Академический Документы

Профессиональный Документы

Культура Документы

RAZ

Загружено:

Mathivanan AnbazhaganАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RAZ

Загружено:

Mathivanan AnbazhaganАвторское право:

Доступные форматы

ENGINEERS STAMP:

CONTRACTORS STAMP:

Issue for Tender

Spanier

Drschticka

Laukemann

Dec 2009

Issue for Draft Tender

Spanier

Drschticka

Laukemann

23.10.2009

PREPARED

CHECKED

APPROVED

DATE

REV

DESCRIPTION

KINGDOM OF SAUDI ARABIA

SALINE WATER CONVERSION CORPORATION

RAS AZ ZAWR POWER AND DESALINATION PLANT-PHASE 1

FICHTNER GMBH & CO. KG

PACKAGE P POWER PLANT

TENDER DOCUMENTS

LOCATION:

TITLE:

East Coast

Volume IX: Part P-B13

INSTRUMENTATION AND CONTROL SYSTEM

PACKAGE:

P Power Plant

SCALE:

DOCUMENT No.:

None

SUBCONTRACTOR:

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

REV:

0

Sheet 1 of 178

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

VOLUME IX: Part P-B13

Instrumentation and Control System

Doc No.:

Page 2 of 178

Rev. 0

List of Contents

1. Control, Instrumentation and Monitoring Systems

1.1

General

1.2

Operation and control philosophy

8

8

12

1.2.1

General

12

1.2.2

Control centers

13

1.2.3

Operation of the main units

15

1.2.3.1

Degree of automation of the main process plants

15

1.2.3.2

Gas turbines generators

16

1.2.3.3

Heat Recovery Steam Generators

16

1.2.3.4

Steam turbine generator(s)

17

1.2.3.5

Common services systems

17

1.2.3.6

Electrical distribution system

18

1.2.3.7

Desalination units (Package D)

18

1.3

Scope of supply and services

18

1.3.1

General

18

1.3.2

Scope of equipment

19

1.3.3

Spare capacity after completion of commissioning

30

1.3.4

Services

30

1.3.5

Erection, cabling, wiring, labeling

32

1.3.6

Commissioning, trial operation, and acceptance tests

33

1.3.7

Documentation

34

1.3.8

Training

34

1.3.9

Special tools and spare parts

34

1.4

Particular Technical requirements

35

1.4.1

General

35

1.4.2

Structure of control functions

36

1.4.3

Field equipment

38

1.4.3.1

General

38

1.4.3.2

Settlement Metering Equipment

38

1.4.4

Distributed control system (DCS)

40

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 3 of 178

Rev. 0

1.4.4.1

General

40

1.4.4.2

Availability and redundancy

42

1.4.4.3

General hardware requirements

45

1.4.4.4

Software requirements

46

1.4.4.5

Process station

47

1.4.4.6

Data highway communication

58

1.4.4.7

Operator station

59

1.4.4.8

System diagnostics and configuration

69

1.4.4.9

Cyber Security

70

1.4.5

Task of the main control loops

71

1.4.5.1

Gas turbine generator unit control

72

1.4.5.2

Heat recovery steam generator unit control

73

1.4.5.3

STG unit control

75

1.4.5.4

LP and HP steam control valves (Scope of Package D)

77

1.4.5.5

Desalination unit control (Scope of Package D)

77

1.4.5.6

Plant master control

78

1.4.6

Signal exchange to other Control Centers

79

1.4.6.1

Signal exchange to the SEC SCADA system

80

1.4.6.2

Signal exchange with Maaden

80

1.4.6.3

Signal exchange with Fuel supplier (Saudi Aramco)

80

1.4.6.4

Signal exchange with SWCC headquarter

81

1.4.7

Burner management system (BMS) and Boiler protection system

(BPS)

81

1.4.7.1

Functional requirements

81

1.4.7.2

Design requirements

82

1.4.7.3

System architecture

82

1.4.7.4

Hardware requirements

83

1.4.7.5

Software requirements

83

1.4.8

Failure of the power supply shall not effect the built-in logic of the

BMS/BPS.Power supply

84

1.4.9

Plant Management System (PMS)

84

1.4.10

CCR equipment

86

1.4.11

Large screen projection panels (LSPP)

86

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

VOLUME IX: Part P-B13

Instrumentation and Control System

Doc No.:

Page 4 of 178

Rev. 0

1.4.12

Conventional fascia alarm system

87

1.4.13

Asset management system / field device tools (FTD)

89

1.5

Interfaces

89

1.6

Terminal points

92

1.7

Inspection and testing

92

2. Emission Monitoring System

93

2.1

General

93

2.2

Layout

93

2.3

Scope of Supply and Services

94

2.4

Particular Technical requirements

95

2.4.1

Exhaust gas Monitoring Stations

95

2.4.2

Effluent Monitoring

99

2.4.3

Cubicles and Measuring Containers

101

2.4.4

Data Acquisition/Storage/Evaluation/Visualization

101

2.4.5

Weather Station

105

2.4.6

Portable Noise Monitoring Equipment

105

2.5

Interfaces

106

2.6

Inspection and testing

106

3. Communication, Clock and Surveillance Systems

107

3.1

General

107

3.2

Scope of supply and services

107

3.2.1

General

107

3.2.2

Scope of supply

108

3.2.2.1

Telephone system

108

3.2.2.2

Portable radio system

109

3.2.2.3

Public address system

109

3.2.2.4

Process related CCTV surveillance system

110

3.2.2.5

Clock system

110

3.2.2.6

Office LAN/WAN system

110

3.2.2.7

Spare capacity after commissioning

111

3.2.2.8

Spare parts and special tools

111

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

VOLUME IX: Part P-B13

Instrumentation and Control System

Doc No.:

Page 5 of 178

Rev. 0

3.2.3

Scope of Services

112

3.2.3.1

General

112

3.2.3.2

Erection, cabling, wiring and labeling

113

3.2.3.3

Commissioning, trial operation and Acceptance tests

113

3.2.3.4

Documentation

114

3.2.3.5

Training

114

Technical requirements

114

3.3

3.3.1

General

114

3.3.2

Telephone system

115

3.3.2.1

General

115

3.3.2.2

Telephone system features

117

3.3.2.3

Interface requirements

120

3.3.2.4

Administration software and diagnostic facility

122

3.3.2.5

Signal tones

122

3.3.2.6

Subscriber facilities

122

3.3.2.7

Voice recording system

123

3.3.2.8

Telephone sets

124

3.3.2.9

Power supply equipment

126

3.3.3

Portable radio system

126

3.3.4

Public address system (PA system)

127

3.3.4.1

General

127

3.3.4.2

Central amplifier station

130

3.3.4.3

Master call stations

134

3.3.4.4

Indoor and outdoor call stations

134

3.3.4.5

Loudspeakers

135

3.3.5

Process related CCTV surveillance system

136

3.3.5.1

General

136

3.3.5.2

CCTV requirements

136

3.3.5.3

Cameras

139

3.3.5.4

Video system accessories

140

3.3.5.5

Interfaces to other systems

140

3.3.6

Clock system

141

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

VOLUME IX: Part P-B13

Instrumentation and Control System

Doc No.:

