Академический Документы

Профессиональный Документы

Культура Документы

Chapter 2

Загружено:

Zeleke TaimuИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chapter 2

Загружено:

Zeleke TaimuАвторское право:

Доступные форматы

DBU

Civil dep't

Surveying I

Chapter 2

Measurement of Horizontal Distances

The units of measurement in any surveying works are those for distances and angles

measurements. Now a day throughout the world distances are expressed in metric systems and

angles are expressed in degree or grad systems.

Methods of Linear Measurements

Every surveyor has to measure the horizontal distance between two points on the surface

of the earth. Measurement of horizontal distance or making linear measurements is

required in chain surveying, traverse surveying, and other types of surveying.

In surveying the distance between two points means a horizontal distance. When slope

distances are measured in the field, these are always reduced to the equivalent horizontal

distances for preparation of map.

Horizontal distance

There are, in general, three methods of making linear measurements:

1. Direct methods

2. Optical methods

3. E.D.M. methods

Direct method using a tape

In this method distances are measured measure mainly on the ground by chain or tape etc. But in

optical method or indirect method observations are made by telescope or distance is not actually

measured in the field and calculations are made for distances by tachometer. In electronic

method distances are measured with instruments that rely on propagation, reflection, and

subsequent reception of either by radio or light waves.

Direct methods may be subdivided into approximate, chaining and taping methods.

.

By Surveying Instructors

2012/2013

DBU

Civil dep't

Surveying I

Approximate method

The following approximate methods are commonly used in reconnaissance surveying

for the measurement of horizontal distances. These methods are also used sometimes to

detect large mistakes in linear measurements obtained with a tape.

1. Pacing: Is a preliminary survey to measure distances by pacing. A

person can determine the distance walked by counting the number of

paces made. The distance is measured roughly and quickly. The

method helps to count the number of paces between the two points of

line. The length of line is obtained by multiplying the number of

spaces and average lengths of spaces covered by the observer.

.

2.

Measuring wheel: A measuring wheel consists of a wheel mounted on

a lower end of rod about 1 m long through a fork. The upper end of the rod has a

handle. The wheel is pushed along the ground. The distance traversed is recorded

on the dial attached the wheel.

Measuring wheel

3. Odometer or Speedometer. Odometer registers the number of

revolutions of the wheel and speedometer gives the total distance

traversed. All automobiles have a speedometer to indicate the speed

and the distance travelled. If the ground is smooth, the speedometer

can be used to measure the distance.

Chaining and taping methods

In the actual surveying, distance is measured by a chain or a tape of different lengths and

accordingly it is called chaining or taping methods. Formerly engineers chain or Gunter chain

was used to measure the distance. The engineers chain was 100ft long and has 100 links each

one foot long. This chain was very convenient in earlier days when distances were measured in

miles, furlong and feet.

By Surveying Instructors

2012/2013

DBU

Civil dep't

Surveying I

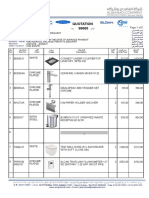

Taping instruments

Various instruments required to measure the distances in chaining or taping are chain or tape,

pegs, arrows, plumb-bob; ranging rods, hand level, etc.

1. Tapes: - are used to measure the length accurately. They are made up of variety of

materials, length and weight. Most commonly used tapes are as follows;

1. Linen or cloth tapes: These tapes are made of linen or cloth. The tape is light and

handy but not very accurate. These tapes are available in length of 10m 20m, 25m

and 30m.

2. Glassfibre tapes: Made of glass fibre and are quite flexible, strong, and nonconductive.

3. Metallic tapes: These tapes are similar to linen tapes but are made of water proof

fabric or glass-fibre in which metallic wires are interwoven. The length varies from

10m to 50m.

4. Steel tapes: The steel tapes are the most commonly used tapes in surveying. They are

more accurate than metallic tapes. They are made of steel or stainless steel strip. They

are available in lengths of 1, 3, 5, 10, 20, 30 and 50ms.

