Академический Документы

Профессиональный Документы

Культура Документы

Interstoff Apparels Ltd. DC-1219872-Costco RE-FE Report

Загружено:

zahidИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Interstoff Apparels Ltd. DC-1219872-Costco RE-FE Report

Загружено:

zahidАвторское право:

Доступные форматы

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 1 of 23

Supplier Certification Program

Initial Certification

Costco Supplier Certification

100% - 85% no critical Audit Valid for facility for 1 year from the date of audit – No further

action required.

99% - 85% with critical Audit Valid for facility for 1 year from the date of audit. Corrective

Action Plan (CAP) is required to be provided with 14 days of audit. No Re-Audit

necessary.

Less than 85% - 70% Audit Valid for 6 months from date of audit. Corrective Action Plan

(CAP) is required to be provided within 14 days of audit. CAP must be completed

prior to re audit within 6 months and will be verified at next audit.

Less than 70% - 60% Audit Valid for 3 months from date of audit. Corrective Action Plan

(CAP) is required to be provided within 14 days of audit. CAP must be completed

prior to the re audit within 3 months.

Less than 60% No Certification, Corrective Action Plan (CAP) is required to be provided

within 14 days of audit. Re Audit must take place within 60 days.

Questions marked CRITICAL (with**) denote Costco’s most essential areas of concern

regarding Quality and Safety. On FAILED audits (total score less than 85%), a re-audit is

required within a certain period for, at minimum, the critical failures OR prior to any new

production of Costco goods.

Re-Audits will not be scheduled unless a CAP has been submitted to Costco and approved for

all noted violations OR your company has communicated with Costco the reasons for non-

compliance and that reasoning was deemed acceptable by Costco.

Question Rating Guideline:

All questions answered as N/A must be supported by an explanation in the remarks section

Score 3 points for each asterisk (**) marked yes and 1 point each for all others marked yes

Subtract the N/A points from the “Maximum possible points available” to get the “Adjustable

Maximum points” under each section if any question marked N/A, and update the “Summary of

The Points That The factory Achieved” table accordingly

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 2 of 23

Factory Information

Factory Name: Interstoff Apparels Ltd.

Address: Chandora, Kaliakoir, Gazipur, Bangladesh

Telephone: (+ 880 06822) 521 19

Fax: (+ 880 06822) 51958

E-Mail: rafiq@icl.bdrmg.com

Agent/Vendor: KHQ Investment

Factory producing Kirkland Signature

YES NO

items

Type of Audit: Initial Audit If Re-Audit: Original Audit Date: NOVEMBER 23, 2011

Re-Audit Report #: DC1114154

Other (please specify): Original Score: 94.08%

Audit Result

Audit Valid for facility for 1 year from the date

of audit. No further action required

Score: 100%-85% with no critical

Audit Valid for facility for 1 year from the date

of audit. Corrective Action Plan required. No Score: 99%-85% with critical

Re-audit necessary.

Audit Valid for facility 6 months from the date

of audit. Corrective Action Plan required. CAP

must be completed prior to re-audit within 6

Score: Less than 85% - 70%

months and will be verified at next audit.

Audit Valid for 3 months from date of audit.

Corrective Action Plan required. CAP must be Score: Less than 70% - 60%

completed prior to the re-audit within 3 months

No Certification

Re-audit within 60 days. Shipment may be held

depending on audit results regardless if Critical

Score: Less than 60%

defect is present or not

Total Score 88.39 %

Date of Audit: November 28, 2012 Auditor: Md. Abdullah Al Mamun Talukder

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 3 of 23

Company Organization Met during Audit? (name of the person)

Managing Director No Md. Shahinur Rahman

Marketing Manager No S. M. Shafiqur Rahman

Plant Manager No Mr. Amzad Hossain

QC/ QA Supervisor / Manager Yes Mr. Anwar Hossain

Factory Manager Yes Mr. Amzad Hossain

Factory has been in operation since 2002

Staff Information

# of Manufacturing Personnel: 3000

# of Quality Controllers: 387

# of Engineers: 15

Production Information

Types of Product Produced: Knit Garments Costco Dept. No (2 digits) 31

Monthly Production Capacity: 150,000 pieces

Required Lead Time: (time between placing 90 days

an order to starting production)

On average how many units of each type of item can be produced daily?

Items Daily Production Quantity

Kids 33000 pieces

Mans 20000 pieces

Ladies 12000 pieces

Manufacture

Major Machinery: Quantity: Remarks:

Date:

Dyeing machine Not provided 09

Stenter macnine Not provided 02

Dryer Not provided 02

Compactor Not provided 02

Sue ding machine Not provided 02

Fabric inspection Not provided 03

Plain machine Not provided 517

Over lock machine Not provided 416

Flat lock machine Not provided 201

Button stitch machine Not provided 28

Hole stitch machine Not provided 28

Bar tack machine Not provided 02

PMD Not provided 10

Snap button machine Not provided 08

Belco attach machine Not provided 02

Back Tape Machine Not provided 19

Fusing machine Not provided 02

Cutting machine Not provided 14

Spreading machine Not provided 2

Band knife machine Not provided 02

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 4 of 23

Metal detector machine Not provided 03 Conveyor belt type

Steam iron Not provided 73

Heat transfer machine Not provided 14

A. METAL DETECTION PROCEDURES (All Critical Questions)

Please note: Costco requires some form of metal detection for all garments produced.

1.) Are metal detectors used? ** Yes No N/A

Type of metal detector: Conveyer belt type

Quantity available for use: 01

Frequency of calibration: 6 times per day

Who is responsible for calibration: Mr. Aminur Rahman (Quality officer)

2.) Are needle guards used? ** Yes No N/A

3.) If needle guards are used, are they used consistently on Yes No N/A

all machines? **

4.) Is there a needle replacement policy in effect? ** Yes No N/A

If so, explain this policy below in remarks:

NOTE: All factories producing wearing apparel are required to have an operable metal detector along with an

efficient policy/procedure in place for metal detection. Costco may approve the factory in-lieu of metal

detectors. Example:

a.) Use of needle guards

b.) Needle replacement policy or

c.) Other means of ensuring no metal is inadvertently left in garments.

