of the curve A indicates the hy

drostatic head of the well bore immediately before the 65

kick with a drill sludge the volume weight of which is

9.2 ppg. The point B gives the formation pressure on

level 3600' which is the under side of the shallow gas

10

zone 26. Going out from geological measurings carried

out earlier, the formation gradient is indicated as 456

psi/foot. The point C indicates the formation pressure

at the upper side of the shallow gas zone on level

3000'. The pressure is like that on level 3600', the

gas pressure being constant everywhere within the shal

low gas zone 26.

The point D indicates the pressure at the 20" casing

shoe, where the geological formation will break down.

The 20" casing shoe is here at a depth of level 1250'.

Point E indicates the pressure at the 20" casing shoe,

if the BOPs are closed after has having penetrated the

well bore.

Point F indicates the pressure at the drill floor 30

permissible back pressure on the divertor when the gas

with the BOP closed. Point G indicates the maximum

kick is circulated out.

The point H indicates the estimated maximum per

missible pressure in the throttle valve when the gas

flows out of a well bore.

The curve I indicates the pressure of a kill sludge

having a volume weight of 10.2 ppg.

The pressure in the hatched field exceeds the strength

of the formation and will make it break down with the

risk of losing the drilling platform and the well bore, as

described previously.

In the FIG. 10 of the drawing the choke valve 17 is

shown being used in connection with a ordinary diver

tor 32. The reference designation 30 indicates the drill

floor, and 33 indicates the rotary table. Otherwise the

drilling platform is of the jack-up type. Immediately

under the rotary table 33 there is placed a divertor 32 of

the conventional design, and between the divertor 32

and the casing pipe 28 there is a spacer spool 34 with a

Braden head 35 for coupling-up the casing pipe 28. The

one outlet pipe of the divertor is used for the return

drilling sludge and is connected to a usual stop valve.

The other outlet 36 of the divertor is conducted over

board from the platform by a divertor pipe 37 and the

choke valve 17 is positioned in the immediate vicinity of

the divertor 32. In case of a kick the divertor 32 is

closed and the choke valve 17 is adjusted to the maxi

mum permissible back pressure and till the hydrostatic

head is reestablished.

FIG. 11 of the drawing shows another embodiment.

Instead of inserting the choke valve 17 into the divertor

pipe 37, a fitting 38 is inserted into the spacer spool 34,

said spool having two branches 39 and 40 which are

curved softly into the flow direction. By this abrasion

will be reduced substantially in proportion to the effect

of a sudden change of the flow directionsuch as it

takes place in an ordinary divertor. In the immediate

vicinity of the branchings 39, 40 each of these is

equipped with a choke valve 17 according to the inven

tion the outlets of which are conducted overboard from

the platform by means of divertor lines 37. Placing them

so is very advantageous as regards conducting the pipes

of the divertor line 37 as regularly as possible. Because

of the entire design of the platform the pipeline from the

usual divertor 37 placed immediately under the rotary

table 33 has essentially more changes of direction com

pared to the lower placing shown in FIG. 11.

It is obvious that the design described above just as

well can be used in connection with a semi-submersible

platform or with a drilling ship, in which case the con

struction will be mounted on top of a telescopic junc

tion 41 (FIG. 11A) between the divertor 32 and the

11

4,709,900

casing pipe 28. The telescopic junction is shown quite

schematically to the left in FIG. 11.

FIG. 12 of the drawing illustrates a design quite dif

ferent from the previous ones, as here the gas from the

shallow gas zone instead of being conducted out at the

12

It should be noticed that all the valves are shown in a

position corresponding to the first hydraulic system 50.

When the valve seat 10 hits the valve element 8 the

pressure of the driving system 52 rises, by which all the

valves shift to a position for the other hydraulic system

51.

The length of stroke of the operating cylinder 14 is

controlled by the valve 58. By opening said valve 58 the

length of stroke is increased and by throttling the valve

58 the stroke is decreased. When the valve is closed the

length of stroke remains unchanged.