5. Invar Tapes. Invar tapes are made of an alloy of steel (64%) and nickel (36%), which

has a very low coefficient of thermal expansion. And used in high precision

measurements such as those for base lines. Invar tapes are used for linear

measurements of very high precision.

a) Steel tape

b) Invar tape

2. Pegs; are used to mark the end or terminal points of a survey line or positions of survey

stations. They are square in section and tapered at one end. The most size of the peg is

25mm*25mm and length is 150cm.

3. Arrows; are also called taping or marking pins between two points which are more than a tape

length apart they are used to mark the positions of the survey stations and the end points of

survey lines. Sometimes their lengths vary from 250mm to 500mm and they are black enamelled.

By Surveying Instructors

2012/2013

DBU

Civil dep't

Surveying I

4. plumb-bob; is pointed metal weight used as centering aid of compass, to transfer theodolite. It

is also required to transfer the point to the ground while chaining along sloping ground. It is also

used for making the ranging poles vertical and transfer point from a line ranger to the ground.

5. Ranging rods or poles; ranging rod is made up of wood, metal or fibre-glass. The process of

locating a number of points on a long survey line is called ranging. Ranging rods are used to

locate intermediate points such that these points lie on the straight line joining the end stations.

They are used as temporary signals to indicate the locations of points or directions of lines.

6. Hand or sprit levels; is required to use to maintain the two ends of the tape in the same

horizontal plane when taping over a slopping or irregular terrain.

Ranging rods hold by ranging rod tripods

plumb bob

Tapping errors and corrections

Error in tapping may be cumulative or compensating. Cumulative errors occurs in the same

direction and tends to accumulate, where as compensating error occurs in either direction, hence

tends to compensate. Errors are positive or negative as they present the result too large or too

small. Errors may arise from the following;

A. Sag in chain or tape; when a distance is measured by stepping or stretching the chain or

tape above the ground due to irregular topography or undulations the tape sags and takes

the form of a catenary and measured distance is more.

B. Change in temperature; length normally becomes more with the increase of

temperature and the measured distance. Thus, the length becomes less than the actual and

error becomes negative. In cold weather, chains or tapes shrink and thus, distance

becomes more than the actual distance and error becomes positive. In both the cases error

is cumulative.

C. Erroneous length of chain or tape; this is an error due to wrong length of the chain or

tape. The wrong length can be original or due to change of temperature, due to pull or

continuous use. If length is more, measured value is less, measured distance is more and

the error is cumulative.

D. Variation of pull; if pull applied in straightening the chain or tape is not equal to that of

the standard pull at which it was calibrated it may increase or decrease and therefore error

is bound to happen. Depending on more or less pulls or always more or less pull, error

may be cumulative or compensating.

By Surveying Instructors

2012/2013

DBU

Civil dep't

Surveying I

E. Bad ranging; takes the chain or tape out of line and measured distance is always more

and thus, error is positive. In measuring distances bad ranging is not very serious. But

when offsetting is to be done on the line, this error is very serious.

F. Personal mistakes; like displacement of arrows, wrong counting of chain, misreading of

tallies of the chain, erroneous booking in the field book, etc., cause error in surveying.

The surveyor and the chain man should be very careful in recording or reading the data

measured.

Tape corrections

Steel tapes are calibrated under a specific temperature and tension. Change in temperature,

tension and mode of support affect the result of taping. The errors caused by these sources

behave according physical laws and can be expressed with mathematic expressions. They are

known as systematic errors.

1. Corrections for absolute length or standardization; the absolute length of the tapes

becomes different from the designated or normal length due to continuous use, wear

and tear, stretch and shrink, and so on. Therefore correction is necessary. The

correction for absolute length is given by;

Ca = C *L

l

Where; Ca = correction for standardization

C = correction per tape length

L= the measured length of the line

l = the designated or nominal tape length.

And correction per tape length is given by;

C = L-l

2. Corrections for temperature; if tape is used at a field temperature different from the

standard temperature then the temperature correction to the measured length is;

C t L t t s

= the coefficient of thermal expansion of the tape material

steel: 0.0000115 m/(m C)

invar: 0.000001 m/(m C)

t = the field temperature

ts = the standardization temperature

Note: The sign of the correction takes the sign of (t- ts).

