Академический Документы

Профессиональный Документы

Культура Документы

Iris

Загружено:

Prithviraj DagaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Iris

Загружено:

Prithviraj DagaАвторское право:

Доступные форматы

International Railway Industry Standard (IRIS) Group

Addendum as per 18th May 2006

to the

IRIS booklet, revision 00, March 2006

The aim of this addendum is to inform you about improvements/clarifications in the IRIS booklet,

revision 00, March 2006.

As per decision of the IRIS Steering Committee the next official revision of the IRIS booklet will be

conducted in 2007. The feedback received by auditors, clients, etc. during the implementation phase

will be analysed by the IRIS Group and communicated to all interested parties via the present

addendum. The addendum is provided in each IRIS booklet or can be accessed via the IRIS Portal

(http://www.iris-rail.org/).

Modifications are marked bold italic.

COVER SHEET

The official language for the IRIS documentation is English. In any case of conflict, the

English original shall be considered as the mandatory one.

CHAPTER 1: IRIS CERTIFICATION PROCESS

4.2 Evaluation process; page 15

IRIS requirements main clauses mean:

• Quality management system (see chapter 3, clause 4)

• Management responsibility (see chapter 3, clause 5)

• Resource management (see chapter 3, clause 6)

• Product realization (see chapter 3, clause 7)

• Measurement, analysis

and improvement (see chapter 3, clause 8)

4.3 Award of certificates; page 15

After an IRIS audit has been passed the certification body is entitled to certify the client. The

certification body shall issue an IRIS certificate revealing the results of the evaluation

process. Form and structure of the IRIS certificate are given by the IRIS Management Centre.

CHAPTER 2: IRIS ASSESSMENT GUIDELINE

1 Review of the audited organization’s documentation; page 18

In addition to the review of the business management manual, the quality policy and the

organization charts, the following must be carried out to ascertain the client’s readiness for the

audit:

Filename: IRIS addendum 2006-05-18.doc confidential and proprietary Page 1 of 7

International Railway Industry Standard (IRIS) Group

CHAPTER 3: IRIS REQUIREMENTS

0.2 Process approach; page 26

Whenever this standard refers to “a process”, this process shall be documented and should be

controlled by appropriate key performance indicators.

0.4 Compatibility with other management systems; page 26/27

NOTE 1……….

….All processes shall be integrated in the business management system and should be controlled

through appropriate key performance indicators (KPIs) and continuously improved.

5.6.2 Review input; page 34

As a minimum the following KPIs shall be reviewed:

• customer on time delivery performance, and

• Non conformities raised by the customer throughout the entire product life

cycle.

7.7.4 Verification of purchased product; page 47

Verification activities of the organization shall include:

a) obtaining objective evidence of the quality of the product from suppliers (e.g.,

accompanying documentation, certificate of conformity, test reports, statistical

records, process control),

b) review of the required documentation,

c) inspection of products upon receipt.

The organization shall define activities accordingly in case of delegation of verification to the

supplier, or supplier certification.

Verification activities of the organization should also include inspection and audit at

supplier’s premises,

8.2.3 Monitoring and measurement of processes; page 52

Each process identified as such in these requirements should be supported by key performance

indicators and targets.

8.3.2 Customer waiver; page 53

Material shipped, which is subject to such a concession, shall be clearly and appropriately

identified. This applies equally to purchase product.

8.4 Control of nonconforming processes; page 53

In the event of process variation, the organization shall have a process in place to:

a) identify and record the variation, and if the process is non conform to take

appropriate action to correct the non conforming process,

b) evaluate whether the process variation has resulted in product non conformity,

and

c) identify and control the non conforming product in accordance with clause 8.3.1.

IRIS Addendum, 18th May 2006 confidential and proprietary Page 2 of 7

International Railway Industry Standard (IRIS) Group

CHAPTER 4: IRIS QUESTIONNAIRE

The purpose of the questionnaire printed in the IRIS Booklet revision 00 is only to show the

principles of the assessment methodology, including maturity levels.

The content presents a former version of the IRIS questionnaire. Due to the received feedback

during the validation phase some of the questions and assessment criteria might be revised.

The mandatory/valid IRIS questionnaire is programmed in the IRIS Audit-Tool, to be used

during the certification process.

