Академический Документы

Профессиональный Документы

Культура Документы

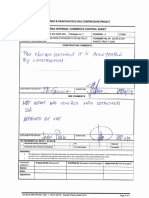

Stopple@R Plugging

Загружено:

Victor DoanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Stopple@R Plugging

Загружено:

Victor DoanАвторское право:

Доступные форматы

STOPPLE Plugging Machine

Sizes: 4-inches and Larger

T. D. Williamson, Inc.

Bulletin No: 1030.001.01

Date: February 2005

Cross Indexing No: n/a

Supersedes: 1030.001.00 (2/99)

Description

Typical Setup

TDW STOPPLE Plugging Machines serve as

temporary block valves installed anywhere in a

piping system. They are used to isolate a section of

line for repairs or additions without interruption of

service.

Hydraulic Cylinder

The STOPPLE Plugging Machine consists of three

major sections: a hydraulic cylinder or jackscrew, a

plugging head housing, and a plugging head.

Bleeder Valve

Features

Housing

Operation of the hydraulic STOPPLE Plugging

Machine is easy due to the location of the control

valve, which is positioned at the lower end of the

hydraulic cylinder. The hydraulically operated

control bar has a direct reading scale visible to the

operator, enabling him to know the plugging head

position at all times.

The TDW STOPPLE Plugging Machine is

available for pipe sizes 4 (DN 100) and

larger.

Equalization

Connection

Plugging Head

SANDWICH Valve

Its maximum operating temperature is 180F

(82C).

* For design code options not listed and additional sizes, consult your sales

representative.

STOPPLE Fitting

Equalization

Connection

ISO 9001 Certified

STOPPLE Plugging Machine

Toll Free

1-888-TDWmSon (839-6766)

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T. D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T. D. Williamson, Inc. in the United States and foreign countries / Copyright 2005. All rights reserved T. D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

T. D. Williamson, Inc.

STOPPLE Plugging Machine

Cylinder Operation

Plugging Heads & Sealing Elements

Jackscrew Operated Cylinder

4 (DN 100) and 6 (DN 150)

Hydraulic Operated Cylinders

6 (DN 150), 8 (DN 200),

10 (DN 250), 12 (DN 300)

14 (DN 350), 16 (DN 400),

18 (DN 450), 20 (DN 500)

22 (DN 550), 24 (DN 600),

26 (DN 650), 30 (DN 750),

36 (DN 900)

Lbs.

69

Kg.

31

Part Number

08-0299-0000

235

107

08-2116-0000

862

391

08-2117-0000

1800 816

08-2118-0000

Fall Protection Assembly

Safety Harness Assembly

Cylinder

08-2116-0000

08-2117-0000

08-2118-0000

08-2119-0000

1030.001.01 - p2

Size

Inches DN

4 100

6 150

8 200

10 250

12 300

14 350

16 400

18 450

20 500

22 550

24 600

26 650

30 750

36 900

Plugging Heads

Weight

Lbs. Kg.

Part Number

7

3

08-2578-0000*

25

11

08-2579-0000*

50

23

08-2580-0000*

90

41

08-2581-0000*

150

68

08-2582-0000*

185

84

08-1892-0000

260 118

08-1893-0000

455 206

08-1894-0000

525 238

08-1895-0000

670 304

08-1896-0000

870 395

08-1897-0000

1050 476

08-1898-0000

1610 730

08-1900-0000

3025 1372 08-2048-0000

Sealing Elements

Weight

Lbs. Kg.

Part Number

1

.5

08-0036-0005

2

.9

08-0040-0005

2

.9

08-0246-0005

4

2

08-0247-0005

5

2

08-0248-0005

7

3

08-0249-0005

9

4

08-0250-0005

12

5

08-0251-0005

19

9

08-0252-0005

24 11

08-0253-0005

37 17

08-0254-0005

40 18

08-1863-0005

64 29

08-1623-0005

77 35

08-2046-0005

*This plugging head is furnished with 2 nose pieces

Fall Protection Assembly

08-2546-0000

08-2547-0000

08-2548-0000

08-2549-0000

When ordering sealing elements specify pipe ID, pressure, material of sealing element desired and number

of bolt holes and bolt circle diameter required. Factory recommends two elements be purchased with each

plugging head, one to be used as a spare. STD Machines are designed for STD weight pipe. If used in heavy or

thin wall pipe, special components may be required.