Rating: Metal Detection (3) out of 4 Critical items rated as "YES" = ( 09 ) Points

Total Score for Section A: ( 09 ) /12

*N/A answers will not be factored into the Maximum Points Available

Item #: Remarks:

It was noted that approximately 90% of the needle guard of the sewing machines are not in

A-3

appropriate height.

Factory has a broken needle policy which covered needle replacement procedure. According to

the policy needle must be replaced on a one for one basis. New needle is issued only when all

A-4 the parts of the broken needle found and registered, if not then the garments of that particular

(Remarks) machine passed through metal detector to find out the broken parts of the needle as well as the

area of that machine took under special consideration to find out all the broken parts by using

magnet. If all needle fragments cannot be found the garment (s) must be destroyed.

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 5 of 23

B. FACILITIES

1. Does the plant layout appear acceptable for the type of Yes No N/A

Product being manufactured? **

2. There is no evidence of damage due to flooding or inadequate drainage? Yes No N/A

3. Does overall maintenance of the premises appear acceptable? Yes No N/A

working toilets

hand washing stations

first aid kits / stations

fire extinguishers

floor free from debris

4. Does the general housekeeping appear tidy and is it Yes No N/A

overseen by appointed management?

5. Are housekeeping schedules established and maintained? Yes No N/A

6. Did you see a complete company quality manual? Yes No N/A

7. Did you see documentation that all production machines are on a Yes No N/A

maintenance schedule and a maintenance team was in place?

8. Were all machines and equipment calibrated and checked to run Yes No N/A

efficiently and are maintenance records readily available? **

9. Did you see that all machines/equipment/fixtures Yes No N/A

were suitable to produce the intended product?

10. Did you see evidence that the factory has a well Yes No N/A

organized maintenance team that could immediately

respond to a machinery breakdown or emergency?

11. Did you confirm that telephones were available Yes No N/A

for employees in case of emergency?

12. Did you confirm electronic communication systems were in place? Yes No N/A

(PC’s with word processing, spreadsheet and e-mail capabilities).

13. Are isles kept clean and free of debris? Yes No N/A

14. Does factory provide a separate area for workers Yes No N/A

break time and eating, away from the production area?

15. There is no evidence of smoking, eating or drinking in the Yes No N/A

production area?

16. Are the lighting and ventilation conditions adequate? Yes No N/A

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 6 of 23

Rating: Facilities -

(2) out of 2 Critical items rated as "YES" = (6) Points

(14) out of 14 Non-critical items rated as "YES" = ( 14 )Points

Total Score for Section B: (20) / 20

*N/A answers will not be factored into the Maximum Points Available

Item #: Remarks:

Factory has updated calibration certificates for the measuring devices e.g,

B-8

measuring tapes, Pull test machine, weighing balance Light boxes, physical

(remarks)

testing equipments (crocking meter, washing machine).

C. QUALITY CONTROL SYSTEM

1. Is factory operating a formal & written internal quality Yes No N/A

control procedure? **

2. Are there adequate internal training programs provided Yes No N/A

for all quality control personnel involved?

3. Are there adequate traceable training records for factory Yes No N/A

personnel?

4. Are the factory’s Q.C. personnel certified or assessed Yes No N/A

before they perform their job as outlined in the Q.C. procedures?

5. Has management defined its quality control objectives? Yes No N/A

If so, are those objectives clearly understood

by personnel?

6. Does the factory use international, national, client’s, Yes No N/A

or its own approved standards to perform in-house

quality control? Explain in remarks.

7. Does the factory have a detailed written plan Yes No N/A

demonstrating how safety requirements on products are

checked in-house?

8. Do detailed Factory Records reflect that products are properly Yes No N/A

checked in accordance with customer requirements &

specifications prior to proceeding to the next production process?

9. Is there Q.C. supervision on all shifts? Yes No N/A

10. Does quality controller fully understand factory’s Yes No N/A

quality policy, quality consciousness and the

importance of the quality assurance concept?

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 7 of 23

11. Does Q.C. personnel have knowledge and expertise on Yes No N/A

products to be made?

12. Are all QA staff a separate team and different personnel from Yes No N/A

the trimming and inspection teams?

13. Is there an adequate number of QA staff to deal with the quality Yes No N/A

and quantity of spot-checking?

Rating: Quality Control Systems –

(1) out of 1 Critical items rated as "YES" = (3) Points

(9) out of 12 Non-critical items rated as "YES" = (9 ) Points

Total Score for Section C: ( 12 ) / 15

*N/A answers will not be factored into the Maximum Points Available

Item #: Remarks:

C-3 Factory does not have any traceable training records for factory personnel.

C-4 QC personals are not certified before they perform their job as outlined in the QC procedures.

It was noted that factory checking some safety requirement on products like pull test and snap

C-7

button test without any detailed written plan.

Factory use international standard like 4 point system for fabric inspection, roll to roll shade

C-6 check, AQL- 0.65 for accessories inspection, traffic light system followed in sewing inline and

(remarks) 100% end line visual inspection for sewing confirmation, AQL- 1.5 for pre final and AQL-2.5 for

final inspection or according to their buyer standard.

D. INCOMING INSPECTIONS

1. Does the factory verify that raw materials meet required Yes No N/A

specifications before use? **

2. Are raw materials properly labeled, stored and traceable? Yes No N/A

3. Are raw materials kept in controlled storerooms/areas to Yes No N/A

avoid theft, loss and any deterioration of quality?

4. If raw materials need inspection before use in production, Yes No N/A

are they properly inspected and are records maintained

and traceable?

5. Is the inspection sampling schedule adequate and can the Yes No N/A

quality of the product be guaranteed with confidence?

6. Are inspection records maintained to prove products Yes No N/A

meet all requirements?

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 8 of 23

7. Are there written inspection instructions available Yes No N/A

rd

as guidelines to 3 party inspectors?

8. If testing equipment is needed during inspection, is there a Yes No N/A

sufficient quantity of equipment in order to do so in timely

manner?

9. Does the factory have a system for lot control of Yes No N/A

raw materials that requires oldest date to be pulled first for

use, “First in/ First out”?

10. Does the factory have a policy and procedure for inspecting Yes No N/A

incoming fabric?

11. Are incoming and outgoing raw materials registered to prevent Yes No N/A

intermingling?

12. Are raw materials kept in controlled storerooms to avoid theft, Yes No N/A

loss and deterioration of quality?