IRIS Addendum, 18th May 2006 confidential and proprietary Page 3 of 7

International Railway Industry Standard (IRIS) Group

ANNEX 1: IRIS scopes of certification

The table contains level 1 and 2 of the rolling stock structure as specified in the current

version (PBS MODTRAIN V4 [1].9-18MAY05) of the technical specifications for interoperability

(TSI). The certification is based on the first level.

No Description – 1st level No Description – 2nd level

1 Car body 1.1 Car body shell

1.2 Under frame

1.3 Floor

1.4 Crash structure

1.5 Windows

1.6 Insulation

1.7 Painting and Sound damping

1.8 Fixing / connecting elements

2 Car body fittings 2.1 Front/End car body fittings

2.2 Roof car body fittings

2.3 Under frame car body fittings

2.4 Lateral car body fittings

3 Guidance 3.1 Motor bogie

3.2 Trailer bogie

4 Power System 4.1 Power supply

4.2 Power generation

4.3 Power conversion

4.4 Power dissipation

4.5 Power storage

5 Propulsion 5.1 Traction Control Unit (TCU)

5.2 Gear box

5.3 Traction motor

5.4 Mechanical transmission

5.5 Power converter

6 Auxiliary systems 6.1 Air supply system

6.2 Hydraulic system

6.3 Auxiliary electric system

6.4 Main Auxiliary Converter equipment

6.5 Low Voltage Power Supply / Battery Charger

6.6 Special Aux. converter equipment

6.7 Battery equipment

6.8 External supply system

6.9 Cooling unit for power and drive systems

6.10 Fire protection system

6.11 Sanding equipment

6.12 Horn

6.13 Flange lubrication device

7 Braking System 7.1 Brake control system

7.2 Friction brake equipment

7.3 WSP equipment

7.4 Magnetic track brake equipment

7.5 Emergency brake equipment

7.6 Eddy current brake equipment

IRIS Addendum, 18th May 2006 confidential and proprietary Page 4 of 7

International Railway Industry Standard (IRIS) Group

No Description – 1st level No Description – 2nd level

8 Interiors 8.1 Interior architecture

8.2 Interior equipment

8.3 Toilet system

8.4 Engine room

8.5 Catering system

9 On board vehicle control 9.1 ETCS

9.2 TCMS

9.3 Heritage ATP unit

9.4 ATO unit

9.5 Fault data logger

9.6 Heritage juridical recorder unit

9.7 Voice recorder

9.8 System, capture unit

9.9 Video surveillance

9.10 Electronic rear mirror

10 Passenger Information 10.1 Public Address System

System 10.2 Safety Alarm Systems

10.3 Central PIS unit

10.4 MMI for train/travel information

10.5 Seat reservation

10.6 Ticketing machine

10.7 Entertainment

11 Communication systems 11.1 Train to wayside communication system

11.2 Onboard communication system

12 Cabling and Cabinets 12.1 Cabling

12.2 Cabinets

13 Door System 13.1 External doors

13.2 Internal doors

14 HVAC 14.1 HVAC control unit

14.2 Air conditioning system

14.3 Heating system

14.4 Air ventilation and distribution System

14.5 Air intake

14.6 Exhaust air unit

14.7 Pressure protection system

15 Tilt System 15.1 Tilt Control Unit

15.2 Actuating System

15.3 Pantograph tilt system

15.4 Tilt monitoring and detection

16 Lighting 16.1 Emergency lighting system

16.2 Exterior lighting system

16.3 Interior lighting system

17 Coupler 17.1 Front coupler

17.2 Intermediate coupler

17.3 Emergency coupler (Towing coupler)

18 Deleted

IRIS Addendum, 18th May 2006 confidential and proprietary Page 5 of 7

International Railway Industry Standard (IRIS) Group

ANNEX 3: Processes/activities to be documented in procedures

The thirteen (13) mandatory required documented procedures1) are listed below. The right column identifies the

mandatory ones required by ISO 9001:2000.

