Академический Документы

Профессиональный Документы

Культура Документы

Concept of Post Weld Heat Treatment PDF

Загружено:

sridharchebroluОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Concept of Post Weld Heat Treatment PDF

Загружено:

sridharchebroluАвторское право:

Доступные форматы

Key Concepts in Welding Engineering

by R. Scott Funderburk

Postweld

Heat Treatment

What is PWHT?

it cools. After welding has been completed, the steel must not be allowed

to cool to room temperature; instead, it

should be immediately heated from

the interpass temperature to the post

heat temperature and held at this temperature for some minimum amount of

time. Although various code and ser-

Postweld heat treatment (PWHT),

defined as any heat treatment after

welding, is often used to improve the

properties of a weldment. In concept,

PWHT can encompass many different

potential treatments; however, in steel

fabrication, the two most common procedures used are post heating and

stress relieving.

When is it Required?

The need for PWHT is driven by code

and application requirements, as well

as the service environment. In general, when PWHT is required, the goal is

to increase the resistance to brittle

fracture and relaxing residual stresses.

Other desired results from PWHT may

include hardness reduction, and material strength enhancements.

The need for post

heating assumes a

potential hydrogen

cracking problem

exists...

vice requirements can dictate a variety

of temperatures and hold times, 450F

(230C) is a common post heating

temperature to be maintained for 1

hour per inch (25 mm) of thickness.

Post heating is not necessary for most

applications. The need for post heatPost Heating

ing assumes a potential hydrogen

cracking problem exists due to a senPost heating is used to minimize the

sitive base metal microstructure, high

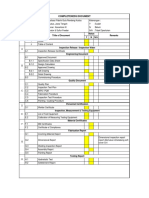

potential for hydrogen induced cracking (HIC). For HIC to occur, the follow- levels of hydrogen, and/or high stresses. Post heating, however, may be a

ing variables must be present (see

code requirement. For example,

Figure 1): a sensitive microstructure,

a sufficient level of hydrogen, or a high ASME Section III and the National

Board Inspection Code (NBIC) both

level of stress (e.g., as a result of

have such provisions. The Section III

highly constrained connections). In

requirement for P-No. 1 materials is

ferritic steels, hydrogen embrittlement

450 to 550F (230 to 290C) for a minonly occurs at temperatures close to

the ambient temperature. Therefore, it imum of 2 hours, while the NBIC

requirement is 500 to 550F (260 to

is possible to avoid cracking in a sus290C) for a minimum of 2 hours.

ceptible microstructure by diffusing

hydrogen from the welded area before Furthermore, post heating is often

Figure 1. Criteria for hydrogen

induced cracking (HIC).

required for critical repairs, such as

those defined under the Fracture

Control Plan (FCP) for Nonredundant

Members of the AASHTO/AWS D1.5

Bridge Welding Code. The FCP provision is 450 to 600F (230 to 315C) for

not less than one hour for each inch

(25 mm) of weld thickness, or two

hours, whichever is less. When it is

essential that nothing go wrong, post

heating can be used as insurance

against hydrogen cracking. However,

when the causes of hydrogen cracking

are not present, post heating is not

necessary, and unjustifiable costs may

result if it is done.

Stress Relieving

Stress relief heat treatment is used to

reduce the stresses that remain locked

in a structure as a consequence of

manufacturing processes. There are

many sources of residual stresses, and

those due to welding are of a magnitude roughly equal to the yield strength

of the base material. Uniformly heating

a structure to a sufficiently high temperature, but below the lower transformation temperature range, and then

uniformly cooling it, can relax these

Welding Innovation Vol. XV, No. 2, 1998

Other Considerations

residual stresses. Carbon steels are

typically held at 1,100 to 1,250F (600

to 675C) for 1 hour per inch (25 mm)

of thickness.

When determining whether or not to

postweld heat treat, the alloying system and previous heat treatment of the

base metal must be considered. The

Stress relieving offers several benefits. properties of quenched and tempered

For example, when a component with

alloy steels, for instance, can be

high residual stresses is machined,

adversely affected by PWHT if the

the material tends to move during the

temperature exceeds the tempering

metal removal operation as the stress- temperature of the base metal. Stress

es are redistributed. After stress

relief cracking, where the component

relieving, however, greater dimensional fractures during the heating process,

stability is maintained during machincan also occur. In contrast, there are

ing, providing for increased dimension- some materials that almost always

al reliability.

require PWHT. For example, chromeIn addition, the potential for stress corrosion cracking is reduced, and the

metallurgical structure can be

improved through stress relieving. The

steel becomes softer and more ductile

through the precipitation of iron carbide at temperatures associated with

stress relieving.

