Академический Документы

Профессиональный Документы

Культура Документы

PID For Embedded Design - Tutorial by Cytron PDF

Загружено:

RamKumarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PID For Embedded Design - Tutorial by Cytron PDF

Загружено:

RamKumarАвторское право:

Доступные форматы

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

Live Search

Ex:Arduino,PIC....

Cytron Online

Store

PID for Embedded Design

Programming/Software

Popular Post

Robot Controller

June 22, 2012 by ober

Getting Started

On Graphical

User Interface

GUI

ByKongWaiWeng

RH2TMag,Vol.4,Mar2010

PIDcontrolsystemisoneofthemostmatureandcommonly

usedcontrolstrategiesintheindustrialfordecadesthanksto

its simple but effective algorithm. In this article, we will

XBee Series 2

Point to Point

Communication

discuss the basic concept of PID controller and how to

implementitintheembeddedsystem.

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

1/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

Introduction

Closedloopcontrolsystemisanessentialtopicforembeddedsystems,

bringing together actuators and sensors with the control algorithm in

software.Forexample,motorspeedcanbecontrolledbyvaryingthe

PWMdutycycleusedtodrivethemotor.Thisistheopenloopcontrol.

However, due to the lack of feedback, the actual motor speed could

not be verified. This is important because driving the motor with the

same PWM duty cycle does not guarantee the motor to run at the

Moisture sensor

module (SNMOISTURE-MOD)

same speed under all circumstances. A motor will run faster in load

freeconditionthanunderloadwiththesamePWMsignal.Inorderto

Categories

control the motor speed, we need to close the loop by adding

feedbackoftheactualmotorspeedtothecontroller.

Besidesspeedcontrol,PIDcontrolsystemcanalsobeusedtocontrol

open all | close all

Buying Guides

CT ARM

otherparameterssuchasposition,temperature,waterlevel,stability,

CT UNO

Easy MP3 Shield

etc.Inthisarticle,wewilldiscusshowtoimplementaPIDcontroller

Espresso Lite V2.0

forpositioncontrolbasedonPR24.

Getting Started

Arduino

G15

LCD

PIC

TheProblemDCMotorPositionControl.

BeforewebegintodesignaPIDcontroller,weneedtounderstandthe

problem. In this example, we want to move the shaft of the motor

fromitscurrentpositiontothetargetposition.

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

Programming/Software

Raspberry Pi

Robots

Serial Communication

USB

Wireless

IoT

News

PIR

Product Guides

Projects

Rainbow Strip

rero

Seminars & Events

ThingSpeak

Uncategorized

Useful Tools / External Referen

2/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

Find Us on

Facebook

CytronTechnologie

9,287likes

LikePage

Bethefirstofyourfriendstolikethis

CytronTechnologiesS

Bhdaddedanevent

Yesterdayat06:33

Wewanttomovetheoutputshaftofthemotorfromcurrentposition

totargetposition

There are a few terms commonly used to describe the PID control

loops,suchas:

ControlVariable(CV)Thisistheoutputofthecontrolloop.In

IoTHandsOnWorkshop101

UniversitiTeknologiMalaysia(UTM)

15peopleinterested4peoplegoin

thiscase,theCVisthedutycycleofthePWMsignalthatdrives

themotor.

Process Variable (PV) This is the feedback value returned by

the system to the controller. In this example, the PV is the

currentangleofthemotorshaft.

Set Point (SP) Set point is the value that we desire for the

system. In our case, the SP is the target position of the motor

shaftinangle.

Error(E) Error refers to the difference between the set point

andtheprocessvariable.Inanotherwords,itmeanshowfarthe

currentpositionofthemotorshaftfromthetargetposition.

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

3/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

TheHardwarePR24

Note:PR24isalreadydiscontinued.Samplecodecanbedownloadhere.

The Cytrons DIY Project Set PR24 (PID Motor Controller) is the best

platformforbeginnertolearnthePIDalgorithm.Ithasthefollowing

features:

PIC16F876Aasthemaincontroller.

GearedDCmotorastheoutput.

Multiturn variable resistor connected to the motor shaft for

positionfeedback.

216CharacterLCDfortuningandtroubleshooting.

