Академический Документы

Профессиональный Документы

Культура Документы

Ductility

Загружено:

SaharAkthamОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ductility

Загружено:

SaharAkthamАвторское право:

Доступные форматы

International Journal of Modern Engineering Research (IJMER)

www.ijmer.com

Vol.2, Issue.5, Sep-Oct. 2012 pp-3517-3521

ISSN: 2249-6645

A Study on the Ductility of Bolted Beam- Column Connections

Shemy S. Babu1, S. Sreekumar2

Department of Civil Engineering College of Engineering, Trivandrum, Kerala

ABSTRACT: The behaviour of beam-column joint plays

an important role in the response of a steel moment

resisting framed structure especially under seismic

excitation. Semi rigid connections like bolted joints, allow

better energy dissipation and provide good response under

lateral loads. In this paper the ductility and energy

dissipation characteristics of semi rigid bolted connections

using double web angle with top and seat angles is

discussed based on experimental investigation. Non-linear

analysis was also performed using finite element method to

compare the results. The study revealed that ductile

behaviour of beam-column connection is improved by

increasing the number of bolts on the top and seat angles

and the thickness of top and seat angles. The analytical

results are in agreement with the experimental results.

Keywords: semirigid connections; beam column joints

I. INTRODUCTION

Structural steel framework with welded joints was

considered as one of the best moment resisting framed

structural system till the 1994 Northridge earthquake. In the

earthquake, many structural steel frames failed due to the

occurrence of brittle fractures at the connections. This

caused the loss of reliability on steel welded moment

resisting frames. Since then, as an alternative, bolted

connections, often called semi-rigid connections, are

considered for design of steel moment resisting frames and

retrofitting works.

The behaviour of beam-column joint plays an

important role in the response of a steel moment resisting

framed structure. It strongly influences the seismic

behaviour and energy dissipation capacities of the moment

resisting frames. The use of bolted joints allows more

energy dissipation and provides a good response under

lateral loads. In structural framework with semi-rigid joints,

the characteristics of connections play a significant role in

the energy-dissipation mechanisms. As rigid connections

are more expensive and difficult to assemble and because

flexible connections do not have the necessary resistance

and stiffness to resist the lateral loads, use of semi-rigid

connections using bolted angles is justified. Semi-rigid

connections with angles connecting the web and flanges of

the beam to the column flange are cheaper and simpler to

assemble when compared to other conservative joint.

Various studies have revealed that semi-rigid steel

frames have the potential to be used in buildings located in

high seismic prone regions. It was found that bolted-angle

connections have stable cyclic response and energy

dissipation capacity depending on the size of the angles and

bolts.

This paper is concerned with the study of structural

response of a typical semi-rigid steel beam-column

connection. In particular, the behaviour of double web angle

bolted beam-column connection is experimentally

investigated under monotonic loading using top and seat

angle sections. Static half cycle load tests were performed

to compare the energy absorption capacity of various

connections. The effect of various joint parameters such as

diameter of bolts, number of bolts on top and seat angle,

thickness of top and seat angles etc. on energy dissipation

capacity of the joint was studied experimentally. Analytical

study on the behaviour of double web angle connections

with and without top and seat steel angle sections

simulating the experimental investigation was performed

with the help of finite element software.

II. RELATED STUDIES

In recent years, a number of research works were

carried out to study the behaviour of semi-rigid connections.

This section deals with the review of the works related to

the semi-rigid connections. Cheol and Young [1] conducted

experimental investigation on the cyclic load behaviour of

steel frames with bolted joints in comparison with welded

joints for an exterior beam column joint. Three different

types of connections viz. semi-rigid connection using high

strength bolts, simple bolted connection and welded

connection were considered in the study for varying effect

of initial stiffness, maximum flexural resistance, failure

modes, ductility and energy dissipation.

Chen et al. [2] discussed a new method of

trimming the beam flanges in order to enhance the ductility

of beam-column connection keeping the ultimate strengths

unaltered and increasing the plastic rotation capacity and

energy dissipation capacity.

Secer and Ozturk [3] studied the dynamic

characteristics of semi-rigid frames and the influence of

connection flexibility on the dynamic characteristics of

frames analytically. Christopoulos et al. [4] presented

characteristics of joints with post-tensioned energy

dissipation connections. The beam-column connections

were modelled as rotational springs attached at the ends of

the members and the load carrying capacity, end member

forces and deformation of frames with semi-rigid

connections were determined using direct stiffness method.