Finally, the chances for hydrogen

induced cracking (HIC) are reduced,

although this benefit should not be the

only reason for stress relieving. At the

elevated temperatures associated with

stress relieving, hydrogen often will

migrate from the weld metal and the

heat affected zone. However, as discussed previously, HIC can be minimized by heating at temperatures

lower than stress relieving temperatures, resulting in lower PWHT costs.

When determining

whether or not to

PWHT, the alloying

system and previous

heat treatment of the

base metal must be

considered

molybdenum steels usually need

stress relieving in the 1,250 to 1,300F

(675 to 700C) temperature range.

Thus, the specific application and steel

must be considered when determining

the need, the temperature and time of

treatment if applied, and other details

regarding PWHT.

The filler metal composition is also

important. After heat treatment, the

properties of the deposited weld can

be considerably different than the as

welded properties. For example, an

E7018 deposit may have a tensile

strength of 75 ksi (500 MPa) in the as

welded condition. However, after

stress relieving, it may have a tensile

strength of only 65 ksi (450 MPa).

Therefore, the stress relieved properties of the weld metal, as well as the

base metal, should be evaluated.

Electrodes containing chromium and

molybdenum, such as E8018-B2 and

E9018-B3, are classified according to

the AWS A5.5 filler metal specification

in the stress relieved condition. The

E8018-B2 classification, for example,

has a required tensile strength of 80

ksi (550 MPa) minimum after stress

relieving at 1,275F (690C) for 1 hour.

In the as welded condition, however,

the tensile strength may be as high as

120 ksi (825 MPa).

The objective of this article is to introduce the fundamentals of postweld

heat treatment; it is not meant to be

used as a design or fabrication guide.

For specific recommendations, consult

the filler metal manufacturer and/or the

steel producer.

For Further Reading

ASM Handbook, Volume 6 Welding, Brazing,

and Soldering. American Society for Metals,

1993.

Bailey, N. Weldability of Ferritic Steels. ASM

International/Abington Publishing, 1994.

Evans, G.M. and Bailey, N. Metallurgy of Basic

Weld Metal. Abington Publishing, 1997.

Metals Handbook, Volume 4 Heat Treating.

9th Edition. American Society for Metals,

1981.

Figure 2. Post heat applied immediately after last pass.

Welding Innovation Vol. XV, No. 2, 1998

Вам также может понравиться

- Robin Sharma WeeklyDesignSystemДокумент1 страницаRobin Sharma WeeklyDesignSystemsridharchebrolu100% (1)

- Do's and Dont's Shop Floor PracticesДокумент19 страницDo's and Dont's Shop Floor Practicessridharchebrolu50% (2)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Code - Aster Application in The Oil&gas FieldДокумент17 страницCode - Aster Application in The Oil&gas FieldSergio PluchinskyОценок пока нет

- Nelson Curve - Model For Predicting Hydrogen AttackДокумент2 страницыNelson Curve - Model For Predicting Hydrogen AttackDries VandezandeОценок пока нет

- DIN 24537en-Grating - Dimension, Load Bearing CapacityДокумент3 страницыDIN 24537en-Grating - Dimension, Load Bearing Capacitysridharchebrolu0% (1)

- Technical Specification GRP PipesДокумент218 страницTechnical Specification GRP PipesNabendu Lodh100% (1)

- Vdocuments - MX Wss m1p94 Atratamento Da ChapaДокумент10 страницVdocuments - MX Wss m1p94 Atratamento Da ChapaDANIEL DIAZОценок пока нет

- Post WeldДокумент4 страницыPost WelddanemsalОценок пока нет

- Artilce - Potential Detrimental Consequences of Excessive PWHT On Steel PropertiesДокумент8 страницArtilce - Potential Detrimental Consequences of Excessive PWHT On Steel PropertieswholenumberОценок пока нет

- Heat Treatment of Welded JointsДокумент26 страницHeat Treatment of Welded Jointslinhcdt3Оценок пока нет

- Welding Journal - March 2012Документ2 страницыWelding Journal - March 2012pkn_pnt9950Оценок пока нет

- Copying and Distributing Are Prohibited Without Permission of The PublisherДокумент16 страницCopying and Distributing Are Prohibited Without Permission of The PublisherMatthew PhillipsОценок пока нет

- Aws WJ 201705Документ165 страницAws WJ 201705Fabricio TarulloОценок пока нет

- SA253MA DetailДокумент16 страницSA253MA Detailksquare2001100% (1)