Processes/activities to be documented in

Procedure Clause

procedures

1 4.1 Transfer / outsourcing of contract activities

2 4.2.3 Control of documents ISO 9001

3 4.2.4 Control of records ISO 9001

4 6.1 Provision of resources

5 6.2.2.2 Training

Design and development validation

6 7.5.6

(test procedures)

7 7.5.8 First article inspection (FAI)

8 7.8.2.3 Maintenance for equipment and tools

9 7.10 RAMS

10 8.2.2 Internal audit ISO 9001

11 8.3.1 Control of nonconforming product ISO 9001

12 8.6.2 Corrective action ISO 9001

13 8.6.3 Preventive action ISO 9001

1)

In respect of the business needs of a client, please note that the coverage of the processes mentioned

above could differ from the titles in the table.

IRIS Addendum, 18th May 2006 confidential and proprietary Page 6 of 7

International Railway Industry Standard (IRIS) Group

ANNEX 6: Terms and definitions for the railway industry

Term Definition

Outsourcing Outsourcing is the temporary delegation of tasks or

activities from internal product realization to an external

entity (3rd party). Outsourcing is the procurement of up to

now self performed services, whereas the duration and

the subject of matter are contractually fixed.

IRIS Addendum, 18th May 2006 confidential and proprietary Page 7 of 7

Вам также может понравиться

- Iris Awareness QuizДокумент2 страницыIris Awareness QuizSudhagarОценок пока нет

- IRIS - PresentationДокумент0 страницIRIS - Presentationramki1980Оценок пока нет

- Whitepaper en Iatf16949Документ12 страницWhitepaper en Iatf16949Archana SinghОценок пока нет

- Inspection In Manufacturing A Complete Guide - 2020 EditionОт EverandInspection In Manufacturing A Complete Guide - 2020 EditionОценок пока нет

- API - 510 General Information and Qualification RequirementsДокумент2 страницыAPI - 510 General Information and Qualification RequirementsVijayshanker GuptaОценок пока нет

- IRIS TrianingДокумент66 страницIRIS TrianingSANKUSIОценок пока нет

- CQI and IRCA Certified ISO 9001:2015 Lead Auditor Training CourseДокумент6 страницCQI and IRCA Certified ISO 9001:2015 Lead Auditor Training CourseMukesh YadavОценок пока нет

- Benifits IATF 16949Документ2 страницыBenifits IATF 16949Disha ShahОценок пока нет

- 7 QC Tools BenefitsДокумент2 страницы7 QC Tools BenefitsGaneshkumar PandiyanОценок пока нет

- Form - Feasibility Review FormДокумент3 страницыForm - Feasibility Review FormmatrixmazeОценок пока нет

- JD KRA LAB TeamДокумент27 страницJD KRA LAB TeamANILОценок пока нет

- Supplier APQP TrainingДокумент32 страницыSupplier APQP TrainingvivekОценок пока нет

- Rules 3rdДокумент47 страницRules 3rdviet579100% (1)

- D.Muthu Swamy: QMS Lead AuditorДокумент4 страницыD.Muthu Swamy: QMS Lead Auditormuthuswamy77Оценок пока нет

- Dead Endclamp Failure AnalysisДокумент26 страницDead Endclamp Failure AnalysisRK KumarОценок пока нет

- Procedure For Top Management and Management Review: Input / Output Diagram ControlsДокумент4 страницыProcedure For Top Management and Management Review: Input / Output Diagram ControlsmuthuselvanОценок пока нет

- IATF 16949-2016 Requirements.Документ24 страницыIATF 16949-2016 Requirements.Gaurav Kansara100% (1)

- Assessment Report/Checklist: Isfahan, IranДокумент19 страницAssessment Report/Checklist: Isfahan, IranAnonymous q8lh3fldWMОценок пока нет

- Astm A 986 - 2016 PDFДокумент3 страницыAstm A 986 - 2016 PDFEmmanuel BoquetОценок пока нет

- UntitledДокумент19 страницUntitledSuresh KumarОценок пока нет

- Statistical Methods For Quality ControlДокумент2 страницыStatistical Methods For Quality ControlAntonio Lara0% (1)

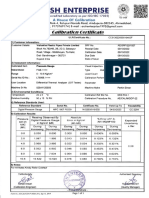

- Calb 4Документ1 страницаCalb 4ranjt53Оценок пока нет

- IATF - International Automotive Task ForceДокумент10 страницIATF - International Automotive Task ForceBeli NovareseОценок пока нет