To apply this correction a thermometer is needed.

Where

By Surveying Instructors

2012/2013

DBU

Civil dep't

Surveying I

3. Correction for pull or tension; if the pull applied to the tape in the field is different

from the standard pull, the pull correction is to be applied to the measured length. The

correction is ;

Cp

Where

P PS L

AE

P = the tension applied in the field.

Ps = the standard/ calibration tension (tape at e.g.: 50N=5kp)

A = the cross sectional area of the tape.

E = Youngs modulus for the tape material (N/ mm2)

L= the observed length.

Note: The sign of the correction takes that of quantity (P-Ps)

To apply this correction a tension handle is needed.

4. Correction for sag; sag causes a recorded distance to be greater than the actual.

Correction is applied when the horizontal chord length is always shorter than the

curved length. A tape supported only at the two ends will sag in the centre by an

amount that is related to its weight and the pull(tension). In the case of a long tape

intermediate supports can be used to reduce the magnitude of the correction.

Cs

Where

w 2 L3

24P 2

w = the weight of the tape per unit length

L = the observed length

P = the tension applied in the field.

Note: If the tape in used on a plane surface, which can be considered, flat then no

Correction is applicable.

To apply this correction a tension handle is needed.

5. Correction for slope; In surveying it is essential that horizontal lengths are

determined. When a distance lies along a uniform slope and when the difference in

height between the two end points has been determined it may be preferable to

measure the distance directly (see also figure 1).

By Surveying Instructors

2012/2013

DBU

Civil dep't

Surveying I

A

h

horizontal distance

Figure 1

Afterwards the horizontal distance can be computed by applying the following

correction:

Cg

Where:

h 2

2s

h =the difference in height between the end points

s =the measured slope distance

6. Correction to mean sea level; In the case of long lines the relationship between the

length measured on the ground and the equivalent length at mean sea level has to be

considered.

distance (Lm)

earths surface

distance to msl (Lmsl)

mean sea level

By Surveying Instructors

2012/2013

DBU

Civil dep't

Surveying I

In the measured length is Lm and the height of the line above datum is H then the

correction to be applied is

C msl Lm

H

R

Exercise on basic tape measurements

1. A survey line was measured with a tape, believed to be 20m long, a length of

284.62m resulted. On checking, the tape was found to measure 19.95m long.

a) What was the correct length of the line?

b) If the line measured is a slope distance and the difference in height

between the end points is 14.20m what would be the reduced

horizontal length used in the plotting of the survey?

c) What reading is required to produce a horizontal distance of 15.08m

between two site pegs, one being 0.66m above the other?

Solution

a) A length of 20m has been booked overall, but actually only a length

of 19.95m has been covered.

19.95 284.62

283.91m

20

Correct length of line =

b) the correction for slope has to be applied:

By Surveying Instructors

2012/2013

DBU

Civil dep't

Cg: =

Surveying I

14.20 2

2 283.91

= 0.36m

The horizontal distance is therefore: 283.91-0.36 = 283.55m

c) the following reading is required:

0.66

15.08 2 15.09m

Slope distance =

Example 2: The distance AB on the ground as measured on a plan drawn to a scale of 1 cm = 50

m, was found to be 500 m. Later it was detected that the surveyor wrongly used a scale of 1 cm

= 40 m in calculations. Find the true length of the line AB.

Solution: Let AB be the correct length on the plan.

The length ab on the plan with the scale of 1 cm = 40 m used for calculating the distance AB on

the ground = 500/40 = 12.5 cm.

The true scale is 1 cm = 50 m.

The true distance on the ground, AB = 50 X 12.5= 625 m.