3.3.7

Office LAN/WAN system

Page 6 of 178

Rev. 0

142

3.4

Interfaces

143

3.5

Terminal points

143

3.6

Inspection and testing

144

4. Generator Rejection Scheme

145

4.1

General

145

4.2

Scope of supply

145

4.3

Functional requirements

146

4.4

Technical requirements

148

4.4.1

Security and Dependability

148

4.4.2

Trip Time Performance

149

4.4.3

Execution Modes

149

4.4.4

User Interface

149

4.4.5

Special Tools

149

4.4.6

Fault Monitoring System

149

5. Integrated Security System

150

5.1

General

150

5.2

Layout

150

5.3

Scope of Supply and Services

151

5.4

Technical Requirements

152

5.4.1

Additional requirements for Intrusion Detection & Assessment

System (IDAS)

153

5.4.2

Additional requirements for Access Control System (ACS)

153

5.4.2.1

Door monitoring

153

5.4.2.2

Administration building access control

154

5.4.2.3

Metal detector

154

5.4.2.4

Under-Vehicle Surveillance System

154

5.4.2.5

Raising arm barrier

155

5.4.2.6

Turnstiles

155

5.4.2.7

Barriers at the gate house

156

5.4.2.8

Design and function

157

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 7 of 178

Rev. 0

5.4.2.9

Equipment

157

5.4.2.10

Operation

158

5.4.2.11

Recorders

159

5.4.2.12

Cards

159

5.4.3

Additional requirements for Video Surveillance System (VSS)

159

5.4.3.1

CCTV monitoring and recording

160

5.4.3.2

Digital video recorders (DVR)

162

5.4.3.3

Monitors

162

5.4.3.4

Redundancies

163

5.4.4

Additional requirements for ID Management System (IDMS)

163

5.4.4.1

Integrated access control and badging system

163

5.4.4.2

Alarm and event recording

164

5.4.4.3

Database and other data requirements

165

5.4.5

General requirements

166

5.4.5.1

Additional requirements for the security systems integration

166

5.4.5.2

Additional requirements for the Security Control Center (SCC)

166

5.4.5.3

Transmission system

171

5.4.5.4

Security equipment tagging

173

5.4.5.5

Security equipment and devices

174

5.4.5.6

Expandability

175

5.4.5.7

System grounding and ventilation fans

175

5.4.5.8

Graphical location maps

175

5.4.5.9

Device overview

177

6. Annexes

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

178

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

VOLUME IX: Part P-B13

Instrumentation and Control System

Doc No.:

Page 8 of 178

Rev. 0

1. Control, Instrumentation and Monitoring Systems

This Part of the Specification covers the supply of the Control,

Instrumentation and Monitoring Systems (P-B13.1), Emission Monitoring

system (P-B13.2), Communication, clock and surveillance systems (PB13.3), Generator Rejection Scheme (P-B13.4) and the Integrated Security

System (P-B13.5) for the RAS AZ ZAWR Power Plant (Package P) and

interfaces to the Water Production Island (Package D).

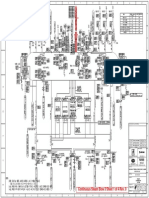

Typical overall DCS architecture is shown in Annex P-C13-1, wherein the

tie-in points to Water Production Island (Package D) are indicated.

The Tenderer shall show details of works involved and functions

achievable. The Tenderer shall submit in the Tender the program of work,

any outage requirements in order to minimize the unavailability of units

already in operation.

1.1

black box

General

The DCS will be applied as a total solution, providing the necessary control

and monitoring means for all main systems of the whole plant, including

also the Package D systems. Main systems are designated as systems

belonging to the main technological process and serving the main purpose

of the plant. The Human Machine Interface in the Central Control Room

with remote central operating and monitoring facilities will be uniform,

using DCS standard workstations. Workstations from proprietary systems

shall not be accepted.

One unified DCS system of the same make and type shall be provided for

the entire plant of Package P and Package D. The DCS system shall be

approved solution for combined cycle power and high pride desalination

plant. Make and type of the overall DCS shall be offered by the contractor

of Package P and the contractor of Package D shall provide the same

make and type of the DCS for all Package D units and equipment.

DCS manufacturer will be subject to SWCC prequalification.

DCS type will be selected upon the submittal at the time of engineering

phase and is subject to SWCC / Engineers approval.

All DCS hardware and software required for Package D units and

equipment will be within the scope of supply and services of the Contractor

of Package D. The integration of Package D part of the DCS into the

overall DCS as well as the coordination work and the merger of Package

D data base with Package P data base is under the scope of work of

Package P Contractor. The overall automation of the entire plant of

Package P and D as well as their operation and control by the Plant

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 9 of 178

Rev. 0

Master Controller (PMC) shall be within the scope of work of Package P

Contractor.

Alternative: Package D Bidder offers a DCS for Package D of different

make and type than the DCS supplied by Package P. In this case, the DCS

offered for Package D shall still fully comply with this Specification. The

interface between the two DCS systems shall be hardwired for all the

interlocks (for control) and protection signals and shall be well defined and

well coordinated by the Contractors of both Packages. Each Contractor of

both Packages shall provide the necessary hardware, such as modules and

interface devices as well as necessary software required for the interface

signals at his end. Cables and cabling work related to the interface signals

from the marshalling cabinets to the DCS cabinets as well as the internal

DCS cabinets wiring, marshalling cross-wiring and field connection of the

cables inside the marshalling cabinets is the responsibility of each Package

Contractor at his end.

Cables and cabling work related to the interface signals from the

marshalling cabinets of Package P to the marshalling cabinets of Package

D is within the scope of Package P. The overall coordination,

commissioning and operation of the interface signals are the responsibility

of Package P Contractor.

This Specification covers the supply of the control, instrumentation and

monitoring equipment for the new installations of RAS AZ ZAWR Power

Generation Island (Package P). This mainly includes those for the

elsewhere specified (Parts P-B1 through P-B8) gas turbine generators

(GTGs), heat recovery steam generator (HRSGs), steam turbine generator

(STG) and auxiliary systems. Over and above that, the control operation and

monitoring of the Water Production Island (Package D) shall be carried

out by means of an extension of the Power Generation Island DCS, as

described under Part D-B10 (Package D). Nevertheless, the

responsibility for the layout of the overall DCS of Power and Desalination

Plant (e.g. system architecture, spare capacities for common equipment and

common functions) shall remain within the hands of the Contractor for the

Power Island (Package P).

The control, instrumentation and monitoring equipment to be provided shall

be suitable for faultless and safe control and supervision of the entire Power

and Desalination Plant during all the operating conditions. All the supplied

control, instrumentation and monitoring equipment shall be suitable for their

installed location, and in particular, all outdoor equipment shall be suitable for

the specified ambient site conditions.