The influence of partial rigidity of beam-column connection

on the behaviour and stability of frames was discussed

(Frederick and Abuyasein, [5]). An expression for fixity

factor, indicating the degree of rigidity of joint was derived

in the study. Kartal et al. [6] conducted numerical studies

for finding the response of frames with semi-rigid

connections under different material and geometric

idealization strategies.

III. EXPERIMENTAL INVESTIGATION

A schematic cantilever type test set up shown in

Fig. 1 was adopted to study the semi rigidity behaviour of

bolted beam-column joints. Ends of the column were

supported and load was applied at the free end of beam

member.

www.ijmer.com

3517 | Page

International Journal of Modern Engineering Research (IJMER)

www.ijmer.com

Vol.2, Issue.5, Sep-Oct. 2012 pp-3517-3521

ISSN: 2249-6645

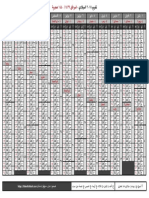

Table. I. Details of specimen tested

Fig. 1. Schematic diagram- Cantilever test set-up

The load was applied gradually and the deflections

at three different points on the beam were measured. The

cantilever test setup was arranged within the straining unit

of 100t AVERY make universal testing machine. The

column member was supported in the top and bottom

compression plate of universal testing machine. Since the

study was focused on the behaviour of connection, the use

of convenient dimensions and boundary conditions adopted

was justified. Considering the limitations in the space

between the compression plates and connection facilities,

suitable height and appropriate section was assumed for the

column member. Standard steel section ISMB

200@25.4kg/m was used for beam and column members.

The schematic diagram of the test setup is shown in Fig.2.

Fig. 3. Experimental setup

The connection details of the specimens tested are

given in Table. I. The test specimen S1 had the connection

with top and seat standard angle section ISA 40406 using

2 numbers of 6mm diameter high strength bolt.

Fig.2. Schematic diagram-test set-up

The column was set free of initial stresses. The

load was applied using a hydraulic jack and a proving ring

of capacity 100kN was used for measurement. The dial

gauges were fixed on the top of the beam member at the

free end at a distance of 100mm, and 200mm from free end.

A photograph of the experimental test setup is shown in

Fig. 3. High strength structural bolts were used for

connections.

The geometrical parameters varied in the study are

the thickness of top and seat angle, number of bolts and the

bolt diameter. The connection details of double web angle

are given in Fig. 4. A gap of 6mm was provided between

the column and beam to allow the rotation without

damaging the column and beam members.

The ultimate condition was assumed as the closure

of gap provided between the beam and column members or

the failure of bolts whichever is earlier. The deflections at

three points on the top of beam as shown in Fig. 2 were

measured using dial gauges.

Fig. 4. Typical connection.

( Inset shows the details of web angle connection).

IV. DUCTILITY

Ductility plays an important role in seismic design.

The joint behaviour has a direct influence on the ductility.

The ductility factor is one of the parameters characterising

the behaviour of a structure or joint in plastic range.

Considering the rotation of joints, rotational ductility factor

is given by (1).

r

u

y

(1)

u is the rotation on ultimate state and y is the rotation

on reaching first yield point of joints.

ENERGY DISSIPATION CAPACITY

The connection stiffness F of beam is related with

moment (M) and rotation of beam at the joint () by (2).

The connection stiffness of column assuming the

connection to be at the centre of column given by (3) can be

www.ijmer.com

3518 | Page

International Journal of Modern Engineering Research (IJMER)

www.ijmer.com

Vol.2, Issue.5, Sep-Oct. 2012 pp-3517-3521

ISSN: 2249-6645

obtained from the analysis of a member fixed at both ends

and subjected to a moment at the centre.

F

(2)

MLC

16 EI C

(anti-clockwise)

(3)

is the rotation of the column at the joint, LC is the length

of column member, E is the Youngs modulus of elasticity

of the material, and IC is the moment of inertia of column

section.

Brick elements with 20 nodes, SOLID 95 available in the

ANSYS element library, were used in the three dimensional

modelling of beam, column angles and bolts. The contact

surfaces including the areas anticipated to be in contact

were defined and paired using contact elements,

CONTA174 and TARGE170. For structural steel used, the

yield stress was taken as 250 N/mm2, ultimate tensile

strength as 410 N/mm2 and % elongation of 23 as per IS

2062:1999. For the high strength bolts used, yield stress of

640 N/mm2, ultimate stress of 800 N/mm2, and 12%

elongation were adopted as per IS 1367 (Part 3):2002. The

modulus of elasticity of steel was taken as 2105 N/mm2.