By Surveying Instructors

2012/2013

DBU

Civil dep't

By Surveying Instructors

Surveying I

2012/2013

Вам также может понравиться

- Lesson 3-4Документ40 страницLesson 3-4Joyce AsisОценок пока нет

- Errors in Chain SurveyДокумент8 страницErrors in Chain SurveyDon Joaquin Lim DalisayОценок пока нет

- Methods of MeasurementДокумент10 страницMethods of Measurementanon_633165161Оценок пока нет

- Chapter Three Measuring Horizontal DistanceДокумент12 страницChapter Three Measuring Horizontal Distanceyared mola100% (1)

- Lecture 1 Distance Correction Problem SolvingДокумент1 страницаLecture 1 Distance Correction Problem SolvingErych E. SinadОценок пока нет

- Ceng 3601-Mid ExamДокумент2 страницыCeng 3601-Mid ExamRefisa Jiru100% (1)

- Constants of TacheometerДокумент6 страницConstants of Tacheometervk100Оценок пока нет

- Triangulation NotesДокумент13 страницTriangulation NotesNagarajHBОценок пока нет

- 117Документ2 страницы117Toni0% (2)

- Chapter Four Geometric Design of Highways: By: Wubamlak A. (MSC in Transportation Engineering)Документ68 страницChapter Four Geometric Design of Highways: By: Wubamlak A. (MSC in Transportation Engineering)Gadisa Tefera100% (1)

- In A Nutshell Problem Set: Measurement of Horizontal DistanceДокумент6 страницIn A Nutshell Problem Set: Measurement of Horizontal DistanceVinloyd YbanezОценок пока нет

- Errors in Tacheometric Surveying: This Study Resource Was Shared ViaДокумент6 страницErrors in Tacheometric Surveying: This Study Resource Was Shared ViaBindeshwar YadavОценок пока нет

- Two Peg TestДокумент24 страницыTwo Peg TestjatteОценок пока нет

- Project For Module 1 - Problem Set With SolutionДокумент23 страницыProject For Module 1 - Problem Set With SolutionNara JoОценок пока нет

- Module 2 Topographic Surveys 2Документ22 страницыModule 2 Topographic Surveys 2Ciara PamorОценок пока нет

- Lab 7 - Profile and Cross-SectionДокумент5 страницLab 7 - Profile and Cross-SectionMuhammad NuraОценок пока нет

- Errors in Measurements and Its Propogation PDFДокумент19 страницErrors in Measurements and Its Propogation PDFPiyush GuptaОценок пока нет

- Horizontal Alignment PDFДокумент15 страницHorizontal Alignment PDFAnteneh Geremew100% (1)

- Stability Experiment 2 UpdateДокумент7 страницStability Experiment 2 UpdateApostrophe Fareez ImprezzaОценок пока нет

- Fundamental of Surveying 2Документ26 страницFundamental of Surveying 2felix mapilesОценок пока нет

- Lab Report No1 (Cmats)Документ6 страницLab Report No1 (Cmats)Allen Jesse Alfonso AtanacioОценок пока нет

- Surveying Lab ReportДокумент12 страницSurveying Lab ReportAmmar MddeniОценок пока нет

- Three-Wire and Reciprocal LevelingДокумент13 страницThree-Wire and Reciprocal LevelingAdonis C. Bibat50% (2)

- CE2080 Practice QuestionsДокумент11 страницCE2080 Practice QuestionsRishabhDuttОценок пока нет

- Traverse SurveyДокумент9 страницTraverse SurveyIkhwan JoniОценок пока нет

- Open Channel Depth Calculator Using VBAДокумент2 страницыOpen Channel Depth Calculator Using VBAmatt gramОценок пока нет

- Ece 2202 - Surveying 1 - August 2012Документ4 страницыEce 2202 - Surveying 1 - August 2012Joe NjoreОценок пока нет

- Complete Field Book (Surveyeying and Levelling 1)Документ33 страницыComplete Field Book (Surveyeying and Levelling 1)M Hussain BashirОценок пока нет

- FW - 1 - Distance by TapingДокумент4 страницыFW - 1 - Distance by TapingJersonFerrerasPuaОценок пока нет

- Lecture 13 - Vertical AlignmentДокумент20 страницLecture 13 - Vertical AlignmentSesay AlieuОценок пока нет

- Introduction To Surveying Instrument Use and Surveying FieldworksДокумент29 страницIntroduction To Surveying Instrument Use and Surveying FieldworksaljonОценок пока нет