PresetsforPIDtuning.

DIYProjectSetPR24PIDMotorController

The sample source code for the PR24 (PID Motor Controller) can be

downloaded from Cytrons website under the PR24 product page

(GithubCytronTechnologies).

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

4/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

TheImplementationofPIDController

ThePIDcontroller,justlikeitsname,comprisesaproportional(P),an

integral (I) and a derivative (D) part. The controller parts are

introduced in the following sections individually and in combined

operation.

ProportionalController

Whenthecurrentpositionofthemotorshaftisstillfarawayfromthe

target position, we want to apply more power to drive the motor

towards the target position so that we can reach there faster. When

the shaft is getting nearer to the target position, we will reduce the

power to slow it down. At the time the shaft reaches the target

position, the motor needs to be stopped. If the shaft position has

overshot,weneedtoapplynegativepowertothemotor(reversethe

motor)tobringitbacktothetargetposition.

In short, this is called proportional controller because the power we

applytothemotorisproportionaltotheerrorofthesystem.

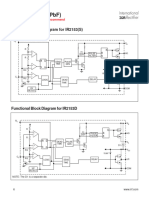

Theblockdiagramofproportionalcontroller

Fromtheblockdiagramofproportionalcontroller,wecanseethatthe

PWM duty cycle (output) is the result of multiplying the error with a

constant,Kp.

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

5/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

Error=SetPointProcessVariable

ControlVariable=Kp*Error

Figurebelowshowstheexampleofproportionalloopimplementedin

Clanguage.

ImplementationofproportionalloopinClanguage

The value of Kp needs to be chosen carefully in order to get the

optimum system response. Lower values for Kp will tend to give

smootherbutslowerresponses.

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

6/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

SystemresponseforproportionalcontrollerwithlowKp

Higher values of Kp will yield much quicker response but may cause

overshoot,wheretheoutputoscillatesbeforesettling.

SystemresponseforproportionalcontrollerwithhighKp

Excessively high values of Kp may even throw the loop into an

unstablestatewheretheoutputoscillateswithouteversettlingatthe

setpoint.

SystemresponseforproportionalcontrollerwithexcessivelyhighKp

IntegralController

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

7/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

As can be seen from the graph of P controller, the actual position of

themotorshaft,whensettlesdownwillnotreachthetargetposition.

This is because when the current position is near to the target

position, the error becomes very small and the computed PWM duty

cycle is too small for the motor to overcome the friction and gravity.

Thesmallerrorthatexistswhenthesystemhassettleddowniscalled

thesteadystateerror.

Steadystateerrorduetothefrictionandgravity

ToovercometheproblemofsteadystateerrorforthePcontroller,I

controller is being introduced. As its name suggests, the integral is

merelyanaccumulatederrorsignalsencounteredsincestartup.

Integral=(Error)

This total is multiplied by a constant, Ki, and is added into the loop

output.UnlikethePcontroller,theIcontrollerisrarelyusedalone,but

mostly in combination with the P or PD controller. When the system

hasalreadysettleddownwithasmallsteadystateerror,theintegral

stillcontinuestoaccumulateuntiltheCVislargeenoughtobringthe

PVinlinewithSP.TheequationsforPIcontrollerareasfollow:

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

8/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

Error=SetPointProcessVariable

Integral=Integral+Error

ControlVariable=(Kp*Error)+(Ki*Integral)

Figure below shows the example of PI controller implemented in C

language.

ImplementationofPIloopinClanguage

JustlikethePcontroller,thevalueofKineedstobechosencarefully.

Toolowthevalue,thesteadystateerroriscorrectedveryslowlytoo

highthevalue,thesystembecomesunstableandoscillates.

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

9/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

SystemresponseforPIcontrollerwithnosteadystateerror

Because the integral can grow quite large when the set point cannot

be reached, some applications stop accumulating the error when the

CVissaturated.

DerivativeController

Letssayyouaredrivingacar,andyouneedtostopyourcarexactly

100m from your current position as soon as possible. If you are

travelling at 10km/h, you would want to accelerate your car so that

you can reach the target sooner. In contrast, if you are cruising at

100km/h,youneedtostartbrakingsothatyoucanstopat100mand

will not overshoot. This is where the derivative controller comes into

play.