The column and beam members were modelled and mapped

meshing consisting of brick elements was performed as

shown in Fig. 6.

Fig. 5 Semi-Rigid Beam Member

VI. RESULTS AND DISCUSSION

PL B 2 LC

PL B 3

PL B 2

3EI B

F

16 EI C

(4)

From (4) the beam connection stiffness, F, can be

determined. Thus the beam rotation and column rotation can

be determined by using (2) and (3). Using and , relative

rotation at joint

( y ) can be computed. The momentrelative rotation curve can be then plotted. The energy

dissipated by the connection is quantified by computing the

area under the moment-relative rotation curve.

V. FINITE ELEMENT ANALYSIS

In the present problem, moment-relative rotation

behaviour of bolted beam-column connection is studied

numerically. As the members associated with the

connection undergo large deformations and rotations,

geometric and material non-linearity are to be accounted in

the problem. Since all the experiments are performed under

static loading condition, a static non-linear structural

analysis is required for simulating the real problem.

Conventional 3D brick elements are inadequate to represent

the realistic contact behaviour in the column-beam interface

and bolt-plate interface under incremental loading

conditions. Contact problems can be efficiently handled

with ANSYS.

Experimental Results

The moment-rotation behaviour of specimens with

different geometric parameters of double web angle

connection with top and seat angle sections discussed is

depicted in Fig. 7. In the figure, two regions, elastic region

followed by yielding, can be noted for all repeated test

cases. The curves of specimens S1 and S2 shown in Fig. 7

indicates that as the diameter of bolt (d) is increased,

ultimate moment and ultimate rotation increased. There was

an increase of 67% in the ultimate moment when the

diameter was increased from 6mm to 10mm.

Table. II shows the effect of the ratio of diameter

of bolt (d) to thickness of angle (t) on energy dissipation.

When number of bolt was doubled an increase of 508% in

energy dissipation was observed for top and seat angle

connection with d/t ratio 1 and an increase of 62% for top

and seat angle connection with d/t ratio 2. As the number of

bolts increased (specimens S1 and S3) there is an increase

in the ultimate rotation with slight increase in ultimate

moment. Hence the ultimate moment and ultimate rotation

depends on the number of bolts as well as the diameter of

bolts. The rotational ductility calculated by (1) and the

energy dissipated are presented in Table. III. There is

considerable energy dissipation capacity for all the

connections with top and seat angles. The energy

dissipation is also higher for angle with more thickness (t)

and large number of bolts (specimen S3).

14000

12000

S1

10000

S2

8000

S3

6000

S4

4000

S5

2000

S6

Moment in kNmm

The deflection of a member with one end free and

other end connected semi-rigidly and subjected to point

load at free end as shown in Fig. 5 is given by (4). IB is the

moment of inertia of the beam cross section. The clockwise

rotation is assumed to be positive and downward deflection

is considered negative.

0

0.000

0.050

0.100

0.150

0.200

0.250

Relative rotation in rad

Fig. 7. Moment- relative rotation curve of specimens with

Angle Sections

Table. II Energy dissipation for different d/t ratios

Fig. 6. Column-beam finite element mesh

www.ijmer.com

3519 | Page

International Journal of Modern Engineering Research (IJMER)

www.ijmer.com

Vol.2, Issue.5, Sep-Oct. 2012 pp-3517-3521

ISSN: 2249-6645

From Table II, on comparing joints with

connection specimens S2 and S3, it is clear that the increase

in the ductility is more if the bolt area is changed by

increasing the number of bolts rather than increasing the

diameter of individual bolt. It is clear from Table III that the

ductility can be improved by increasing the number of bolts

as well as the angle thickness.

Table. III. Energy dissipated by the connection

The moment-relative rotation curve under static

half cycle loading of double web angle connection

(specimen S7) in comparison with top and bottom seat

angle connection (specimen S5) is depicted in Fig. 8.

12000

Moment in kNmm

10000

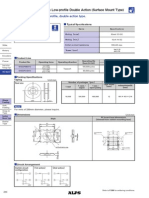

Finite Element Analysis using ANSYS10

Finite element model of one of the specimen S1 is

shown in Fig. 10. In the nonlinear analysis, a maximum

load of 30kN was taken and the solution was converged at

the ninth sub step (corresponding load was 27kN). The

deflected shape of the beam-column joint is shown in Fig.