- Tacheometry: Lesson 23 Basics of Tacheometry and Stadia SystemДокумент20 страницTacheometry: Lesson 23 Basics of Tacheometry and Stadia SystemMuhammed AliОценок пока нет

- Chain SurveyingДокумент3 страницыChain SurveyingUlfathbary AB100% (3)

- Geometric Design Note Plus ProblemsДокумент48 страницGeometric Design Note Plus ProblemsAndenet Ashagrie50% (2)

- HW Engineering I Solution To Selected Workout ProblemsДокумент12 страницHW Engineering I Solution To Selected Workout ProblemsHaile GuebreMariamОценок пока нет

- Fundamentals of Surveying - Omitted MeasurementsДокумент12 страницFundamentals of Surveying - Omitted MeasurementsJulius CodiamatОценок пока нет

- What Would Be The Effect On The Results If The Venturi Meter Were Not HorizontalДокумент4 страницыWhat Would Be The Effect On The Results If The Venturi Meter Were Not HorizontalWilliam Arthur Mackloren0% (1)

- Lecture Notes-Module I - Lecture 1 PDFДокумент7 страницLecture Notes-Module I - Lecture 1 PDFmadhuripathakОценок пока нет

- Chapter 7: Flow NetsДокумент12 страницChapter 7: Flow NetsYhancie Mae Torres0% (1)

- Surveying Ii (Final 31.12.2018) - 1 PDFДокумент214 страницSurveying Ii (Final 31.12.2018) - 1 PDFVicky rubanОценок пока нет

- Surveying Lab ManualДокумент33 страницыSurveying Lab Manualhima sagarОценок пока нет

- Lesson 2 - Chain SurveyingДокумент34 страницыLesson 2 - Chain SurveyingBryanОценок пока нет

- Horizontal and Vertical CurvesДокумент29 страницHorizontal and Vertical CurvesSandro SorianoОценок пока нет

- Compound CurveДокумент4 страницыCompound CurveChery Davalos Dote100% (2)

- Dcc20063 - Engineering Survey Lab Report 4: CurveДокумент17 страницDcc20063 - Engineering Survey Lab Report 4: CurvewawaОценок пока нет

- The Engineer'S Transit and Theodolite: Lesson 30Документ8 страницThe Engineer'S Transit and Theodolite: Lesson 30jake maramot100% (1)

- Experiment No. 2 Intersection Method - Plane Table SurveyingДокумент3 страницыExperiment No. 2 Intersection Method - Plane Table SurveyingSwapnil ShindeОценок пока нет

- 14 Making and Curing Concrete Test Specimens in The FieldДокумент6 страниц14 Making and Curing Concrete Test Specimens in The FieldJohn MarkОценок пока нет

- Report Lab#4Документ8 страницReport Lab#4ibrahim100% (2)

- Unit 2 Tacheometric Surveying: StructureДокумент14 страницUnit 2 Tacheometric Surveying: Structuresharonlly toumasОценок пока нет

- Compound CurveДокумент15 страницCompound CurveRohit100% (1)

- Tacheometric Constants PDFДокумент10 страницTacheometric Constants PDFAditya100% (2)

- Tape Corrections Bsce 2ya 5Документ13 страницTape Corrections Bsce 2ya 5PHEBY MOOG100% (1)

- Surveying RevisionДокумент15 страницSurveying RevisionDenis WaweruОценок пока нет

- Spot Speed StudyДокумент8 страницSpot Speed Studyvino0% (1)

- Surveying Distance TopicДокумент14 страницSurveying Distance Topicgreyproperties88Оценок пока нет

- Chapter-Five: Basic Operations in SurveyingДокумент29 страницChapter-Five: Basic Operations in SurveyingEba GetachewОценок пока нет

- Horizontal Distance MeasurementДокумент16 страницHorizontal Distance MeasurementAlfonso John AnthonyОценок пока нет

- Learning Module 2 CE 245Документ20 страницLearning Module 2 CE 245Benmark JabayОценок пока нет

