Академический Документы

Профессиональный Документы

Культура Документы

211-04 Steering Column

Загружено:

Miguel AngelАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

211-04 Steering Column

Загружено:

Miguel AngelАвторское право:

Доступные форматы

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Steering Column General Specification

Item

Upper column

Specification

Manual column with tilt and reach adjustment

Torque Specifications

Description

Heatshield lower bolts (2) to steel pinion tower

Heatshield upper bolt (1) to plastic seal

Steering column bolts

Steering wheel bolt

Universal joint to steering gear bolt*

* New nuts/bolts must be fitted

1 of 1

Nm

3.2

2.4

25

48

25

lb-ft

2.3

1.77

18

35

18

23/02/2012 11:26 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Part Number

-

Steering Column - Steering Column

Description and Operation

COMPONENT LOCATION

Item

Part Number

Description

Outer bracket

Energy management plate

Inner bracket

Clockspring, steering wheel angle sensor and steering wheel module

Right Hand (RH) multifunction switch

Steering wheel

Left Hand (LH) multifunction switch

Steering column adjustment lever

Electric steering column lock

10

Upper yoke

11

Outer tube

12

Inner tube

13

Lower yoke

14

Clamp bolt

NOTE: On North American Specification (NAS) vehicles, a running change was introduced during 2008 Model Year (MY) to

disable the electric steering column lock. Under the change, the internal electronics (printed circuit board (PCB), motor, etc.)

of the lock have been removed and the lock has been disabled in the car configuration file. The change is incorporated on VIN

(vehicle identification number) 082896, 085531, 085622, 085685, 085832, 085891, 085942, 085987, 086049, 086081,

086123, 086178, 086276, 086287, 086309, 086363, 086383, 086389, 086398, 086403 and 091770 onwards.

NOTE: Items 10, 11, 12 and 13 are components of the intermediate shaft.

OVERVIEW

The steering column is bolted to a magnesium steering column frame which is an integral part of the cross-car beam located

behind the instrument panel. The cross car beam is manufactured from a combination of steel tension members and ultra-

1 of 3

23/02/2012 11:26 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

lightweight diecast magnesium carriers. The beam not only forms an armature around which the fascia is constructed, but is

also an integral part of the vehicle's crash structure.

Steering wheel position can be moved by adjusting the column upper for reach or rake, whilst soft-stops are used to minimize

adjustment noise in fore-aft movements. The adjustable upper column is designed to manage crash energy in the horizontal

plane.

The intermediate shaft can collapse telescopically to prevent uncontrolled steering wheel displacement during an impact.

The column lintermediate shaft is produced from steel tube for good rigidity. This is bonded to a stiff thin-walled elastomer to

isolate road noise.

IMPACT PROTECTION

In a serious impact, the steering column is designed to manage two simultaneous events; the intermediate shaft must isolate

the steering wheel from any movement of the steering rack (if the angle of the steering wheel changes it will affect the way in

which the airbag deploys towards the driver).

In addition, to prevent excessive force causing injury as the driver strikes the airbag, the whole upper-column assembly is

designed to progressively move forwards as the driver contacts the airbag. This motion helps to safely and progressively

decelerate the driver. The steering column has a 'Horizontal Load Limiting' system which differs from conventional designs

that rely on movement along the column axis.

Horizontal Load Limiting System

Item

Description

Conventional steering column design

Horizontal load limiting system

Mismatch between direction of force and motion

Motion aligned to force

The Horizontal Load Limiting System provides a progressive and stable load limiting characteristic as shown in 'B' in the

illustration. Loads applied to the column cause the column to move horizontally with the driver. This movement is controlled

by an energy management plate. The plate has leaves which peel back in a controlled manner, absorbing energy and allowing

the column to move with the driver.

The plate is bolted to the steering column outer bracket attached to cross-car beam and the inner bracke

Pyrotechnic Additional Load Device - North American Specification (NAS) Only

NOTE: Steering column shown deployed for clarity

2 of 3

23/02/2012 11:26 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Item

Description

Energy management plate

Pin

Pyrotechnic device

Electrical connector

On NAS market vehicles, an additional pyrotechnic device is fitted to provide increased energy absorption to allow for a driver

not wearing a seat belt. If the driver is wearing a seatbelt and a crash situation occurs, the device is not activated.