11. The load-deflection and moment-rotation curves for

specimen S1 obtained analytically and experimentally were

compared in Fig. 12. Deflection at free end of beam is

designated as dl in the graph.

For the specimen S2 the solutions get converged to

a load of 39.5kN (14th substep). The moment-relative

rotation curve for specimen S2 obtained analytically and

experimentally was plotted as shown in Fig. 13. Similar

behaviour was observed in the elastic range without much

variation, but there was a deviation of less than 10% of

analytical result from the experimental values was seen in

the inelastic region. A clear indication of slip at bolt was

observed near yield point during experiment and the effect

was not simulated analytically. This has resulted in the

deviation of analytical result from experimental result in

post elastic region. The load-deflection curve for specimen

S7 obtained analytically and experimentally was compared

as shown in Fig. 14. For the specimen S6 the solutions get

converged to a load of 15kN. The moment-rotation curve

for specimen S5 obtained analytically and experimentally

was plotted as shown in Fig. 15.

8000

S7-(double web

angle connection)

6000

4000

S5-(double web

angle connection

with top and seat

angle)

2000

0

0

0.05

0.1

0.15

0.2

0.25

Re lative rotation in radians

Fig. 8. Moment-relative rotation curve under

From Fig. 8, it is evident that the energy absorption

static half

cycle

loading was improved by using top and

capacity

of the

connection

seat angles. The energy absorption was increased by 180%

by providing seat angles in addition to web angles for

moment resistant connection under study. On testing the

double web angle connection specimen S7, it was found

that the bolts connecting the web angle were bent and the

gap was closed. But for the specimen S5 with top and seat

angle there was yielding of seat angle followed by breaking

of bolt in the seat angle with relatively less bending of the

bolts connecting the web angles. The leg of seat angle

connecting to the column flange was yielded as shown in

Fig. 9.

Fig. 10. Model of specimen S1

Fig. 11 Deformed model

Fig. 9 Deformed seat angle

There was only less than 10 % variation in the

analytical result when compared with experimental result.

On comparing the analytical and experimental results it can

be seen that for same load (or moment), the deflection (or

relative rotation) is more in the experimental result. This

may be due to the slip in the bolt.

www.ijmer.com

3520 | Page

International Journal of Modern Engineering Research (IJMER)

www.ijmer.com

Vol.2, Issue.5, Sep-Oct. 2012 pp-3517-3521

ISSN: 2249-6645

VII.

CONCLUSION

Based on the experimental and analytical

investigation conducted on bolted steel beam-column joint,

the following conclusions are drawn.

The use of top and seat angles improved the energy

dissipation capacity. The energy dissipation of the

connection increases as the thickness of top and seat

angles and number of bolts increases.

Increasing the number of bolts rather than increasing the

diameter of bolt in the connection with top and bottom

seat angles improves ductility.

The maximum difference observed between the analytical

and experimental results is less than 10%.

a) Load-deflection curve

NOTATIONS

E

- Youngs modulus of elasticity of the material

F

- Connection stiffness of beam

IC

- Moment of inertia of column section.

b) Moment-relative rotation curve

Fig. 12 Specimen S1-6mm thick angle, 2nos 6mm bolt

Ib

- Moment of inertia of the beam cross section.

LC

- Length of column member

- Moment

- Rotation of the column at the joint

- Rotation of beam at the joint

- Rotation on ultimate state

- Rotation on reaching first yield point of joints.

- Deflection at free end of beam.

u

y

d1

REFERENCES

[1]

Fig. 13. Specimen S2-6mm thick angle, 2nos 10mm bolt

[2]

[3]

[4]

[5]

Fig. 14 Specimen S7-double web angle connection

[6]

Cheol, M.Y., and Young, M.K., Cyclic Behaviour of

Bolted and Welded Beam to Column Joints, International

Journal

of

Mechanical

Sciences,

doi:10.1016/j.ijmecsci.2006.09.022.

Chen, S.J., Yeh, C.H and Chu, J.M., Ductile Steel Beamto-Column Connections for Seismic Resistance, Journal of

Structural Engineering, ASCE, Vol 122(11), 1996, pp 12921299.

Secer, M. and A. U. Ozturk, An Investigation for SemiRigid Frames by Different Connection Models,

Mathematical and Computational Applications, Vol 10, No

1, 2005, pp 35-44.

