Академический Документы

Профессиональный Документы

Культура Документы

Загружено:

Bahman MatouriОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Загружено:

Bahman MatouriАвторское право:

Доступные форматы

Spfe#riiii

Combustion-Drive Tests

W.E,

SHOWAI-TER

ABSTRACT

This paper discusses

some oi the results

of

cotnbu stron-drive tests which were made. in a test

cel[ using a sand bed 10 in. in diameter x 10.ft

long. The test method is illustrated

and described.

The relationship

between the API gravity of the

in situ oil and the amount of air required for combustion drive is discussed

in detail. other things

constant,

t be air requirement

for combustion

drive

increases

as the API gravity of the in situ oil

If the test results

apply to actual

decreases.

reserm irs, the lowest-priced

oils may cost the

most to recover by this method.

Irz/orma~ion is shown which indicates

that the

effect

of pressure

on the amount of bydrocarbofi

br.aned is not large. A method o/ predicting

air

requirements

from the API gravity of the in situ

oil is presented.

INTRODUCTION

Combustion drive is the term used to identify

the process of interstitial or in situ burning as an

oil recovery method. Part of the in situ oil is

burned to generate the energy needed to produce

the remainder of the oil.

Combustion drive as an oil recovery mechanism

remains an economic uncertainty

in spite of aH

the work that has been done by the industry in

both laboratory and field}-6 This paper will show

some of theresults of tests which were made in a

test cell fo~ the purpose of studying the nature of

the combustion-drive process. It will present data

which indicate that the API gravity of the in situ

oil is a significant indicator of the amount of air

required to drive a burning front through oil sand.

Air requirement varies inversely as the API gravity

of the in situ oil.

UNION

OIL

BRE&

CALIF.

CO,

OF

CALIFORNIA

resistance heaters which, by means of an automatic

controller, maintained adjacent sections of the wall

of the pipe at temperatures equal to the temperatures

of the contained sand. Each heater covered 6

linear in. of the pipe. By this means lateral heat

loss from the sand section was minimized, thereby

causing the sand section to simulate more closely

a hor~zontal increment

of a combustion-drive

reservoir.

Fig. 1 shows a schematic diagram of the test

assembly, Thermocouples to measure the temperature

in the sand were located every 6 in. along the length

of the sand section. The pipe containing the sand

was enclosed in a cell designed for an operating

pressure of 500 psig. The inlet air pressure was

controlled at the inlet, and the gas fIow rate was

controlled and measured at the outlet of the cell.

The oil sand used for the tests was prepared by

mixing first water and then oil with the non consolidated sand using a closed mixer similar to a

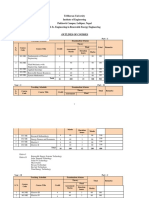

cement mixer. Table 1 shows a screen analysis of

the sand. Ninety per cent of the sand was 100 mesh

or finer. This sand was a mixture of 80 per cent

No. 120 Nevada White Sand and 20,per cent Tennessee

Hi-Fusion Moulding Sand No. 3. The Nevada sand

was a clean silica sand. The Tennessee sand con-

fk%_M!wT

TH

ALVE

EXPERIMENTAL

The tests were performed in a cell which t&iIized

a cylindrical sand section 10 in. in diamerer x 104t

long, The thin-walled metal pipe which held the

sand waa wound with twenty external electrical

Originul

office

Psper

,

1962,

manuscript

Aw,

presented

in Lo e

lRef=en=es

-M +R CH .

received

3, 1962. Revised

at37th

in Societ y of Petroleum

manuscript

Annusl

Fsll

.%%eles, Calif.

given

at end of P-e.

received

Meeting

Jan.

EnKlneers

11, 1963.

of SP 1?. Oct.

7-10,

FIG.

SCHEMATIC

.

PRODUCTION WITHDRAWN

HERE

OF COMBUSTION-DRIVE

CELL,

.

TEST

63

1963

..