- A Review On Effect of Preheating And/Or Post Weld Heat Treatmemt (PWHT) On Mechanical Behaviour of Ferrous MetalsДокумент7 страницA Review On Effect of Preheating And/Or Post Weld Heat Treatmemt (PWHT) On Mechanical Behaviour of Ferrous MetalsNagarajan PitchandiОценок пока нет

- Effect of Heat Treatments On The Mechanical Properties of Welded Joints of Alloy Steel by Arc WeldingДокумент10 страницEffect of Heat Treatments On The Mechanical Properties of Welded Joints of Alloy Steel by Arc WeldingFiras RocktОценок пока нет

- PWHT Case StudiesДокумент5 страницPWHT Case Studiestbmari100% (1)

- Stainless Steels For Cryogenic Applications - KEY To METALS ArticleДокумент3 страницыStainless Steels For Cryogenic Applications - KEY To METALS Articlekumarpankaj030Оценок пока нет

- Heat Treatment RequirementsДокумент7 страницHeat Treatment RequirementsarunradОценок пока нет

- Review of Type IV Cracking of Weldments in 9Документ64 страницыReview of Type IV Cracking of Weldments in 9Krishnan SanthanarajОценок пока нет

- Arc Welding - Calculator ChartДокумент3 страницыArc Welding - Calculator ChartDr. Ladeesh V GopinathОценок пока нет

- UДокумент1 страницаUmohd as shahiddin jafriОценок пока нет

- Basics of Piping System Thermal Expansion For Process EngineersДокумент14 страницBasics of Piping System Thermal Expansion For Process EngineersGoce VasilevskiОценок пока нет

- Sysweld Welding ReportДокумент23 страницыSysweld Welding ReportAsiahKuzaimanОценок пока нет

- Fe-C Phase DiagramДокумент34 страницыFe-C Phase DiagramYoung-long Choi100% (1)

- Welding Eng Lab GuidenceДокумент15 страницWelding Eng Lab Guidencewan yusufОценок пока нет

- Welding Upto Gas WeldingДокумент26 страницWelding Upto Gas Weldingrams789Оценок пока нет

- Aws WJ 201401 PDFДокумент139 страницAws WJ 201401 PDFeduardo huancaОценок пока нет

- Fatigue and Brittle Fracture of Carbon Steel Process PipelineДокумент10 страницFatigue and Brittle Fracture of Carbon Steel Process PipelineEsteban Matias RodriguezОценок пока нет

- Thermanit MTS 3 - GTAWДокумент1 страницаThermanit MTS 3 - GTAWdnageshm4n244Оценок пока нет

- ThesisДокумент48 страницThesismuhammad amir100% (1)

- WJ 2016 07Документ158 страницWJ 2016 07JastenJesusОценок пока нет

- PWHTДокумент17 страницPWHTsam1971100% (8)

- Weldability PDFДокумент60 страницWeldability PDFS GoudaОценок пока нет

- A10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsДокумент9 страницA10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsXОценок пока нет

- Manufacturing Process - Module2.0Документ33 страницыManufacturing Process - Module2.0Fiza KamaОценок пока нет

- B. Importance of Preheat, Interpass, DHT, Isr, PWHTДокумент19 страницB. Importance of Preheat, Interpass, DHT, Isr, PWHTJay ShahОценок пока нет

- T23 Field Weld Guidelines Rev 01Документ4 страницыT23 Field Weld Guidelines Rev 01tek_surinderОценок пока нет

- MT 03 - Mechanical Properties and Tests, A-Z Abbrev (Tinius Olsen - Kul 1)Документ25 страницMT 03 - Mechanical Properties and Tests, A-Z Abbrev (Tinius Olsen - Kul 1)zingerОценок пока нет

- Effect of Heat InputДокумент9 страницEffect of Heat InputshrikantajitОценок пока нет

- SAW ThesisДокумент96 страницSAW ThesisvikasgahlyanОценок пока нет

- Heat Treatment of SteelДокумент11 страницHeat Treatment of SteelMohamed El-gammalОценок пока нет

- Induction BendingДокумент2 страницыInduction BendingshaonaaОценок пока нет

- Definition of Girth WeldДокумент2 страницыDefinition of Girth WeldHung ChengОценок пока нет

- Effect of Heat Input On Microstructure and Mechanical Properties of The TIG Welded Joints of AISI 304Документ10 страницEffect of Heat Input On Microstructure and Mechanical Properties of The TIG Welded Joints of AISI 304Kaushik SenguptaОценок пока нет

