Академический Документы

Профессиональный Документы

Культура Документы

KNS 3621 Lab 6 Lab Manual

Загружено:

Anonymous 7oXNA46xiNАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

KNS 3621 Lab 6 Lab Manual

Загружено:

Anonymous 7oXNA46xiNАвторское право:

Доступные форматы

UNIVERSITI MALAYSIA SARAWAK

FACULTY OF ENGINEERING

CIVIL ENGINEERING DEPARTMENT

KNS 3621

CIVIL ENGINEERING LABORATORY 6

LABORATORY MANUAL

(Edited : December 2009)

CIVIL ENGINEERING LABORATORY 6

KNS 3621

LABORATORY MANUAL

CONTRIBUTED BY :

Jethro Henry Adam

Law Puong Ling

Wan Hashim Wan Ibrahim

Zamri Bujang

Mohamad Raduan Kabit

PREPARED BY :

Jethro Henry Adam

TABLE OF CONTENT

Lab Code

Title

Page

W1

Suspended Solids

W2

pH, Acidity & Alkalinity

W3

Biochemical Oxygen Demand

11

W4

Chemical Oxygen Demand

15

W5

Coagulation & Flocculation

18

T1

Spot Speed Study

21

T2

Traffic Volume

26

Safety First

29

Guidelines for Laboratory Report

30

Floc Size Chart

32

Survey Form for Volume Study at an Intersection

33

Appendix

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

TITLE :

W1 Suspended Solids

THEORY :

Solids refer to matter suspended or dissolved in water or wastewater. Solids content

are one of the major physical characteristics of water or wastewater. Knowing the

solids content of the water, we can determine the type, characteristics and source of

the water.

Solids may affect water or effluent quality adversely in a number of ways. Waters

with high dissolved solids generally are of inferior palatability and may induce an

unfavorable physiological reaction in transient consumer. Waters high in suspended

solids may be esthetically unsatisfactory.

Solids analyses are important in the control of biological and physical wastewater

treatment processes and for assessing compliance with regulatory wastewater effluent

limitations.

OBJECTIVE :

To determine and differentiate solids characteristics such as suspended solids, total

solids and volatile suspended solids in wastewater sample.

APPARATUS :

a) Evaporating dishes

b) Muffle furnace (for operation at 550 oC)

c) Drying oven (for operation 103 105 oC)

d) Analytical balance (to 0.1 mg)

e) Dessicator

f) Graduated cylinder

g) Beaker

h) Glass-fiber filter papers

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

PROCEDURE :

Preparation

1. Mark 2 CF/C (glass-fibber) filter papers as A and B.

2. Wash evaporating dish with distilled water.

3. Dry filter papers and evaporating dish in oven at 105 oC for 1 hour.

4. Remove filter papers and evaporating dish from the oven after 1 hour.

5. Store and cool filter paper marked A and evaporating dish in dessicator.

Meanwhile place filter paper marked B into muffle furnace at 550 + 5 oC for 4

minutes. Later, store it in dessicator.

6. Weigh immediately before use and record the empty filter paper (X) and empty

evaporating dish (D).

A) Suspended Solids (SS)

1. Put filter paper A on a filter cone.

2. Filters 20 ml of distilled water. Repeat the process 3 times to make sure that the

filter paper is clean.

3. Filter 100 ml of effluent water sample.

4. Take out the filter paper and place it in evaporating dish.

5. Dry at 103 105 oC until it is completely dry (until weight change is less than 4%

or 0.5 mg; normally about 1 hour in the oven).

6. Cool in dessicator and weight the filter paper and residue (Y).

7. Record the following :

Suspended Solids, SS (mg/l) =

Y X 1000

ml sample

where, X = weight of empty filter paper (mg)

Y = weight of filter paper + dried residue (mg)

8. Repeat the experiment and record the average value.

B) Volatile Suspended Solids (VSS)

1. Repeat procedure 1 7 in (A) using filter paper B.

2. Ignite the filter paper in the muffle furnace at 550 + 5 oC for 4 minutes

2

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

3. Cool at room temperature and then in dessicator.

4. Weight the filter paper and the residue (Z).

5. Record the followings :

Volatile Suspended Solids, VSS (mg/l) =

Fixed Suspended Solids, FSS (mg/l) =

Y Z 1000

ml sample

Z X 1000

ml sample

where, X = weight of empty filter paper (mg)

Y = weight of filter paper + dried residue before ignition (mg)

Z = weight of filter paper + dried residue after ignition (mg)

9. Repeat the experiment and record the average value.

C) Total Solids (TS)

1. Pour 100 ml sample into evaporating dish.

2. Evaporate to dryness on a steam bath or in a drying oven. When evaporating in a

drying oven, lower temperature to approximately 2 oC below boiling to prevent

splattering.

3. Dry evaporated sample for at least 1 hour in an oven at 103 105 oC until it is

completely dry (until weight change is less than 4% or 0.5 mg).