..m

TABLE

IN

U.

lSi

COMBIJa

,ALYSIS

, ,.. I+ DRIVE

OF

SAND

TEST

Weight

S, Screen

Held

Size

Per

30

0.04

0.04

50

0.36

70

0.84

100

5.44

140

29.75

200

42.80

270

12.72

*Of

Cent

on Screen

40

7.92*

Pan

was

USED

CELL

thin,

5L) par

largely

quartz.

cent

was

kaolin.

The

{emainder

tained approximately 18 per cent kaolin. The eftective air permeability y before ignition ior the individual

tests varied from 200 to 950 md.

Oil production from the cell was measured dry

after removing the water by di st ill ation,.

Exhaust gas from the cell was sampled periodically and tested (by mears of a mass spectrometer)

for its principal ingredients,

including C02, CO

and 02. The C02 content of the exhaust gas was

recorded continually by a C02 analyzer.

Burning was initiated by means of an electrical

heater. Tests were performed at pressures

up to

500 psig and at raies of burning as low as I ft/D of

flame-front advancement. Sixteen tests will be discussed.

The quantity of hydrocarbon burned (fuel con

sumption) was calculated pnly for a portion of the

sand section in which burning had been as uniform

as possible.

This was usually the 4 linear ft of

sand starting 4 ft from the upstream sand face and

ending 2 ft from the downstream sand face. Values

for the amount of hydrocarbon burned were calculated

from the volume of the oxides of carbon produced

while that section of sand was burning. This method

excluded the nonequilibrium

burning which took

place during and subsequent to ignition and in the

vicinity of the flanges around the downstream sand

face.

DISCUSSION

This discussion

is concerned principally

with

the relationship between the API gravity of the in

situ oil and the volume of air required co drive a

burning front through oiI sand. It is proposed that

the air requirement can be predicted. It depends

mainly on the quantity of the fuel for combustion;

the quantity of the fuel for combustion can be predicted from the API gravity of the in situ oiI. The

API gravity appears to be a satisfactory

indicator

of the fuel-for-combustion

content of the in situ oil.

Air requirement i:; also affected by the character of

the rock, but that was held constant for the oilgravity tests.

The discussion

of fuel consumption will be in

terms of 1 cu ft of oil sand because this unir can

be readily employed in reservoir calculations.

Fuel

consumption is defined as the quantity of the fuel

for combustion (quantity of hydrocarbon burned) per

5A

cubic foot of oil sand.

It is visualized that a definite burning front moves

through the sand, much in the way that the burning

front moves through a cigarette. The burning front

mnves

...- .- to its fuel supply leaving behind fuel-depleted

sand; it moves to its fuel supply because the fuel

consists of the immobile part of the in situ oil. It

moves only as faat as it depletes ita fuel supply.

The burning front follows the air flux channels

through the sand, becauae at usual pressures many

pore volumes of compressed air must pass through

an incremental volume of oil sand to furnish the

oxygen required to bum the fuel therein contained.

As the burning front moves through the oil sand it

sends out a vanguard of heat. Heat moves forward

by conduction, as sensible he~t in liquid and gas

which is flowing forward, and as heat of vaporization in vapor, part of which is involved in a repeating c ycIe of vaporizing, moving forwsrd to cooler ~

~egions and condensing.

The wave of hot fltids

flushes volatile and mobile interstitial

substances

from the path of the burning front. Residual hydrocarbon (coke) which is sufficiently nonvolatile

:F~J

immobile to resist the flushing action of the heat

wave is advanced upon by the burning front and

consumed as fuel for combustion. It seems reasonable to expect that in such a process low-gravity

crude oils will furnish more fuel for combustion

than will high-gravity crudes.

To evaluate the relationship between oil gravity

and fuel consumption,

seven different crude oils

ranging in gravity from 40 to 11 API were tested.

These natural crude oils are identified in Table 2.

The test conditions, except for pressure and rate of

burning, were the same for all of the tests. It had

been established

previously

that the effect of

varying the pressure and the rate of burning, within

the range in question, was not large. The initial

conditions and results of the oil-gravity tests are

summarized on Table 3.