The Specification stipulates the minimum requirements for the design,

scope of supply of the required equipment and materials, fabrication,

inspection, testing and commissioning of the systems. The Contractor shall

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 10 of 178

Rev. 0

be responsible for the design of all hardware, software, interfaces to other

systems, system testing, documentation, delivery, installation, supervision

and field support for the systems as defined within this Specification.

All instrumentation and control works/ equipment not expressly called for

in this specification, but necessary at the discretion of the Engineer, for the

complete and proper installation and operation of the plant equipment and

accessories shall be performed and provided by the Contractor at no

additional cost to SWCC.

Make and type of PLC systems as well of the field instruments are subject for

approval of SWCC/ Engineer.

General design criteria for the instrumentation and control equipment are

stipulated in Part P-B03.

The Contractor shall adhere to the functional requirements, design criteria

and system configuration contained in this document. Where there is a

conflict between the requirements of the Specification and the Contractors

current standard system/technology, this shall be clearly defined in writing

as a deviation to the Specification. The Contractor may propose alternative

improved performance features as long as the system is made up of plant

proven hardware and software modules.

A general description and a layout of the Power and Desalination Plant are

included in Part P-A3.

The following explanation shall be considered as main aspects for the

technical concept of the Instrumentation & Control Systems. The plant

instrumentation and control equipment shall be selected and designed in

such a way that the operation as described below and the following

functions shall be performed for each power plant block and for the

desalination plant.

The concept shall take full advantage of the currently available integrated

control system technology to maximize plant performance and availability

as well as to achieve a cost-effective installation. To achieve this, the

control protective and supervisory functions required for the central

operation of all the plant facilities shall be implemented in a uniformed

Distributed Control System (DCS). But the DCS system should be

segregated at its automation level for the power plant blocks, common

systems and the desalination plants, such that each unit/system shall have its

own dedicated DCS process control station. This is required to achieve the

highest availability of the Plant. (see also Annex P-C13-1)

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 11 of 178

Rev. 0

Start-up, generator synchronization and loading of the GT units, the

HRSGs, ST, the demineralization plant and all auxiliary equipment from

the Central Control Room while using all the main full automatic start-up

and shut down sequence step and automatic function group programs

with one pushbutton operation for each unit of the power block.. Semiautomatic and manual modes shall also be provided for operator

selection.

Automatic start-up sequence will also be provided for all auxiliary

equipment in the plant.

Full automatic start-up and shutdown sequences will be provided for the

desalination units based on function group control. Minimum preparation

work which consists of filling of lines and establishment of the

recirculation system can be carried out locally and respectively by the

operator from the CCR operator stations prior to the full automatic

sequence.

Plant / Unit Master Controller-coordinated power plant block operation,

capable of handling unscheduled load changes as well as scheduled load

ramps.

Complete supervision of the whole plant, including the GTs, STs,

ROs, the thermal Desalination plant and auxiliary systems in the plant

Safe operation in case of Unit island/ house load operation

Automatic contribution to grid frequency control

Integration of the requirements of AGC (automatic generator control)

Safe shutdown of the units/ power plant block. Full automatic shutdown

sequences shall also be provided for all plant units and auxiliary

equipment including unloading, breaker opening and shutdown

The DCS system shall be applied as a homogeneous solution, providing the

necessary control means basically for the whole plant. However, depending

on the kind of the process hardware it should be allowed using package

controls for the gas turbines and for the control (governing) and protection

system of the steam turbines. In any case, the variety of the main control

systems in the Plant shall be limited to the minimum, i.e. the DCS type shall

follow either the type of the BPST/CEST or of the GTG control system. The

main controller of the GT, BPST/CEST, HRSG should be part of the DCS

and directly interfaced without gateways. This shall be a proven solution for

similar combined cycle power and desalination plants.

The BMS (Burner Management System) of HRSGs as a certified fail-safe

system shall be part of the DCS.

Interfacing with package control systems shall use standard interfaces and

protocols. However protection signals shall be connected hard-wired in

triple redundancy (e.g. 2 out of 3). Control signals shall be connected hardwired in dual redundancy. Emergency push buttons shall be provided for the

major plant equipment such as boiler, turbine and generator etc.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

VOLUME IX: Part P-B13

Instrumentation and Control System

Doc No.:

Page 12 of 178

Rev. 0

The Human Machine Interface in the Central Control Room shall be

uniform, using the same DCS standard workstations.

The use of black box systems with PLC's or local controls for ancillary

plants or systems is limited to secondary systems, i.e. systems which are not

affect the availability or the performance of the plant. The accepted black

box systems are mentioned in Part P-B03 clause 6.2. Only some special

cases can be considered subject to the Employer/Engineers approval. PLC

systems shall be of uniform type, compatible with the main DCS system and

shall be built single fault tolerant in all aspects. The application and the

manufacturer/type of these control systems shall be subject to

Employer/Engineer's approval.

The remote central operating and monitoring facilities will be installed in

the Central Control Room.

The Plant common auxiliary systems will be controlled by the DCS

workstations in the CCR, too.

The plant shall be interfaced with the LDC, with Saudi Aramco for Fuel

supply and metering and SWCC headquarter for limited amount of signals.

The plant shall be interfaced with Maaden for required amount of signals.

(see Annex P-C13-4)

1.2

1.2.1

Operation and control philosophy

General

The plant will be designed for base load operation, however, it shall be

possible to achieve a considerable turndown of power generation whilst

maintaining to full water production. This means, for the power and steam

generation units, in addition to base load operation, automatic start-up and

shut-down functions are also required for the on-line regulation of Power

and Desalination Plant.

Although part load operation of the desalination units will be infrequent, the

units shall be capable of unrestricted operation between 60% and 100%.

During the normal on-line operation of the plant, the main operatorfunctions, as carried out from the Central Control Room (CCR), shall be

those of supervision and selection of the appropriate pattern of running plant

to meet the electrical load and steam demand targets with optimum fuel

economy, generation and production security within any operational plant

constraints.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 13 of 178

Rev. 0

The essential plant operational management functions of starting up,

shutting down and load demand setting of the power and steam production

units shall remain directly under the operators control whilst the on line

regulation of the plant components (e.g. turbines, boilers, etc.) shall be fully

automated.

The automation shall meet the following objectives:

consistent start-up and shut-down of the plant under all operational

conditions;

to achieve minimum run up and loading times consistent with pre-set

thermal stress limits;

to meet the request of block control and plant master control

to meet plant output demand set by the load dispatcher;

to minimize fuel consumption during start-up, shut-down and normal online operational cycle;

to maximize plant life expectancy;

to simplify operation

The essential common plant systems (e.g. boiler feed, fuel, cooling water,

etc.) shall be automated to leave the overall control co-ordination of these

areas in the hands of the operator to ensure maximum flexibility of

operation.

The control system shall be designed so, that the plant can be safely

operated with a minimum number of operators.

A plant management system (PMS) shall allow access to all information of

the DCS and other related control, diagnostic and monitoring systems for

the shift supervisor, management like superintendent and operators.