13. Does the factory possess a fabric inspection machine? If so, Yes No N/A

is there a policy/procedure for it’s usage on all material?

14. Does the factory have its own light box? Yes No N/A

15. Are faulty fabrics / raw materials well separated in order to avoid Yes No N/A

mixing?

16. Are different shade lots of fabric well separated in order to avoid Yes No N/A

mixing?

Rating: Incoming Inspections –

( 1) out of 1 Critical items rated as "YES" = ( 3 ) Points

(15 ) out of 15 Non-critical items rated as "YES" = (15) Points

Total Score for Section D: ( 18 ) / 18

*N/A answers will not be factored into the Maximum Points Available

Item #: Remarks:

D-1 Factory use international standard like 4 point system for fabric inspection, roll

(remarks) to roll shade check, AQL- 0.65 for accessories inspection

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 9 of 23

D-7 Factory preserves approved samples, Pre Production meeting minutes, Fabric

(Remarks) construction details, Measurements as a reference for the auditors.

E. IN PROCESS QUALITY CONTROL

1. Are all toolings fully tested and evaluated with all Yes No N/A

measurements and safety issues?

2. Are samples of pilot run, or approved client samples Yes No N/A

carefully reviewed by engineers and/or quality staff to see that

all safety aspects are being met?

3. Is the factory able to perform pre-development testing? Yes No N/A

4. Is there an In Process QC system to prepare for mass Yes No N/A

production? **

5. Is there any documentation from either engineering, Yes No N/A

Q.C. department or top management to authorize

mass production?

6. Are there line patrols by quality controllers or other Yes No N/A

means to monitor the compliance of the product to

meet safety requirements? **

7. Does factory use international or other approved Yes No N/A

standards to carry out in-process inspection? Are

there records?

8. Do records reflect the action taken on the rejected Yes No N/A

lots?

9. Do records show rejected lots are well identified and Yes No N/A

segregated from accepted lots?

10. Is there a system or policy in place for permanently removing Yes No N/A

non-conforming manufactured items?

11. Are there clearly written criteria/instructions Yes No N/A

available for employees to follow?

12. Are there approved samples attached to all areas Yes No N/A

to give inspectors or workers a guideline?

13. Is the inspection and test equipment reliable to Yes No N/A

verify the conformance of the semi-finished final product?

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 10 of 23

14. Are the inspection defects charted, analyzed, and Yes No N/A

monitored to improve the problems encountered?

15. Are QC supervisors and management easily identifiable? Yes No N/A

(e. g. QC supervisors and management wear certain colored vest/shirt

uniforms, other than badges)

16. Are rejected lots well-identified and segregated from accepted? Yes No N/A

17. Are shade batches separated in a lay while cutting? Yes No N/A

18. Are cutting panels checked before they are put into the sewing floor? Yes No N/A

19. Is there a tearing test for fused parts? Yes No N/A

20. Are cutting panels properly placed into containers / boxes? Yes No N/A

21. Are workers wearing protective gloves while operating cutting machines? Yes No N/A

Rating: In-Process Quality Control -

(2) out of 2 Critical items rated as "YES" = ( 6) Points

(13 ) out of 19 Non-critical items rated as "YES" = ( 13) Points

Total Score for Section E: ( 19 ) / 25

*N/A answers will not be factored into the Maximum Points Available

Item #: Remarks:

Factory does not preserve any defect rework reports. However, factory preserves inspection

E-8, E-9

reports along with defect quantities.

E-11 Working instructions are not given in pressing area.

E-12 No reference sample found at ironing area.

QC supervisors or personnel were not provided with identification uniform to be worn for easy

E-15

identification.

Factory has no physical segregation between accepted cut panels and rejected cut panels.

E-16 Factory provided a reject box, but workers are observed to keep damage cut panel bundles in

same table where cut panel inspection take place.

F. FINAL INSPECTION

1. Do factory’s quality controllers perform any internal Yes No N/A

final inspection on merchandise? **

2. Are international, client’s or other approved standards Yes No N/A

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 11 of 23

used? For example: USA federal and state regulations.

3. Are there written internal inspection reports/logs and are Yes No N/A

they properly filed and traceable to review quality of products?

4. Are customer drawings/specifications readily available Yes No N/A

from quality control or posted on each line? **

5. Does factory perform internal mechanical tests on finished Yes No N/A

goods to safeguard the product’s quality? If so, note below

how often.

6. Are there records to show factory has regularly performed Yes No N/A

such mechanical safety tests?

7. Are inspection and testing records maintained and readily available? Yes No N/A

8. Does the factory have a process for quantity of sample size Yes No N/A

pulled for internal review and inspection?

9. Are there normal procedures that require acceptable Yes No N/A

inspection reports in order to authorize and shipment of products?

10. Does factory perform check on functionality of final production? Yes No N/A

11. Does the factory have a process by which to review and Yes No N/A

compare finished product at different stages of production run

for customers order? – beginning, middle or at the end of

production run?

12. Are measurement audit conducted during final inspection? Yes No N/A

13. Are dummies (fit models) used to check the fit and hang aspects Yes No N/A

of the finished garments?

14. If some operations are sub-contracted out, will the factory send its Yes No N/A

QC to the sub-contractor’s site for monitoring the quality and are

the out-inspection records readily available?

Rating: Final Inspection -

(2) out of 2 Critical items rated as "YES" = ( 6 ) Points

(11) out of 11 Non-critical items rated as "YES" = ( 11 ) Points

Total Score for Section F: ( 17 ) / 17

*N/A answers will not be factored into the Maximum Points Available

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 12 of 23

Factory performs internal mechanical tests on finished goods. Besides this, factory has an

F-5 (Note)

internal lab where factory is doing physical and chemical tests.

F-14 Factory has no operations which are subcontracted out, however they do embroidery which is

(Remarks) outsourced from their sister concern named Southeast textile limited and Anam clothing limited.

G. FINISHING AND PACKAGING

1. Is the packaging area clean and free of contaminants? Yes No N/A

2. Are there any safeguards to prevent another company’s Yes No N/A

products from being packaged into master cartons for another order?

3. Is there any control to prevent any defective or rejected Yes No N/A

products from being packed into master cartons? **

4. Are semi-finished products well segregated from final Yes No N/A

finished products in the packing area?

5. Are finished approved products packed promptly for best Yes No N/A

manufacturing process in order to avoid dust and dirt?