The pyrotechnic device is located below the energy management plate. When the system detects that the driver's seat belt is

not buckled, and a crash situation occurs which activates the airbags, the device fires, which retracts the pin engaged in a

hole in the central leaf in the energy management plate. This provides the required increase in energy absorption to allow for

the additional loading caused by the unrestrained driver.

3 of 3

23/02/2012 11:26 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Steering Column - Steering Column

Diagnosis and Testing

For additional information.

REFER to: Steering System (211-00 Steering System - General Information, Diagnosis and Testing).

1 of 1

23/02/2012 11:27 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Steering Column - Steering Wheel

Removal and Installation

Removal

1. Make the SRS system safe.

Refer to: Supplemental Restraint System (SRS) Depowering and

Repowering (501-20, General Procedures).

2. Remove the driver air bag module.

Refer to: Driver Air Bag Module (501-20B Supplemental Restraint

System, Removal and Installation).

3.

Torque: 48 Nm

1 of 3

23/02/2012 11:27 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

4.

CAUTION: Protect the surrounding trim to avoid

damage.

NOTE: Do not disassemble further if the component is

removed for access only.

Remove the 2 Torx screws.

Disconnect the electrical connector.

5.

CAUTION: Protect the surrounding trim to avoid

damage.

Remove the 2 Torx screws.

Disconnect the electrical connector.

2 of 3

23/02/2012 11:27 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

6. Remove the steering wheel control switch harness.

7.

Installation

1. Install the steering wheel cover.

2. Install the wiring harness

3. Install the cruise speed control switch.

4. Install the horn switch.

5. Install the steering wheel.

6. Install the driver air bag module.

Refer to: Driver Air Bag Module (501-20B Supplemental Restraint

System, Removal and Installation).

3 of 3

23/02/2012 11:27 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Steering Column - Steering Column

Removal and Installation

Special Tool(s)

501-106

Remover, Driver Air Bag

Removal

1. Make the SRS system safe.

Refer to: Standard Workshop Practices (100-00 General Information,

Description and Operation).

2. Remove the driver lower air bag.

Refer to: Driver Lower Air Bag Module (501-20B Supplemental

Restraint System, Removal and Installation).

3. Remove the steering column lower cowl.

1 of 6

23/02/2012 11:27 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

4. Remove the steering column upper cowl.

5.

CAUTION: Take extra care not to damage the clips.

Release the steering column wiring harness.

2 of 6

23/02/2012 11:27 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

6. If installed, disconnect the SRS ride-down electrical

connector concealed at the rear of the steering column.

7. Remove the steering column universal joint clamp bolt

and release the shaft.

3 of 6

23/02/2012 11:27 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

8. Remove the steering column assembly.

9. NOTE: Do not disassemble further if the component is

removed for access only.

Using the special tool, remove the driver air bag

module.

Special Tool(s): 501-106

Carefully release the 2 clips.

4 of 6

23/02/2012 11:27 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

10.

WARNING: Do not probe supplemental restraint

system (SRS) electrical connectors.

Disconnect the 3 electrical connectors.

11. Remove the steering wheel.

12.

CAUTION: Make sure that the clockspring rotor

does not rotate.

Remove the clockspring.

Installation

1. Install the steering column and tighten the bolts.

Torque: 25 Nm

2.

WARNING: Make sure that a new bolt is installed.

Connect the steering shaft universal joint and tighten the bolt.

Torque: 25 Nm

3. Install the clockspring.

4. Install the steering wheel.

5 of 6

23/02/2012 11:27 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Torque: 40 Nm

5. WARNINGS:

The SRS electrical connectors are unique. DO NOT force, or

attempt to connect electrical connectors to the wrong sockets.

Driver air bag module installation can be confirmed by hearing 2

audible clicks, 1 for each spring. The module edges should also be

flush with the steering wheel.

Install the driver air bag module.

6. If installed, connect the SRS ride-down electrical connector concealed

at the rear of the steering column.

7. Secure the wiring harness to the steering column.

8. Connect the steering column electrical connectors.

9. Install the steering column upper cowl.

10. Install the steering column lower cowl.

11. Install the driver lower air bag module.

Refer to: Driver Lower Air Bag Module (501-20B Supplemental

Restraint System, Removal and Installation).