STOPPLE Housings

Housings For Jackscrew Cylinders:

Inches DN

Lbs.

4

100

32

6

150

56

Housings For Hydraulic Cylinders:

6

150

56

8

200

92

10

250

128

12

300

200

14

350

327

16

400

410

18

450

480

20

500

600

22

550

770

24

600

935

26

650

1075

30

750

1425

36

900

1550

Class 150

Kg.

Part Number

15

08-0319-0000

25

08-0322-0000

25

42

58

91

148

186

218

272

349

424

488

646

703

08-0270-0000

08-0202-0000

08-0203-0000

08-0204-0000

08-0205-0000

08-0206-0000

08-0207-0000

08-0208-0000

08-0209-0000

08-0210-0000

08-0211-0000

08-0212-0000

08-0423-0000

Lbs.

43

73

Class 300

Kg.

Part Number

20

08-0320-0000

33

08-0323-0000

Lbs.

60

75

Class 600

Kg.

Part Number

27

08-0300-0000

34

08-0302-0000

73

130

185

285

410

535

655

735

985

1225

1410

1795

2100

33

59

84

129

186

243

297

333

447

556

640

814

953

75

187

270

350

570

660

955

1025

1365

1740

1875

2440

5130

34

85

122

159

259

299

433

465

619

789

851

1107

2327

08-0276-0000

08-0213-0000

08-0214-0000

08-0215-0000

08-0216-0000

08-0217-0000

08-0218-0000

08-0219-0000

08-0220-0000

08-0221-0000

08-0222-0000

08-0223-0000

08-0360-0000

08-1715-0000

08-1716-0000

08-1645-0000

08-1646-0000

08-1647-0000

08-0131-0000

08-0132-0000

08-1648-0000

08-1664-0000

08-1649-0000

08-1864-0000

08-1650-0000

08-2257-0000

Note: Housings are equipped with flanges which are drilled, faced and pressure-rated to match ANSI Class 150, 300 or 600 flanges.

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T. D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T. D. Williamson, Inc. in the United States and foreign countries / Copyright 2005. All rights reserved T. D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

T. D. Williamson, Inc.

STOPPLE Plugging Machine

1030.001.01 - p3

Approximate Dimensions for Determining Machine Clearances

Size

Inches DN

4

100

6

150

8

200

10

250

12

300

14

350

16

400

18

450

20

500

22

550

24

600

26

650

30

750

36

900

A*

Inches mm

11

280

14

356

17

432

20

508

22

559

24

610

27

686

30

762

32

813

35

889

37

940

40

1015

45

1143

52

1321

B*

Inches

14

17

19

23

25

32

35

39

42

46

52

52

60

67

mm

356

432

483

533

610

787

889

991

1041

1168

1321

1321

1524

1803

Inches

58

58

85

85

85

124

124

124

124

166

166

166

166

166

L

mm

1473

1473

2159

2159

2159

3150

3150

3150

3150

4216

4216

4216

4216

4216

Inches

72

75

104

108

110

156

159

163

166

212

218

218

226

233

mm

1829

1905

2642

2743

2794

3962

4039

4140

4216

5385

5537

5537

5740

5918

*Maximum with 600 Class Flange.

Plugging Head Specifications

The TDW 660/760 Tapping Machine power

unit normally operates 6 (DN 150) through 12

(DN 300) plugging machines. The power unit for

the 1200 Tapping Machines operates 14

(DN 350) and larger.

Hydraulic cylinder (08-2116-0000) is

furnished with hydraulic couplings for 660/760

Tapping Machine power unit.