4. Cool the evaporating dish in dessicator and weight the dish and its residue (E).

5. Record the following :

Total Solids, TS (mg/l) =

E D 1000

ml sample

where, D = weight of empty evaporating dish (mg)

E = weight of evaporating dish + dried residue (mg)

10. Repeat the experiment and record the average value.

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

RESULT :

A) Suspended Solids (SS)

1

Average

Sample volume (ml)

Filter paper, X (mg)

Filter paper + dried residue, Y (mg)

Suspended solids, SS (mg/l)

B) Volatile Suspended Solids (VSS)

1

Average

Sample volume (ml)

Filter paper, X (mg)

Filter paper + dried residue before

ignition, Y (mg)

Filter paper + dried residue after

ignition, Y (mg)

Volatile suspended solids, VSS (mg/l)

Fixed suspended solids, FSS (mg/l)

C) Total Solids (TS)

1

Average

Sample volume (ml)

Evaporating dish, D (mg)

Evaporating dish + dried residue, E (mg)

Total solids, TS (mg/l)

DISCUSSION :

1) List down the standard values of solids content in wastewater.

2) Discuss the significant of the values in wastewater treatment.

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

TITLE :

W2 pH, Acidity & Alkalinity

THEORY :

Some of the major parameters of chemical characteristics of water are pH, acidity and

alkalinity. Measurement of pH is one of the most important and frequently used tests

in water chemistry. pH value gives indication whether the sample is acidic or alkaline.

Acidity of water is its quantitative capacity to react with a strong base to a designated

pH. Acidity is a measure of an aggregate property of water and can be interpreted in

terms of specific substances only when chemical composition of the sample is known.

Strong mineral acids, weak acids and hydrolyzing salts may contribute to the

measured acidity.

Alkalinity of water is its acid-neutralizing capacity. Alkalinity is a measure of

aggregate property of water and can be interpreted in terms of specific substances

only when the chemical composition of the sample is known.

OBJECTIVE :

To determine and compare pH, acidity and alkalinity values of water samples.

APPARATUS :

a) pH meter

h) Buffer solutions

b) Beakers

i) 0.02 N NaOH

c) Conical flasks

j) Methyl orange

d) Burette

k) Phenolphthalein

e) Graduated cylinder

f) Pipette

g) Distilled water

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

PROCEDURE :

A) pH

Calibration

1. Rinse the pH meter probe with distilled water and dry it.

2. Place the probe into pH 10 buffer solution and allow the pH reading to settle.

3. Adjust the pH meter until it gives pH 10 reading.

4. Take out the probe from the buffer solution. Rinse and dry the probe.

5. Place the probe into pH 4 buffer solution and allow the pH reading to settle.

6. Adjust the pH meter until it gives pH 4 reading.

7. The pH meter is now calibrated.

pH Reading

1. Turn on and calibrate your pH meter.

2. After rinsing the second calibration buffer off of the probe, submerge it in the

sample to be tested.

3. Swirl the container with sample in gently to ensure a constant supply of fresh

sample be in contact with the probe.

4. Allow enough time for the meters reading to stabilize.

5. When finished, give the probe one final rinse, and return the cap to it with fresh

storage solution.

6. Repeat the experiment with other water samples.

B) Acidity

Using result and samples from (A), determine which indicator to be used in the

titration :

pH 0 4.5 ~ methyl orange (colour change from red to yellow/orange)

pH 4.5 8.3 ~ phenolphthalein (colour change from colourless to pink)

1. Pipette 50 ml of sample into conical flask.

2. Add 0.2 ml (5 drops) of indicator into the flask.

3. Record the initial 0.02 N NaOH in the burette.

4. Titrate the sample and stop titration when the colour changes.

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

5. Record the final burette reading.

6. Repeat the experiment 2 times.

7. Calculate the acidity as mg/l CaCO3 :

Acidity (mg/l CaCO3) =

A N 50,000

ml sample

where, A = volume of NaOH tritrant used (ml)

N = normality of NaOH

C) Alkalinity

Using result and samples from (A), determine which titration to be used :

pH > 8.3 ~ two titration stages; first using phenolphthalein (pink to colourless)

and then methyl orange (red to yellow/orange)

pH 4.5 8.3 ~ single titration using methyl orange (red to yellow/orange)

1. Pipette 50 ml of sample into conical flask.

2. Add 0.2 ml (5 drops) of appropriate indicator into the flask.

3. If the pH of the sample is more than 8.3, follow the followings :i) Record the initial 0.02 N H2SO4 in the burette.

ii) Titrate using H2SO4 and phenolphthalein as indicator (pink to colourless).

iii) Record the final volume in the burette and repeat the experiment 2 times.

iii) Calculate the phenolphthalein alkalinity.

iv) To the same sample, add methyl orange indicator to find total alkalinity (colour

change from yellow/orange to red).

v) Record the final volume in the burette and repeat the experiment 2 times.

vi) Calculate the total alkalinity.

Phenolphthalein alkalinity, P (mg/l CaCO3) =

Total alkalinity, T (mg/l CaCO3) =

A N 50,000

ml sample

B N 50,000

ml sample

where, A = volume of H2SO4 tritrant used in the first titration (ml)

B = total volume of H2SO4 tritrant used (ml)

N = normality of H2SO4

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

4. If the pH of the sample is between 4.5 and 8.3, follow the followings :i) Record the initial 0.02 N H2SO4 in the burette.

ii) Titrate using H2SO4 and add methyl orange indicator to find total alkalinity

(colour change from yellow/orange to red).

iii) Record the final volume in the burette and repeat the experiment 2 times.

vi) Calculate the total alkalinity.