The two cylinders 59 and 60 are slave cylinders

showing the respective positions of the cylinders 54 and

55. These signals are transmitted to a readiing scale on

a control panel.

Hydraulic pressure is produced by a hydraulic pump

water surface 31 is conducted out immediately above

the sea bed 25.

The choke valves 17 and the branching device 38 are

positioned immediately above the sea bed, the latter

being connected with the top of the casing by means of 10

a Braden head 42. The reference designation 43 indi

cates a baseplate for the casing pipes. Above the

branching device 38 follow in succession a Braden head

44, a BOP 45 and a flexible junction for the pipe 34 up 15

to the submersible drilling platform or to the drilling

ship.

The reference number 47 illustrates controlling de 61.

The steering system shown has the advantage, that

vices for the choke valves 17 and the BOP 45. The

you

can control the choke valve completely with one

reference designations 48, 49 indicate connecting lines

hand lever. At the same time you may be in

to said control device, so that it can be operated from 20 single

formed as to the wear on the valve element and thus

the drilling platform.

The outlets from the choke valve 17 can freely be

estimate how much longer the choke valve will be

conducted in the direction and distance desired, e.g. in

the direction of the prevailing current of the sea, so that 25

the escape from the drilling is carried away from there

thus reducing the risk of aerating the water under the

rig or the drilling ship.

In the FIG. 13 of the drawing is illustrated a hydrau

lic steering system for steering the movement of the 30

drawing.

FIG. 15 of the drawing quite schematically illustrates

a hydraulic system for the valve shown in FIG. 7. The

single chambers pressing the valve element into the

valve seat 10 within the choke valve 17. The valve seat

10 is the component which bends the end of the valve

element 8 and presses the latter into the passage of the

valve, thus choking the flow of gas and liquid.

The hydraulic operating cylinder 14 can be activated

*by two separate hydraulic systems. The first hydraulic

*-system 50 can move the valve seat 10 over its total

stroke. The other hydraulic system 51 can move the

*:::valve seat 10 over its total length of operation.

A control system selects between the two hydraulic

systems 50, 51 going out from a pre-determined maxi

mum pressure in a driving system 52 which corresponds

to the rise of pressure taking place in the first hydraulic

35

system 50, when the valve seat 10 hits the valve element

8. When said pressure is reached, the control valves 45

automatically shift to the other hydraulic system 51.

In addition, a manual system enables the operator to

shift between said two systems.

When the operating cylinder 14 reaches its bottom

position, which is the position where the piston rod 16 50

is totally out of the cylinder 14, the hydraulic flow

direction will automatically be reversed.

The other hydraulic system 51 comprises a spring

operated cylinder 53 and with oil on on the spring

loaded side of the piston, said piston being operated by 55

another hydraulic cylinder 54.

The spring-actuated cylinder 53 has a volume which

corresponds to the quantity of oil needed to move the

operating cylinder 10 the length of one working stroke.

A spring-actuated hydraulic cylinder 55 in the first 60

hydraulic system 50 has a volume which is needed to

move the operating cylinder 10 one full length of

stroke.

By the other hydraulic system 51 the operating cylin

der 10 forces oil to a tank 56. At the return stroke of the 65

cylinder 53 caused by the spring actuating, oil is sucked

from the tank 56 to the cylinder 53 through a one-way

valve 57.

reliable in function.

A control and scale unit is shown in FIG. 14 of the

flow passage of the valve can be set under pressure by

Even though the valve here is described especially in

connection with shallow gas blow-outs from oil or gas

wells, it is obvious that the employment of the valve is

not limited to this special field. For instance it is very

suitable for all arrangements where heavily abrasive

liquids or gas flow through the choke valve.

a series of valves.

It has to be taken into consideration that the well

control plan for shallow gas blow-outs are not the exact

science which can be used for deeper blow-outs where

the casing show allows for much higher pressure read

ings. There are no exact equations or computer pro

grames which can be used to calculate the weight of

kill-mud, pump strokes or choke pressure required to

circulate out the incoming gas.