1.2.2

Control centers

The control system shall be so designed, that full control and supervision of

the complete Power and Desalination Plant (power/ steam generation and

water production) shall be possible from a main CCR. The CCR shall be the

operational focus for the whole Power and Desalination Plant from where

all major plant items such as the GTGs, HRSGs, supplementary firing, STG,

thermal desalination units, RO and auxiliary systems like gas reducing

stations, feedwater, fuel oil system, electrical system etc. shall be capable of

being started, on-line regulated and shut-down.

The design, engineering and layout of the whole Central Control Room,

including the portion delivered by Package D with operator workstations,

printers and large screen device shall be carried out in the Package P

scope and shall be sub-contracted to a specialized company, which shall

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

VOLUME IX: Part P-B13

Instrumentation and Control System

Doc No.:

Page 14 of 178

Rev. 0

make the design, interior architecture, lighting, color, material and furniture

according to the state-of-art of the latest technology in CCR design

worldwide and shall comply with the international ergonomic standards.

It shall also be considered in the design that the general overall process

information to be displayed on the large screen monitors shall be visible to

all persons.

The interior design and execution of the CCR is fully under the scope of

work of Package P Contractor and the proposed specialized SubContractor shall be submitted with all qualification documents for

Employer/ Engineers approval.

In addition, there shall be a number of Local Electronic Rooms (LERs)

located in the main plant areas as follows:

each GT (adjacent to relevant GT unit)

HRSG;

STG

desalination units;

RO plant

Seawater Intake.

Fuel gas system

Fuel oil system

Compressed air system

Blending Plant and Potable Water System

Water Treatment Plant

These LERs shall serve for the accommodation of the control cabinets of the

DCS and PLC.

The LERs of each GTG shall be equipped with one Local Operator Station

(LOS). During normal operation the LERs (GTGs) shall be unmanned.

These LERs shall only be used during first start-up, emergency situation

and during maintenance. However, all control and supervisory facilities

available in the CCR shall, in general, be provided in the LER of GTG to

ensure that there is always a full back-up control facility in the event of a

major failure within the CCR area. Therefore, each GTG shall be provided

with one (1) operator station (one VDU, keyboard, mouse) located in the

LER for each GTG.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

where is the

location

Doosan

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 15 of 178

Rev. 0

Beside the Central control room (CCR) a local control room (LCR) shall be

foreseen for plants as follows:

Chlorination plant

CO2-plant and limestone plant (common LCR)

Each of these LCRs shall be equipped with one redundant operator station.

These LCRs shall have the same environmental conditions like the CCR (air

conditioned, dust free, vibration free, etc.).

The control cabinets of the DCS system will be established beside in a LER.

1.2.3

1.2.3.1

Operation of the main units

Degree of automation of the main process plants

The plant shall be designed with high degree of optimized automation,

safety protection and minimum of operator interface. The following

operational sequences relating to gas turbine generation, HRSG, steam

turbine generation, RO and thermal desalination units will be fully

automated, requiring the minimum of operator intervention under normal

conditions.

Cold start after maintenance

Defined as a start after major maintenance activities.

The start up of operation of the HRSG; SG and all supportive auxiliary

systems shall be coordinated remotely and supervised from the CCR, but

local field operators might be needed for venting, dewatering, draining of

pipelines etc. and other manual activities. The start up of GT might be

coordinated from local GT compartment, instead of CCR.

Normal Cold Start

Defined as a cold start that has not been preceded by major maintenance

activities.

The operation of the HRSG and all supportive auxiliary systems shall be

coordinated remotely from the CCR from where all control procedures

are initiated and supervised.

Warm Start - applies to GT, ST, HRSG units only

Defined as a start-up after an overnight shutdown. This will be carried

out and coordinated remotely from the CCR.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 16 of 178

Rev. 0

Hot Start

Defined as a start-up following a plant trip.

Fully coordinated from the CCR.

Normal and Emergency Shutdown

Fully coordinated from the CCR.

Electrical load management to meet plant output demand set by the load

dispatcher

Normal operation shall require in general a minimum of attendance by field

operators throughout the plant.

All the start-up sequences shall be designed for starting the unit as first unit

or as subsequent unit.

The essential common plant systems including the seawater system, the

condensate return, fuel supply and cooling water systems will be automated

to the group level, which leaves the overall control coordination of these

areas in the hands of the operator to ensure maximum flexibility of

operation.

1.2.3.2

Gas turbines generators

The operation of the GTGs, as specified in Part P-B1 shall be fully

automated. The automation shall provide for comprehensive control,

monitoring, and safe operation of GTGs from the Power Control Desk in

CCR (normal) and Local Operating Stations in LERs either through

independent GTG control systems interfaced to DCS, or through DCS

integrated GTG control systems (preferred). Automatic starting (with a

single command), synchronizing, loading and shutting down of the gas

turbine generators shall be provided. The only operator intervention

required shall be to select the fuel to be used and to set the load. The switchover from gas firing to oil firing shall be automatic, and switch-back from

oil to gas firing shall be manual. Fuel changeover should not create

disturbances in the operation.

1.2.3.3

Heat Recovery Steam Generators

The HRSGs, as specified in Part P-B2 shall be controlled, monitored and

operated from Power Control Desk in CCR (normal).

The start-up, loading and transfer to control mode of each HRSG shall be

automated from the point at which the turbine exhaust gas is admitted to the

HRSG. Preparation prior to HRSG starting shall be remotely by operators

initiation to satisfy the necessary pre-start conditions. Supplementary firing

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 17 of 178

Rev. 0

shall cut in and cut out automatically based on boiler load demand and GTG

load in addition to manual operating facility. However, the burner light up

and shut-down sequence as well as supervision shall be fully automated.

The HRSG initial preparations including start up of auxiliaries may be

initiated from the group, sub-group and drive level as appropriate. Initial

preparation shall be enabled with one single command. However once the

gas turbine exhaust gas enters the HRSG, the subsequent warm up and

loading sequence shall be fully automated.

1.2.3.4

what is this?

Steam turbine generator(s)

The STG(s) under normal operation will be supplied with live steam from

the HRSGs.

The operation of the STG shall be fully automated. Each STG, and its

associated auxiliary systems, as specified in Part P-B4 shall be controlled,

monitored, and operated from Power Control Desk in CCR (normal), either

through independent STG control system interfaced to DCS, or through

DCS integrated STG control system (preferred). The automation shall

provide for STG start-up, synchronization, automatic speed and voltage

regulation, exhaust pressure control during plant upsets, and shut-down. The

control systems shall provide for efficient and safe operation of STG(s) and

its auxiliaries through all the operating scenarios.

A Thermal Stress Evaluator (TSE) shall be provided. It shall monitor,

display and control the thermal stress levels of the turbine. It shall

automatically co-ordinate with the auto run up program in order to ensure

that the permissible turbine stress levels are never exceeded.

Control of the turbine in automatic mode is possible from plant DCS. Also

control of the turbine/generator on functional group level is operable from

plant DCS.