If not, are they properly stored and protected until packing?

6. Do workers wear gloves, hats/caps, shoe covers when Yes No N/A

necessary?

7. Is there an established and posted packing procedure for product Yes No N/A

according to the customers specific requirements?

8. Is the weight of packed master cartons randomly checked to Yes No N/A

avoid product shortages? If not, is there a procedure to avoid

the possibility of shortages?

9. Are packed master cartons well stored in a covered area or a Yes No N/A

good shelter to keep from exposure to climate conditions which

could compromise final appearance or structural integrity?

10. Is there equipment to use for stamping the date code, lot code, Yes No N/A

and case number?

11. Does the facility have a working barcode scanner to verify Yes No N/A

that the barcode on packaging is correct?

12. Does the facility have a policy for storing and stacking Yes No N/A

finished cartons prior to shipment? **

13. Is a filter connected to the water pipe used for steam boiler in pressing? Yes No N/A

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 13 of 23

14. Have the steam boilers been examined periodically by outside Yes No N/A

Certified engineers and are those maintenance records readily

available?

15. Are cleaning liquids and agents properly stored to avoid catching fire Yes No N/A

or being inhaled by workers?

16. Are scales used to accurately obtain the carton weight? If so, how Yes No N/A

often are those scales calibrated? Answer in remarks below.

17. If laundry or washing machines are used, are there any written Yes No N/A

procedures for wastage water treatment?

Rating: Finishing and Packaging -

(2) out of 2 Critical items rated as "YES" = (6 ) Points

( 13 ) out of 15 Non-critical items rated as "YES" = ( 13 ) Points

Total Score for Section G: ( 19 ) / 21

*N/A answers will not be factored into the Maximum Points Available

Item #: Remarks:

Factory has randomly checked weight of packed master cartons to avoid

G-8 product shortages but no records maintained to track or cross check product

shortage.

There is no equipment to use for stamping the date code, lot code, and case

G-10

number.

G-16 (Note) Calibrated weight measuring scales used for obtaining carton weight.

Factory does not have any washing plant. But factory have an effluent

G-17 (Note)

treatment plant for treatment of the waste water of dyeing and printing section.

H. NON-CONFORMING MATERIALS

1. Is there a documented procedure for non-confirming materials? Yes No N/A

If so, are those procedures clearly understood and implemented

by factory personnel and are records readily available?? **

2. Are non-conforming materials properly segregated at all stages? Yes No N/A

3. Are non-conforming materials easily identifiable? Yes No N/A

4. Is scrap or non-conforming material easily distinguished from Yes No N/A

good product?

5. Is there a corrective action procedure for non-conforming Yes No N/A

materials? **

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 14 of 23

6. Can the factory demonstrate how they handle non-conforming Yes No N/A

materials such as product that fails the mechanical tests? If so,

does this demonstration coincide with its written procedure?

7. Can the factory supply solid proof to guarantee non-conforming Yes No N/A

materials/products are unquestionably segregated from conformed

production and will not intermingle?

8. Does the factory have a process for notification to client when Yes No N/A

non-compliant product is identified as being introduced into the

production run?

9. Is it found that there are no workers wearing garments identical to Yes No N/A

garments being produced?

Rating: Non-Conforming Materials -

(1) out of 2 Critical items rated as "YES" = ( 3 ) points

(3) out of 7 Non-critical items rated as "YES" = (3) points

Total Score for Section H: (6) / 13

*N/A answers will not be factored into the Maximum Points Available

Item #: Remarks:

Alter/reject/ Ok garments are not segregated at all the production process. Factory has

H-2 provided alter/reject box in sewing, finishing section but it is not functional. Worker are not

aware about alter/reject box.

Non conforming materials are segregated at all stage but no proper marking system found to

H-3, H-4 identify the non-conforming product. In sewing section factory has provided separate

alter/reject box but no identification found at those box.

Factory does not track the re-work activity and non conformance products to ensure re work

H-5

quality.

Factory does not have a process for notification to client when non-compliant product is

H-7

identified as being introduced into the production run.

I. COMMUNICATION, DOCUMENTATION CONTROL AND WORK MOVEMENT

1. Does factory management and key staff understand English Yes No N/A

sufficiently to ensure communication with vendor/US Rep/Retailer?

2. Is there an adequate and formal system for receiving and Yes No N/A

applying line drawing, procedures, design change?

3. Are approved line drawings and specifications used properly, Yes No N/A

filed in chronological sequence and traceable?

4. Are line drawings, records and specifications that reflect an Yes No N/A

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 15 of 23

adequate history of changes readily available?

5. In the case of authorized subcontracting, does factory Yes No N/A

provide adequate supervision and specifications to ensure

compliance to the requirements of client’s standards? **

6. Does the factory conduct a 100% inspection on all subcontracted Yes No N/A

work? **

7. Does factory have clear written instructions to its departments, Yes No N/A

delegating authority to stop production if the products do not

meet the safety requirements of client’s standards?

8. Is technical information clearly identified to QA personnel with Yes No N/A

adequate controls to insure process is replicated throughout

the production run?

9. Does factory have a policy for keeping all client’s technical Yes No N/A

project information confidential?

10. Does the factory have an efficient policy to notify the client and Yes No N/A

advise/discuss any failure on processing problems?

11. Does the factory retain copies of internal test reports? Yes No N/A

If yes, note type of test reports in remarks section.

12. Does the factory retain copies of external test reports? If yes, Yes No N/A

note type of test reports in remarks section.

13. Do records show the daily production output of each section? Yes No N/A

14. Are pre-production samples or pilot lots evaluated in writing with Yes No N/A

comments attached?

15. Do records show that regular pre-production meetings are held Yes No N/A

before a new style is put into production?

Rating: Communication, Documentation Control and Work Movement

(0 ) out of 0 Critical items rated as "YES" = ( 0 ) Points

(13) out of 13 Non-critical items rated as "YES" = (13 ) points

Total Score for Section I: (13 ) / 13

*N/A answers will not be factored into the Maximum Points Available

Item #: Remarks:

Factory has no operations which are subcontracted out, however they do embroidery from their

I-5, I-6 (Note)

sister concern Southeast textile ltd and Anam clothing limited.

