Академический Документы

Профессиональный Документы

Культура Документы

AISI 1018 MildLow Carbon Steel

Загружено:

Fikri RahimИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AISI 1018 MildLow Carbon Steel

Загружено:

Fikri RahimАвторское право:

Доступные форматы

AISI 1018 Mild/Low Carbon Steel

AISI1018Mild/LowCarbonSteel

WrittenbyAZoM

Jul52012

TopicsCovered

Introduction

ChemicalComposition

PhysicalProperties

MechanicalProperties

ElectricalProperties

Machining

Weldability

HeatTreatment

Normalizing

Forging

Tempering

Annealing

StressRelieving

CaseHardening

CoreRefining

Carburizing

ApplicationsofAISI1018Mild/LowCarbonSteel

Introduction

AISI1018mild/lowcarbonsteelhasexcellentweldabilityandproducesauniformand

hardercaseanditisconsideredasthebeststeelforcarburizedparts.AISI1018mild/low

carbonsteeloffersagoodbalanceoftoughness,strengthandductility.Providedwith

highermechanicalproperties,AISI1018hotrolledsteelalsoincludesimprovedmachining

characteristicsandBrinellhardness.

Specificmanufacturingcontrolsareusedforsurfacepreparation,chemicalcomposition,

rollingandheatingprocesses.Alltheseprocessesdevelopasupremequalityproductthat

aresuitedtofabricationprocessessuchaswelding,forging,drilling,machining,cold

drawingandheattreating.

ChemicalComposition

Saved from URL: http://www.azom.com/article.aspx?ArticleID=6115

/4

AISI 1018 Mild/Low Carbon Steel

Element

Content

Carbon,C

0.140.20%

Iron,Fe

98.8199.26%(asremainder)

Manganese,Mn

0.600.90%

Phosphorous,P

0.040%

Sulfur,S

0.050%

PhysicalProperties

PhysicalProperties

Density

Metric

Imperial

7.87g/cc

0.284lb/in3

MechanicalProperties

MechanicalProperties

Metric

Imperial

Hardness,Brinell

126

126

Hardness,Knoop(ConvertedfromBrinellhardness)

145

145

Hardness,RockwellB(ConvertedfromBrinellhardness)

71

71

Hardness,Vickers(ConvertedfromBrinellhardness)

131

131

TensileStrength,Ultimate

440MPa 63800psi

TensileStrength,Yield

370MPa 53700psi

ElongationatBreak(In50mm)

15.0%

15.0%

ReductionofArea

40.0%

40.0%

ModulusofElasticity(Typicalforsteel)

205GPa 29700ksi

BulkModulus(Typicalforsteel)

140GPa 20300ksi

PoissonsRatio(TypicalForSteel)

0.290

0.290

Machinability(BasedonAISI1212steel.as100%machinability)

70%

70%

ShearModulus(Typicalforsteel)

80.0GPa 11600ksi

ElectricalProperties

ElectricalProperties

Metric

English

Comments

Electricalresistivity@0C(32F)

0.0000159cm 0.0000159cm annealedcondition

@100C/212F

0.0000219cm 0.0000219cm annealedcondition

@200C/392F

0.0000293cm 0.0000293cm annealedcondition

Machining

ThemachinabilityofAISI1018mild/lowcarbonsteelisgradedat78%ofB1112.

Weldability

AISI1018mild/lowcarbonsteelcanbeinstantlyweldedbyalltheconventionalwelding

Saved from URL: http://www.azom.com/article.aspx?ArticleID=6115

/4

AISI 1018 Mild/Low Carbon Steel

processes.WeldingisnotrecommendedforAISI1018mild/lowcarbonsteelwhenitis

carbonitridedandcarburized.

Lowcarbonweldingelectrodesaretobeusedintheweldingprocedure,andpostheating

andpreheatingarenotnecessary.Preheatingcanbeperformedforsectionsover50

mm.Postweldstressrelievingalsohasitsownbeneficialaspectslikethepreheating

process.

HeatTreatment

TheheattreatmentforAISI1018mild/lowcarbonsteelconsistsofthefollowingprocesses:

Normalizing

AISI1018mild/lowcarbonsteelshouldbeheatedat890C940Candthencooled

instillair.

Forging

Thisprocessrequiresheatingbetween1150C1280CandAISI1018mild/low

carbonsteelishelduntilthetemperaturebecomesconstant.