Total alkalinity, T (mg/l CaCO3) =

B N 50,000

ml sample

where, B = total volume of H2SO4 titrant used (ml)

N = normality of H2SO4

5. From Table W2 1 below, determine which forms of alkalinity are present.

Result of titration

Hydroxide

Alkalinity

(CaCO3)

Carbonate

Alkalinity

(CaCO3)

Bicarbonate

Concentration

(CaCO3)

P=0

P < T

P = T

P > T

P = T

0

0

0

2P T

T

0

2P

2P

2(T P)

0

T

T 2P

0

0

0

TABLE W2 1

RESULT :

A) pH

Sample

pH

A

1

2

Average

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

B) Acidity

Sample with pH 0 4.5

Sample

Burette

Reading

A

1

B

3

Initial

Final

Volume

Average

Sample with pH 4.5 8.3

Sample

Burette

Reading

A

1

B

3

Initial

Final

Volume

Average

C) Alkalinity

Sample with pH < 8.3

Sample

Burette

Reading

A

1

B

3

Initial

Final

Volume

Average

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

Sample with pH > 8.3

Sample

Burette

Reading

A

1

Initial

Final 1

Volume 1

Average 1

Final 2

Volume 2

Average 2

Calculate the acidity and alkalinity of the samples and record the results :

Sample

Parameters

A

pH

Acidity (mg/l CaCO3)

Alkalinity (mg/l CaCO3)

DISCUSSION :

1) Give comments on the results.

2) What are the significant of the parameters pH, acidity and alkalinity in water

treatment processes.

10

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

TITLE :

W3 Biochemical Oxygen Demand (BOD)

THEORY :

Biochemical Oxygen Demand (BOD) is a chemical procedure for determining how

fast biological organisms use up oxygen in water. It is used in water quality

assessment and could be considered as an indication of the quality of a water source.

The lower the Dissolved Oxygen (DO) value, the more polluted the water is.

The BOD testing is usually performed over a 5-day period at 20 Celsius. It measures

the molecular oxygen utilized during a specified incubation period for the

biochemical degradation of organic material (carbonaceous demand) and the oxygen

used to oxidize inorganic material (such as sulfides and ferrous iron). It also may

measure the amount of oxygen used to oxidize reduced forms of nitrogen (nitrogenous

demand) unless their oxidation is prevented by an incubator.

The BOD concentration in most wastewaters exceeds the concentration of dissolved

oxygen (DO) available in an air-saturated sample. Therefore, it is necessary to dilute

the sample before incubation to bring the oxygen demand and supply into appropriate

balance.

OBJECTIVE :

To use the Winkler titration method to determine the BOD value of water sample.

APPARATUS :

a) Beakers

g) BOD bottles

m) Sulfuric acid

b) Conical flasks

h) Reagent bottles

n) Manganous sulphate solution

c) Burette

i) Incubator

o) Alkali-iodide-azide reagent

d) Graduated cylinder

j) Distilled water

p) Concentrated sulfuric acid

e) Pipette

k) Dilution water

q) Natrium thiosulphate titrant

f) Volumetric flasks

l)

Starch solution

11

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

PROCEDURE :

A) Preparation of sample

1. Prepare 3 litre of dilution water by adding 1 ml of the following prepared

solutions per litre of distilled water : phosphate buffer, magnesium sulphate

(MgSO4), calcium chloride (CaCl2), ferric chloride (FeCl3), and aliltiourea (ATU).

2. Aerated the dilution water by shaking it in a partially filled bottle.

3. Label two 1 litre of volumetric flasks with sample and blank respectively. The

flask labeled blank is use as control to make sure that the dilution water used is

not polluted.

4. Transfer 200 ml of water sample into the flask labeled sample and add dilution

water until it reach the 1 litre level (this will gives a dilution 1/5 of the sample).

Shake the flask thoroughly.

5. To the blank flask, transfer 1 litre of dilution water.

6. Label 4 clean BOD bottles as 1 4.

7. Fill bottle 1 & 2 with solution from blank flask and bottle 3 & 4 with solution

from sample flask.

8. Cover the bottles carefully.

9. Determine the initial (day zero) dissolved oxygen value for solution in bottle 1 & 3

using Winkler titration method (Section B).

10. Incubate bottle 2 & 4 for 5 days + 1 hour at temperature 20 + 1 oC.

11. Determine the dissolved oxygen values of solutions in bottle 2 & 4 after 5 days.

B) Dissolve Oxygen (DO)

1. To the sample collected in a 250 300 ml reagent bottle, add 1 ml manganous

sulfate (MnSO4) solution, followed by 1 ml alkali-iodide-azide reagent. (If

pipettes are dipped into sample, rinse them using distilled water before returning

them to reagent bottles).

2. Stopper carefully to exclude air bubbles and mix by inverting bottle few times.

Allow to settle. Shake the bottle again and allow to settle.

3. When precipitate has settled sufficiently (to approximately half the bottle volume)

add 1 ml concentrated sulfuric acid.

12

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

4. Restopper and mix by inverting several times until dissolution is complete.

5. Transfer 100 ml of the solution into a 250 ml conical flask.

6. Titrate with 0.0125M natrium thiosulfate (Na2S2O3) solution to a pale straw

colour.