- Properties of NickelДокумент60 страницProperties of NickelchodekiranОценок пока нет

- GMAW of Creep Resistant SteelsДокумент5 страницGMAW of Creep Resistant SteelsJustin Morse100% (1)

- Weldability of MaterialsДокумент5 страницWeldability of MaterialsclnОценок пока нет

- Microstructural FeaturesДокумент27 страницMicrostructural FeaturesHagen_of_TronjeОценок пока нет

- Arcelormittal Pressure Vessel PDFДокумент10 страницArcelormittal Pressure Vessel PDFImmanuel SОценок пока нет

- Coating Thickness: MeasurementДокумент3 страницыCoating Thickness: Measurementjmpateiro1985Оценок пока нет

- Alloy Solutions To Metal Dusting Problems in The Chemical Processing IndustryДокумент8 страницAlloy Solutions To Metal Dusting Problems in The Chemical Processing IndustryGiuseppe Di RuoccoОценок пока нет

- 4.3. Residual Stresses and Distortion in WeldmentsДокумент11 страниц4.3. Residual Stresses and Distortion in WeldmentsprokulisОценок пока нет

- Part (3) Welding Practice : - Welding Passes - Welding Directions - Welding Sequences - Welding DefectsДокумент10 страницPart (3) Welding Practice : - Welding Passes - Welding Directions - Welding Sequences - Welding DefectsMohamedMostafaОценок пока нет

- WeldDecayTesting TechSheet Sfs PDFДокумент0 страницWeldDecayTesting TechSheet Sfs PDFNooruddin SheikОценок пока нет

- Annealing (Metallurgy) WikiДокумент4 страницыAnnealing (Metallurgy) WikiStephen MontelepreОценок пока нет

- Ferrite Limitation For SS316LДокумент12 страницFerrite Limitation For SS316LAntonio PerezОценок пока нет

- Application Notes Welding (English)Документ8 страницApplication Notes Welding (English)metallurgist100% (6)

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesОт EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesОценок пока нет

- Fracture and Fatigue: Elasto-Plasticity, Thin Sheet and Micromechanisms ProblemsОт EverandFracture and Fatigue: Elasto-Plasticity, Thin Sheet and Micromechanisms ProblemsJ. C. RadonОценок пока нет

- Mechanisms of Deformation and Fracture: Proceedings of the Interdisciplinary Conference Held at the University of Luleå, Luleå, Sweden, September 20-22, 1978От EverandMechanisms of Deformation and Fracture: Proceedings of the Interdisciplinary Conference Held at the University of Luleå, Luleå, Sweden, September 20-22, 1978Оценок пока нет

- PPG NDT 04 UT For Forging Rev 01Документ5 страницPPG NDT 04 UT For Forging Rev 01sridharchebroluОценок пока нет

- Project MGMT MappingДокумент1 страницаProject MGMT MappingsridharchebroluОценок пока нет

- Brag Klaus SUMMARYДокумент5 страницBrag Klaus SUMMARYsridharchebroluОценок пока нет

- PPG NDT 03 DPT Rev 02Документ8 страницPPG NDT 03 DPT Rev 02sridharchebroluОценок пока нет

- The Prosperity Formula ReportДокумент20 страницThe Prosperity Formula ReportabarrientosvОценок пока нет

- Sap Ecc 6.0 PP ModuleДокумент91 страницаSap Ecc 6.0 PP ModulesridharchebroluОценок пока нет

- Gas Cutting - by KiranДокумент40 страницGas Cutting - by KiransridharchebroluОценок пока нет

- Brainwave Entrainment Manual: by Mark MccoidДокумент12 страницBrainwave Entrainment Manual: by Mark MccoidsridharchebroluОценок пока нет

- HPF WorkbookДокумент27 страницHPF Workbooksridharchebrolu100% (2)

- HPF WorkbookДокумент27 страницHPF Workbooksridharchebrolu100% (2)

- Manasa Devi Mantra TeluguДокумент1 страницаManasa Devi Mantra Telugusridharchebrolu60% (5)

- Weekly Rhythm RegisterДокумент6 страницWeekly Rhythm RegistersridharchebroluОценок пока нет

- Developing and Controlling The Project Schedule (PMBOK® Guide Fifth Edition) Course TranscriptДокумент89 страницDeveloping and Controlling The Project Schedule (PMBOK® Guide Fifth Edition) Course TranscriptsridharchebroluОценок пока нет