The margin between control and catastrophe is small

and good timing and training of the personel is critical.

Shallow gas moves to the surface so fast that it often

has surprised the drilling crew by sending the kelly

bushing flying in the air. At this critical moment it is

important to know that the back-up tool is available.

By using this choke valve in connection with the well

trained crew the platform will have a second chance

which is otherwise not available on today's drilling rigs.

I claim:

1. A choke valve comprising:

an inlet at an upstream end thereof;

an outlet at a downstream end thereof;

a flexible tubular element between said inlet and said

outlet;

a central passage in said flexible tubular element for

permitting a flow of a fluid from said inlet to said

outlet;

means for deforming a downstream end of said flexi

ble tubular element into a controllable position

selectively constricting said central passage; and

said means for deforming further including means for

successively deforming additional portions of said

flexible tubular element into said controllable posi

4,709,900

13

tion as deformed portions at said downstream end

of said flexible tubular member are abraded away

by said flow of a fluid, whereby an operating life

time of said choke valve can be made as long as

14

6. A choke valve according to claim 1 wherein:

said means for deforming includes a plurality of annu

lar passages surrounding said flexible tubular ele

desired by increasing a length of said flexible tubu- 5

lar element and an operational range of said means

for deforming.

2. A choke valve according to claim 1 wherein said

central passage includes a diameter substantially equal

to a diameter of said inlet and said outlet, when said

10

flexible tubular member is in an undeformed condition.

3. A choke valve according to claim 1 wherein said

means for deforming includes:

an annular support adjacent said inlet;

an upstream end of said flexible tubular member abut

ting and being supported by said annular support;

ment;

each of said annular passages being independently

capable of receiving a pressurized fluid, whereby

an adjacent portion of said central passage is de

formed into said controllable position; and

said means for successively deforming includes means

for successively pressurizing said annular passages,

beginning with downstream ones thereof and pro

gressively pressurizing ones upstream, whereby

abrasion of said flexible tubular element at de

formed portions thereof is accommodated.

15 7. A choke valve according to claim 6 wherein said

means for successively deforming includes progres

sively

depressurizing ones of said annular passages

an annular valve seat at a downstream end of said

downstream of a furthest-upstream pressurized annular

flexible tubular member;

passage, whereby further wear on portions of said flexi

saidsaidvalve

seat including in conical surface contacting 20 ble

tubular element which have previously been

downstream end of said flexible tubular mem

abraded is reduced.

ber; and

8. A choke valve according to claim 1 wherein said

and means for forcibly urging said conical surface in flexible

element includes a plurality of annular

an axial direction against said downstream end of groovestubular

about on inner surface thereof, said plurality of

said flexible tubular member, whereby said down- 25 annular grooves providing weak points permitting

stream end of said flexible tubular member is de

abraded portions of said flexible tubular element to

formed into its constricting position in said central break

off and be carried away with said flow.

passage.

9. A choke valve according to claim 8 wherein said

4. A choke valve according to claim 3, wherein said flexible tubular element includes a plurality of annular

means for forcibly urging includes at least one cylinder 30 grooves about on outer surface thereof, said plurality of

having a driving rod movable in response to admission. annular grooves providing weak points permitting

of a pressurized fluid into said cylinder, and means for abraded portions of said flexible tubular element to

connecting motion produced by said at least one cylin break off and be carried away with said flow.

der and driving rod to said valve seat.

10. A choke valve according to claim 1 wherein said

35 flexible tubular element includes a plurality of annular

5. A choke valve according to claim 4 wherein:

said at least one cylinder includes at least four cylin grooves about on outer surface thereof, said plurality of

ders angularly spaced about an axis of said choke annular grooves providing weak points permitting

valve; and

abraded portions of said flexible tubular element to

...s said valve seat includes radially extending members break off and be carried

away with said flow.