- PART III: Basic Survey Observations: 3.1. Horizontal DistanceДокумент34 страницыPART III: Basic Survey Observations: 3.1. Horizontal DistancealjonОценок пока нет

- College of Engineering: Debre Berhan UniveristyДокумент2 страницыCollege of Engineering: Debre Berhan UniveristyZeleke TaimuОценок пока нет

- Debre Berhan UniversityДокумент108 страницDebre Berhan UniversityZeleke Taimu100% (1)

- Strap or Cantilever Footings ExampleДокумент14 страницStrap or Cantilever Footings ExamplehОценок пока нет

- Habtamu Fentahun Id 1044Документ40 страницHabtamu Fentahun Id 1044Zeleke TaimuОценок пока нет

- X-Coordinet y - CoordineteДокумент3 страницыX-Coordinet y - CoordineteZeleke TaimuОценок пока нет

- Asmamaw Belay ID 07000694Документ37 страницAsmamaw Belay ID 07000694Zeleke TaimuОценок пока нет

- Project Cover PageДокумент5 страницProject Cover PageZeleke TaimuОценок пока нет

- Dam Foundation Treatment: GroutingДокумент27 страницDam Foundation Treatment: GroutingZeleke TaimuОценок пока нет

- Pile Foundation: Capacity AnalysisДокумент43 страницыPile Foundation: Capacity AnalysisZeleke TaimuОценок пока нет

- Wks SBD NCB Section 9Документ6 страницWks SBD NCB Section 9Zeleke TaimuОценок пока нет

- Project Cover PageДокумент5 страницProject Cover PageZeleke TaimuОценок пока нет

- Wind & Earth QuakeДокумент18 страницWind & Earth QuakeZeleke TaimuОценок пока нет

- Chapter 6 Pile FoundationДокумент77 страницChapter 6 Pile FoundationZeleke TaimuОценок пока нет

- Sieve Analysis at 1 Meter: Description of Sample: For Geotechnical InvestigationДокумент41 страницаSieve Analysis at 1 Meter: Description of Sample: For Geotechnical InvestigationZeleke TaimuОценок пока нет

- Wks SBD NCB Section 5Документ1 страницаWks SBD NCB Section 5Zeleke TaimuОценок пока нет

- ActivatorДокумент1 страницаActivatorZeleke TaimuОценок пока нет

- Soil Mechanics I.handoutДокумент114 страницSoil Mechanics I.handoutZeleke Taimu100% (1)

- Chapter 6 Pile FoundationДокумент37 страницChapter 6 Pile FoundationZeleke TaimuОценок пока нет

- Wks SBD NCB Section 7Документ17 страницWks SBD NCB Section 7Zeleke Taimu100% (1)

- The Federal Democratic Republic of Ethiopia: Standard Bidding Document (SBD)Документ1 страницаThe Federal Democratic Republic of Ethiopia: Standard Bidding Document (SBD)Zeleke TaimuОценок пока нет

- Pavement History: Portland Cement ConcreteДокумент23 страницыPavement History: Portland Cement ConcreteZeleke TaimuОценок пока нет

- Chapter Two Bidding Procedures and Contract TypesДокумент31 страницаChapter Two Bidding Procedures and Contract TypesZeleke TaimuОценок пока нет

- User's Guide: Federal Democratic Republic of EthiopiaДокумент65 страницUser's Guide: Federal Democratic Republic of EthiopiaZeleke Taimu100% (1)

- Wks SBD NCB Section 8Документ3 страницыWks SBD NCB Section 8Zeleke TaimuОценок пока нет

- Chapter 4 Part 1Документ20 страницChapter 4 Part 1Zeleke TaimuОценок пока нет

- Chapter-: Time Control and MonitoringДокумент54 страницыChapter-: Time Control and MonitoringZeleke TaimuОценок пока нет

- Construction Site Supervision COTM 3231Документ20 страницConstruction Site Supervision COTM 3231Zeleke TaimuОценок пока нет

- Chapter-Five: Cost Control and MonitoringДокумент11 страницChapter-Five: Cost Control and MonitoringZeleke TaimuОценок пока нет