1.2.3.5

Common services systems

Common service shall be fully automated and monitored from the CCR as

part of the DCS.

The main steam systems, as specified in Part P-B5 including high pressure

steam system, steam bypass system, medium pressure steam system, low

pressure steam system, and deaerating steam system shall be, as a minimum,

fully automated for control, monitoring and operation from Common

Services Control Desk in CCR.

The main water systems as specified in Part P-B5 including boiler

feedwater system, condensate system, make-up water system shall be, as a

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

VOLUME IX: Part P-B13

Instrumentation and Control System

Doc No.:

Page 18 of 178

Rev. 0

minimum, fully automated for control, monitoring and operation from

Common Services Control Desk in CCR.

The common fuel systems, as specified in Part P-B6 including fuel gas

system, and diesel fuel oil system shall be, as a part of the DCS, fully

automated for control, monitoring and operation from Common Services

Control Desk in CCR.

In addition, other common services systems, as specified in other Parts of

Package P as well of Package D including waste water systems,

seawater supply system, closed cooling water system, service air and

instrument air system, potable water blending reservoir system, and other

systems shall also be controlled and monitored by the DCS and shall be

operated from Common Services Control Desk in CCR.

1.2.3.6

Electrical distribution system

The electrical distribution system of Power and Desalination Plant, as

specified in Part P-B12 and D-B09 shall be controlled and monitored via

DCS from the Electrical Control Desk in the CCR (normal). This shall, as a

minimum but not limited to, include operation and monitoring of LV & MV

switchgear, UPS, DC systems, etc.

1.2.3.7

Desalination units (Package D)

The desalination units, as specified in Package D shall be controlled,

monitored and operated, via the DCS, from the Water Control Desk in CCR.

The automation shall provide for automatic start-up, normal operation, and

shut-down from CCR of the desalination units. Start-up shall be enabled

with function group commands. The preparatory works for start-up and final

stages of shut-down shall be done from CCR.

1.3

1.3.1

Scope of supply and services

General

This sub-section sets out the scope for the control, instrumentation and

monitoring equipment for the installations covered by this Specification as

well as supplies and services, but without excluding other necessary

components and services not mentioned. This includes all control,

instrumentation and monitoring equipment within the CCR and LERs, and

associated field mounted equipment, which fulfils the control,

instrumentation and monitoring tasks as specified in the various parts and

sections. Sufficient instrumentation to the satisfaction of the Engineer shall

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 19 of 178

Rev. 0

be provided to meet appropriately the operational and safety requirements

of the plant.

The Contractor shall be responsible for all engineering, design,

manufacture, programming, configuration, documentation, materials,

supplies, factory and field testing, delivery, installation, start-up, tuning and

initial operation through completion of the work specified.

1.3.2

Scope of equipment

Field Equipment

all measuring and signal conditioning equipment (e.g. sensors,

transmitters, switches, analyzers, flowmeters, etc.) installed in the field

as well as in the CCR and LERs.

four (4) portable programmers (handheld computers) of each type (or

with the related software) for programming and calibration of SMART

transmitters and positioners.

all local instrumentation necessary for general start-up preparation, shutdown, local plant supervision and maintenance, including at least the

following:

Pumps

Suction and discharge pressure gauges

Gland sealing pressure gauge (if applicable)

Strainers and

Filters.

Differential pressure gauges

Heat exchangers

Temperature and pressure gauges upstream and

downstream, both tube side and shell side.

Lubrication and

Cooling systems

Pressure/temperature gauges, flow indicators at

appropriate locations to enable proper system

monitoring.

Tanks and Vessels

Level indicators, pressure and temp. gauges.

Common process

headers

Pressure, and temperature gauges

any other field equipment as required for the specified mode of operation

and for a safe and satisfactory operation and supervision of the plant.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 20 of 178

Rev. 0

Distributed Digital Control System (DCS)

All main systems shall be controlled by DCS. The typical overall DCS

architecture is shown in Annex P-C13-1, wherein the tie-in points between

Power and Desalination Plant (Package D) are indicated.

The plants main control system shall be a distributed digital control system

(DCS) in accordance with the technical requirements specified under Part

P-B13.1.4.4, including:

The DCS shall cater for the following main functions:

Signal acquisition, conditioning and processing

Closed-loop control

Open-loop control and interlocks

Plant and Unit Coordinator

Plant and Unit Master Control/ Load Control

Function group controls, sub-group controls and drive controls

Plant and equipment protection

Alarm and status annunciation

Data communication

Data displaying and information presentation to the operating staff

Data storage for periodic or post-trip analysis of the plant or equipment

analysis in form of curves, tables and lists (redundant historian server)

Supervision and plant performance calculation

System engineering and diagnostic

The following is a minimum list of systems to be controlled and monitored

by the DCS, but not limited to:

GT Units with their auxiliaries (if no package control was agreed, but in

this case operation and monitoring via DCS operator stations is required

at least)

HRSG including circulation systems, vent and drain systems, etc.

HRSG duct firing burner control and management system

Feedwater supply systems including auxiliaries

Steam system

Steam turbine control, start-up, run-down and protection and Steam

turbine auxiliaries (oil supply, turning device, drainage, etc.), (if no

package control was agreed, but in this case operation and monitoring via

DCS operator stations is required at least)

Steam Turbine Supervisory system (at least monitoring)

Evacuation systems

Condensate system

Circulating water system

Closed cooling water system

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 21 of 178

Rev. 0

Instrument and compressed air system (monitoring, pre-selection and

automatic change over)

Block related fuel supply systems

Black Start Diesel (monitoring and overall control)

Fuel gas compressors. (monitoring, automatic change over)

Diverter dampers of the HRSG.

The DCS shall include as a minimum, but not limited to the following

systems/equipment:

Single fault tolerant fiber optical plant (highway) bus (at least100 MB/s).

Redundant Fiber Optical Terminal (CCR LAN) Bus.

Redundant Processing Units and Server Units shall be provided to

connect the Plant Bus/highway bus to the Terminal Bus /CCR LAN.

Operator stations and large screen monitors in CCR, which are specified

somewhere else in the specification.

Local operator stations, which are specified somewhere else in the

specification.

Engineering stations, which are specified somewhere else in the

specification.

Diagnostic stations, which is specified somewhere else in the

specification.

Plant Management System (PMS)

PMS operator stations, which are specified somewhere else in the

specification.

Redundant optical switches to connect the DCS process control stations

to the plant highway bus redundantly and for bus-to-bus connection.

DCS process control station shall be designed to maximize the plant/ unit/

systems availability. Non-availability of any DCS process control station

shall affect a minimum process function. All DCS process control stations

shall be redundant and segregated according to their function, which shall

be provided at least as follows:

Each GTG (if no package control was agreed) shall be provided with

DCS process control stations for:

GTG Governor Controller.

Sequence and Auxiliaries Control.

Measurements and Supervisory System.

Failsafe Protection System.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 22 of 178

Rev. 0

Each HRSG shall be provided with the following DCS process control

stations:

Boiler Control System.

Boiler Failsafe Protection System.