Table 3 shows that the initial water and oil

saturations

of the sand were 20 and 60 per cent

respectively,

in all but one case. Regarding these

initial conditions, none of the sand packs produced

fluid under air drive until after burning had been

initiated.

The burning rates for, clifferent tests

varied from as low as 1 tk/D to as high as 7 ft/D.

Burning rate is controlled by the rate of air injection.

Burning temperature varied from a low of 650F to

a high of 950F. Fuel consumption for the individual

TABLE

DESCRIPTION

OF

CRUDE

OILS

USED

IN

-. -...,

Test

(API)

Source

Guodalupe,

3, 3A,

8.15

17.0

Stearns,

Brea.Olinda

25.0

Stearns,

Brea.01

30.0

.%msinena,

35.0

Bornsdall.ODee,

7.

40.0

Padelfwd,

SOCIETY

OF

South

PETROLEUM

of Oi I

11*O

12.5

Santa

Maria

Valley

Belridge

inda

Whittier

Resocrans

Rasecrans

ENGINEERS

JO URN AI.

tests ranged from a high of 3.0 lb/cu ft of oil sand

to a low of 0.S lb/cu ft, and variea inversely with

the API gravity of the in situoil.

TABLE

3-VARIATION

AIR REQUIREMENT

Oil

Gravity

VS

CONSUMPTION

OIL GRAVITY

Initfpl

Fuel consumption for the individual tests is

plotttdon

Fig. 2 against the APIgravieyof

the in

situ oil used for the individual tests. The relationship is approximately Iirtear for oil gravities between

40 and 17 APL Below 17 API, however, fuel

consumption increases very rapidly aa oil gravity

decreases, The curve terminates at 40 API because

crude oil with a gravity above 40 API did not

deposit a sufficient amount of fuel-for-combustion

to generate enough heat to sustain a moving combus~ion front.

Fig. 2 and Table 3 show only those tests in which

all the conditions except pressure and rate, and in

one case saturation,

were constant. There were,

however, 11 mom-or-less comparable tests using

the 17 API oil, These can be used to estimate

test reliability y. The average value of fuel consumption for 11 tests using 17 API oil was 1.43 Ib/cu ft.

The coefficient of dispersion for the 11 values of

consumption was t 6 per cent.

AIR

REQUIREMENT

VS OIL

GRAVITY

The volume of air required to drive a burning

front chro ugh oil sand depends prisnaril y on the

auantitv of the fuel for combustion. While this is

~elieved to be principally true, there are at least

three other factora which also affect the air requirement. First, the composition of the fuel for combustion with respect- to the number of atoms of

hydrogen per atom of carbon has an effect on the

amount of oxygen (and, therefore, air) required to

burn a given quantity of hydrocarbon. Where the

C/H ratio* is lower, the air required per pound of

fuel will be greater, at usual conditions, because

pound-for-pound

more 02 is reqaired to oxidize

~This 1S the atomic

rntio

of methene

woutd

welsht

be 12/4

ratio.

= 3.

Far

example,

the

C/H

Soo

:<:

400

300

3.0

*O

-t

200

1.0

00

,~

API

;0

GRAVITY

OF

FIG,

;0

IN

SITU

;0

AT

60

[00

.0

F,

OIL

2 COMBUSTION-DRXVE

FUEL CONSUMPTION

AND AIR REQUIREMENT VS OIL GRAVITY.

Test

FUEL

WITH

CONSUMPTION

OIL GRAVITY

Initial

(API)

FUEL

OF

(Nominal)

Product

011

Water

.