7. Add 5 drops of starch solution and continue titration to first disappearance of blue

colour.

8. Record the reading and repeat the titration process.

9. Calculation : 1 ml 0.0125M Na2S2O3 = 1 mg/l DO.

RESULT :

Sample type

: ______________________

Dilution ratio : ______________________

Day 0 Dissolved Oxygen

Sample

Burette Reading

Blank (Bottle 1)

(i)

(ii)

Sample (Bottle 3)

(i)

(ii)

Initial

Final

Volume

Average

DO (mg/l)

Day 5 Dissolved Oxygen

Sample

Burette Reading

Blank (Bottle 2)

(i)

(ii)

Sample (Bottle 4)

(i)

(ii)

Initial

Final

Volume

Average

DO (mg/l)

13

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

Calculate the BOD of the water sample :

BOD5 (mg/l) =

D1

D2

B1

B2 f

where, D1 = DO of diluted sample immediately after preparation (mg/l)

D2 = DO of diluted sample after 5 days incubation at 20 oC (mg/l)

B1 = DO of seeded blank just before incubation (mg/l)

B2 = DO of seeded blank after incubation (mg/l)

P = decimal volumetric fraction of sample used

f = ratio of seed in diluted sample to seed in seeded blank

DISCUSSION :

1) Why does aliltiourea (ATU) solution need to be add while preparing the sample?

2) Simply discuss the factors that affect the BOD value in the experiment.

3) Comment on the BOD value obtains from the experiment.

14

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

TITLE :

W4 Chemical Oxygen Demand

THEORY :

Chemical oxygen demand (COD) is defined as the amount of a specified oxidant that

reacts with the sample under controlled conditions. The basis for the COD test is that

nearly all organic compounds can be fully oxidized to carbon dioxide with a strong

oxidizing agent under acidic conditions. The quantity of oxidant consumed is

expressed in terms of its oxygen equivalence.

COD test measures the oxidation of organic matters that can be degraded both

biologically and non-biologically. This is why the COD value is higher than BOD5

value.

OBJECTIVE :

To determine COD value of water sample using open reflux method.

APPARATUS :

a) Reflux apparatus

l) Ferroin indicator solution

b) Beakers

m) Concentrate sulphuric acid containing

c) Conical flasks

d) Burette

e) Graduated cylinder

f) Pipette

g) Distilled water

argentum sulphate

n) Standard potassium dichromate

solution, 0.04167 M

o) Standard ferrous ammonium sulphate

titrant, (approximately 0.25 M)

h) Analytical balance (to 0.1 mg)

i) Glass rod

j) Mercuric sulphate crystals/powder

k) Glass beads

15

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

PROCEDURE :

Reflux of Water Sample

1. Pour 50 ml distilled water into refluxing flask A and 50 ml water sample into

refluxing flask B.

2. Add 1 g mercuric sulphate (HgSO4), 3 4 glass beads into each flask.

3. Very slowly, add 5 ml sulphuric acid (H2SO4) reagent containing argentum

sulphate (Ag2SO4) to each flask and mix well to dissolve HgSO4.

4. Add 25 ml 0.04167 M potassium dichromate (K2Cr2O7) solution to each flask and

mix well.

5. Very slowly, add the remaining 70 ml H2SO4 and continue swirling and mixing

while adding the acid.

Caution : Mix reflux mixture thoroughly before applying heat to prevent local

heating of flask bottom and a possible blowout of flask contents.

6. Attach both flasks to condenser and reflux for 2 hours.

7. After 2 hours, off the switch and let the flasks cool down.

8. Disconnect the flasks from the condenser and let them cool down in the sink.

9. Pour the reflux into a 500 ml conical flask and add distilled water until 350 ml.

Note : Make sure all reflux is poured well by rinsing the refluxing flask with

distilled water few times. Make sure that there are no glass beads being

poured into the conical flask.

10. Titrate with ferrous ammonium sulphate (Fe(NH4)2(SO4)2) titrant using 2-3 drops

ferroin indicator (the colour changes from yellow to blue-green to reddish brown).

Caution : Very careful with the titration as the colour changes very fast. Take as

the end point of titration the first sharp colour change from blue-green

to reddish brown that persists for 1 minute or longer).

Molarity of Fe(NH4)2(SO4)2, FAS titrant

1. Pour 25 ml of 0.04167M K2Cr2O7 solution into 250 ml conical flask.

2. Add distilled water to 100 ml.

3. Add 30 ml concentrated H2SO4 and let it cool.

4. Titrate with Fe(NH4)2(SO4)2 titrant (FAS) using 2-3 drops of ferroin indicator.

16

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

5. Calculate the molarity of FAS solution :

Molarity of FAS, M =

K 0.25

F

where, K = volume of 0.04167M K2Cr2O7 solution titrated (ml)

F = volume of FAS used in titration (ml)

RESULT :

Molarity of Fe(NH4)2(SO4)2, FAS titrant

Volume of 0.04167M K2Cr2O7 solution : ___________________ ml

FAS titrant

Burette Reading (ml)

Molarity (M)

Initial

Final

Volume

Initial

FAS titrant volume (ml)

Final

Volume

COD Calculation

Sample

Blank (Flask A)

Water sample (Flask B)

Calculate the COD value of the water sample :

COD (mg/l) =

A B M 8000

ml sample

where, A = volume of FAS used for blank (ml)

B = volume of FAS used for sample (ml)

M = molarity of FAS

DISCUSSION :

1) What are the advantages and disadvantages of COD testing compared to BOD.