900Cistheminimumtemperaturerequiredfortheforgingprocess.

Thesteelisthencooledinairafterthisprocess.

Tempering

AISI1018mild/lowcarbonsteelistemperedatbetween150C200Cfor

improvementofcasetoughness.Thisprocesshaslittleornoeffectonhardness.

TheoccurrenceofgrindingcracksisreducedwhenAISI1018mild/lowcarbonsteel

istemperedattheabovementionedtemperature.

Annealing

TheAISI1018mild/lowcarbonsteelisheatedat870C910Candallowedtocool

inafurnace

StressRelieving

500C700CisrequiredtorelievestressinAISI1018mild/lowcarbonsteelthatis

latercooleddowninstillair.

Saved from URL: http://www.azom.com/article.aspx?ArticleID=6115

/4

AISI 1018 Mild/Low Carbon Steel

CaseHardening

Thisprocessrequiresheatingtobecarriedoutbetween780C820C.AISI1018

mild/lowcarbonsteelisthenquenchedinwater.

CoreRefining

Thisisanoptionalprocessthatrequiresheatingat880C920C.

AISI1018mild/lowcarbonsteelafterbeingheatedismoistenedinoilorwater.

Carburizing

Carburizingtakesplaceat880C920C.

ApplicationsofAISI1018Mild/LowCarbonSteel

Itisusedinbending,crimpingandswagingprocesses.

Carburizedpartsthatincludeworms,gears,pins,dowels,noncriticalcomponentsof

toolanddiesets,toolholders,pinions,machineparts,ratchets,dowelsandchain

pinsuseAISI1018mild/lowcarbonsteel.

Itiswidelyusedforfixtures,mountingplatesandspacers.

Itissuitablyusedinapplicationsthatdonotneedhighstrengthofalloysteelsand

highcarbon.

Itprovideshighsurfacehardnessandasoftcoretopartsthatincludeworms,dogs,

pins,liners,machineryparts,specialbolts,ratchets,chainpins,oiltoolslips,tierods,

anchorpins,studsetc.

Itisusedtoimprovedrilling,machining,threadingandpunchingprocesses.

Itisusedtopreventcrackinginseverebends.

Saved from URL: http://www.azom.com/article.aspx?ArticleID=6115

/4

Вам также может понравиться

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363От EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363Оценок пока нет

- The Iron Puddler My life in the rolling mills and what came of itОт EverandThe Iron Puddler My life in the rolling mills and what came of itОценок пока нет

- AISI 4130: Category Type Steel GradeДокумент2 страницыAISI 4130: Category Type Steel Gradetjt4779Оценок пока нет

- A 1031 - 04 Qtewmze - PDFДокумент4 страницыA 1031 - 04 Qtewmze - PDFqueno1Оценок пока нет

- Aluminium 2014 t6 2014 t651Документ3 страницыAluminium 2014 t6 2014 t651Agung Sapto AjiОценок пока нет

- Interlloy 440C MartensiticДокумент4 страницыInterlloy 440C MartensiticGuillaume BoyerОценок пока нет

- Liquid NitridingДокумент7 страницLiquid NitridingSenthil_kumar_palaniОценок пока нет

- Riview On Cold Drawing Process PDFДокумент7 страницRiview On Cold Drawing Process PDFAmandeep Singh GujralОценок пока нет

- Interpretation and Classification of Non-Metallic Inclusions - MPC20160040-DL.000109386-1.Pdf0Документ10 страницInterpretation and Classification of Non-Metallic Inclusions - MPC20160040-DL.000109386-1.Pdf0Nick pilipenkoОценок пока нет

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Документ5 страницSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiОценок пока нет

- Outokumpu Forta Range Stainless Steel DatasheetДокумент16 страницOutokumpu Forta Range Stainless Steel DatasheetNicola D'ettoleОценок пока нет

- About En19Документ1 страницаAbout En19ramanamurtytv7176Оценок пока нет

- ASM Material Data SheetДокумент2 страницыASM Material Data SheetShankar PranavОценок пока нет

- Aa 6060-6063Документ261 страницаAa 6060-6063RubenОценок пока нет

- Sa 266Документ5 страницSa 266Alejo ZabalaОценок пока нет

- Astm A-240Документ12 страницAstm A-240Dionatas AlcântaraОценок пока нет

- Hydraulic Rod Bending MachineДокумент14 страницHydraulic Rod Bending Machinek.santhosh kumar50% (2)