011

1 Lo

19* 1

20

60

12,5

16.5

30

50

17.0

16.6

20

60

3A

17,0

17.0

20

60

25.0

23.6

20

60

30.0

29.6

20

60

35,0

35.6

20

60

40.0

40.9

20

60

Average

Burning

Test

1

(%

Exhaust

a~a~~

( scf/mhr/f@)

Nominal

Pressure

During

%tura?lon

(percentage

of

pore space)

rest

(ISSIQ)

3s0

300

200

200

450

4s0

200

200

Exhaust

Gas

COmpasltion*

(.01

per

AND

Burning

Rate

(ft/D)

0.9

1.4

5*2

0.s

6,7

6.5

1.0

0,9

C@~~&.

Re~~r*

(1~%)

(s%%)

cent)

c~o~z

..

2

3

780

840

940

0.29

0.33

0.95

15,0 106 1,3

12,2 2.3 4.6

11.s 1.7 3.4

3.0

1.8

1.4

205

3A

730

0.13

14.0

1.7

1.5

1.4

250

780

0.95

10.8

2.8

3.5

1.2

240

830

O*88

11.4

2.5

3.5

1.0

195

670

0.11

13.8

1.5

0.7

0.94

170

650

0095

13.4

1.7

1.9

*Ccmmcted

for use in Eqs. 1 and

mass-spectrometer

test results.

2. Average

O*77

of ali

.510

350

140

sensible

hydrogen than carbon. Considering

one set of

typical conditions, 12 per cent more air is required

to burn a pound of hydrocarbon with a C/H ratio of

6 than is required to burn a pound of hydrocarbon

with a C/H tatio of 12. Second, the relative amount

of carbon which is incompletely

oxidized and

appears in the exhaust gas as CO will affect the

air requirement because twice as many atoms of

oxygen per atom of cstbon ace required to produce

C% as compared to CO. Third, some oxygen appears

in the exhaust gas. The air requirement is increased

by an amount necessary to supply that quantity of

oxygen which is in the exhsust gss. All three of

these factors may vary somewhat.

The last column on Table 3 shows values of the

air required per cubic foot of oil sand, These

values were determined taking into account the

afore-mentioned

three factors, The exhaust gas

volume will usually be smaller than the corresponding. injected air volume as a result of the fact that

some of the 02 in injected air is used Up in the

formation of water. This effect is offset to a degree

by the fact that 1 mol of 02 will produce 2 mol of

CO, but the CO content of. exhaust gas is usually

so small that the net effect is an exhaust gas

volume at standard conditions which is less than

the injected air volume at standard conditions.

The upper curve on Fi~ 2 shows air requirement

.

vs the API gravity of the in situ crude oil. The

combined effect of the three factors was rather

uniform from test to test for the teats shown on

Fig, 2. A smooth curve approximately parallel to

the fuel-consumption

curve cart be drawn through

the points. If, however, more data points were

avaiIable

for tests which were similar to those

represented on Fig. 2 except for variations in the

.

M>\n CH,

.

1963

Ss

combined effect of the three factors,

the aitrequirement points could be expected rb be scattered

and to occupy a band across the top of the chart.

Individual points would be higher, or Iower, in the

band according to the degree to which the combined

effect of the three factors tended to increase or

minimize the air requirement. The lower boundary of

the band OFpoints, would probably be approximately

parallel to the fuel-consumption

curve and would

represent absolute minimum values of air requirement

for associated

values

of fuel consumption.

An

indication of this scattering is shown on Fig. 12

at 170 API where there are two identical values of

fuel consumption,

but one of the corresponding

values of air requirement is higher than the other.

Apparently,

each of the three factors and fuel

consumption can be affected either independently

or to different degrees by variations in environmental

or operational conditions. There is probably room

for more study in this area.

-.

PRESSURE

It was stated earlier that varying the pressure

did not have a very large effect on the quantity of

fuel for combustion. This is illustrated

for one

crude oil on Fig, 3 where the fuel consumption

for nine tests and plotted against test pressures,

These were Tests 8 through 15 (Table 4) and Tests

3 and 3A (Table 3). The test pressure

is che

pressure of the air upstream of the inlet sand face.

The data indicate that, although fuel consumption

does increase with pressure, the magnitude of the

effect is not large.

Fig. 3 also shows a plot of air requirement vs

test pressure.