2) Comment on the COD value obtains from the experiment.

3) Find the ratio of BOD5 and COD values of this experiment with W3 and give your

comments.

17

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

TITLE :

W5 Coagulation & Flocculation

THEORY :

Fresh water need to undergo few stages of treatment processes before being

distributed for consumption. One of the processes is sedimentation that removes

suspended solids from the water by gravity settling. During the sedimentation process

the greater portion of suspended solids settle out leaving the clear solution which

contains a relatively small quantity of fine suspended particles. Coagulation and

flocculation processes remove these finely divided particles that would otherwise

remain in the effluent. Coagulation of a colloidal suspension results in the joining of

minute particles by physical or chemical means. Flocculation results in the formation

of a larger, settleable structure by bridging. Mechanical flocculation requires gentle

circulation of the particles to provide good contact and good growth of floc. Addition

of chemical reagent (coagulant) will speed up the process and improve product quality

Coagulation and flocculation tests which also commonly called jar tests will indicate

the optimum coagulant dosages for removal of turbidity and colour, including pH

adjustment. They also yield information on the rate of agglomeration as a function of

energy input, settleability of the particular floc formed and the clarity of the

supernatant.

OBJECTIVE :

To determine the optimum dose of coagulant using jar test method.

APPARATUS :

a) Jar tester apparatus

e) Analytical balance

i) Distilled water

b) Burette

f) Magnetic stirrer

j) Alum stock solutions

c) Beakers

g) pH meter

k) Sulfuric acid

d) Pipette

h) Turbidimeter

l) Natrium hydroxide

18

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

Figure W5 1 Jar Tester

PROCEDURE :

1. Prepare alum stock solution by dissolving 2.5 g aluminum sulphate (Al(SO4)3 into

1000 ml of distilled water. Each 1.0 ml of this solution is equal to 5.0 ppm when

added to 500 ml of water sample.

2. Mark each of 6 one liter beakers as A to F.

3. Fill each beaker with 500 ml water sample.

4. Measure the initial pH and turbidity of the water sample.

5. Put each beaker on a magnetic stirrer and add alum solution according to the

dosage below :

Beaker

Dosage (ppm)

50

75

100

125

150

6. Fill in 2 different burettes with sulfuric acid (H2SO4) and natrium hydroxide

(NaOH) respectively for pH correction purpose.

7. Check pH of each beaker and slowly titrate either H2SO4 or NaOH to each beaker

so that the pH is fixed to 6.5.

8. Place the beakers in the jar tester and start the stirrers all on a fast speed of 100

rpm for 1 minute. This is to ensure the dispersion of the coagulant throughout the

sample.

19

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

9. Reduce the stirrer speed to 30 rpm to allow flocculation to take place.

10. Note the size and appearance of the floc formed (refer Appendix C).

11. Stop the stirring after 20 minutes and allow the floc to settle for 30 minutes.

12. Measure the depth of the sludge in each beaker.

13. Determine pH and turbidity of the supernatant (the clear liquid above the solids)

of each beaker; taking special care to collect the sample free from floating and

settled floc.

14. Plot graph of turbidity vs. coagulant dosage.

RESULT :

Water sample pH

: __________

Water sample turbidity : __________ NTU

Parameter

Alum dosage (ppm)

Beaker

A

0

B

25

C

50

D

75

E

100

F

125

Alum volume (ml)

Initial pH

Adjusted pH

Final pH

Floc size

Depth of sludge (mm)

Turbidity (NTU)

DISCUSSION :

1) What are other chemical or material that can be used as coagulant replacing alum?

2) What is the optimum dose of alum for this experiment?

3) Comment on your results.

4) Discuss other factors that need to be considered in coagulation and flocculation

processes.

20

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

TITLE :

T1 Spot Speed Study

THEORY :

Speed is an important transportation consideration, because highway users relate

speed to economics, safety, time, comfort, and convenience. Spot speed studies are

designed to measure speeds at specific locations under the traffic and environmental

conditions prevailing at the time of the study.

OBJECTIVE :

a) To be able to carry out spot speed study along a stretch of road.

b) To be able to carry out spot speed data analysis.

c) To determine speed characteristics along the stretch of road.

APPARATUS :

a) Radar Gun

b) Safety Vest

c) Clipboard

d) Pen

e) Stop Watch

PROCEDURE :

The successful of spot speed study is based on the position of the radar unit which

needs to address the following considerations:

a) Capabilities of the radar unit. The unit should be set up and calibrated

according to manufacturers specifications and instructions.

21

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

b) Minimizing the angle of incidence. The larger the angle of incidence between

the radar beam and the direction of travel of the target vehicle, the larger the

cosine error. An angle of less than 15 degrees keeps the error under 2 mph.

c) Concealing the unit from the view of motorists will avoid motorist distraction

(a safety concern) and reaction (a potential source of bias). The crew and

equipment may be concealed b vegetation or roadside structures.