12. Connect the battery ground cable.

Refer to: Specifications (414-00 Battery and Charging System General Information, Specifications).

13. If a new steering column has been installed, configure the steering

column lock using Land Rover approved diagnostic equipment.

6 of 6

23/02/2012 11:27 AM

Вам также может понравиться

- 205 01 DriveshaftДокумент13 страниц205 01 DriveshaftMiguel AngelОценок пока нет

- 205-04 Front Drive HalfshaftsДокумент18 страниц205-04 Front Drive HalfshaftsMiguel AngelОценок пока нет

- Cable Reel ManualДокумент27 страницCable Reel ManualcristianОценок пока нет

- Emergency Braking System for EOT CranesДокумент7 страницEmergency Braking System for EOT CranesHarish Gupta (JSHL)Оценок пока нет

- 206-06 Hydraulic Brake ActuationДокумент19 страниц206-06 Hydraulic Brake ActuationMiguel AngelОценок пока нет

- John Deere 329D Skid Steer Loader (Manual Controls) Service Repair Manual (TM11431)Документ15 страницJohn Deere 329D Skid Steer Loader (Manual Controls) Service Repair Manual (TM11431)laopaodun100% (1)

- Rear AxleДокумент6 страницRear AxleThomas A. EDISSONОценок пока нет

- Wheel Bearing Hub Knuckle Upper Arm and Lower Arm 8212 Front Removal and Installation PDFДокумент5 страницWheel Bearing Hub Knuckle Upper Arm and Lower Arm 8212 Front Removal and Installation PDFMichael HernandezОценок пока нет

- Parking Brake System: SectionДокумент8 страницParking Brake System: Sectionfrank1220uОценок пока нет

- Evoque TransДокумент16 страницEvoque TransdanОценок пока нет

- Technical ManualДокумент109 страницTechnical Manualleo_turfОценок пока нет

- Manette 4SNДокумент13 страницManette 4SNOthmanОценок пока нет

- Rear Axle ReplacementДокумент4 страницыRear Axle ReplacementY. VásquezОценок пока нет

- Airbag: Airbag System, Safety PrecautionsДокумент11 страницAirbag: Airbag System, Safety Precautionsmefisto06cОценок пока нет

- 016 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - Off VehicleДокумент106 страниц016 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - Off VehicleGedas GvildysОценок пока нет

- ARMY TM 9-2320-280-20-1 HMMWV Unit Mantainance Vol 1 JUL04Документ889 страницARMY TM 9-2320-280-20-1 HMMWV Unit Mantainance Vol 1 JUL04RockWagonОценок пока нет

- Instructions To Mod. Zyt5402tzj Mobile Drilling RigcariierДокумент50 страницInstructions To Mod. Zyt5402tzj Mobile Drilling RigcariierYimmy Alexander Parra MarulandaОценок пока нет

- CPE ManualДокумент32 страницыCPE ManualSarah PerezОценок пока нет

- Ford Think Service Manual - Section 3 PowertrainДокумент16 страницFord Think Service Manual - Section 3 PowertrainDennis Jason AntiОценок пока нет

- Cargo Hook With Hydraulic Release: Mcdonnell Douglas (Hughes) MD 369 Series and 500N HelicoptersДокумент39 страницCargo Hook With Hydraulic Release: Mcdonnell Douglas (Hughes) MD 369 Series and 500N HelicoptersjoejeffОценок пока нет

- 211-00 General InfoДокумент8 страниц211-00 General InfoMiguel AngelОценок пока нет

- Installation and Service Instructions For 180-210 C-Face MotorsДокумент4 страницыInstallation and Service Instructions For 180-210 C-Face MotorsAnonymous gMMbTAQlОценок пока нет

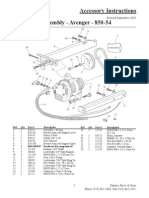

- Alternator Installation Instructions for Avenger 850-54Документ6 страницAlternator Installation Instructions for Avenger 850-54cristi_stoiciucОценок пока нет

- H1 Srs Airbag System: To IndexДокумент118 страницH1 Srs Airbag System: To IndexKwun Hok ChongОценок пока нет