Here the scattering

of the airrequirement points due to variations in the combined

effect of the three factors is apparent. Because of

this scattering,

the points are ahown in a shaded

area.

.

.

-

-.

...+

BURNING

RATE

Within the limits of these tests, burning rate

appears to have very little effect on fuel consumption,

This is indicated by two pairs of teats, each pair

of which waa alike except for burning rate. The

pairs are Tests 3 and 3A (Table 3) and Tests 8

and 9 (Table 4). The burning rates for Tests 3 and

,7, Apl

CRUDE

OIL

TABLE

FUEL

4EFFECT

CONSUMPTION

Test

.

.-

200

300

TEST

PRESSURE,

400

500

. ..--

Water

..-.

(psig)

17

18.0

60

470

17

17.7

20

60

470

1.9

10

17

18.3

20

60

45

2.4

17.4

20

60

450

4.8

12*

:;

1 7*8

20

60

300

5.3

13*

14+

17

17

19.2

20

60

200

5.2

17*7

20

60

500

5.4

15*

17

18.6

20

60

330

6,0

CO O,

(lb/ft8)

11*

how:

%-

Burning

During

oil

.m

5.2

Exhaust

GOS FIOW

Tmr:

Rate

(scf/min/f#)

Test

CO,

(scf/ftg)

1,000

0.81

15.1

3,3

O*15

1,6

255

835

0,29

15.2

3.5t

0.01

1,5

225

10

830

0.27

15.3

3.5

0.23

1.2

180

11*

826

0.s3

10.0

3.4

5,5

1,4

290

12*

830

0.90

11.4

3,7

3.6

1.4

255

}3

815

0,92

14*

907

0.90

15*

883

0.94

10.9

2.8

4,3

Note:

Tests

11, 12 and

contain

clay.

* Adinbatic

** (&.ected

mass.

13 were

mnde

using

1.4

o sand

heaters

not used.

fOr use in Eqs. 1 and 2. Average

spec,!rometer

test

275

which

of all

did net

sensible

results.

t Assumed.

3A were 5.2 and 0.8 ft/D, respectively.

The fuel

consumption for both Tests 3 and 3A was 1.4 lb/cu ft.

Tests 8 and 9 were similar to Tests 3 and 3A

except for pressr,ue. Tests 8 and 9 were made at

470. psig while Tests 3 and 3A were made at 200

psig. All four of the tests were performed with

crude from the same well, but Tests 8 and 9 were

done 15 months after Tests 3 and 3A. The burning

rates for Tesrs 8 and 9 were 5.2 and 1.9 ft/D,

respectively.

The values of fuel consumption for

Tests 8 and 9 were 1.6 and 1.5 lb/cu ft, respectively.

It is probably significant that, even though the

fuel consumption was the same for each of these

pairs of tests, the air requirement was higher at

the higher burning rate for both pairs. (AH four of

these tests appear on the plot of pressure vs fuel

consumption and have contributed ~o the establishment of that correlation. )

1

TABLE

5PRODUCTION

BELRIDGE

I

100

Pr#;cl

{Nominal)

ON

Nominal

rhs,r,~m

Initial

oil

10

EXPERIMENT

.--,

-0.

14

157

-o-

15

1s3

0.19

-o-

12

154

17.43

0.19

0.10

13

162

16.10

0.15

0.10

172

14,s9

0.19

0,21

173

6,90

0,07

1,8

378

0006

18.68

0.10

18,2S

D

E

DATASOUTH

RECOVERY

~-

18.32

WELL

TktERMAL

00

PRESSURE

REQUIREMENT

Initial

e- . . -------

-1

OF TEST

AND

AIR

0.26

7.64

2.1

10

258

PSIG

*These

FIG. 3 COMBUSTION-DRIVE

FUEL

AND AIR REQUIREMENT VS TEST

CONSUMPTION

PRESSURE.

reports

< are

exhaust

about

published

gas

the .%th

with

the

anal yses

Belr idge

eansent

were

thermal

of Mobil

taken

from

recovery

Oil

tmpubl i shed

experiment

and

CO.