*: * * * *

aligned for urging by said at least four cylinders. 40

45

50

55

65

Вам также может понравиться

- Diverter Drilling System For Well Control Full GuideДокумент19 страницDiverter Drilling System For Well Control Full GuiderahulОценок пока нет

- United States Patent: Nierode (10) Patent N0.: (45) Date of PatentДокумент15 страницUnited States Patent: Nierode (10) Patent N0.: (45) Date of PatentoreОценок пока нет

- Diverter Procedure While Drilling Fixed: Last Updated On Tue, 24 Jun 2014Документ4 страницыDiverter Procedure While Drilling Fixed: Last Updated On Tue, 24 Jun 2014AmitabhaОценок пока нет

- Differential sticking preventionДокумент6 страницDifferential sticking preventionMEUBROОценок пока нет

- Reservoir Normal Pressure Clay MudДокумент6 страницReservoir Normal Pressure Clay MudJohanes SiraitОценок пока нет

- Bottom Hole Completion TechniquesДокумент9 страницBottom Hole Completion Techniquesakshitppe11Оценок пока нет

- High Pressure Inflatable Packer ToolsДокумент3 страницыHigh Pressure Inflatable Packer ToolsKim MissonОценок пока нет

- Preventing Ultra-Deepwater BlowoutsДокумент4 страницыPreventing Ultra-Deepwater Blowoutsgplese0Оценок пока нет

- Condensate Wells Are Wells That Contain Natural Gas, As Well As A Liquid Condensate. ThisДокумент7 страницCondensate Wells Are Wells That Contain Natural Gas, As Well As A Liquid Condensate. ThisRuth OjileОценок пока нет

- Well Intervention: Christmas TreeДокумент4 страницыWell Intervention: Christmas TreeAnonymous p6pNOLu670Оценок пока нет

- Top HoleДокумент2 страницыTop HoleArdalan FezziОценок пока нет

- Section 3, Drilling and Well CompletionДокумент17 страницSection 3, Drilling and Well CompletionhammamiОценок пока нет

- Drilling Kicks and How to Prevent ThemДокумент14 страницDrilling Kicks and How to Prevent ThemGhavban DavidОценок пока нет

- OIL WELLДокумент3 страницыOIL WELLAugustine AmutaОценок пока нет

- Part 6 - Underground BlowoutsДокумент8 страницPart 6 - Underground BlowoutsJohnSmithОценок пока нет

- Shallow Gas Guidelines - Kingdom DRL ServicesДокумент19 страницShallow Gas Guidelines - Kingdom DRL ServicesMohamed MahmoudОценок пока нет

- Well Production ProblemsДокумент22 страницыWell Production ProblemsMohammed Khaled Al-ThobhaniОценок пока нет

- Question Bank 2015Документ74 страницыQuestion Bank 2015Jayakumar ViswanathanОценок пока нет

- United States Patent: BittnerДокумент8 страницUnited States Patent: BittneronlyaqmalОценок пока нет

- Drilling TechnologyДокумент3 страницыDrilling TechnologyMinesh ShahОценок пока нет

- Spe 9529 Pa PDFДокумент9 страницSpe 9529 Pa PDFJessica KingОценок пока нет

- Well Stimulation ServicesДокумент6 страницWell Stimulation ServicesAfzal AktharОценок пока нет

- Completion (Oil and Gas Wells)Документ6 страницCompletion (Oil and Gas Wells)sidharththerrothОценок пока нет

- BOP Equipments Use and TestingДокумент17 страницBOP Equipments Use and TestingAjay Kumar100% (2)

- Oil and Gas Wellsite Production Operations ExplainedДокумент37 страницOil and Gas Wellsite Production Operations ExplainedMahmoud EidОценок пока нет

- Understanding Well Control TechniquesДокумент27 страницUnderstanding Well Control TechniquesKhairi OmarОценок пока нет

- Workover Planning, Equipment & OperationsДокумент35 страницWorkover Planning, Equipment & OperationsSAI KIRAN KOOCHIMANCHIОценок пока нет

- Oil Well DrillingДокумент21 страницаOil Well DrillingMoonking 03Оценок пока нет

- Chapter 20 - FishingДокумент21 страницаChapter 20 - FishingBlanca OrtegaОценок пока нет