Selection of target vehicles should be selected randomly that represent the population

of vehicles under study. Sufficient number of spot speed observations should be made

to allow statistical analysis to be carried out. A minimum sample size can be

determined for a desired degree of statistical accuracy by using equation (1) to

calculate the number of speeds to be measured.

N = (SK/E)2

(1)

where, N = minimum number of measured speeds

S = estimated sample standard deviation, mph

K = constant corresponding to the desired confidence level

E = permitted error in the average speed estimate, mph

Standard deviation can be estimated using previous speed studies under similar

conditions of study or from speed monitoring data at a nearby location. In the absence

of these data, Table T1 1 can be used as a basis of estimation. For greatest accuracy,

calculate the actual standard deviation of the data, and check to see if the sample size

was adequate. If not, additional data would have to be collected under the same

conditions as the first study.

Table T1 1 Standard Deviations of Spot Speeds for Sample-Size Determination

Traffic Areas

Rural

Intermediate

Urban

Highway Type

Two-lane

Four-lane

Two-lane

Four-lane

Two-lane

Four-lane

Rounded-Values

Average Standard Deviation

Mph

Kph

5.3

8.5

4.2

6.8

5.3

8.5

5.3

8.5

4.8

7.7

4.9

7.9

5.0

8.0

Source: Box and Oppenlander, 1976, p. 80

22

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

The constant K, corresponds to confidence-level values as shown in Table T1 2. In

this study use a confidence-level of 95%. The permitted error, E, reflects the precision

required in estimating the mean speed. Typical permitted errors range from 1.0 to

5.0 mph. In this lab, use E = 3.0

Table T1 2 Constant Corresponding to Level of Confidence

Constant, K

Confidence Level (%)

1.00

1.50

1.64

1.96

2.00

2.50

2.58

3.00

68.3

86.6

90.0

95.0

95.5

98.8

99.0

99.7

Source: Box and Oppenlander, 1976, p. 81

RESULTS / ANALYSIS :

1) Prepare a speed data as shown in Table T1 3.

2) Prepare a frequency Distribution Table T1 4.

3) Plot a frequency distribution curve.

4) Plot a cumulative distribution curve.

5) Determine the mean speed using equation (2).

f i ui

... (2)

fi

6) Determine standard deviation using equation (3).

f i ui

s

f i ui

fi

fi 1

... (3)

7) Calculate the following :(a) 85th percentile speed, P85. Discuss the use of the 85th percentile speed in traffic

engineering.

23

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

(b) 50th percentile speed, P50.

(c) Time mean speed.

(d) Pace, i.e. the specified increment of spot speed, usually 10 mph, which

includes the greatest number of speed measurements.

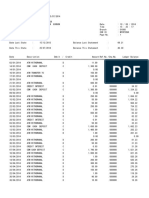

Table T1 3 Speed Data Obtained from the Study

Car No.

Speed (kph)

Car No.

Speed (kph)

Car No.

Speed (kph)

24

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

Table T1 4 Frequency Distribution Table

Speed

Class

(kph)

Class

Midvalue,

ui

Class

Frequency,

fi

fiui

Percentage

Cumulative

of

percentage

Observations

of all

in Class

observations

25

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

TITLE :

T2 Traffic Volume

THEORY :

Engineers often use counts of the number of vehicles or pedestrians passing a point,

entering an intersection, or using a particular facility. Road and transportation

authorities use extensive amount of traffic volume in their decision making processes

in order to improve the current status of transportation facilities. Thus, in this

laboratory, the proper way of carrying out traffic volume study is being explained.

OBJECTIVE :

a) To demonstrate the procedure to carry out traffic volume study.

b) To carry out vehicle classification based on Malaysian Traffic Condition.

c) To be able to carry out traffic volume analysis.

APPARATUS :

a) Stop watches

b) Survey Form (Appendix I)

c) Pen

d) Safety Vest

e) Clipboard

26

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

PROCEDURE :

1. Select a group which consists of six members.

2. Select a intersection to carry out the study.

3. Check Checklist

Ensure that all stop watches are set at the same time.

Ensure that the survey forms are adequate

Ensure number of pens are adequate

Use Enough Clipboard

Bring along an authorization letter from the relevant agency (In this lab, an

authorization letter from the Dean is sufficient).

Ensure that all members of the team have the name and phone number of

supervisor at site.

4. Review the purpose and type of count to be performed.

5. Review time period and time interval required.

6. Fill in header information as detail as possible.

7. Observers location

a) Able to view traffic clearly

b) Wear proper dressing and safety vest

8. Data recording

a) Data should be kept properly and organized

b) Labeled data correctly

c) Labeled forms correctly: count location, observers name, time of study,

weather condition

d) State clearly vehicle movements, classification, time intervals

e) Use the following vehicle classifications as in Table T2 1:

Table T2 1 Vehicle Classifications

Vehicle Class

1

2

3

4

5

Vehicle Type

Passenger Cars

Motorcycles

Trailers

Lorry

Busses

27

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

f) Sketch The Site by providing complete information

9. Data Reduction : converting tally marks into numbers, summarizing data by

calculating subtotals and totals, arranging the data to enable analysis being

conducted efficiently.