Failsafe BMS for the Supplementary Firing Burners.

Each ST shall be provided with the DCS process control stations for:

ST control, Governor control (if no package control was agreed)

Sequence and Auxiliaries Control.

Measurement and Supervisory System.

Failsafe Protection System (if no package control was agreed)

Identical DCS process control stations shall be provided for the fuel gas

supply system/ gas compressors per unit.

Separate DCS process control stations shall be provided for the fuel gas

common system.

DCS process control stations shall be provided for the fuel oil system.

DCS process control stations shall be provided for the steam and water

systems.

DCS process control stations shall be provided for closed circuit cooling

water system, chemical dosing and chemical sampling system.

DCS Process Control Stations shall be provided for the condensate and

feed water system.

DCS process control stations shall be provided for each of the diverter

damper package for each HRSG.

DCS process control stations shall be provided for the Plant Master

Controller and Plant Protection Co-ordination.

DCS process control stations shall be provided for the electrical system

of the power plant following the specified segregation principles and

shall be located near to the switchgear panels.

DCS process control stations shall be provided for any other

equipment/system not mentioned above but deemed to be necessary at

the discretion of the Employer/Engineer.

In order to maximize the availability and the reliability of the plant/ units/

process, the total number of process control station will be defined at

beginning of the engineering phase based on the final plant configuration.

Redundant interface modules and serial data links to the PLC black box

control panels, which are specified elsewhere and subject to the

Employer/Engineer's approval.

Redundant interface modules and serial data links to the Substation

Control and Monitoring System (SCMS) as well to LDC including a

interface cubicle (located in 380kV substation).

Plant highway bus connection shall be provided and connected to the

Package D DCS cubicles distributed in the Plant.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 23 of 178

Rev. 0

Each unit shall be provided with separate marshalling cabinets, which shall

be supplied from the supplier of the DCS cabinets and shall have the same

material, color and size.

Maxi-Thermipoint connection or similar, reliable modern connection

technology shall be used inside the marshalling cabinets. .Each marshalling

cabinet with doors from the front and the back side shall be provided with

20% spare capacity in the termination blocks to be counted after completion

of commissioning. The number of marshalling cabinets to be provided for

each unit/system shall be decided taking into consideration the quantity and

size of cables in-and-out. It shall be ensured that in no way the marshalling

cabinets are over-crowded with cables in the entrance opening and/or inside

the cabinet. This all is subject to the Employer/Engineers approval.

Any other equipment not specified above but deemed to be necessary shall

also be provided at the discretion of the Employer/ Engineer.

Integration of Water Production Island (Package D)

All DCS equipment directly assigned to Water Production Island (Package

D) as shown in Annex D-C10-1 and described in more detail in Part DB10 shall be integrated in the overall DCS supplied under the Contract for

the Power Generation Island (Package P). Furthermore, all facilities and

software functions commonly used by Water Production Island and Power

Generation Island, e.g. central data base of DCS, shall be under coordination and responsibility of the Contractor for Power Generation Island.

Plant Management System (PMS)

A Plant Management System (PMS) as highest level in the control hierarchy

shall comprise at least

redundant PMS server

Operator stations for shift supervisor, superintend office and engineering

room with color laser printer

Operator station for each of the operator desks (each power block,

common systems, RO, each thermal desalination part)

network

data exchange to Office LAN (for access for unlimited number of staff)

WEB access to PMS from office PCs

License for unlimited use and unlimited tags for SWCC

Integration of data provided by Package D

High end quality hardware and software tools should be used for the PMS.

(The PMS can be of PI system or equivalent.)

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 24 of 178

Rev. 0

Various PLC based control systems for package equipment (if

approved by the client)

including two programming devices for each type of PLC together with all

required software licenses.

Asset management system/field device tool (FDT)

The asset management system for instruments, transmitters and actuators

shall consist of:

Centralized configuration and diagnosis station including hardware, all

necessary programs and software tools

Redundant server

Suitable number of portable handheld devices

Two (2) operator stations in the engineering room (one (1) for each

package)

Sufficient number of licenses (at least 5)

Integration of data provided by Package D

Vibration Monitoring System (VMS)

The vibration monitoring system shall consist of:

Centralized configuration and diagnosis station including hardware, all

necessary programs and software tools

Redundant server

Suitable number of portable handheld devices

Two (2) diagnosis stations for the control room (one (1) for each

package)

Engineering station for the engineering room

Diagnosis station for the T&I (Test & Inspection) office

Sufficient number of licenses (at least 5)

Necessary field equipment

Integration of data provided by Package D

The principle of the system is shown in Annex P-C13-8.

The requirements for the vibration monitoring system are described in Part

P-B03-4.9.

Central Control Room Equipment

Normal operation of the plant shall be performed from VDUs of the

operator desks in the CCR. One operator shall have two operator stations

containing two VDU each. For the overview different large screen panels

have to be installed in the CCR, too.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 25 of 178

Rev. 0

For operation of the complete Power and Desalination Plant different

operator areas shall be foreseen as follows:

power generation control desks (for each block)

common facilities and services control desk

water control desks (1x RO, 3x thermal desalination, 1x desalination

common systems)

and control desk for electrical services

The CCR shall, as a minimum, accommodate the following equipment:

Five (5) or six (6), if relevant Power Control Desks (PCDs) each

comprising of:

Three (3) operating stations

each operating station consists of two TFT-based Visual Display

Units (VDU) with a dedicated CPU and graphic display controller,

keyboards and mouse, related to each PCD the following equipment

shall be provided:

one (1) hardcopy laser printer (color and black/white),

one (1) Large Screen Projection Panel (LSPP),

hard-wired emergency shut-down push-buttons for each of the

GTGs, HRSGs and STGs,

one (1) control desk

two (2) operators chairs;

Water Control Desks (in the Scope of Package D, D-B10)

comprising of 5 control desks:

Desk for RO (two (2) operator stations)

Desk for thermal desalination part 1 (three (3) operator stations)

Desk for thermal desalination part 2 (three (3) operator stations)

Desk for thermal desalination part 3 (three (3) operator stations)

Desk for desalination common (three (3) operator stations)

each operator station shall consist two TFT-based Visual Display

Units (VDU) with a dedicated CPU and graphic display controller,

keyboard and mouse,

related to each desk section the following equipment shall be

provided:

one (1) hardcopy laser printer (color and black/white),

one (1) Large Screen Projection Panel (LSPP),

hard-wired emergency shut-down push-buttons,

one (1) control desk

two (2) operators chairs;

Remark: Furniture (desk and chairs) to be supplied by Package P

because of identical design of these pieces of furniture.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

VOLUME IX: Part P-B13

Instrumentation and Control System

Doc No.:

Page 26 of 178

Rev. 0

one (1) Electrical/ Common Services Control Desk comprising of:

three (3) operating stations , each consists of two TFT-based Visual

Display Units (VDU) with a dedicated CPU and graphic display

controller, keyboards, mouse,

one (1) Large Screen Projection Panel (LSPP),

one (1) hardcopy laser printer (color and b/w)),

one (1) control desk

four (4) operators chairs;

one (1) Shift Supervisors Operator Desk comprising of:

one (1) operating stations , each consists of two TFT-based Visual

Display Units (VDU) with a dedicated CPU and graphic display

controller, keyboards, mouse,

one (1) laser printer (color),

one (1) control desk

one (1) shift supervisors chair;

Operator Stations for crosswise operation (for each of the above

mentioned desks), each consists of one TFT-based Visual Display Units

(VDU) with a dedicated CPU and graphic display controller, keyboards,

mouse

(see as reference therefore Annex P-C13-5)

All control desks shall be supplied with audible/ visual equipment for the

DCS alarms and annunciations which shall be of different tones for

different units

LCD indicators (red color, 120 mm TEXT height) shall be provided in

the CCR panel for display the total power production and the total power

export as well for the water production and water export.