The derivative of any variable describes how that variable changes

overtime.InaPIDcontroller,thederivativeistherateofchangeof

theerror.Indigitalform,itcanbedescribedas:

Derivative=ErrorLastError

whereErroristhecurrenterrorvalueandLastErroristheerrorvalue

forthepreviousiteration.

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

10/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

Negative values of derivative indicate an improvement (reduction) in

theerrorsignal.Forexample,ifthelasterrorwas20andthecurrent

erroris10,thederivativewillbe10.Whenthesenegativevaluesare

multiplied with a constant, Kd, and are added to the output of the

loop,itcanslowdownthesystemwhenapproachingthetarget.

Just like the I controller, the D controller is rarely used alone, but

mostly in combination with the P or PI controller. The equations for

thePDcontrollerareasfollow:

LastError=Error

Error=SetPointProcessVariable

Derivative=ErrorLastError

ControlVariable=(Kp*Error)+(Kd*Derivative)

Figure below shows the example of PD controller implemented in C

language.

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

11/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

ImplementationofPDloopinClanguage

The damping effect of the D controller allows the system to have a

highervalueofKpand/orKiwithoutovershooting.Inconsequent,this

will give the system a better response time to set point changes.

However,toohighthevalueofKdwillalsohavenegativeeffect.The

Dcontrollertensetoamplifythenoiseexistsinthefeedbackloop.If

theKdistoohigh,thesystemwillbecomejerkyifthefeedbackloopis

noisy.

MainMenu

HOME

PROJECTS

CATEGORIES

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

LOGIN/REGISTER

SHOP AT CYTRON

FORUM

12/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

SystemresponseforPDcontroller

JoiningThemTogetherPIDController

ByjoiningtheP,IandDcontroller,wecantaketheadvantagesofthe

combined benefits from each controller. We have the P controller for

fastsystemresponse,Icontrollertocorrectthesteadystateerrorand

Dcontrollertodampenthesystemandreduceovershoot.

TheblockdiagramofPIDcontroller

FromtheblockdiagramofPIDcontroller,wecanseethattheoutput

oftheloopismerelythesumofoutputfromP,IandDcontroller.The

equationsforthePIDloopareillustratedbelow:

LastError=Error

MainMenu

HOME

PROJECTS

CATEGORIES

Error=SetPointProcessVariable

LOGIN/REGISTER

SHOP AT CYTRON

FORUM

Integral=Integral+Error

Derivative=ErrorLastError

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

13/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

ControlVariable=(Kp*Error)+(Ki*Integral)+(Kd*Derivative)

Figure below shows the example of PID controller implemented in C

language.

ImplementationofPIDloopinClanguage

MainMenu

HOME

PROJECTS

CATEGORIES

LOGIN/REGISTER

SHOP AT CYTRON

FORUM

SystemresponseforthecorrectlytunedPIDcontroller

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

14/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

Summary

PID controller is a simple yet effective control system widely used in

industrial.However,toimplementthePIDcontrollerissimple,butnot

thetuning.TheprocessoftuningthePIDparameters(Kp,KiandKd)

is a continuous trial and error process. There is no exact way to

calculate the value for the parameters unless the whole system is

mathematically modeled and simulated. Experience is an important

factortogettheoptimumPIDparametersbasedontheobservationof

the system behavior during the tuning process. If you have inquiry,

feelfreetodiscussinourtechnicalforum.

References:

DennisClarkandMichaelOwings:BuildingRobotDriveTrains.

Thomas Braunl: Embedded Robotics Mobile Robot Design and

ApplicationswithEmbeddedSystems.

http://en.wikipedia.org/wiki/PID_controller

http://www.expertune.com/tutor.html

http://www.newportus.com/products/techncal/techncal.htm

http://www.dprg.org/tutorials/200310a/motorcontrol.pdf

MainMenu

Related Posts:

HOME

PROJECTS

CATEGORIES

LOGIN/REGISTER

SHOP AT CYTRON

FORUM

How RC Servo Works?