- Project Delivery Methods: ARE 413 Construction Management Class-5Документ43 страницыProject Delivery Methods: ARE 413 Construction Management Class-5Zeleke TaimuОценок пока нет

- VULCAN Instruction Manual ALL-A4Документ94 страницыVULCAN Instruction Manual ALL-A4Ayco DrtОценок пока нет

- STOD-OTP-PMT-0805-HS-SPE-0001 Specification For Temporary Construction Camps and Ancillary FacilitiesДокумент25 страницSTOD-OTP-PMT-0805-HS-SPE-0001 Specification For Temporary Construction Camps and Ancillary Facilitiesjfl2096Оценок пока нет

- ICON Catalog LocationsДокумент16 страницICON Catalog LocationsTools StuffsОценок пока нет

- Sabre-Baggage Management and Analysis SystemДокумент24 страницыSabre-Baggage Management and Analysis Systemdifaini anugrahОценок пока нет

- Final Upcat Mock ExamДокумент24 страницыFinal Upcat Mock Examjbgonzales8Оценок пока нет

- Error Number Mentor GraphicsДокумент30 страницError Number Mentor GraphicsMendesОценок пока нет

- Velocloud OverviewДокумент29 страницVelocloud OverviewFebri RawlinsОценок пока нет

- SunstarДокумент189 страницSunstarSarvesh Chandra SaxenaОценок пока нет

- Seismic Design & Installation Guide: Suspended Ceiling SystemДокумент28 страницSeismic Design & Installation Guide: Suspended Ceiling SystemhersonОценок пока нет

- Synthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Документ9 страницSynthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Ved PrakashОценок пока нет

- Battery Power Management For Portable Devices PDFДокумент259 страницBattery Power Management For Portable Devices PDFsarikaОценок пока нет

- RTE Online Application Form For Admission Year 2018 19Документ6 страницRTE Online Application Form For Admission Year 2018 19sudheer singhОценок пока нет

- Logcat 1693362990178Документ33 страницыLogcat 1693362990178MarsОценок пока нет

- Bomba FlightДокумент2 страницыBomba FlightGustavo HRОценок пока нет

- Misc Forrester SAP Competence CenterДокумент16 страницMisc Forrester SAP Competence CenterManuel ParradoОценок пока нет

- Sd-1-Parts-Book Manual Propietario SpreaderДокумент30 страницSd-1-Parts-Book Manual Propietario Spreadergabriel sanchezОценок пока нет

- REE Copy PDFДокумент9 страницREE Copy PDFJake ZozobradoОценок пока нет

- Excel CatДокумент132 страницыExcel Catjuanf_scribdОценок пока нет

- Data Structure Algorithm Using C PresentationДокумент245 страницData Structure Algorithm Using C PresentationdhruvwОценок пока нет

- Iso 9974-2Документ4 страницыIso 9974-2willianОценок пока нет

- EM000039Rev1 PDFДокумент1 страницаEM000039Rev1 PDFGustavo RiveraОценок пока нет

- Cable Ties DatasheetДокумент7 страницCable Ties DatasheetGovind ChaudhariОценок пока нет

- Yucca Mountain Safety Evaluation Report - Volume 2Документ665 страницYucca Mountain Safety Evaluation Report - Volume 2The Heritage FoundationОценок пока нет

- Project Presentation SurveyingДокумент14 страницProject Presentation SurveyingSACHIN MEENAОценок пока нет

- Suzuki B-King Indicator Mod CompleteДокумент9 страницSuzuki B-King Indicator Mod Completehookuspookus1Оценок пока нет

- Paper AeroplaneДокумент19 страницPaper Aeroplanejkb SudhakarОценок пока нет

- Quotation 98665Документ5 страницQuotation 98665Reda IsmailОценок пока нет

- Alloc 150 DMДокумент301 страницаAlloc 150 DMSheik Mohamed ImranОценок пока нет

- Republic Act No. 10913 - Anti-Distracted Driving ActДокумент4 страницыRepublic Act No. 10913 - Anti-Distracted Driving Act...Оценок пока нет

- Water System PQДокумент46 страницWater System PQasit_mОценок пока нет