Hydraulic cylinders (08-2117-0000, 08-21180000, and 08-2119-0000) are furnished with

hydraulic couplings for 1200 Tapping Machine

power units.

with Jackscrew Cylinder

4 (DN 100) and 6 (DN 150)

with Hydraulic Cylinders

*6 (DN 150), 8 (DN 200), 10 (DN 250), 12 (DN 300)

14 (DN 350), 16 (DN 400), 18 (DN 450), 20 (DN 500)

22 (DN 550), 24 (DN 600), 26 (DN 650),

30 (DN 750)

36 (DN 900)

Control Bar

Travel

Inches

mm

48

1219

Max. Operating

Pressure

psi

bar

900

62

72

102-1/2

1829

2604

900

750

62

52

140

140

3556

3556

625

1000

43

70

NOTE: This chart is applicable to STOPPLE equipment ordered from and manufactured at the Tulsa Manufacturing Plant. STOPPLE equipment

ordered from and manufactured at TDW (SA) in Belgium is designed for a standard maximum operating pressure of 1,000 psi (70 bar).

For STOPPLE equipment requiring higher pressure ratings or sizes other than those indicated in the above chart, consult the factory.

*When ordering 6 (DN 150) STOPPLE equipment, please specify either jackscrew or hydraulic cylinder.

Hydraulic cylinder (08-2117-0000) can be

used with the 660/760 power unit with the

purchase of a conversion kit (08-0384-0000).

If other power unit to hydraulic cylinder

combinations are to be used, be sure to specify

so that proper couplings can be furnished.

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T. D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T. D. Williamson, Inc. in the United States and foreign countries / Copyright 2005. All rights reserved T. D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

T. D. Williamson, Inc.

Plugging Without Shutdown - Typical Procedure

1. Weld Fittings

1030.001.01 - p4

2. Make Taps

2 Threaded-O-Ring Purge &

Equalization Fittings

1200 Tapping Machine

Section of line

to be replaced.

SANDWICH

Tapping Valve

STOPPLE Fitting

Bypass

Fitting

Bypass

Tapping Valve

Flow

Flow

STOPPLE Fittings with LOCK-O-RING Flanges* are welded on each end of the section to be isolated. Bypass

fittings with LOCK-O-RING Flanges and equalization fittings are welded to the line.

A Tapping Valve* is mounted on each fitting and taps are made through the valves into the pipeline. The cutter

is withdrawn after each tap, the valve closed, and tapping machine removed.

*See LOCK-O-RING Flanges, Bulletin 1120.001.

*See SANDWICH Valve, Bulletin 1020.001.

3. Plug Line

4. Recover Valves

STOPPLE

Plugging Machine

New Section

STOPPLE

Plugging Machine

Blind Flange

LOCK-O-RING

Flange

Bypass Line

Flo

Blind Flange

Flow

Flow

LOCK-O-RING

Flange

Flo

Flow

Bypass connections are made and the bypass valves are opened. STOPPLE Plugging Machines are mounted

and the plugging heads are lowered through valves into sealing position. After the new section is tied in,

pressure is equalized by connection from the STOPPLE Housing to the pipeline (See A).

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

Tapping machine cutters are replaced with LOCK-O-RING Plugs, and tapping machines (or machine) are

mounted on valves. The LOCK-O-RING Plugs are lowered into position inside LOCK-O-RING Flanges. Tapping

machines are removed, valves recovered, and blind flanges installed.