- Construction of Box Culvert and Road Work On Nala From PWD Road To Dargah Near Sat Beno's Temple at Lignite Mines BhavnagarДокумент10 страницConstruction of Box Culvert and Road Work On Nala From PWD Road To Dargah Near Sat Beno's Temple at Lignite Mines Bhavnagarraj kumarОценок пока нет

- Conceptual Design of Buildings: Module C Design of Steel Members and JointsДокумент9 страницConceptual Design of Buildings: Module C Design of Steel Members and JointssubrahОценок пока нет

- Heucophos Zcp-Plus / Heucorin RZ: Solvent BasedДокумент2 страницыHeucophos Zcp-Plus / Heucorin RZ: Solvent BasedXuxo XuxitoОценок пока нет

- Astm d2468Документ1 страницаAstm d2468processpipingdesignОценок пока нет

- MIL-C-81751B (Metallic Ceramic)Документ27 страницMIL-C-81751B (Metallic Ceramic)RJ Enterprises SharedОценок пока нет

- Products Inc.: A Subsidiary of FC Industries, IncДокумент2 страницыProducts Inc.: A Subsidiary of FC Industries, IncEdy AcuñaОценок пока нет

- Chemistry Investigatory Project Study of Constituent of AlloysДокумент19 страницChemistry Investigatory Project Study of Constituent of AlloysVaishnavi.V NathanОценок пока нет

- Part - I Chapter - Iv Explanatory Notes TO Tender ScheduleДокумент41 страницаPart - I Chapter - Iv Explanatory Notes TO Tender ScheduleHetal PatelОценок пока нет

- Review Dokumen PG. RendengДокумент10 страницReview Dokumen PG. RendengFarhan PutraОценок пока нет

- 12 Samss 007Документ33 страницы12 Samss 007marghoobОценок пока нет

- New Concession Stand Roofing Siding EstimateДокумент5 страницNew Concession Stand Roofing Siding EstimateFerdinand UbaldoОценок пока нет

- Advances in Concrete TechnologyДокумент10 страницAdvances in Concrete TechnologytusshaarpatilОценок пока нет

- Class Designation Code: Page 8 of 8Документ1 страницаClass Designation Code: Page 8 of 8Yemmina Madhusudhan100% (2)

- Soil Nail and Rock Anchor For Deep ExcavationДокумент21 страницаSoil Nail and Rock Anchor For Deep ExcavationMark Anthony Agnes AmoresОценок пока нет

- ASTM G1 Standard Practice-1Документ8 страницASTM G1 Standard Practice-1bmalinovicОценок пока нет

- SPAN MSIG - Vol.3 - Sewer Network and Pump StationДокумент153 страницыSPAN MSIG - Vol.3 - Sewer Network and Pump StationkhuanozОценок пока нет

- Quailty Assurance of CementДокумент31 страницаQuailty Assurance of CementMohammed AlkhafajiОценок пока нет

- Weamco Truncated Cone BP112 PDFДокумент2 страницыWeamco Truncated Cone BP112 PDFRajОценок пока нет

- 4082-Indian Standard For Meterial StorageДокумент14 страниц4082-Indian Standard For Meterial StorageDeepak Garg100% (1)

- Horizontal Tank ChecklistДокумент3 страницыHorizontal Tank ChecklistA.P.100% (1)

- 2 Construction WorkДокумент53 страницы2 Construction WorkShuvam AdhikariОценок пока нет

- Refractories T1 TheoryДокумент12 страницRefractories T1 TheoryslchemОценок пока нет

- Moihq Abf b01 Arc SHD 2710 00Документ1 страницаMoihq Abf b01 Arc SHD 2710 00ayman ammarОценок пока нет

- Heat-Shrinkable Tubing (WCSM) : Heavy Low Voltage Insulation and Outer Sealing TubingsДокумент2 страницыHeat-Shrinkable Tubing (WCSM) : Heavy Low Voltage Insulation and Outer Sealing TubingshenriquezrsОценок пока нет

- Proforma For Maintaining Record of Conducting Departmental AuctionДокумент12 страницProforma For Maintaining Record of Conducting Departmental AuctionVemajala GaneshОценок пока нет

- Checklist For Minimum Technical Requirements For Pipeline ApplicationsДокумент13 страницChecklist For Minimum Technical Requirements For Pipeline ApplicationsAbu Huraira100% (1)

- Carbon Steel Forgings For Pressure Vessel ComponentsДокумент5 страницCarbon Steel Forgings For Pressure Vessel ComponentsFrancisco PizarroОценок пока нет

- REPORTTT (Repaired) PDFДокумент161 страницаREPORTTT (Repaired) PDFHeartless GuitaristОценок пока нет