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 16 of 23

rd

Factory perform external test through 3 party testing company (Bureau Veritas / SGS etc) for

I-12(remarks) color fastness to wash, color fastness to light, color fastness to crocking ,Dimensional stability

,tensile strength, pilling resistance and others garments test as per their buyer requirement.

J. HANDLING OF COMPLAINTS

1. Is there a procedure for the handling, investigating and Yes No N/A

resolving customer/product complaints? **

2. Are customer complaint handled by factory management? Yes No N/A

3. Are the complaints analyzed and root causes investigate? Yes No N/A

4. Are corrective and preventive actions taken to eliminate the Yes No N/A

non-conformity?

5. Is the corrective and preventive plan communicated with the Yes No N/A

customer?

6. Are there traceable records for the handling of complaints? Yes No N/A

7. Do records show that the corrective and preventive actions Yes No N/A

are properly conducted and monitored to client satisfaction?

Rating: Handling of Complaints:

(1) out of 1 Critical items rated as "YES" = (3 ) points

Total Score for Section J: (3) / 3

*N/A answers will not be factored into the Maximum Points Available

Item #: Remarks:

J-1

It was noted that, factory does not face any complain from their client yet.

(Remarks)

K. TRANS-SHIPMENT INFORMATION – (All Critical Points) **

1. Is the factory free from any evidence of trans-shipping? ** Yes No N/A

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 17 of 23

2. Does all WIP (Work in Progress) present at the time of audit Yes No N/A

have appropriate paperwork? **

3. Is the correct Country of Origin on all paperwork? ** Yes No N/A

4. Is the factory free from any evidence of diverted shipments from Yes No N/A

Other countries? **

5. There is no evidence of contraband production. ** Yes No N/A

6. There is no evidence of fraudulent labels. ** Yes No N/A

7. Can WIP (Work in Progress) be completed within this factory? ** Yes No N/A

8. There is no evidence that the factory is subcontracting our garment Yes No N/A

Production. **

Rating: Trans-shipment Information

( 8 ) out of 8 Critical items rated as "YES" = ( 24 ) points

Total Score for Section K: (24 ) / 24

*N/A answers will not be factored into the Maximum Points Available

Item #: Remarks:

Its confirmed by last shipment documents Verification of Costco Canada, PO

#45009992,Style No# Harg 1003/1004/1005/1007,Total cartons : 2000 ; that

K-1

the factory free form trans-shipping. Factory direct shipped from Chittagong

port (Port of loading) to buyer destination Canada. (Port of Discharge).

Additional Questions - Information Only (No Points Achievable)

1. Is the facility monitored by security cameras, gated or guards? Yes No N/A

2. Does the factory have an in-house testing facility? Yes No N/A

3. List any Factory Accreditations. Yes No N/A

4. Does the factory possess any other accreditations? Yes No N/A

Remarks:

1. Factory has installed CCTV to monitor the key entrance and exits and security

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 18 of 23

guards are posted to ensure security of the premises.

Factory has in house testing facility to conduct test for product’s safety and

2.

quality assurance.

3. Factory has ISO 9001:2008 and WRAP certification.

Factory Name: Interstoff Apparels Ltd

Address: Chandora, Kaliakoir, Gazipur, Bangladesh

Initial Audit Re Audit

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 19 of 23

SUMMARY OF THE POINTS THAT THE FACTORY ACHIEVED

Maximum Points Total Points

SECTIONS

Available Achieved

A. Metal Detection – Critical Points 12 09

B. Facilities 20 20

C. Quality Control System 15 12

D. Incoming Inspections 18 18

E. In-Process Quality Control 25 19

F. Final Inspection 17 17

G. Finishing and Packaging 21 19

H. Non-Conforming Materials 13 06

I. Communication, Document

13 13

Control, Work Movement

J. Handling of Complaints 03 03

K. Trans-Shipment Information - 24

24

Critical Points

Total Points Available 181 (B)

Total Points Achieved 160 (A)

Audit Result: Total Score in %=88.39

(A/B X100%)

28 Critical questions (with **) worth 3 points each (84 possible points). Total Score less than 85%

constitutes an automatic failed audit and re-auditing is required within 60 days for, at minimum, the

critical failures OR prior to any new production of Costco goods.

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 20 of 23

Digital Photo Records

Factory Outlook Factory Name Dyeing section

Dyeing finishing Chain mail gloves used in Cutting Sewing section

section

Ironing section Packing and folding section Fabric store

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 21 of 23

Accessories store Finished carton store Sample section

Pattern making section with CAD Fabric relaxation area Cut panel numbering

facility

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 22 of 23

Cut panel stored in separate boxes Printing section. Fusing section

color wise.

Cutting section Snap button attachment section Calibrated pull test machine

Reference sample in sewing line End line inspection Final inspection

Metal detector Reject box for metal contaminated Test card for calibration Metal

garments detector

Rev: June 27, 2012

Soft-lines/Textile Factory Capability Audit

Report No.: 1219872 Date of Report: 29-11-2012 Page 23 of 23

Weighing balance for Cartons Bar code scanner Broken needle register

Button pull test machine Dummy used for fitting Light box

confirmation

Traffic light introduced in the sewing

section.

Fabric inspection machine Shade band Band knife cutting machine

Separate

Rev: boxes

June 27, 2012found for alter / reject Workers are keeping damage cut Needle guard are not in appropriate

/ okay in sewing section. panel bundles in same table where cut height.

panel inspection taking place.

Вам также может понравиться

- Automotive Quality Management Systems A Complete Guide - 2020 EditionОт EverandAutomotive Quality Management Systems A Complete Guide - 2020 EditionОценок пока нет

- Vendor Rejection and Debit PolicyДокумент6 страницVendor Rejection and Debit PolicysharanОценок пока нет

- Needle Metal Contamination Control SOP 2Документ16 страницNeedle Metal Contamination Control SOP 2vikkas vermaОценок пока нет

- BP-5.1.2D OJT Effectiveness SHEET - Level-2Документ1 страницаBP-5.1.2D OJT Effectiveness SHEET - Level-2shinuОценок пока нет

- SOP of MachinesДокумент2 страницыSOP of MachinesSangram Kandekar100% (1)

- Root Cause Analysis - ToolДокумент11 страницRoot Cause Analysis - ToolmuneerppОценок пока нет