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T. D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T. D. Williamson, Inc. in the United States and foreign countries / Copyright 2005. All rights reserved T. D. Williamson, Inc. / Printed in USA

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 2 Straight Line Diag.Документ1 страница2 Straight Line Diag.Nix GabrielОценок пока нет

- Army Ammo and Explosives Storage in The US 1775-1995Документ118 страницArmy Ammo and Explosives Storage in The US 1775-1995glcarton100% (1)

- Aci-305r 91 PDFДокумент20 страницAci-305r 91 PDFSiddharth Garg100% (1)

- Structural Investigation of Historic Buildings - David C FischettiДокумент10 страницStructural Investigation of Historic Buildings - David C FischettiMohammad Javad AarabiОценок пока нет

- Weida Subsoil PipeДокумент4 страницыWeida Subsoil PipeOngОценок пока нет

- BS en 206Документ7 страницBS en 206amit_halcrow100% (1)

- Bomba Calpeda NM 25-160aeДокумент12 страницBomba Calpeda NM 25-160aeMarvin TorresОценок пока нет

- Vantage Engine Service ManualДокумент40 страницVantage Engine Service ManualWaseem Khan100% (1)

- Bearing MaintenanceДокумент34 страницыBearing MaintenanceThiMinhKhuyenОценок пока нет

- Kem Microconcrete - NДокумент2 страницыKem Microconcrete - NIrfan BiradarОценок пока нет

- Wire Rope-Steel TechnicalДокумент37 страницWire Rope-Steel TechnicalAndreea LucaОценок пока нет

- Service Manual: Air ConditionerДокумент70 страницService Manual: Air Conditionerboroda2410Оценок пока нет

- Noise Guide For Local GovernmentДокумент187 страницNoise Guide For Local GovernmenttertfgdfgdfgdfgdggdОценок пока нет

- Bored-Piling Mar2016 PDFДокумент4 страницыBored-Piling Mar2016 PDFrajaОценок пока нет

- QSCV Kamran AssocRICSДокумент2 страницыQSCV Kamran AssocRICSMuhammad UsmanОценок пока нет

- Introduction To Structural Analysis-Part 1Документ30 страницIntroduction To Structural Analysis-Part 1Hiew Ching YongОценок пока нет

- Ft50get'08 Ft60det'08: 1G6C2-300F1 2G6C2-300F1Документ57 страницFt50get'08 Ft60det'08: 1G6C2-300F1 2G6C2-300F1Muhammad Safri Adi ZamilОценок пока нет

- 2016 KB Spec Book 2 Wall CabinetsДокумент20 страниц2016 KB Spec Book 2 Wall CabinetsMarium ZahidОценок пока нет

- Engro'S Experience: in The Construction and Start Up of A Jumbo-Scale PlantДокумент43 страницыEngro'S Experience: in The Construction and Start Up of A Jumbo-Scale PlantAjay SastryОценок пока нет

- Ssangyong - Compliance Statement-02022017Документ11 страницSsangyong - Compliance Statement-02022017rexОценок пока нет

- Cost EsДокумент2 страницыCost EsJely Taburnal BermundoОценок пока нет

- MOS For Metallic Conduit InstallationДокумент23 страницыMOS For Metallic Conduit InstallationAhmed MhnaОценок пока нет

- Hammerhead Pier On Spread Footing PDFДокумент83 страницыHammerhead Pier On Spread Footing PDFRammiris ManОценок пока нет

- Cib2010 - Design-Bid-Build Versus Design-Build - The Client's ChoiceДокумент14 страницCib2010 - Design-Bid-Build Versus Design-Build - The Client's ChoiceVan khuongОценок пока нет

- The Influence of Construction Side Effects On ExisДокумент19 страницThe Influence of Construction Side Effects On ExisJose Leo MissionОценок пока нет

- Manual Elevators Y, A, G, X, S Series BNC DC Lift SystemДокумент20 страницManual Elevators Y, A, G, X, S Series BNC DC Lift SystemFranklin Jose Almera AcostaОценок пока нет

- Internal Forces in A Beam: Shear ForceДокумент52 страницыInternal Forces in A Beam: Shear ForceCho Wing SoОценок пока нет

- TROX Chilled Beam Design GuideДокумент60 страницTROX Chilled Beam Design GuideBRYMOENОценок пока нет

- DODGE Torquearm PDFДокумент186 страницDODGE Torquearm PDFCesar Dominguez ParedesОценок пока нет

- 9 TH Plate (Sub)Документ12 страниц9 TH Plate (Sub)hemantОценок пока нет