I

SOCIETY

S6

.. .

I

OF

PET ROI. EIIM

ENGINEERs

JO

IJRX,il,

&.COMBUSTION

RELATIONSHIPS

Mention

was

made earlier of three factors in

addition to the quantity of the fuel for combustion

(fuel consumption) which also affect air requirement.

These factors are the C/H ratio of the fuel for

combustion (hydrocarbon burned), the amount of CO

and C% in the exhaust gas, and the amount of 02

in the exhauat gas, The C/H ratio of the hydrocarbon ~

burned can be calculated from the results of exhaust

gas analyses using Eq. 1. This equation is derivable

from stoichiomeeric consideration.

A+B

R=

where

.(1)

. ..*

21 -L4+B+C)

2.37

+Ji

6

R = C/H ratio of the hydrocarbon

A = per cent CO z in the exhaust

burned,

gas,

B = per cent CO in the exhaust gas, and

C = per cent 02 in the exhaust gas.

The volume of air required to burn 1 lb of hydrocarbon can be calculated using Eq. A This equation

is also derivable from stoichiometric considerations.

v=

( )1

R

2.667 (A +

R-PI

A4B

COMBUSTION-DRIVE

WELL

Table 5 shows data from an actual combu:tion&lve producing weI1. The exhaust gas ana[yses

from this well were corrected to a methane-free

basis nnd averaged, month by month. For each month

the CO + C02, the CO/CO z and the 02(C0 z were

calculated. Using curves developed from Eq, 1 and

2, rhe C/I-l ratio of ,the fuel for combustion and the

volume of air required to burn a pound of fuel were

determined

for each month. Examination of this

Iatter column of resuks

wilf show that, when

significant amounts of oxygen began to appear in

the gas from this well, the volume of injected air

required to bum a pound of fuel roughly doubled.

This means that for Months G and H on~half of the

gas production from the well represented

air that

was injected and subsequently

produced withoutbeneficial

effect beyond transferring

heat and

kinetic energy.

The over-all fuel consumption

for the South

Belridge thermal-recovery

experiment can be calcul ated from published information. s The value is

approximately

Fig. 2.

1.9 lb/cu

ft. This value fits well on

PRODUCTION AND TEMPERATURE

PROFILES

0.01873

. . . . . . . ..?..

AN. ACTUAL

PRODUCING

.,

(2)

where V = volume of air required to bum 1 lb of

hydrocarbon, scf (32F, 1 atm).

With this information and with a value fpr the

fuel consumption per cubic foot of oil sand predicted

from the API gravity of the in situ oil, the volume

of oil sand burned out by a given volume of air can

be calculated.

With other information about the

reservoir,

the combustion-drive

engineer can use

the foregoing method to sharpen his estimates of

such things as the location of the burning front, the

need for supplementary compressor capacity,

the

proper time to shut-in a producing well and the

advisable rates of injeccion in the various injection.

that the test resdts apply to

wells. This assumes

reservoirs.

When exhaust gas analyses are used as just set

forth, they should be corrected to an extraneous.gas-free basis. In other words, the percentages

of

CO, C02 and 02 should be recafculateti eliminating

H2 and any gases which were not in the air or are

not products of combustion such as hydrocarbon

Fig. 4 shows a typical plot of oil and water

production from the test cell.

Fig. 5 shows- a typical plot of four temper&zre

profiles along the length of the cell at four different

positions

of the burning front, It will be noted

that the time required to burn 2 linear ft decreased

by three-foutrhs of an hour for each successive

2

linear ft. This probably illustrates

the dilution

effect. The in situ oil downstream of the burning

front undergoes continual dilution by oil of higher

gravity which is being driven ahead of the burning

front. The diluting oil is of higher gravity because

gases.