Data Exchange (SQL-/ WEB-server) including firewall for data

exchange to other systems (e.g. office LAN, enterprise systems) and

necessary software licenses, if any

Furthermore equipment of communication systems (e.g. telephone) shall

be built into each control desk or in panel.

Gas detection and fire detection panel /desk, fire fighting panel, panels

for building management system (HVAC, chiller plant), CCTV as well

the black start panel shall be considered for installation within the CCR,

too.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 27 of 178

Rev. 0

one (1) set of furniture consisting, as a minimum, of one (1) integrated

filing cabinet (total length min. 10m) and one (1) integrated side board

for each of the above mentioned desks, one (1) writing desk with

adequate space for spreading an A0-size drawing on top, one (1)

common filing cabinet for storing drawings and documents, and one

common (1) side board, wall whiteboard (min. 1000mm x 1500mm),

lockers (min. 2m) for spare and consumables

Printer desks / sideboards

Fire proof cabinet for software and data holder storage

Meeting area (table and chairs)

Regarding to the modern design of the control room area all doors, windows

including shutter or venetian blinds, partition walls have to be planned,

supplied and installed.

The restroom/ toilets and the kitchenette of control room area have to be

fit out with all sanitary installation and kitchen furniture (sink,

refrigerator, stove, microwave, kitchen things, all other furniture as well

table and chairs).

Specialized company shall do the final design/ layout of the Central Control

Room. This documentation is subject to separate approval. The design of

arrangement, lighting, colors, interior architecture and materials, etc., shall

be prepared by careful consideration of the ergonomic aspects and up-todate control room design principles.

Local Electronic Room (LER) equipment.

The LERs shall mainly accommodate the DCS process stations or PLC

cubicles.

In addition, the LER for each GTG shall be provided with the following

equipment:

one (1) Local Operator Station (LOS):

The LOS shall be complete with VDU, keyboard, mouse or track-ball

and the conventional control elements, such as emergency shut-down

push-buttons.

one (1) set of furniture consisting, as a minimum, of two (2) operator

chairs, one (1) writing desk with adequate space for spreading an A0-size

drawing on top and for accommodating the specified (ref: Sub-section PB12.10) telephone instrument(s), one (1) filing cabinet for storing

drawings and documents, and one (1) side board.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 28 of 178

Rev. 0

Local Control Room (LCR) equipment.

The LCRs shall be provided with the following equipment, each:

two (2) Local Operator Stations (LOS):

The LOSs shall be complete with TFT based VDU, keyboard, mouse

and the conventional control elements, such as emergency shut-down

push-buttons.

one (1) printer

one (1) hardcopy printer

one (1) set of furniture consisting, as a minimum, of two (2) operator

chairs, one (1) writing desk with adequate space for spreading an A0size drawing on top and for accommodating the specified (ref: Subsection P-B12.10) telephone instrument(s), one (1) filing cabinet for

storing drawings and documents, and one (1) side board.

Engineering and Diagnostic Room Equipment

An engineering room shall be located adjacent to CCR, and shall, as a

minimum, accommodate the following supply:

One (1) Engineering Station and one (1) Diagnostic and Documentation

Station for each of the DCS sections comprising of:

two (2) TFT based Visual Display Units (VDU) each with a dedicated

CPU and graphic display controller, keyboards, mouse,

one (1) A4/ A3 -format color laser printer,

two (2) chairs;

one (1) desk for accommodating the above mentioned equipment with

adequate space for spreading an A0-size drawing on top

Two cabinets for each DCS section

Furniture for one (1) Engineering Station and one (1) Diagnostic and

Documentation Station for each of the Package D DCS sections

comprising of same equipment like for Package P

four (4) sets of working desks and chairs

one (1) storage cabinet for keeping consumables;

one (1) cabinet for keeping ready-to-refer essential plant documentation

and drawings;

one (1) filing cabinet (min. 15m)

One PMS station including desk/ chair

One CEMS station including desk/ chair

Operator stations for asset management system / FDT (2x) including

desk/ chair

One vibration monitoring system (VMS) for diagnostic. including desk/

chair

Two personal computers with office applications

Fire proof cabinet for software and data holder storage

One fire proof cabinets for routine backup software

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 29 of 178

Rev. 0

Additional Engineering stations have to be provided during

commissioning and tuning period in sufficient number that parallel

commissioning works can be carried out independent for the different

systems and process areas.

Portable stations (e.g. Laptop) for diagnostic and programming functions

shall be included in the scope with the relevant functions for diagnostic and

programming features for programmable components e.g. transmitters and

actuators.

Settlement metering equipment

A special billing and metering system shall be installed for accounting all

media exported to Maaden and SEC as well to PS 1. The metering system

shall consist of settlement meters, back-up meters and quality

measurements, described in the tables below.

Fuel gas supply pipeline to

Maaden

Process water (from thermal

desalination) to Maaden *

Potable water to Maaden*

* in the scope of Package D

Device

Flow meter

Location

Plant boundary

Flow meter

Plant boundary

Flow meter

Plant boundary

A metering system foreseen for the media exchange to SEC/ SWCC shall be

foreseen, which consists of settlement meters, back-up meters and quality

measurements, described in the tables below:

Each power connection to SEC

380 kV substation and 13.8 kV

substation

Drinking water to Substation*

Device

CT / VT

Meter

Flow meter

Quality

measurement

Location

Substation

Relay and

protection room of

substation

Plant boundary

Plant boundary

* in the scope of Package D

A metering system foreseen for the fuel supply systems shall be supplied,

which consists of settlement meters, back-up meters and quality

measurements, described in the tables below.

Fuel gas supply pipeline

Back-up fuel supply

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

Device

Flow meter to

SWCC plant

Flow meter

Location

Plant boundary

Ship unloading

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 30 of 178

Rev. 0

Device

Location

station / Pipeline

An automatic meter reading system shall be supplied for collection and

validation of all metering signals.

A commercial billing system shall be provided for accounting.

All meter signals shall be considered in the metering systems which

included also the meters supplied by Package D.

Miscellaneous equipment

Conventional alarm annunciation system with fascia, installed in the CCR

for a small number of selected alarms of critical systems, e.g. 380kV,

230kV (200 alarms shall be the basis for the offer).