- Brake System 1 PDFДокумент43 страницыBrake System 1 PDFKarthi KeyanОценок пока нет

- BrakeДокумент39 страницBrakeMohammad Abubakar SiddiqОценок пока нет

- Distribución Fiesta KD2014Документ23 страницыDistribución Fiesta KD2014Marcelo MartinelliОценок пока нет

- 205-06 Rear Drive HalfshaftsДокумент22 страницы205-06 Rear Drive HalfshaftsMiguel AngelОценок пока нет

- Front Axle: SectionДокумент25 страницFront Axle: Sectiontomallor101Оценок пока нет

- Humvee Service 1Документ889 страницHumvee Service 1Gara PedrazaОценок пока нет

- Section 10 - Power Take-OffДокумент19 страницSection 10 - Power Take-OffMiller Andres ArocaОценок пока нет

- Humvee Service 2Документ953 страницыHumvee Service 2Gara PedrazaОценок пока нет

- Manual Manutenção Guincho WarnДокумент35 страницManual Manutenção Guincho WarnAnderson K LimaОценок пока нет

- 2011 Ford Expedition Backup Camera RemovalДокумент6 страниц2011 Ford Expedition Backup Camera RemovalErikОценок пока нет

- Clch-svx01b-En 0801 Energy Wheels For T-Series IomДокумент28 страницClch-svx01b-En 0801 Energy Wheels For T-Series Iomh2odavidОценок пока нет

- Steering Column Tilt PDFДокумент26 страницSteering Column Tilt PDFDaniel OlariОценок пока нет

- Powertrain Specs and Removal ProceduresДокумент16 страницPowertrain Specs and Removal ProceduresTOSHAОценок пока нет

- TM9 2320 260 34 1Документ660 страницTM9 2320 260 34 1ferran_alfonsoОценок пока нет

- Eee 1Документ23 страницыEee 1Dany LutzОценок пока нет

- Cap. 32Документ149 страницCap. 32Marcos ValdezОценок пока нет

- ACFrOgA-8u3Zi5xFimnR2twGIAR XM 1KM eb9M5yAVQlQaPUftir ttiG38JZ683E p-uvv8f8iyrSkHSm4UjBP2DaHTvFIR3JmerfXdpfovmicTsXQSp5hQFOz2sMДокумент27 страницACFrOgA-8u3Zi5xFimnR2twGIAR XM 1KM eb9M5yAVQlQaPUftir ttiG38JZ683E p-uvv8f8iyrSkHSm4UjBP2DaHTvFIR3JmerfXdpfovmicTsXQSp5hQFOz2sMYN Motors Yonnier PintoОценок пока нет

- Bolens Lawn Tractor RepairДокумент46 страницBolens Lawn Tractor Repairdakehi1188342157% (7)

- Focus RS Cylinder Head RemovalДокумент20 страницFocus RS Cylinder Head RemovalRobertSorokanich75% (4)

- VW 1.8L 4-Cylinder Turbo Engine GuideДокумент71 страницаVW 1.8L 4-Cylinder Turbo Engine GuideJai Bhandari100% (2)

- 303-01 - 2.3L EcoBoost - Removal and Installation - Engine Front CoverДокумент40 страниц303-01 - 2.3L EcoBoost - Removal and Installation - Engine Front CoverCARLOS LIMADAОценок пока нет

- Scissor Lift ManualДокумент30 страницScissor Lift Manualvalmiki briseñoОценок пока нет

- Clockspring Removal and Installation PDFДокумент6 страницClockspring Removal and Installation PDFMichael HernandezОценок пока нет

- 206-07 Power Brake ActuationДокумент12 страниц206-07 Power Brake ActuationMiguel AngelОценок пока нет

- Baker Aerialscope Manual de OperacionesДокумент40 страницBaker Aerialscope Manual de OperacionesPillaChantasОценок пока нет

- XJ250S Drawworks PDFДокумент20 страницXJ250S Drawworks PDFAnacleta GomezОценок пока нет

- TM 9 2320 272 24 4 PDFДокумент842 страницыTM 9 2320 272 24 4 PDFJosh HarberОценок пока нет

- ARMY TM 9-2320-280-20-2 HMMWV Unit Mantainance Vol 2 JUL04Документ953 страницыARMY TM 9-2320-280-20-2 HMMWV Unit Mantainance Vol 2 JUL04RockWagonОценок пока нет