Christopoulos,C., Filiatrault,A., Uang,C.M., and Folz,B.,

Post Tensioned Energy Dissipating Connections for

Moment-Resisting Steel Frames, Journal of Structural

Engineering, Vol 128(9), 2002,pp 1111-1120.

Frederick, G.R., and Abuyasein, O.A., Analysis of Frames

with Semi-Rigid Joints, Computers and Structures, Vol 52,

No 6, 1994, pp 1161-1168.

Kartal M.E., Basaga H.B., Bayraktar A. and Muvafik M.,

Effects of Semi-Rigid Connection on Structural Response,

Electronic Journal of Structural Engineering, eJSE, Vol 10,

2010, pp 22-35.

Fig. 15 Specimen S6-3mm thick angle, 2nos 6mm bolt

www.ijmer.com

3521 | Page

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Avalon Astoria Service Manual PDFДокумент106 страницAvalon Astoria Service Manual PDFexchangenriОценок пока нет

- A Beginner's Guide To Fragility, Vulnerability, and RiskДокумент104 страницыA Beginner's Guide To Fragility, Vulnerability, and RiskSaharAkthamОценок пока нет

- Calender 2018 and 1339-1440Документ1 страницаCalender 2018 and 1339-1440SaharAkthamОценок пока нет

- Steel Construction and Bridges Allowable Stress DesignДокумент263 страницыSteel Construction and Bridges Allowable Stress DesignSaharAkthamОценок пока нет

- Connection DetailsДокумент7 страницConnection DetailsSaharAkthamОценок пока нет

- Connection DetailsДокумент7 страницConnection DetailsSaharAkthamОценок пока нет

- FracasДокумент12 страницFracasSaharAkthamОценок пока нет

- Seismic Behavior of Steel StructuresДокумент60 страницSeismic Behavior of Steel StructuresSaharAkthamОценок пока нет

- Jabary & Madabhushi 2015 Soil Dynamics and Earthquake EngineeringДокумент8 страницJabary & Madabhushi 2015 Soil Dynamics and Earthquake EngineeringSaharAkthamОценок пока нет

- 30 Day Decluttering ChallengeДокумент1 страница30 Day Decluttering ChallengeSaharAktham100% (1)

- Vulnerability PDFДокумент30 страницVulnerability PDFSaharAkthamОценок пока нет

- Saunders Construction-What Is A Seismic - RetrofitДокумент18 страницSaunders Construction-What Is A Seismic - RetrofitArnav Anuj KasarОценок пока нет

- PlaxisДокумент16 страницPlaxisAlejandro CastañónОценок пока нет

- CompressionДокумент10 страницCompressionSaharAkthamОценок пока нет

- CompressionДокумент10 страницCompressionSaharAkthamОценок пока нет

- Egyptian Code For Loads - 2012Документ230 страницEgyptian Code For Loads - 2012SaharAkthamОценок пока нет

- Steel Construction and Bridges Allowable Stress DesignДокумент263 страницыSteel Construction and Bridges Allowable Stress DesignSaharAkthamОценок пока нет

- Fea Bathe Part 1Документ498 страницFea Bathe Part 1SaharAkthamОценок пока нет

- Opensees Command Language Manual: Open System For Earthquake Engineering Simulation (Opensees)Документ465 страницOpensees Command Language Manual: Open System For Earthquake Engineering Simulation (Opensees)bobyОценок пока нет

- 07 Matrix FrameДокумент72 страницы07 Matrix FrameAminatul Fadillah MarpaungОценок пока нет

- Derivative RulesДокумент1 страницаDerivative Rulesitsfantastic1Оценок пока нет

- Pregatirea Suprafetelor Pentru VopsireДокумент4 страницыPregatirea Suprafetelor Pentru VopsireValentin GalbenОценок пока нет

- Scratch2Cards PDFДокумент12 страницScratch2Cards PDFdeep_p69Оценок пока нет

- Squared5x5 PDFДокумент1 страницаSquared5x5 PDFSaharAkthamОценок пока нет

- AI Dummies PDFДокумент52 страницыAI Dummies PDFSaharAkthamОценок пока нет

- FE Other CBT SpecsaДокумент4 страницыFE Other CBT SpecsaAdrian GallegosОценок пока нет

- FE Civil CBT SpecsДокумент4 страницыFE Civil CBT SpecsBarry OcayОценок пока нет