1.3.3

Spare capacity after completion of commissioning

At least 20% free channels of each I/O modules shall be available after

final commissioning for future modification.

At least 20% free space shall be available in all cubicles, junction boxes and

marshalling racks after final commissioning for future ad-on items. This

free space shall be distributed inside the cubicles in such a way that

additional terminals, equipment or modules may be added to any group of

controls. At least 20% spare cores shall be provided in each control and

monitoring cable. All spare cores shall be terminated.

Each module shall be sized such that no more than 60% of its installed

capacity is utilized during normal operation and shall not exceed 80% even

under extreme load condition.

1.3.4

Services

The Contractor shall provide all services required for a safe, reliable,

efficient and trouble free instrumentation and control equipment, complete

in every respect, without excluding other necessary services not mentioned

below. These services shall include but not be limited to:

design of all equipment to be supplied

examining of interface documentation

co-ordination and integration of all DCS equipment/functions supplied

under Package D, Part D-B10

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 31 of 178

Rev. 0

co-ordination and integration of all central control room equipment

supplied under Package D, Part D-B10 in order to ensure a uniform

layout and design of CCR

Detailed study of a specialized company for CCR design and layout

including the lighting, color, material, interior architecture etc.

considering carefully the ergonomic standards and the up to date control

design principles.

co-ordination and interfacing with external or separate systems like

Continuous Emission Monitoring System (CEMS)

Water quality monitoring system

Vibration monitoring system (VMS)

Plant Management System (PMS)

Asset management system / Field device tool

SCMS and SCADA system

Black start diesel generator

Fire and gas detection system and fire fighting system (FGAP)

HVAC Building management system

and others

co-ordination and integration of Package D related signals / data in the

PMS, VMS, asset management system / field device tool and CEMS /

water quality monitoring system

documentation of all equipment to be supplied including revision of

existing documentation where modified

programming of all digital equipment

testing in the Contractors/Vendors workshop and on site (FAT and SAT)

packing, transportation to site, unloading and proper storing

on time delivery of all documents needed for proper assembly

handling from site storage to the point of final installation

erection of all parts to be supplied

commissioning of all equipment

loop checks from field instruments to DCS operator station

trial operation

acceptance tests

The Contractor is responsible for the co-ordination of the interfaces and

overall design of all package control equipment or other control equipment

supplied by other sub-contractors and for making sure that the design of this

equipment and the submitted documentation is in line with the General

Project Requirements (Part-P-A3) and Technical Specification (Part-PB03), but it is expected that this co-ordination activities shall be done by the

supplier of the main control, instrumentation and monitoring equipment.

The Contractor (Package P) is responsible for the overall DCS layout and

design of the entire Power and Desalination Plant. Special attention shall be

drawn to all facilities (hardware and software) commonly used by Package

P&D.

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 32 of 178

Rev. 0

As far as the final execution of the work is concerned all design data,

interlocking conditions, control loops and logic diagrams supplied by the

various sub-contractors shall be checked, verified and closely coordinated

with the other sub-contractors of the corresponding equipment. For this

purpose close collaboration with all sub-contractors supplying control

equipment shall be arranged.

All important design documents shall be submitted for approval to the

Engineer. The Contractor shall submit a detailed time schedule for the

drawing approval procedure at the beginning of the design phase.

1.3.5

Erection, cabling, wiring, labeling

The scope of this Contract covers complete erection, cabling and wiring of

all control, instrumentation and monitoring equipment and shall comply

especially with the General Requirements stated under Part P-B02 and PB03.

Connection of process stations and other central equipment supplied by

Contractor Package D, Water Production Island, to the data highway of

the overall DCS shall be done by Contractor Package P, Power Plant,

including all required cables and installation materials. However, the

redundant bus interface modules with their software and bus protocol inside

the DCS process stations of Package D plant shall be provided by

Contractor of Package D. Generally all necessary I&C cable and cable

trays between Package P and D shall be provided by the Package P

contractor. The connection works at the interfaces (e.g. at terminal strip in

the interface cubicles) of Package D shall be carried out by Package D

contractor.

The Contractor shall be, in all cases, fully responsible for the correct

installation and erection with regard to the measuring and control functions

of all the supplied equipment.

The Contractor shall make all necessary provisions for the site testing and

commissioning of the control and instrumentation systems which include

but shall not be limited to the following:

the test calibration of all instruments prior to installation. The

instrumentation used for calibration or check of operational

instrumentation shall carry a valid test certificate from an approved

authority and not from the contractor.

the functional test of instruments once installed;

the loop testing of all measurement and control loops;

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 33 of 178

Rev. 0

the site demonstration test required confirming that all control and

supervisory function conform to their respective functional specification.

All tests performed on site, including the results and deficiencies, shall be

recorded and the test protocols shall be submitted to the Engineer for

approval.

All cabling for the field equipment in the scope of this Contract, shall be

supplied, laid, labeled and terminated.

For the supplied field cabling all necessary cable routes, supporting

traywork and intermediate marshalling shall be provided. Marshalling

cabinets shall be provided in the central control building or in the LER.

A common system of earthing for cable armoring, cable screens, signal

cubicle earthing shall be agreed with Engineer.

All field equipment including local instruments, transducers, valves,

actuators, sensors, junction boxes, cabinets shall have nameplates with the

instrument tag number and descriptor. All equipment in CCR, LER and

LCR, control module, power supply, circuit breakers, fuses and control

systems shall have name plates. The nameplates shall be fixed to the

mounting plate, the mounting brackets or junction box. Loosely attached

nameplates by wires are not acceptable. Label material and writing shall be

selected to withstand the environmental conditions where they are mounted.

The label size and fixing place shall be selected to allow easy reading.

Inside the control cabinets, all control equipment shall be labeled.

1.3.6

Commissioning, trial operation, and acceptance tests

The Contractor shall be entirely responsible for the commissioning of the

DCS in conjunction with the plant system. Commissioning shall be carried

out in accordance with the commissioning procedures prepared by the

Contractor and approved by the Engineer.

The scope includes:

adjustment of control parameters, alarm limits and other adjustable

parameters;

optimization of closed loop control systems;

modification or correction of control functions during optimization, if

necessary, VDU displays, logs, etc;

optimization of alarm annunciation and SER functions and the associated

printing functions;

trial operation;

FICHT-5296110-v5-RAZ_TD_P-B13.DOC

RAS AZ ZAWR POWER AND DESALINATION PLANT PHASE 1

Subject:

Doc No.:

VOLUME IX: Part P-B13

Instrumentation and Control System

Q

Page 34 of 178

Rev. 0

performance of acceptance tests;

correction of any latent errors found within the DCS.

The general requirements regarding inspection and testing are included in

Part A5 of the Specification.

1.3.7

Documentation

All documents and information requiring checking and approval by the

Engineer in accordance with Part A3 shall be submitted.

All important design documents shall be submitted for approval to the

Engineer as per approved procedure.

1.3.8

Training