- Cqi 9 Errata AIAGДокумент5 страницCqi 9 Errata AIAGRafael AlvesОценок пока нет

- IATF ManualДокумент62 страницыIATF ManualqualityОценок пока нет

- Irqb Guideline 3 Maintenance Rev01Документ46 страницIrqb Guideline 3 Maintenance Rev01Delong KongОценок пока нет

- For Receving Gauges - Master Sample: Gauge Callibration Work InstructionsДокумент1 страницаFor Receving Gauges - Master Sample: Gauge Callibration Work InstructionsAnkur Gupta100% (1)

- RNS - NDT - MT - 001 Rev.0Документ10 страницRNS - NDT - MT - 001 Rev.0Goutam Kumar DebОценок пока нет

- Quality Manual1111Документ35 страницQuality Manual1111Nizar KhalidОценок пока нет

- SUPPLIER Supplier - Self - Assessment - 2015 PDFДокумент6 страницSUPPLIER Supplier - Self - Assessment - 2015 PDFOwenevan EvanowenОценок пока нет

- Is 1363 - 2 2002Документ13 страницIs 1363 - 2 2002Sourav HaitОценок пока нет

- MSE507 Lean Manufacturing: Basic Elements of Cell DesignДокумент22 страницыMSE507 Lean Manufacturing: Basic Elements of Cell DesignaejaztumОценок пока нет

- Z-SCORE - Inter Lab Comparison of Mechanical TestingДокумент2 страницыZ-SCORE - Inter Lab Comparison of Mechanical TestingAnubhav LakhmaniОценок пока нет

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceДокумент2 страницыMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceRohit VishwakarmaОценок пока нет

- Requirements Comparison TS16949 VDA61Документ22 страницыRequirements Comparison TS16949 VDA61TarunaiОценок пока нет

- Test Paper: Fifo & TraceabiltyДокумент2 страницыTest Paper: Fifo & TraceabiltyAtul SharmaОценок пока нет

- PSWДокумент2 страницыPSWLinda G. CordovaОценок пока нет

- Audit SkillsДокумент36 страницAudit SkillsSudhagarОценок пока нет

- Calibration Procedure FOR Calipers General: Technical ManualДокумент8 страницCalibration Procedure FOR Calipers General: Technical ManualrcmetrologyОценок пока нет

- Clauses IATF16949 2016Документ2 страницыClauses IATF16949 2016Javier BustamanteОценок пока нет

- Stellantis Ex PSA Scorecard Quick Reference Guide July 2021Документ3 страницыStellantis Ex PSA Scorecard Quick Reference Guide July 2021白子健Оценок пока нет

- Problem Solving Techniques Case StudyДокумент33 страницыProblem Solving Techniques Case Studyshradha_DAIMSRОценок пока нет

- 7 QC ToolsДокумент81 страница7 QC ToolsDonny Agus PrasetyoОценок пока нет

- Clause Topic Type of Documented Information RequirementДокумент2 страницыClause Topic Type of Documented Information RequirementnagarajОценок пока нет

- Asq 13485Документ32 страницыAsq 13485Darren TanОценок пока нет

- Senthilkumars CMM Programmer Kumars CMM ProgrammerДокумент2 страницыSenthilkumars CMM Programmer Kumars CMM ProgrammerSenthil Kumar0% (1)

- PPAP Part Submission Warrant.Документ4 страницыPPAP Part Submission Warrant.aperezpi26606Оценок пока нет

- Supplier Assessment FormДокумент5 страницSupplier Assessment FormTerence279Оценок пока нет

- Chapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Документ12 страницChapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Vikram BillalОценок пока нет

- Global Quality Manual Iso 9001 2015Документ17 страницGlobal Quality Manual Iso 9001 2015Viswatej ChoudaryОценок пока нет

- Audit Report Ash HandlingДокумент1 страницаAudit Report Ash HandlingchandrashekharОценок пока нет

- Work Instruction For Inspection & ReportingДокумент2 страницыWork Instruction For Inspection & ReportingDeepak DasОценок пока нет

- 54-Pressure Gauge OIT Calibration CartificateДокумент1 страница54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- Design Failure Modes and Effects Analysis (DFMEA) of Self Propelled Onion Harvester (TIFAN Vehicle)Документ13 страницDesign Failure Modes and Effects Analysis (DFMEA) of Self Propelled Onion Harvester (TIFAN Vehicle)IJRASETPublicationsОценок пока нет