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

15/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

Line-Following Robot Using LSA08 in

Serial Mode with PID

How does Stepper Motor Works Part 1

How Does Stepper Motor Works Part 2

Embedded, PIC Microcontroller, PID Control

19 5583 views

Prev Post

Next Post

WIZnet Serial to Ethernet

Gateway with PIC

Interfacing servo motors

controllers (SC08A and SC16A)

Microcontroller

using Arduino

MainMenu

HOME

PROJECTS

CATEGORIES

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

LOGIN/REGISTER

SHOP AT CYTRON

FORUM

16/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

Related Post

Line-Following

Robot Using

LSA08 in Serial

Mode with PID

Controller

Using MDD10A

with CIKU

Getting Started

with MPLAB X

IDE

Quadrature

Encoder

2 thoughts on PID for Embedded Design

vamsi krishna says:

July 25, 2013 at 1:27 am

nice tutorial . is there any tutorial for implementing

the fuzzy logic in microcontroller for motor control

tinku jangid says:

August 24, 2014 at 5:33 pm

MainMenu

HOME

can u tell me how much we will generate in relate to

get a xed or set point frequency

PROJECTS

CATEGORIES

LOGIN/REGISTER

SHOP AT CYTRON

FORUM

Leave a Reply

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

17/18

11/10/2016

PIDforEmbeddedDesignTutorialbyCytron

Your email address will not be published. Required elds are

marked *

Comment

Name *

Email *

Website

PostComment

Notify me of follow-up comments by email.

Notify me of new posts by email.

Cytron Technologies 2016

MainMenu

HOME

Seo wordpress plugin by www.seowizard.org.

PROJECTS

CATEGORIES

http://tutorial.cytron.com.my/2012/06/22/pidforembeddeddesign/

LOGIN/REGISTER

SHOP AT CYTRON

FORUM

18/18

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Zomato Restaurant Clustering & Sentiment Analysis - Ipynb - ColaboratoryДокумент27 страницZomato Restaurant Clustering & Sentiment Analysis - Ipynb - Colaboratorybilal nagoriОценок пока нет

- 25 Middlegame Concepts Every Chess Player Must KnowДокумент2 страницы25 Middlegame Concepts Every Chess Player Must KnowKasparicoОценок пока нет

- Colfax MR Series CompresorДокумент2 страницыColfax MR Series CompresorinvidiuoОценок пока нет

- Volvo BL 71 ManualДокумент280 страницVolvo BL 71 ManualAlberto G.D.100% (2)

- Contoh Exposition TextДокумент1 страницаContoh Exposition TextKristin SeranОценок пока нет

- Grade 3 - Unit 1 Increase and Decrease PatternДокумент7 страницGrade 3 - Unit 1 Increase and Decrease PatternKyo ToeyОценок пока нет

- Hockney-Falco Thesis: 1 Setup of The 2001 PublicationДокумент6 страницHockney-Falco Thesis: 1 Setup of The 2001 PublicationKurayami ReijiОценок пока нет

- A Comparison of The Performance of Mono-Si and Poly-Si Photovoltaic Modules Operating Under Kosovo Climate ConditionДокумент11 страницA Comparison of The Performance of Mono-Si and Poly-Si Photovoltaic Modules Operating Under Kosovo Climate ConditionRamKumarОценок пока нет

- Understanding Smart Sensors, Third EditionДокумент10 страницUnderstanding Smart Sensors, Third EditionRamKumarОценок пока нет

- PV PlantДокумент21 страницаPV PlantRamKumarОценок пока нет

- Bridge Rectifier - Definition, Construction and WorkingДокумент14 страницBridge Rectifier - Definition, Construction and WorkingRamKumarОценок пока нет

- Highly Compact AC-AC Converter Achieving A High Voltage Transfer RatioДокумент8 страницHighly Compact AC-AC Converter Achieving A High Voltage Transfer RatioRamKumarОценок пока нет

- Programming Pic Microcontrollers PDFДокумент117 страницProgramming Pic Microcontrollers PDFRamKumarОценок пока нет

- 0132975165Документ24 страницы0132975165RamKumarОценок пока нет

- 12v Battery Charger Circuit With Auto Cut Off - Circuits GalleryДокумент40 страниц12v Battery Charger Circuit With Auto Cut Off - Circuits GalleryRamKumar0% (1)