- Material SpecificationДокумент9 страницMaterial SpecificationMuthu GaneshОценок пока нет

- Astm 666Документ7 страницAstm 666JOSEPH REFUERZOОценок пока нет

- Reduction of Unforged Bar Bulb in Engine Valve ManufacturingДокумент6 страницReduction of Unforged Bar Bulb in Engine Valve ManufacturingSurajОценок пока нет

- Aisi 4340 Alloy Steel (Uns g43400)Документ4 страницыAisi 4340 Alloy Steel (Uns g43400)Muhamad Ikbal TrismanaОценок пока нет

- A-313 - 98Документ7 страницA-313 - 98José Ramón GutierrezОценок пока нет

- Steckel Mill 1 PDFДокумент178 страницSteckel Mill 1 PDFSomnathNaskarОценок пока нет

- ASTM A572 Steel - Grade 50Документ1 страницаASTM A572 Steel - Grade 50FWICIP100% (1)

- Geomet 500 PDFДокумент2 страницыGeomet 500 PDFKaran Chadha100% (1)

- Advantages and Disadvantages of Powder MetallurgyДокумент2 страницыAdvantages and Disadvantages of Powder Metallurgyvinslin67% (6)

- Final Report PDFДокумент32 страницыFinal Report PDFJon SnowОценок пока нет

- AL Alloy Details With WeldingДокумент36 страницAL Alloy Details With WeldingVelmohanaОценок пока нет

- Suhm Spring Works-Spring Materials Issue 9a en US v1Документ37 страницSuhm Spring Works-Spring Materials Issue 9a en US v1DizzixxОценок пока нет

- AMS4930LДокумент8 страницAMS4930Lremaja1249Оценок пока нет

- Reaction Injection MoldingДокумент8 страницReaction Injection MoldingAmeer_Takashim_9385Оценок пока нет

- The Mechanical and Microstructural Study of Welded Aa7075 Using Different Filler MetalsДокумент17 страницThe Mechanical and Microstructural Study of Welded Aa7075 Using Different Filler MetalsIndra SetiyadiОценок пока нет

- Powder Components Heat Treatment PDFДокумент47 страницPowder Components Heat Treatment PDFsmani170Оценок пока нет

- AISI 1050 Steel, As RolledДокумент2 страницыAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoОценок пока нет

- A8557Документ2 страницыA8557Nauman AliОценок пока нет

- Alform 700 MCДокумент9 страницAlform 700 MCCarlos Nombela PalaciosОценок пока нет

- M Selvam Fabrication SupervisorДокумент4 страницыM Selvam Fabrication SupervisornaguОценок пока нет

- 9.optimisation in Design of Mechanical Scissor LiftДокумент5 страниц9.optimisation in Design of Mechanical Scissor LiftAmit GhadeОценок пока нет

- 21 CR Mo V511Документ1 страница21 CR Mo V511uksrajОценок пока нет

- Pre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsДокумент3 страницыPre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsmukeshkumarjОценок пока нет

- Is 4454Документ2 страницыIs 4454kpsrajОценок пока нет

- Product Description Wire RodДокумент3 страницыProduct Description Wire RodEngr Farrukh RehanОценок пока нет

- CI Properties TTT CompiledДокумент8 страницCI Properties TTT CompiledRajesh N Priya GopinathanОценок пока нет

- Heat Treatment ProcessesДокумент7 страницHeat Treatment Processessonu100% (1)

- A 108 - 03 - Qtewoa - PDFДокумент7 страницA 108 - 03 - Qtewoa - PDFHanifiantoОценок пока нет

- Engineering - Bulletin - Calculating Thread StrengthДокумент2 страницыEngineering - Bulletin - Calculating Thread StrengthrobigedОценок пока нет

- Is Phosphorus Bad For SteelДокумент19 страницIs Phosphorus Bad For SteelKarun Dev100% (1)

- 722M24 Steel EN40BДокумент1 страница722M24 Steel EN40BRobert StuartОценок пока нет

- Manual 2266Документ9 страницManual 2266Farea Yusuf KhanОценок пока нет

- Astm A27 (2010) PDFДокумент4 страницыAstm A27 (2010) PDFStuar TencioОценок пока нет

- Permaglide Glijlagers LRДокумент76 страницPermaglide Glijlagers LRVitor GodoyОценок пока нет