- Prevent Sheet Metal Burr Formation with Proper Tooling and Process ControlsДокумент5 страницPrevent Sheet Metal Burr Formation with Proper Tooling and Process ControlsMajad RazakОценок пока нет

- IPQC General FormatДокумент17 страницIPQC General FormatMohd Isa HarunОценок пока нет

- PROJECT:0.654.0303.00-CMR162-3 DATE: February/2015 APPROVED BY: Leman Özgüler/Quality Manager Revision: 0 Total Page: 1/1Документ1 страницаPROJECT:0.654.0303.00-CMR162-3 DATE: February/2015 APPROVED BY: Leman Özgüler/Quality Manager Revision: 0 Total Page: 1/1Metin DemirciogluОценок пока нет

- COUNTER MEASURE of Customer ComplaintДокумент2 страницыCOUNTER MEASURE of Customer Complaintpreetam kumarОценок пока нет

- RBAC Supplier Packaging Approval FormДокумент1 страницаRBAC Supplier Packaging Approval Formcong daОценок пока нет

- QAP K-HouseДокумент4 страницыQAP K-HouseAbhinash TamangОценок пока нет

- IPC-TM-650 Test Methods ManualДокумент4 страницыIPC-TM-650 Test Methods ManualSSmyLoginОценок пока нет

- IATF 16949 Sanctioned Interpretations 1 9 SIs FinalДокумент8 страницIATF 16949 Sanctioned Interpretations 1 9 SIs FinalOdagil BanzatoОценок пока нет

- Calibration Training: ReferencesДокумент5 страницCalibration Training: ReferenceshoussОценок пока нет

- ISO Audit ProcedureДокумент3 страницыISO Audit Procedurekyunjae JetomoОценок пока нет

- Dis 6 W 2 HДокумент14 страницDis 6 W 2 HBalachandar SathananthanОценок пока нет

- MARATHAN MOTOR SOP Recruitment ProcedureДокумент4 страницыMARATHAN MOTOR SOP Recruitment Procedurerishi gautamОценок пока нет

- Interested-Parties-Needs-expectations-As-Per - ISO TS 22163Документ8 страницInterested-Parties-Needs-expectations-As-Per - ISO TS 22163AnkurОценок пока нет

- October - 20 Monthly Meeting PresentationДокумент17 страницOctober - 20 Monthly Meeting PresentationMahmud Al HasanОценок пока нет

- Supplier Quality Manual: Zetor Tractors A.S. Trnkova 111 628 00 BRNOДокумент42 страницыSupplier Quality Manual: Zetor Tractors A.S. Trnkova 111 628 00 BRNOumtОценок пока нет

- Rejection Record.Документ10 страницRejection Record.karan shahОценок пока нет

- Updates Dec09 AIAG FMEA-Ranking-TablesДокумент3 страницыUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- Indian Standard: Sampling Inspection ProceduresДокумент24 страницыIndian Standard: Sampling Inspection ProceduresarunrathikaОценок пока нет

- In-House Calibration SheetДокумент4 страницыIn-House Calibration SheetKannan MurugesanОценок пока нет

- Controls:: Measuring Instruments in ImteДокумент5 страницControls:: Measuring Instruments in ImteDhinakaranОценок пока нет

- QA Forging Job DescriptionДокумент2 страницыQA Forging Job DescriptionParveen (Atam Valves)Оценок пока нет

- TKW Fasteners ProfileДокумент37 страницTKW Fasteners ProfileRishi GautamОценок пока нет

- In-Line Inspection FORMAT - 1Документ3 страницыIn-Line Inspection FORMAT - 1Nishu Jalotia0% (1)

- Electric Wire PDFДокумент102 страницыElectric Wire PDFGoswami kinjalОценок пока нет

- Engineering & Design Division In-Process Inspection RecordДокумент1 страницаEngineering & Design Division In-Process Inspection Recordrishi gautamОценок пока нет

- IMS-TUL-01-IMS Turtil DiagramДокумент1 страницаIMS-TUL-01-IMS Turtil DiagramRohit SoniОценок пока нет

- Tds Nitric Acid HuchemsДокумент3 страницыTds Nitric Acid HuchemsB.R SinghОценок пока нет

- Quality Control PlanДокумент10 страницQuality Control PlanGAURAV SHARMAОценок пока нет

- Controlling The Defects of Paint Shop PDFДокумент4 страницыControlling The Defects of Paint Shop PDFRahul SasidharanОценок пока нет

- Risk Assessment - AHUДокумент5 страницRisk Assessment - AHUManzur AhmadОценок пока нет

- pure cotton pvt ltd final inspection reportДокумент4 страницыpure cotton pvt ltd final inspection reportTarun PariharОценок пока нет

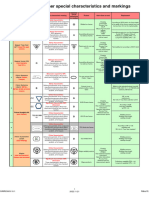

- Customer Special CharacteristicsДокумент1 страницаCustomer Special Characteristicspundhir12898Оценок пока нет

- JD Manager-Machine ShopДокумент2 страницыJD Manager-Machine ShopParveen (Atam Valves)Оценок пока нет

- Skype: Mizan - Mehben: B SC in Textile Engineering (ADUST)Документ87 страницSkype: Mizan - Mehben: B SC in Textile Engineering (ADUST)Fathi MustafaОценок пока нет

- CNC HMC Acc CheckДокумент2 страницыCNC HMC Acc CheckKalees WaranОценок пока нет

- Word TSL FILEДокумент14 страницWord TSL FILEKumbhar p.s.100% (1)

- 9-Point Testing ProcedureДокумент1 страница9-Point Testing ProcedureJahangir Alam SohagОценок пока нет

- Report No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeДокумент1 страницаReport No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeRohit VishwakarmaОценок пока нет

- Aatcc tm179-207 Skew TwistДокумент53 страницыAatcc tm179-207 Skew Twistsklim ericОценок пока нет

- Hot Chemical TestДокумент3 страницыHot Chemical TestUSBid Inc.Оценок пока нет

- Taurus Slim Series 9mmpt709Документ19 страницTaurus Slim Series 9mmpt709daks4u100% (1)

- QA Manual SupplierДокумент22 страницыQA Manual SupplierbrianbagalayОценок пока нет

- Container Loading Procedure PDFДокумент8 страницContainer Loading Procedure PDFZAHID UMARОценок пока нет