10. Data Analysis : Carried out once data reduction is completed.

11. Count period : Should be representative of the time of the day, day of the week, or

month of the year. However, in this lab session, the count period should be three

hours. Ensure that each person in the group start counting at the same time.

12. Time Interval : Every Fifteen minutes.

13. Protect yourself from the weather.

RESULT / ANALYSIS :

1) Analyse your data using graphical forms, bar chart, graphs and summary tables.

2) Identify Peak Hour Volume in vehicle per hour.

3) Identify Peak Hour Volume in PCU (Use PCE equivalent as in Table T2 2).

4) Calculate the Peak Hour Factor (PHF).

PHF = Hourly Volume/ (4 x Peak 15-min Volume)

5) Calculate service Flow Rate for the intersection.

Service Flow rate = Hourly Volume/PHF

Table T2 2 PCE Factor (Arahan Teknik (Jalan) 8/86)

Type of Vehicle

Passenger car

Motorcycle

Light vans

Medium lorries

Heavy lorries

Rural

1.00

1.00

2.00

2.50

3.00

Urban

1.00

0.75

2.00

2.50

3.00

Traffic Signal

1.00

0.33

2.00

1.75

2.25

28

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

APPENDIX A

SAFETY FIRST

Follow all instructions carefully.

Appropriate clothing must be worn in the lab. No loose clothing or jewelry around

operating equipment. Do not wear open toe shoes or sandal in operating

laboratories.

Do not operate equipment or carry on experiments unless the instructor/technician

is present in the laboratory.

Assure that necessary safety equipment is readily available and in usable

condition.

Become familiar with safety precautions and emergency procedures before

undertaking any laboratory work.

All injuries, no matter how small, must be reported.

29

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

APPENDIX B

GUIDELINES

All laboratory works should be conducted within the period given.

The laboratory rules and regulations apply throughout the lab sessions.

Lab report should be submitted ONE (1) WEEK after every lab session.

Each lab group is to submit only ONE (1) report per lab session (GROUP

SUBMISSION).

Attendance for every lab session is COMPULSORY. No mark will be given to

any report(s) submitted without attending the lab session(s).

Reports must be written in the following format :

Formatting guidelines

Font type & size : Times new roman, 12

Spacing

: 1.5 spacing

Margin

: left (1.5), right (1.25), top (1) and

bottom (1)

Front Cover

: See below

Tape binding

Content guidelines

Cover page

Table of content

Lab code & title of experiment

Theory / Introduction

Objectives

Procedure

Your own word!

Do NOT copy/scan

from the lab manual!!!!!

Result

Discussion

Conclusion &/ recommendation

References

30

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

Cover page format

31

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

APPENDIX C

FLOC SIZE CHART

32

Sheet No. :

Weather :

VEHICLE CLASSIFICATION

...

TIME

Client :

VEHICLE CLASSIFICATION

..

..

...

And :

Date :

Day :

VEHICLE CLASSIFICATION

Project :

..

Intersection of : .

Observer :

VEHICLE CLASSIFICATION

..

..

..

..

KNS 3621 Civil Engineering Laboratory 6

Faculty of Engineering

Universiti Malaysia Sarawak

APPENDIX D

SURVEY FORM FOR VOLUME STUDY AT AN INTERSECTION

33

Вам также может понравиться

- 10Документ2 страницы10Anonymous 7oXNA46xiNОценок пока нет

- Tutorial Lateral Earth Pressure: Coulomb's Method: Prepared By: Dr. Hjh. Siti Noor Linda Bt. Hj. TaibДокумент9 страницTutorial Lateral Earth Pressure: Coulomb's Method: Prepared By: Dr. Hjh. Siti Noor Linda Bt. Hj. TaibAnonymous 7oXNA46xiNОценок пока нет

- 8Документ2 страницы8Anonymous 7oXNA46xiNОценок пока нет

- Geotechnical Engineering Geotechnical Engineering KNS 2163Документ31 страницаGeotechnical Engineering Geotechnical Engineering KNS 2163Anonymous 7oXNA46xiNОценок пока нет

- Lecture 7 2012Документ62 страницыLecture 7 2012Anonymous 7oXNA46xiNОценок пока нет

- OP Issued: Luxury Living in Petra JayaДокумент4 страницыOP Issued: Luxury Living in Petra JayaAnonymous 7oXNA46xiNОценок пока нет

- Lect1 KNS2163 Slope Updated2103Документ60 страницLect1 KNS2163 Slope Updated2103Anonymous 7oXNA46xiNОценок пока нет

- Cpt2-1 Idealization of Load S1 0910Документ14 страницCpt2-1 Idealization of Load S1 0910Anonymous 7oXNA46xiNОценок пока нет

- Vol.1 Borelog RecordДокумент307 страницVol.1 Borelog RecordAnonymous 7oXNA46xiNОценок пока нет

- Tutorial Retaining WallДокумент14 страницTutorial Retaining WallAnonymous 7oXNA46xiNОценок пока нет

- Cpt2-2 Idealization of Load S1-0910Документ19 страницCpt2-2 Idealization of Load S1-0910Anonymous 7oXNA46xiNОценок пока нет

- Structural Analysis: R. C. HibbelerДокумент14 страницStructural Analysis: R. C. HibbelerAnonymous 7oXNA46xiNОценок пока нет