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- Chevy Differentials: How to Rebuild the 10- and 12-BoltОт EverandChevy Differentials: How to Rebuild the 10- and 12-BoltРейтинг: 5 из 5 звезд5/5 (8)

- Semi-Active Suspension Control Design for VehiclesОт EverandSemi-Active Suspension Control Design for VehiclesРейтинг: 5 из 5 звезд5/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideОт EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesОт EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesРейтинг: 5 из 5 звезд5/5 (1)

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesОт EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesРейтинг: 5 из 5 звезд5/5 (1)

- RR Classic 87-91 Workshop Manual Part SRR652USWMAДокумент864 страницыRR Classic 87-91 Workshop Manual Part SRR652USWMAEmmanuel Romero0% (1)

- Laf 0091-10-1e Towbar Electrics 13 Pin Vplft0077Документ7 страницLaf 0091-10-1e Towbar Electrics 13 Pin Vplft0077Miguel AngelОценок пока нет

- 204-01 Front SuspensionДокумент33 страницы204-01 Front SuspensionMiguel AngelОценок пока нет

- 204-02 Rear SuspensionДокумент44 страницы204-02 Rear SuspensionMiguel AngelОценок пока нет

- 205-02 Rear Drive Axle DifferentialДокумент50 страниц205-02 Rear Drive Axle DifferentialMiguel Angel100% (1)

- 204-06 Ride and Handling OptimizationДокумент7 страниц204-06 Ride and Handling OptimizationMiguel AngelОценок пока нет

- 206-03 Front Disc BrakeДокумент13 страниц206-03 Front Disc BrakeMiguel AngelОценок пока нет

- 204-04 Wheels and TyresДокумент20 страниц204-04 Wheels and TyresMiguel Angel100% (1)

- 206-04 Rear Disc BrakeДокумент17 страниц206-04 Rear Disc BrakeMiguel AngelОценок пока нет

- 206-09B Anti-Lock Control - Traction ControlДокумент1 страница206-09B Anti-Lock Control - Traction ControlMiguel AngelОценок пока нет

- 204-00 General InfoДокумент6 страниц204-00 General InfoMiguel AngelОценок пока нет

- 204-05 Vehicle Dynamic SuspensionДокумент2 страницы204-05 Vehicle Dynamic SuspensionMiguel AngelОценок пока нет

- 211-02 Power SteeringДокумент23 страницы211-02 Power SteeringMiguel AngelОценок пока нет

- 211-00 General InfoДокумент8 страниц211-00 General InfoMiguel AngelОценок пока нет

- 206-00 General InfoДокумент16 страниц206-00 General InfoMiguel AngelОценок пока нет

- Driveline System - General Information - Driveline System: Principles of OperationДокумент4 страницыDriveline System - General Information - Driveline System: Principles of OperationMiguel AngelОценок пока нет

- 206 09A Anti Lock ControlДокумент11 страниц206 09A Anti Lock ControlMiguel AngelОценок пока нет

- 205-06 Rear Drive HalfshaftsДокумент22 страницы205-06 Rear Drive HalfshaftsMiguel AngelОценок пока нет

- 206-06 Hydraulic Brake ActuationДокумент16 страниц206-06 Hydraulic Brake ActuationMiguel AngelОценок пока нет

- 206-07 Power Brake ActuationДокумент12 страниц206-07 Power Brake ActuationMiguel AngelОценок пока нет

- 211-05 Steering Column SwitchesДокумент13 страниц211-05 Steering Column SwitchesMiguel AngelОценок пока нет

- 206-09C Anti-Lock Control - Stability AssistДокумент18 страниц206-09C Anti-Lock Control - Stability AssistMiguel AngelОценок пока нет

- 211-03 Steering LinkageДокумент5 страниц211-03 Steering LinkageMiguel AngelОценок пока нет

- Validation Evidence of The Motivation For Teaching Scale in Secondary EducationДокумент12 страницValidation Evidence of The Motivation For Teaching Scale in Secondary EducationNasr-edineOuahaniОценок пока нет