- Baofeng Uv-5r Ce Certificate 18-211428Документ3 страницыBaofeng Uv-5r Ce Certificate 18-211428anshadОценок пока нет

- Nabl Electrical TestingДокумент104 страницыNabl Electrical Testingram27_rajiОценок пока нет

- Quality Audit Handbook PDFДокумент59 страницQuality Audit Handbook PDFmadmaxjune17557Оценок пока нет

- Supplier Web Share Downloads CQI-15 Welding System AssessmentДокумент50 страницSupplier Web Share Downloads CQI-15 Welding System AssessmentMostafa Abd El Alem83% (6)

- TE24EX1 - IRIS Rev.04 Product Scopes - EN - Rev00Документ7 страницTE24EX1 - IRIS Rev.04 Product Scopes - EN - Rev00sankusi_rkflОценок пока нет

- Electrodynamic Suspension SystemДокумент88 страницElectrodynamic Suspension SystemPrithviraj Daga100% (1)

- MaglevДокумент21 страницаMaglevPrithviraj DagaОценок пока нет

- Tractive Effort PDFДокумент8 страницTractive Effort PDFPrithviraj DagaОценок пока нет

- Gear DesignДокумент18 страницGear DesignJitendra BagalОценок пока нет

- GearboxesДокумент24 страницыGearboxesPrithviraj Daga100% (2)

- Bombardier TraxxДокумент12 страницBombardier TraxxPrithviraj DagaОценок пока нет

- BT PresentationДокумент34 страницыBT PresentationPrithviraj DagaОценок пока нет

- Sheet Metal Bend AllowanceДокумент3 страницыSheet Metal Bend AllowancePrithviraj DagaОценок пока нет

- MD Spur DesignДокумент8 страницMD Spur DesignPrithviraj DagaОценок пока нет

- Transient Stress Analysis On Spur GearДокумент8 страницTransient Stress Analysis On Spur GearPrithviraj DagaОценок пока нет

- Sheet Metal Design-Handbook-Rev3 PDFДокумент12 страницSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Contact Stress Analysis of Spur Gear Teeth PairДокумент6 страницContact Stress Analysis of Spur Gear Teeth PairPrithviraj DagaОценок пока нет

- Gear StressДокумент12 страницGear StressPrithviraj Daga100% (1)

- Railways Technical InformationДокумент88 страницRailways Technical InformationPrithviraj Daga100% (2)

- Analysis Guide Machine Design WP ENGДокумент10 страницAnalysis Guide Machine Design WP ENGPrithviraj Daga100% (3)

- Polyurethane (PU) : HistoryДокумент28 страницPolyurethane (PU) : HistoryPrithviraj Daga83% (12)

- GD&T IntroductionДокумент147 страницGD&T IntroductionPrithviraj Daga100% (6)

- Shipping, Logistics Management - Container Dimensions, Container Capacity, Rating, Tare Mass and Payload of ContainersДокумент4 страницыShipping, Logistics Management - Container Dimensions, Container Capacity, Rating, Tare Mass and Payload of ContainersPrithviraj Daga80% (5)

- ProE Wildfire 4 Tutorial 4-3D AnnotationsДокумент26 страницProE Wildfire 4 Tutorial 4-3D AnnotationsPrithviraj Daga100% (3)

- Pro/E - Efficient Wall Thickness Analysis Methods For Optimal Design of Casting PartsДокумент9 страницPro/E - Efficient Wall Thickness Analysis Methods For Optimal Design of Casting PartsPrithviraj DagaОценок пока нет

- ProCNC - Design Guide ForCost Effective Machined Parts - IVДокумент4 страницыProCNC - Design Guide ForCost Effective Machined Parts - IVPrithviraj DagaОценок пока нет

- Tutorials For Pro Engineer Wildfire 2.0Документ101 страницаTutorials For Pro Engineer Wildfire 2.0shuklahouseОценок пока нет

- A.tcharkhtchi-Simulation of Roto Molding ProcessДокумент28 страницA.tcharkhtchi-Simulation of Roto Molding ProcessPrithviraj Daga100% (1)

- Consumer Product Design WP ENGДокумент8 страницConsumer Product Design WP ENGPrithviraj DagaОценок пока нет