- Nitrogen Handling PurgingДокумент9 страницNitrogen Handling PurgingJeet Singh100% (1)

- Coiled-Tubing Completion Procedure Reduces Cost and Time For Hydraulically Fractured WellsДокумент8 страницCoiled-Tubing Completion Procedure Reduces Cost and Time For Hydraulically Fractured WellsKamran Haider TunioОценок пока нет

- 01 - Dr. Simon Tseytlin Tseytlin ConsultingДокумент16 страниц01 - Dr. Simon Tseytlin Tseytlin ConsultingРоман ЖуковОценок пока нет

- Horizontal Drilling Shale GasДокумент7 страницHorizontal Drilling Shale GasSam BamОценок пока нет

- To Uploadc OCW Well ControlДокумент59 страницTo Uploadc OCW Well ControlMuhammad FauzanОценок пока нет

- Drilling Terms and AbbreviationsДокумент69 страницDrilling Terms and Abbreviationsnissefar007Оценок пока нет

- Kickt1 130322051753 Phpapp02Документ48 страницKickt1 130322051753 Phpapp02Rocard NgomaОценок пока нет

- Drilling Engineering CH6 WellControl-UTM PDFДокумент59 страницDrilling Engineering CH6 WellControl-UTM PDFJohn IanОценок пока нет

- PWC01F05Документ1 страницаPWC01F05Mohamed AbozeimaОценок пока нет

- SWE Training Manual PDFДокумент371 страницаSWE Training Manual PDFALBERTO OLIVEROS100% (1)

- Oh DSTДокумент30 страницOh DSTWanderererОценок пока нет

- Coiled Tubing Unit for Well Servicing and Sand RemovalДокумент40 страницCoiled Tubing Unit for Well Servicing and Sand RemovalPratimaОценок пока нет

- Drilling Fluids Guide for Well ConstructionДокумент21 страницаDrilling Fluids Guide for Well ConstructionFernando AybarОценок пока нет

- Drilling and Completions SandstoneДокумент71 страницаDrilling and Completions SandstoneidownloadbooksforstuОценок пока нет

- Underground BlowoutsДокумент6 страницUnderground BlowoutsOKORIEОценок пока нет

- 03 Stabilizing PDFДокумент10 страниц03 Stabilizing PDFJhon Jairo Maestre UribeОценок пока нет

- Fundamentals of Petroleum Engineering WELL COMPLETION AND STIMULATION Mohd Fauzi Hamid Wan Rosli Wan Sulaiman Department of Petroleum Engineering Faculty of Petroleum & Renewable EnginДокумент29 страницFundamentals of Petroleum Engineering WELL COMPLETION AND STIMULATION Mohd Fauzi Hamid Wan Rosli Wan Sulaiman Department of Petroleum Engineering Faculty of Petroleum & Renewable Enginqazim786Оценок пока нет

- Repair Shallow Casing Leaks Oil WellsДокумент7 страницRepair Shallow Casing Leaks Oil WellsrabeemhОценок пока нет

- Factors Influencing Well Completion DesignДокумент6 страницFactors Influencing Well Completion DesignMahesh sinhaОценок пока нет

- Notes 4Документ19 страницNotes 4Ruben ChirinosОценок пока нет

- All-in-One Oilfield Engineering ReferenceДокумент105 страницAll-in-One Oilfield Engineering ReferenceNur ArasyiОценок пока нет

- Dictionar de Petrol Si GazeДокумент8 страницDictionar de Petrol Si GazeLaPoupeeОценок пока нет

- Underbalance CompletionsДокумент7 страницUnderbalance CompletionsNgo Van HieuОценок пока нет

- Overtopping of Spillway Chutes and Stilling Basin Failure Best PracticesДокумент38 страницOvertopping of Spillway Chutes and Stilling Basin Failure Best PracticesYuverОценок пока нет

- Well Completion Module 1Документ10 страницWell Completion Module 1Adetula Bamidele OpeyemiОценок пока нет