- Social Factors - HIRAДокумент8 страницSocial Factors - HIRARS MANIKANDANОценок пока нет

- PFMEA Process Failure Modes and Effects AnalysisДокумент15 страницPFMEA Process Failure Modes and Effects AnalysisPrakash RanjanОценок пока нет

- QMS 1004255 SENSATA GSQM - Rev P No Markup BLACK PDFДокумент54 страницыQMS 1004255 SENSATA GSQM - Rev P No Markup BLACK PDFJossie FuentesОценок пока нет

- Samples Inspection ReportДокумент5 страницSamples Inspection ReportArun GuptaОценок пока нет

- SD-SCD-QF75 Factory Audit Checklist Rev.0Документ6 страницSD-SCD-QF75 Factory Audit Checklist Rev.0Asma DahaboОценок пока нет

- Self Certification Process SOP & Eligibility - v2.0Документ5 страницSelf Certification Process SOP & Eligibility - v2.0Nikhil JaiswalОценок пока нет

- Sony-Kaga Quality and Delivery Performance ReviewДокумент13 страницSony-Kaga Quality and Delivery Performance ReviewDustin RobertsonОценок пока нет

- SQEF0002 A TTI MIL QMS Audit Check ListДокумент69 страницSQEF0002 A TTI MIL QMS Audit Check ListĐỗ Thành NhươngОценок пока нет

- Substation Grid Availability EvaluationДокумент3 страницыSubstation Grid Availability EvaluationDildar HossainОценок пока нет

- Class Room Audit Case Studies For PracticeДокумент6 страницClass Room Audit Case Studies For Practicegaurav kumar100% (1)

- Supplier Assessment Report-Cooperation Company of Cixi Yuyang Waterproof Material Co., Ltd.Документ15 страницSupplier Assessment Report-Cooperation Company of Cixi Yuyang Waterproof Material Co., Ltd.Monica Najarro GutierrezОценок пока нет

- Recent 1067 MCQ 2021 - 22 (Exambd - Net)Документ132 страницыRecent 1067 MCQ 2021 - 22 (Exambd - Net)Rahat fahimОценок пока нет

- Word List of Rizvi PDFДокумент82 страницыWord List of Rizvi PDFzahidОценок пока нет

- Food PoisoningДокумент4 страницыFood PoisoningzahidОценок пока нет

- Jenny Hillemann's CV: Post-doctoral researcher in managementДокумент1 страницаJenny Hillemann's CV: Post-doctoral researcher in managementzahidОценок пока нет

- Asian Countries and Their Capitals and Currencies PDFДокумент3 страницыAsian Countries and Their Capitals and Currencies PDFzahidОценок пока нет

- Coming To Study in New ZealandДокумент2 страницыComing To Study in New ZealandzahidОценок пока нет

- Bangladesh Labour Act 2006Документ15 страницBangladesh Labour Act 2006Rabeya SultanaОценок пока нет

- How Your Brain Learns English PDFДокумент8 страницHow Your Brain Learns English PDFzahidОценок пока нет

- 500 Real English PhrasesДокумент38 страниц500 Real English PhrasesIon Sava100% (2)

- Road To University of Saskatchewan Saskatoon CanadaДокумент7 страницRoad To University of Saskatchewan Saskatoon CanadazahidОценок пока нет

- Short Cut Math PDFДокумент181 страницаShort Cut Math PDFzahidОценок пока нет

- 80 Rules To Solve Sentence Correction PDFДокумент19 страниц80 Rules To Solve Sentence Correction PDFzahid100% (1)

- Canadian Citizenship: Facts and Perspectives: Harbord Collegiate Institute November 25, 2005Документ33 страницыCanadian Citizenship: Facts and Perspectives: Harbord Collegiate Institute November 25, 2005zahidОценок пока нет

- Game of HSA PDFДокумент1 страницаGame of HSA PDFNahid KhannaОценок пока нет

- Guide To Living Studying in NZ - English PDFДокумент54 страницыGuide To Living Studying in NZ - English PDFzahidОценок пока нет

- Achieve Ielts BookДокумент178 страницAchieve Ielts BookJeon100% (2)

- Job Reference Letter SampleДокумент1 страницаJob Reference Letter SamplezahidОценок пока нет

- Word List of Rizvi PDFДокумент82 страницыWord List of Rizvi PDFzahidОценок пока нет

- Ielts Buddy Ebook Task 1 Excerpt PDFДокумент9 страницIelts Buddy Ebook Task 1 Excerpt PDFTuan30% (10)

- Word List of Rizvi PDFДокумент82 страницыWord List of Rizvi PDFzahid100% (1)

- Angles and Lines ExplainedДокумент20 страницAngles and Lines ExplainedvaveenaОценок пока нет

- BCS Preliminary Subjective Notes by Samad AzadДокумент63 страницыBCS Preliminary Subjective Notes by Samad AzadEngr. Sagor Dutta92% (26)

- NIFT Students Explore Marketing Activities of MerchandisingДокумент49 страницNIFT Students Explore Marketing Activities of MerchandisingzahidОценок пока нет

- The Daily Star (29-03-15) PDFДокумент2 страницыThe Daily Star (29-03-15) PDFzahidОценок пока нет

- Advanceenglishgrammarbytanbircox 140103120207 Phpapp01Документ63 страницыAdvanceenglishgrammarbytanbircox 140103120207 Phpapp01rehan3038Оценок пока нет

- New Age (26-03-15) PDFДокумент2 страницыNew Age (26-03-15) PDFzahidОценок пока нет

- 100 Writing Mistakes in EnglishДокумент44 страницы100 Writing Mistakes in Englishfranc_estors100% (3)

- Merchandising SystemДокумент60 страницMerchandising SystemMuhammad_Hasan_163888% (8)

- Bengali Section - All Previous Years Bank QuestionДокумент17 страницBengali Section - All Previous Years Bank QuestionZahid HassanОценок пока нет

- TRI 3005 Garment Washing Techniques For Cotton ApparelДокумент13 страницTRI 3005 Garment Washing Techniques For Cotton Apparelapi-26494555Оценок пока нет

- 7 ELECTRICAL PARTS LIST TITLEДокумент14 страниц7 ELECTRICAL PARTS LIST TITLEokeinfoОценок пока нет

- 1306a-E87tag6 PN3049Документ2 страницы1306a-E87tag6 PN3049Md Sh100% (2)