- Its Me... BOND..JAMES BONDДокумент1 страницаIts Me... BOND..JAMES BONDAnonymous 7oXNA46xiNОценок пока нет

- Cover Lab Students ReportДокумент1 страницаCover Lab Students ReportAnonymous 7oXNA46xiNОценок пока нет

- Kns2133 Course Plan 21112Документ2 страницыKns2133 Course Plan 21112Anonymous 7oXNA46xiNОценок пока нет

- Disahkan Benar: TarikhДокумент7 страницDisahkan Benar: TarikhAnonymous 7oXNA46xiNОценок пока нет

- Result & Calculation:: D 1 D 2) (B1 B 2) PДокумент1 страницаResult & Calculation:: D 1 D 2) (B1 B 2) PAnonymous 7oXNA46xiNОценок пока нет

- Slot: Tuesday, 2 P.M. - 3.50 P.M & Wednesday, 12 Noon. - 1.50 P.M Lab: Traffic & Water & Wastewater EngineeringДокумент2 страницыSlot: Tuesday, 2 P.M. - 3.50 P.M & Wednesday, 12 Noon. - 1.50 P.M Lab: Traffic & Water & Wastewater EngineeringAnonymous 7oXNA46xiNОценок пока нет

- Assignments 2 N 3Документ1 страницаAssignments 2 N 3Anonymous 7oXNA46xiNОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Mounting BearingДокумент4 страницыMounting Bearingoka100% (1)

- RCC Design of Toe-Slab: Input DataДокумент2 страницыRCC Design of Toe-Slab: Input DataAnkitaОценок пока нет

- Bank Statement SampleДокумент6 страницBank Statement SampleRovern Keith Oro CuencaОценок пока нет

- Algorithm - WikipediaДокумент34 страницыAlgorithm - WikipediaGilbertОценок пока нет

- Mercury 150HPДокумент5 страницMercury 150HP이영석0% (1)

- Jetweigh BrochureДокумент7 страницJetweigh BrochureYudi ErwantaОценок пока нет

- Final Project Report GMS BtechДокумент68 страницFinal Project Report GMS Btech02Musaib Ul FayazОценок пока нет

- Microeconomics: Production, Cost Minimisation, Profit MaximisationДокумент19 страницMicroeconomics: Production, Cost Minimisation, Profit Maximisationhishamsauk50% (2)

- 950 MW Coal Fired Power Plant DesignДокумент78 страниц950 MW Coal Fired Power Plant DesignJohn Paul Coñge Ramos0% (1)

- (ACYFAR2) Toribio Critique Paper K36.editedДокумент12 страниц(ACYFAR2) Toribio Critique Paper K36.editedHannah Jane ToribioОценок пока нет

- WHO Partograph Study Lancet 1994Документ6 страницWHO Partograph Study Lancet 1994Dewi PradnyaОценок пока нет

- Reference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsДокумент43 страницыReference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsNisha JosephОценок пока нет

- Floor Paln ModelДокумент15 страницFloor Paln ModelSaurav RanjanОценок пока нет

- Stock Prediction SynopsisДокумент3 страницыStock Prediction SynopsisPiyushPurohitОценок пока нет

- The "Solid Mount": Installation InstructionsДокумент1 страницаThe "Solid Mount": Installation InstructionsCraig MathenyОценок пока нет

- ArpitResumeISM PDFДокумент1 страницаArpitResumeISM PDFchethan rОценок пока нет

- Service Manual Lumenis Pulse 30HДокумент99 страницService Manual Lumenis Pulse 30HNodir AkhundjanovОценок пока нет

- Steam Source Book PDFДокумент108 страницSteam Source Book PDFJose Levican A100% (1)

- 6 AsianregionalismДокумент32 страницы6 AsianregionalismChandria Ford100% (1)

- Huawei Core Roadmap TRM10 Dec 14 2011 FinalДокумент70 страницHuawei Core Roadmap TRM10 Dec 14 2011 Finalfirasibraheem100% (1)

- Creative Thinking (2) : Dr. Sarah Elsayed ElshazlyДокумент38 страницCreative Thinking (2) : Dr. Sarah Elsayed ElshazlyNehal AbdellatifОценок пока нет

- BMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Документ9 страницBMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Siva MohanОценок пока нет

- Accounting II SyllabusДокумент4 страницыAccounting II SyllabusRyan Busch100% (2)

- (ENG) Visual Logic Robot ProgrammingДокумент261 страница(ENG) Visual Logic Robot ProgrammingAbel Chaiña Gonzales100% (1)

- Project Management: Chapter-2Документ26 страницProject Management: Chapter-2Juned BhavayaОценок пока нет

- Quality in CRДокумент10 страницQuality in CRkaushikcrОценок пока нет

- Management in English Language Teaching SummaryДокумент2 страницыManagement in English Language Teaching SummaryCarolina Lara50% (2)

- The Concept of ElasticityДокумент19 страницThe Concept of ElasticityVienRiveraОценок пока нет

- Bba Colleges in IndiaДокумент7 страницBba Colleges in IndiaSumit GuptaОценок пока нет

- YeetДокумент8 страницYeetBeLoopersОценок пока нет