- T6: Type Abbreviations: Selection TableДокумент1 страницаT6: Type Abbreviations: Selection TableRicardo MotaОценок пока нет

- Midas Expert Training 01 Midas Gen PDFДокумент115 страницMidas Expert Training 01 Midas Gen PDFYasela100% (1)

- ALTECH PE-HD A 2010/506 GF10: Technical Data SheetДокумент2 страницыALTECH PE-HD A 2010/506 GF10: Technical Data SheetPhung LucОценок пока нет

- SUP032BR: Esp. E74104 Rev.01Документ5 страницSUP032BR: Esp. E74104 Rev.01kimanski01Оценок пока нет

- Building PlanДокумент1 страницаBuilding Planshaik moizОценок пока нет

- Ce6506 Ctep NotesДокумент183 страницыCe6506 Ctep NotesPriya ThangamuthuОценок пока нет

- IP Rating HagerДокумент20 страницIP Rating Hagervinesh_viswanathan_3Оценок пока нет

- RIM-C Floating Floor SystemДокумент5 страницRIM-C Floating Floor SystemUnited Construction Est. TechnicalОценок пока нет

- Ultratech Cement: Particulars Test Results Requirements ofДокумент1 страницаUltratech Cement: Particulars Test Results Requirements ofjitendraОценок пока нет

- Manual Calefa 1 PlantaДокумент29 страницManual Calefa 1 PlantanegrorocksОценок пока нет

- 03300Документ27 страниц03300uddinnadeemОценок пока нет

- Plasma or Flame Spraying SynthesisДокумент6 страницPlasma or Flame Spraying SynthesisOmeyya TanveerОценок пока нет

- Hardie Plank Installation GuideДокумент1 страницаHardie Plank Installation GuideBrandon VieceliОценок пока нет

- W11 Normal and Higher Strength Hull Structural Steels W11Документ45 страницW11 Normal and Higher Strength Hull Structural Steels W11Fernando ReyesОценок пока нет

- Soil Structure Berbagai Macam Struktur TanahДокумент17 страницSoil Structure Berbagai Macam Struktur TanahFauziah AlmunawarohОценок пока нет

- 20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelДокумент5 страниц20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelzhenyupanОценок пока нет

- NPSHДокумент7 страницNPSHsateesh chandОценок пока нет

- Efunda - Plate Calculator - Clamped Circular Plate With Uniformly Distributed Loading-12.06.2017Документ2 страницыEfunda - Plate Calculator - Clamped Circular Plate With Uniformly Distributed Loading-12.06.2017vinay1999Оценок пока нет

- Polystone P Homopolymer: Technical Data SheetДокумент1 страницаPolystone P Homopolymer: Technical Data Sheetmuchamad yasinОценок пока нет

- Indian Standard: Code of Practice FOR Design and Construction Pile Foundations OFДокумент44 страницыIndian Standard: Code of Practice FOR Design and Construction Pile Foundations OFKhushaliОценок пока нет

- Guidance-On-The-Design-Construction-And-Testing-Of-Standard-Rail Tank-Cars-For-The-Transport-Of-Chemicals-In-BulkДокумент15 страницGuidance-On-The-Design-Construction-And-Testing-Of-Standard-Rail Tank-Cars-For-The-Transport-Of-Chemicals-In-BulkarisandiyusufОценок пока нет

- Retrowrap Materials Performance FactsДокумент2 страницыRetrowrap Materials Performance FactsMОценок пока нет

- 10 Torsion TestДокумент16 страниц10 Torsion Testfrankjono75% (4)

- 0.6mm Low-Profile, Double Action TypeДокумент3 страницы0.6mm Low-Profile, Double Action TypeshyhuОценок пока нет

- PB02-HRH-001 Hot Reheat Steam SystemДокумент1 страницаPB02-HRH-001 Hot Reheat Steam SystemzhangОценок пока нет

- PRIMOTECH - Solar Water HeaterДокумент14 страницPRIMOTECH - Solar Water HeaterPrimotech EnergyОценок пока нет

- B353 OL3 026-1 - Pres - RevD-02 - Ba - UpdateДокумент49 страницB353 OL3 026-1 - Pres - RevD-02 - Ba - UpdateVraja DasiОценок пока нет

- RVC05 150FLG Ex PDFДокумент5 страницRVC05 150FLG Ex PDFengp3077Оценок пока нет