- Itp Installation of Ats Panel Rev.00Документ2 страницыItp Installation of Ats Panel Rev.00syed fazluddinОценок пока нет

- Design & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Документ58 страницDesign & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Vaibhav Soni100% (1)

- M2 106 TaДокумент26 страницM2 106 TaFERNANDO FERRUSCAОценок пока нет

- LHD Toro0010 (13 Yd3) PDFДокумент2 страницыLHD Toro0010 (13 Yd3) PDFDaniel LopezОценок пока нет

- Asce 7 Seismic ExampleДокумент7 страницAsce 7 Seismic ExampleKatherine Prado100% (1)

- As Minas - 2 - História de ValongoДокумент7 страницAs Minas - 2 - História de Valongoesvalongoefab3Оценок пока нет

- 7.6 Control of Monitoring and Measuring DevicesДокумент2 страницы7.6 Control of Monitoring and Measuring Devicesejub6447Оценок пока нет

- GAPS Guidelines: Deep Fat FryersДокумент4 страницыGAPS Guidelines: Deep Fat FryersAsad KhanОценок пока нет

- Aspire Manual PumpДокумент19 страницAspire Manual Pumpsouhaib alviОценок пока нет

- Brochure - Valves For Oil & Gas Industries (En) .Документ28 страницBrochure - Valves For Oil & Gas Industries (En) .ABULARA2K6Оценок пока нет

- Openreach New Site Builder's Info PackДокумент36 страницOpenreach New Site Builder's Info Packgrahamcox_81100% (1)

- Design & Detailing of Prestressed Building Floors in Singapore Using Eurocode May 2015 PDFДокумент151 страницаDesign & Detailing of Prestressed Building Floors in Singapore Using Eurocode May 2015 PDFjohnkoh99Оценок пока нет

- Main Point of StandardДокумент5 страницMain Point of StandardAMIT SHAHОценок пока нет

- Pds Epilux 218 Hs VocДокумент2 страницыPds Epilux 218 Hs VocmuthukumarОценок пока нет

- OBS II The Adjustable Wellhead For Exploration Drilling FullДокумент24 страницыOBS II The Adjustable Wellhead For Exploration Drilling FullAli Boubenia100% (1)

- ReportДокумент18 страницReportKrishna KKОценок пока нет

- Chandu ResumeДокумент2 страницыChandu ResumenandigamchanduОценок пока нет

- Lessons Learned From Infrastructure Operation in The CUTE ProjectДокумент11 страницLessons Learned From Infrastructure Operation in The CUTE Projectmavroudisd3710Оценок пока нет

- LE Pyroshield Syn XHvy 9000 - 9011 Product InfoДокумент4 страницыLE Pyroshield Syn XHvy 9000 - 9011 Product InfoDiegoAlvarezHuguezОценок пока нет

- DPR of PaushДокумент16 страницDPR of PaushAnonymous 1nsq38LqxbОценок пока нет

- Wa600-3 PDFДокумент143 страницыWa600-3 PDFanggieОценок пока нет

- 680S, 800S, 810SJ, 860SJ JLG Parts EnglishДокумент516 страниц680S, 800S, 810SJ, 860SJ JLG Parts EnglishServicios y Repuestos Jeremy Azhael 2320 C.AОценок пока нет

- Introduction of Aluminum FormworkДокумент19 страницIntroduction of Aluminum FormworkJanice YuanОценок пока нет

- BPДокумент36 страницBPThiruvenkatasamy Elangovan100% (2)

- FNW Hangers PDFДокумент32 страницыFNW Hangers PDFAnonymous gr5Pr9AVОценок пока нет

- The Best of AFN 5 PDFДокумент220 страницThe Best of AFN 5 PDFJohnny KlinkОценок пока нет

- Inspeccion Power Train D10TДокумент9 страницInspeccion Power Train D10TDiego PizarroОценок пока нет

- Water Sizing Chart With FORMULA 8.15.11Документ10 страницWater Sizing Chart With FORMULA 8.15.11mnt6176Оценок пока нет

- Brosur Shan WangДокумент10 страницBrosur Shan Wangirfan effendiОценок пока нет

- Folder-Small L & B-EnGДокумент16 страницFolder-Small L & B-EnGRodrigo GonçalvesОценок пока нет