- Software Steps F2812Документ2 страницыSoftware Steps F2812RamKumarОценок пока нет

- Direct AC-AC Step-Down Single-Phase Converter With Improved PerformancesДокумент4 страницыDirect AC-AC Step-Down Single-Phase Converter With Improved PerformancesRamKumarОценок пока нет

- ECE462 Motor Lab Experiment2Документ14 страницECE462 Motor Lab Experiment2RamKumarОценок пока нет

- 117276Документ8 страниц117276RamKumarОценок пока нет

- DSPACE Solutions For ControlДокумент34 страницыDSPACE Solutions For ControlRamKumarОценок пока нет

- Sample CVFormat 1Документ2 страницыSample CVFormat 1subham.sharmaОценок пока нет

- Hanwha Q Cells Data Sheet Qpeak L-g4.2 360-370 2017-10 Rev02 NaДокумент2 страницыHanwha Q Cells Data Sheet Qpeak L-g4.2 360-370 2017-10 Rev02 NazulfikarОценок пока нет

- Optimized Maximum Power Point Tracker For Fast Changing Environmental ConditionsДокумент7 страницOptimized Maximum Power Point Tracker For Fast Changing Environmental ConditionsSheri ShahiОценок пока нет

- BiografijaДокумент36 страницBiografijaStjepan ŠkalicОценок пока нет

- The Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityДокумент7 страницThe Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityIJAR JOURNALОценок пока нет

- Ultracold Atoms SlidesДокумент49 страницUltracold Atoms SlideslaubbaumОценок пока нет

- I. Learning Objectives / Learning Outcomes: Esson LANДокумент3 страницыI. Learning Objectives / Learning Outcomes: Esson LANWilliams M. Gamarra ArateaОценок пока нет

- Crypto Wall Crypto Snipershot OB Strategy - Day Trade SwingДокумент29 страницCrypto Wall Crypto Snipershot OB Strategy - Day Trade SwingArete JinseiОценок пока нет

- 11.3.1 Some Special CasesДокумент10 страниц11.3.1 Some Special CasesSiddharth KishanОценок пока нет

- The Scope and Method of Economics: © 2007 Prentice Hall Business Publishing Principles of Economics 8e by Case and FairДокумент36 страницThe Scope and Method of Economics: © 2007 Prentice Hall Business Publishing Principles of Economics 8e by Case and FairLangson phiriОценок пока нет

- Project Quality Plan (JFJS-788)Документ18 страницProject Quality Plan (JFJS-788)mominОценок пока нет

- G10 Lesson2 DLPДокумент13 страницG10 Lesson2 DLPAngeles, Mark Allen CОценок пока нет

- Img 20150510 0001Документ2 страницыImg 20150510 0001api-284663984Оценок пока нет

- Acting White 2011 SohnДокумент18 страницActing White 2011 SohnrceglieОценок пока нет

- Modular Q1 WK3-4Документ3 страницыModular Q1 WK3-4JENIFFER DE LEONОценок пока нет

- OM CommandCenter OI SEP09 enДокумент30 страницOM CommandCenter OI SEP09 enGabriely MuriloОценок пока нет

- LP32HS User Manual v1Документ52 страницыLP32HS User Manual v1tonizx7rrОценок пока нет

- IR2153 Parte6Документ1 страницаIR2153 Parte6FRANK NIELE DE OLIVEIRAОценок пока нет

- 0012 Mergers and Acquisitions Current Scenario andДокумент20 страниц0012 Mergers and Acquisitions Current Scenario andJuke LastОценок пока нет

- Pathophysiology of Myocardial Infarction and Acute Management StrategiesДокумент11 страницPathophysiology of Myocardial Infarction and Acute Management StrategiesnwabukingzОценок пока нет

- Practice Problems - Electrochemical CellДокумент5 страницPractice Problems - Electrochemical CellYehia IbrahimОценок пока нет

- 19 Dark PPT TemplateДокумент15 страниц19 Dark PPT TemplateKurt W. DelleraОценок пока нет

- Jul - Dec 09Документ8 страницJul - Dec 09dmaizulОценок пока нет