- Oil and Gas Artificial Fluid Lifting TechniquesОт EverandOil and Gas Artificial Fluid Lifting TechniquesРейтинг: 5 из 5 звезд5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingОт EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingРейтинг: 5 из 5 звезд5/5 (3)

- Dec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964Документ4 страницыDec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964KrozeОценок пока нет

- Us 6250486Документ14 страницUs 6250486KrozeОценок пока нет

- Us8608097 PDFДокумент10 страницUs8608097 PDFKrozeОценок пока нет

- Us 3616264Документ4 страницыUs 3616264KrozeОценок пока нет

- Variable capacity staged cooling DX geothermal heat pumpДокумент44 страницыVariable capacity staged cooling DX geothermal heat pumpKrozeОценок пока нет

- Us 3195038Документ10 страницUs 3195038KrozeОценок пока нет

- Us 3376803Документ26 страницUs 3376803KrozeОценок пока нет

- United States Patent: (21) Appl. N0.: 13/226,109 (Continued)Документ17 страницUnited States Patent: (21) Appl. N0.: 13/226,109 (Continued)KrozeОценок пока нет

- Aug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitДокумент6 страницAug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitKrozeОценок пока нет

- United States Patent (19) (11) Patent Number: 5,179,332Документ14 страницUnited States Patent (19) (11) Patent Number: 5,179,332KrozeОценок пока нет

- Us 7006327Документ11 страницUs 7006327KrozeОценок пока нет

- Us 6633161Документ21 страницаUs 6633161KrozeОценок пока нет

- Low inductance high energy inductive ignition systemДокумент18 страницLow inductance high energy inductive ignition systemKrozeОценок пока нет

- Low inductance high energy inductive ignition systemДокумент18 страницLow inductance high energy inductive ignition systemKrozeОценок пока нет

- United States Patent (19) : (45) Date of Patent: Oct. 12, 1999Документ17 страницUnited States Patent (19) : (45) Date of Patent: Oct. 12, 1999KrozeОценок пока нет

- United States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000Документ18 страницUnited States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000KrozeОценок пока нет

- Us 5818319Документ30 страницUs 5818319KrozeОценок пока нет

- Us 5379832Документ16 страницUs 5379832KrozeОценок пока нет

- Coil Array Design Enhances Resolution and Depth of Investigation for Induction Logging ToolsДокумент21 страницаCoil Array Design Enhances Resolution and Depth of Investigation for Induction Logging ToolsKrozeОценок пока нет

- Patent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsДокумент11 страницPatent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsKrozeОценок пока нет

- Patent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsДокумент11 страницPatent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsKrozeОценок пока нет

- United States PatentДокумент14 страницUnited States PatentKrozeОценок пока нет

- United States PatentДокумент25 страницUnited States PatentKrozeОценок пока нет

- Us 4774914Документ25 страницUs 4774914KrozeОценок пока нет

- United States PatentДокумент15 страницUnited States PatentKrozeОценок пока нет

- United States PatentДокумент15 страницUnited States PatentKrozeОценок пока нет

- Us 6577888Документ12 страницUs 6577888KrozeОценок пока нет

- United States Patent (19) (11) Patent Number: 5,207,074Документ18 страницUnited States Patent (19) (11) Patent Number: 5,207,074KrozeОценок пока нет

- United States Patent (19) : 16 VoltageДокумент12 страницUnited States Patent (19) : 16 VoltageKrozeОценок пока нет

- Us 4866424Документ14 страницUs 4866424KrozeОценок пока нет

- Leapfroggers, People Who Start A Company, Manage Its Growth Until They Get Bored, and Then SellДокумент3 страницыLeapfroggers, People Who Start A Company, Manage Its Growth Until They Get Bored, and Then Sellayesha noorОценок пока нет

- Managing operations service problemsДокумент2 страницыManaging operations service problemsJoel Christian Mascariña0% (1)

- (Lesson 10-1) - Quality Assurance, Hemocytometry, Thoma PipetsДокумент22 страницы(Lesson 10-1) - Quality Assurance, Hemocytometry, Thoma PipetselleОценок пока нет