- 440C 1Документ4 страницы440C 1svk1234Оценок пока нет

- Distortion in Heat TreatmentДокумент34 страницыDistortion in Heat TreatmentAmit100% (1)

- Altemp X-750 PDFДокумент2 страницыAltemp X-750 PDFeugenio.gutenbertОценок пока нет

- Is 1573 - Zinc Plating On Iron & Steel PDFДокумент21 страницаIs 1573 - Zinc Plating On Iron & Steel PDFSandeep MatetiОценок пока нет

- Astm A 879-06Документ3 страницыAstm A 879-06Bill100% (1)

- Tesla SYSTEM AND METHOD FOR FACILITATING PULSED SPRAY QUENCH OF EXTRUDED OBJECTSДокумент20 страницTesla SYSTEM AND METHOD FOR FACILITATING PULSED SPRAY QUENCH OF EXTRUDED OBJECTSJoey KlenderОценок пока нет

- Ball JointДокумент5 страницBall JointFranciscus Xaverius Bayu SetiawanОценок пока нет

- Determination of Forming Limit Curves On ARGOMДокумент58 страницDetermination of Forming Limit Curves On ARGOMEduardo Felippe de SouzaОценок пока нет

- Integrated Computational Materials Engineering (ICME) for Metals: Concepts and Case StudiesОт EverandIntegrated Computational Materials Engineering (ICME) for Metals: Concepts and Case StudiesОценок пока нет

- AcmvSECTION 3.7 PACS Rev 2016Документ58 страницAcmvSECTION 3.7 PACS Rev 2016Fikri RahimОценок пока нет

- Airport SignsДокумент5 страницAirport SignsFikri Rahim100% (1)

- 1.0 PM (IPte) Yaris Price ListДокумент1 страница1.0 PM (IPte) Yaris Price ListFikri RahimОценок пока нет

- Lampiran 1 Dan 2 PDFДокумент3 страницыLampiran 1 Dan 2 PDFFikri RahimОценок пока нет

- Role of Hopt, Hodt & So: Cawangan Pengurus An Projek KompleksДокумент13 страницRole of Hopt, Hodt & So: Cawangan Pengurus An Projek KompleksFikri RahimОценок пока нет

- Safety Management System: Editor: Department: Document OwnerДокумент76 страницSafety Management System: Editor: Department: Document OwnerFikri RahimОценок пока нет

- Boeing Commercial BackgrounderДокумент5 страницBoeing Commercial BackgrounderFikri RahimОценок пока нет

- RE YTZCAirConditioner ManualДокумент8 страницRE YTZCAirConditioner ManualFikri RahimОценок пока нет

- Elevators and EscalatorsДокумент38 страницElevators and EscalatorsFikri RahimОценок пока нет

- Bck-777 Family BackgrounderДокумент7 страницBck-777 Family BackgrounderFikri RahimОценок пока нет

- Gantz ChartДокумент2 страницыGantz ChartFikri RahimОценок пока нет

- TECHNICAL REPORT - FahmiДокумент14 страницTECHNICAL REPORT - FahmiFikri RahimОценок пока нет

- Ergonomics in Welding ShopДокумент6 страницErgonomics in Welding ShopFikri RahimОценок пока нет

- MSD ErgoДокумент4 страницыMSD ErgoFikri RahimОценок пока нет

- World Class ManufacturingДокумент6 страницWorld Class ManufacturingFikri RahimОценок пока нет

- E205 PDFДокумент24 страницыE205 PDFFikri RahimОценок пока нет

- Welding Safety31650 PDFДокумент21 страницаWelding Safety31650 PDFFikri RahimОценок пока нет

- Design Check FiguresДокумент1 страницаDesign Check FiguresFikri RahimОценок пока нет

- 10 Hussien and MutasherДокумент23 страницы10 Hussien and MutasherFikri RahimОценок пока нет

- MET2013 Clays JohnДокумент48 страницMET2013 Clays JohnFikri RahimОценок пока нет

- Sept. 18, 1923. - Bicycle Stand: Original Filed April 16 - 1921'Документ3 страницыSept. 18, 1923. - Bicycle Stand: Original Filed April 16 - 1921'Fikri RahimОценок пока нет