- Lec 6Документ15 страницLec 6Katevarapu Venkateswara RaoОценок пока нет

- The Reactivity Series PDFДокумент33 страницыThe Reactivity Series PDFSandipan Chakraborty100% (1)

- SS Chapter 01 Introduction To A Machine ArchitectureДокумент56 страницSS Chapter 01 Introduction To A Machine ArchitecturehayatОценок пока нет

- Instructions For Use: Washing MachineДокумент60 страницInstructions For Use: Washing MachinePara RegistrosОценок пока нет

- Mobile Equipment: Components, Systems and SolutionsДокумент8 страницMobile Equipment: Components, Systems and SolutionsJobiar HossainОценок пока нет

- Salesforce Object Relationships: What Is Lookup Relationship in SalesforceДокумент4 страницыSalesforce Object Relationships: What Is Lookup Relationship in SalesforceYash Patel-YashuОценок пока нет

- DIP Lecture9Документ11 страницDIP Lecture9Dilbag SinghОценок пока нет

- Laser Theodolite ManualДокумент24 страницыLaser Theodolite Manualp2342Оценок пока нет

- Temperature InversionДокумент1 страницаTemperature InversionprdyumnОценок пока нет

- Computer Basics Study GuideДокумент11 страницComputer Basics Study GuidePrerak DedhiaОценок пока нет

- M.tech Machine SyllabusДокумент41 страницаM.tech Machine SyllabusSyed Faiz Quadri0% (1)

- Yield Management and ForecastingДокумент23 страницыYield Management and ForecastingMandeep KaurОценок пока нет

- 25 L SUPER Reflux Still Ins With Z FilterДокумент16 страниц25 L SUPER Reflux Still Ins With Z FiltertoffeloffeОценок пока нет

- Algologicalmerida Ionescu Et AlДокумент17 страницAlgologicalmerida Ionescu Et AlRaed AwwadОценок пока нет

- Theoretical Basis For Propulsive Force GenerationДокумент10 страницTheoretical Basis For Propulsive Force GenerationSolGriffinОценок пока нет

- Weekly Home Learning Plan - KindergartenДокумент3 страницыWeekly Home Learning Plan - KindergartenMae Escobin BetonggaОценок пока нет

- Instructions For Using WinplotДокумент38 страницInstructions For Using WinplotClaudia MuñozОценок пока нет

- MAGNA START - New Generation Slip-Ring Motor Starter: December 5, 2015Документ7 страницMAGNA START - New Generation Slip-Ring Motor Starter: December 5, 2015udhayОценок пока нет

- Actuarial Valuation LifeДокумент22 страницыActuarial Valuation Lifenitin_007100% (1)

- COmplete CДокумент335 страницCOmplete Cdeep11680Оценок пока нет

- Cathodic Disbondment Test of Pipeline Coatings (Attached Cell Method)Документ4 страницыCathodic Disbondment Test of Pipeline Coatings (Attached Cell Method)Alex OliveiraОценок пока нет

- FP35 Hearing Aid Analyzer TrainingДокумент85 страницFP35 Hearing Aid Analyzer TrainingPamela Tamara Fernández EscobarОценок пока нет

- PLATQREFДокумент4 страницыPLATQREFManjunath ReddyОценок пока нет

- SBC Code 301Документ350 страницSBC Code 301Marwan Mokhadder100% (6)

- Schlenk Line Techniques: Liquid NДокумент15 страницSchlenk Line Techniques: Liquid NMarinoChavarroCordobaОценок пока нет

- 4PH0 2P Que 20130605Документ20 страниц4PH0 2P Que 20130605Sakib Ex-rccОценок пока нет

- Truss Problem: Q.1:A Four Bar Truss Element Is Shown in Figure. Determine The FollowingДокумент9 страницTruss Problem: Q.1:A Four Bar Truss Element Is Shown in Figure. Determine The FollowingAVINASHОценок пока нет

- College Department Course: B.E Course Code 18CSL67 Student Name USN Mini Project Title Under Taken at Internal Guide SynopsisДокумент3 страницыCollege Department Course: B.E Course Code 18CSL67 Student Name USN Mini Project Title Under Taken at Internal Guide Synopsismohit kunduОценок пока нет

- Fire Magic 2019 Catalog PDFДокумент56 страницFire Magic 2019 Catalog PDFgallegos7386Оценок пока нет