- Amended ComplaintДокумент38 страницAmended ComplaintDeadspinОценок пока нет

- DEFCON ManualДокумент13 страницDEFCON Manualbuyvalve100% (1)

- Admission Checklist (Pre-) Master September 2021Документ7 страницAdmission Checklist (Pre-) Master September 2021Máté HirschОценок пока нет

- Industry Life Cycle-Plant Based CaseДокумент3 страницыIndustry Life Cycle-Plant Based CaseRachelle BrownОценок пока нет

- VSP-12Way - Is Rev.03Документ55 страницVSP-12Way - Is Rev.03Marcelo AlmeidaОценок пока нет

- A - Bahasa Inggris-DikonversiДокумент96 страницA - Bahasa Inggris-DikonversiArie PurnamaОценок пока нет

- Nmea Components: NMEA 2000® Signal Supply Cable NMEA 2000® Gauges, Gauge Kits, HarnessesДокумент2 страницыNmea Components: NMEA 2000® Signal Supply Cable NMEA 2000® Gauges, Gauge Kits, HarnessesNuty IonutОценок пока нет

- ViscosimetroДокумент7 страницViscosimetroAndres FernándezОценок пока нет

- Terminología Sobre Reducción de Riesgo de DesastresДокумент43 страницыTerminología Sobre Reducción de Riesgo de DesastresJ. Mario VeraОценок пока нет

- Macdonald v. National City Bank of New YorkДокумент6 страницMacdonald v. National City Bank of New YorkSecret SecretОценок пока нет

- MTS Material Testing SolutionsДокумент34 страницыMTS Material Testing SolutionskarthegreОценок пока нет

- Oscar Ortega Lopez - 1.2.3.a BinaryNumbersConversionДокумент6 страницOscar Ortega Lopez - 1.2.3.a BinaryNumbersConversionOscar Ortega LopezОценок пока нет

- 2014 March CaravanДокумент48 страниц2014 March CaravanbahiashrineОценок пока нет

- 59 - 1006 - CTP-Final - 20200718 PDFДокумент11 страниц59 - 1006 - CTP-Final - 20200718 PDFshubh.icai0090Оценок пока нет

- Stellar Competent CellsДокумент1 страницаStellar Competent CellsSergio LaynesОценок пока нет

- Part 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentДокумент12 страницPart 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentjosethompsonОценок пока нет

- Forecasting AssignmentДокумент1 страницаForecasting AssignmentVarun Singh100% (1)

- HandoverДокумент2 страницыHandoverKumaresh Shanmuga Sundaram100% (1)

- Nexus Undercarriage Cross Reference GuideДокумент185 страницNexus Undercarriage Cross Reference GuideRomanОценок пока нет

- Courier - Capstone WebApp - Round 3 ReportДокумент23 страницыCourier - Capstone WebApp - Round 3 Reportmarmounette26Оценок пока нет

- Denys Vuika - Electron Projects - Build Over 9 Cross-Platform Desktop Applications From Scratch-Packt Publishing (2019)Документ429 страницDenys Vuika - Electron Projects - Build Over 9 Cross-Platform Desktop Applications From Scratch-Packt Publishing (2019)Sarthak PrakashОценок пока нет

- Quality Risk ManagementДокумент29 страницQuality Risk ManagementmmmmmОценок пока нет

- Best Homeopathic Doctor in SydneyДокумент8 страницBest Homeopathic Doctor in SydneyRC homeopathyОценок пока нет

- BIU and EU functions in 8086 microprocessorДокумент12 страницBIU and EU functions in 8086 microprocessorDaksh ShahОценок пока нет

- DX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Документ6 страницDX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Welissa ChicanequissoОценок пока нет

- 2.4 Adams Equity TheoryДокумент1 страница2.4 Adams Equity TheoryLoraineОценок пока нет

- InvoiceДокумент1 страницаInvoiceAnurag SharmaОценок пока нет