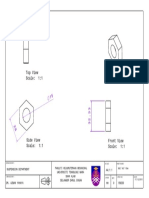

- Isometric View Scale: 1:1 Top View Scale: 1:1Документ1 страницаIsometric View Scale: 1:1 Top View Scale: 1:1Fikri RahimОценок пока нет

- Isometric View Scale: 1:1 Top View Scale: 1:1Документ1 страницаIsometric View Scale: 1:1 Top View Scale: 1:1Fikri RahimОценок пока нет

- TMTДокумент44 страницыTMTShilpa Singhal100% (2)

- Lecture 4 Ferrous MetalДокумент39 страницLecture 4 Ferrous MetalRafeeq AhmadОценок пока нет

- Astm F 4 - 66 R99Документ2 страницыAstm F 4 - 66 R99phaindikaОценок пока нет

- Index of Material Specs PDFДокумент6 страницIndex of Material Specs PDFAndres Fitria FarrelОценок пока нет

- Stainless Steels An Introduction and Their Recent DevelopmentsqqwДокумент11 страницStainless Steels An Introduction and Their Recent Developmentsqqwaghosh704100% (2)

- Alloy Steel Incl Ball Bearing MTD16 (13325) W - 07122018Документ7 страницAlloy Steel Incl Ball Bearing MTD16 (13325) W - 07122018vipin51Оценок пока нет

- P460NHДокумент3 страницыP460NHDanijel RadenkovicОценок пока нет

- Carbon Steel HandbookДокумент138 страницCarbon Steel HandbookRajul SaxenaОценок пока нет

- ASTM A193A193M - Jtvo9242Документ13 страницASTM A193A193M - Jtvo9242Nayth Andres GalazОценок пока нет

- Norsok M 121 AluminiumДокумент17 страницNorsok M 121 Aluminiumale_f_79Оценок пока нет

- Astm A 1008-A 1008M-04Документ7 страницAstm A 1008-A 1008M-04NilüferKarayel0% (1)

- Cqi-9 Heat Threatment DetailsДокумент34 страницыCqi-9 Heat Threatment DetailshaydarkasnaklarОценок пока нет

- VCMO140Документ3 страницыVCMO140samsul hudaОценок пока нет

- Ochsenkopf Oferta Firmy OchsenkopfДокумент28 страницOchsenkopf Oferta Firmy OchsenkopftunznathОценок пока нет

- Alloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Документ1 страницаAlloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Bouchra SonsuzaОценок пока нет

- Asme Section II A Sa-29 Sa-29mДокумент26 страницAsme Section II A Sa-29 Sa-29mAnonymous GhPzn1xОценок пока нет

- Phosphor Bronze Rod, Bar, and Shapes: Standard Specification ForДокумент5 страницPhosphor Bronze Rod, Bar, and Shapes: Standard Specification FormahfuzОценок пока нет

- Metallurigcal Examinaiton of The Armour of A Panther TankДокумент17 страницMetallurigcal Examinaiton of The Armour of A Panther Tankcjnjr1Оценок пока нет

- Aws CwiДокумент102 страницыAws CwiAziz Rana100% (2)

- API 571 Exercises, Rev2Документ11 страницAPI 571 Exercises, Rev2ariyamanjula2914100% (4)

- Al 1Документ13 страницAl 1Abhijith GajjagowniОценок пока нет

- TALAT Lecture 5103: Corrosion Control of Aluminium - Forms of Corrosion and PreventionДокумент20 страницTALAT Lecture 5103: Corrosion Control of Aluminium - Forms of Corrosion and PreventionCORE MaterialsОценок пока нет

- Astm 514Документ3 страницыAstm 514alexissalazarОценок пока нет

- Self-Drilling Screws: Key BenefitsДокумент8 страницSelf-Drilling Screws: Key BenefitsGabriel MacedoОценок пока нет

- As 2809.2-2008Документ37 страницAs 2809.2-2008TPОценок пока нет

- Tempering MartensiteДокумент21 страницаTempering Martensitejardel de matosОценок пока нет

- Dillinger Dillimax Dillidur BrochureДокумент12 страницDillinger Dillimax Dillidur BrochureVictorОценок пока нет

- Cutting HardoxДокумент20 страницCutting HardoxapОценок пока нет

- FAB 91 Final PDFДокумент491 страницаFAB 91 Final PDFVijayan MunuswamyОценок пока нет

- Sa 105 PDFДокумент10 страницSa 105 PDFkumarОценок пока нет