- Atomic 4 Parts ListДокумент72 страницыAtomic 4 Parts ListRobertОценок пока нет

- 2 1105693707 PDFДокумент61 страница2 1105693707 PDFAguinaldo OliveiraОценок пока нет

- Falk Steelflex PDFДокумент2 страницыFalk Steelflex PDFWesleyОценок пока нет

- Smart BoomДокумент10 страницSmart BoomKevine Khaled100% (1)

- History-TAPP Quiz No. 001Документ5 страницHistory-TAPP Quiz No. 001Ranier PablicoОценок пока нет

- L P GДокумент11 страницL P GPhi MacОценок пока нет

- Cineo 2560servicemanualДокумент732 страницыCineo 2560servicemanualjrusalen1100% (1)

- Aseptic FillingДокумент5 страницAseptic FillingMIKEОценок пока нет

- Bond strength of cementitious screeds on concrete bearing floorsДокумент88 страницBond strength of cementitious screeds on concrete bearing floorsAbdul HafeezОценок пока нет

- Brochure For York ChillerДокумент8 страницBrochure For York ChillervenkatearОценок пока нет

- Art Deco in Mumbai: (Theaters)Документ9 страницArt Deco in Mumbai: (Theaters)abhishekОценок пока нет

- MTL Product OverviewДокумент56 страницMTL Product OverviewAries dОценок пока нет

- Wan Bao Construction Limited: Register of Legal and Other RequirementsДокумент49 страницWan Bao Construction Limited: Register of Legal and Other RequirementsVictorОценок пока нет

- RPS Modrobs PDFДокумент3 страницыRPS Modrobs PDFHarsha NОценок пока нет

- Concrete Filled Steel TubeДокумент12 страницConcrete Filled Steel TubeYogendra SINGH PATEL100% (1)

- English Handout For Engineering (Diktat)Документ104 страницыEnglish Handout For Engineering (Diktat)Raden Mas Lukmana Tejo100% (2)

- Electrical Load Calculations for Building ConstructionДокумент16 страницElectrical Load Calculations for Building ConstructionKitz DerechoОценок пока нет

- Final - Notif September 2007Документ347 страницFinal - Notif September 2007api-26042912Оценок пока нет

- Samsung AC Manual PDFДокумент56 страницSamsung AC Manual PDFSaravanan VkОценок пока нет

- Portal Crane Systems - Dynamic Storm Brake System IIДокумент2 страницыPortal Crane Systems - Dynamic Storm Brake System IIpresydentyОценок пока нет

- EINWOOD Catalogue 2Документ40 страницEINWOOD Catalogue 2jcedricaquinoОценок пока нет

- H815 Design of All-Plywood BeamsДокумент29 страницH815 Design of All-Plywood BeamsbabshuagОценок пока нет

- Commutation Failure in HVDC PDFДокумент2 страницыCommutation Failure in HVDC PDFCodyОценок пока нет

- Diagrama Hidraulico 320d FM HarvesterДокумент1 страницаDiagrama Hidraulico 320d FM HarvesterMatiasОценок пока нет

- UT Dallas Syllabus For Mech3350.001.11s Taught by Wooram Park (wxp103020)Документ2 страницыUT Dallas Syllabus For Mech3350.001.11s Taught by Wooram Park (wxp103020)UT Dallas Provost's Technology GroupОценок пока нет

- MAXGRIPДокумент1 страницаMAXGRIPjchessaОценок пока нет

- Sectional LayoutДокумент7 страницSectional LayoutNickol Hardway100% (1)

- Tks RP Retrieval Tool: Installation, Operation & Maintenance InstructionsДокумент30 страницTks RP Retrieval Tool: Installation, Operation & Maintenance Instructionssaiful anwarОценок пока нет

- Guidelines for Implementing Process Safety ManagementОт EverandGuidelines for Implementing Process Safety ManagementОценок пока нет

- Safety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849От EverandSafety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849Рейтинг: 4 из 5 звезд4/5 (5)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesОт EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesРейтинг: 5 из 5 звезд5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsОт EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsРейтинг: 4 из 5 звезд4/5 (11)

- Chemical Process Safety: Learning from Case HistoriesОт EverandChemical Process Safety: Learning from Case HistoriesРейтинг: 4 из 5 звезд4/5 (14)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- Incidents That Define Process SafetyОт EverandIncidents That Define Process SafetyОценок пока нет

- Safety Fundamentals and Best Practices in Construction IndustryОт EverandSafety Fundamentals and Best Practices in Construction IndustryОценок пока нет

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationОт EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationОценок пока нет

- Inherently Safer Chemical Processes: A Life Cycle ApproachОт EverandInherently Safer Chemical Processes: A Life Cycle ApproachРейтинг: 5 из 5 звезд5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersОт EverandRules of Thumb for Maintenance and Reliability EngineersРейтинг: 4.5 из 5 звезд4.5/5 (12)

- A Complete Guide to Safety Officer Interview Questions and AnswersОт EverandA Complete Guide to Safety Officer Interview Questions and AnswersРейтинг: 4 из 5 звезд4/5 (1)

- The Invisible Rainbow: A History of Electricity and LifeОт EverandThe Invisible Rainbow: A History of Electricity and LifeРейтинг: 4.5 из 5 звезд4.5/5 (21)

- One Health: Integrated Approach to 21st Century Challenges to HealthОт EverandOne Health: Integrated Approach to 21st Century Challenges to HealthJoana C. PrataОценок пока нет

- Radium Girls: Women and Industrial Health Reform, 1910-1935От EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Рейтинг: 4.5 из 5 звезд4.5/5 (4)

- Fire Fighting Pumping Systems at Industrial FacilitiesОт EverandFire Fighting Pumping Systems at Industrial FacilitiesРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesОт EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EОт EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EРейтинг: 3 из 5 звезд3/5 (6)

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceОт EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceРейтинг: 5 из 5 звезд5/5 (1)

- Guidelines for Process Safety in Bioprocess Manufacturing FacilitiesОт EverandGuidelines for Process Safety in Bioprocess Manufacturing FacilitiesОценок пока нет

- Establishing an occupational health & safety management system based on ISO 45001От EverandEstablishing an occupational health & safety management system based on ISO 45001Рейтинг: 4 из 5 звезд4/5 (5)