Preliminary

estimates of air requirement which

are needed before a project is started could be made

from information like that shown in Fig, 2. When

the pro ject is underway and exhaust gas analyses

are available, the preliminary estimates could be

refined, if necessary, using Eqs. 1 and 2.

MA RCIi,

1963

o~

012345.6789104

DISTANCE

OF

UPSTREAM

FIG,

BURNING

SAND

FRONT

FACE

FROM

, FEET

TYPICAL

PLOT OF OIL AND WATER PRODUCTION FROM CELL (TEST 4),

s?

TABLE

Air R#ueyt,

Oil Sand

Tes~efibor

.

Ref.

9,0

9*O

805

9.6

12,3

13

14

1s

16

17

18

DISTANCE

FROM

UPSTREAM

SAND

FACE,

FEET

P.LOT SHOWING FOUR TEMPERFIG. 5 - TYPICAL

ATURE

PROFILES

ALONG THE LENGTH OF THE

SAND SECTION (TEST 8).

some of the residuum, the fuel for combustion, is

absent. Also, some cracking may have occurred.

The downstream oil, being continually

diluted,

continually

deposits

less-and-less

fuel for combustion. The magnitude of this effect, of course,

would be different for a radial system than it was

for the linear system of the cell.

REMARKS

No attempt has been made to extrapolate these

test results to an entire reservoir. This discussion

has been limited, purposely, to a consideration

of

that part of the oil sand which has been burned

through by the burning front. The values of fuel

consumption reported herein are intended to represent

portions of the reservoir burned through by the

burning front, and are not necessarily

reservoir

values in the sense of being an average value for

an entire reservoir. In an actual reservoir there are

many other factors to consider which are beyond

the intended scope of this discussion,

For example,

all the ramifications

of fingering and consequent

by-passing

with lowered sweep efficiency would

have to be considered in the determination of a

figure for fuel consumption

or air requirement

which would represent an entire reservoir.

The ability to estimate the vohame of reservoir

burned through by the burning front per unit of air,

limited as it is, is useful and contributes to making

a complete reservoir study.

The data shown here are for California crude oils,

asphaltic

in nature. It is not the intent to imply

that the correlations shown here are final and are

universally

applicable.

Rather, the intent is to

contribute to finding out to what extent they apply

by submitting

them for comparison

with other

existing data srtd with data which will become

avail able in the future.

CONCLUSIONS

The conclusion to be drawn from the data presented

is that, other things being equal, the air required

for combustion drive could be substantially

higher

for reservoirs containing low-gravity oils than for

reservoirs containing high-gravity oils. This means

that the cost of supplying air varies inversely

with the posted price of the in situ oil, The lowestpriced oils may cost the most co recover by tl@

s8

7

6

5

6

7

5

245

219

251

295

358

301

Eq,

2,

Fig.

243

228

235 :

255

345

230

method.

The API gravity of the in situ oil can be used

to predict fuel consumption

which, in turn, can

be used together with exhaust gas analyses to

to determine the

estimate

the air requirements,

volume of reservoir burned through at any time,

and to aid in day-to-day combustion-drive re servoir

engineering. This assumes that appropriate correlations are avaiIable,

REFERENCES

L

V. S.: k Situ Combustion Experiments

in London,

Oil and Gas Jour. (June 2, 1958) VOL

56, No. 22, 129.

2. Martin, William L,, Alexa rider, John D. and Dew, John

N.: Process

Variables of In Situ Combustion)),

Traris,,

AIME (1958) VOL 213, 2S,

Swaminsthan,

3. Benham, A. L, and Poettmsnn, Fred H.: The .fiermal

Racovery

Process

An Analysis

of Laboratory

Data,

Trams,,

AIME (1958) VOL 213,

Combustion

406,

4. Kuhn, C. S. and Koch, R. L: In-Situ Combustion,

Oil asd Gas ]our, (Aug. 1953) Vol. .52, No. 14, 92

Results

5, Gates, C. F, and Ramey, H. J,, Jr.: Field

of South Belrid~

Themml

Recovery

Experiment;,

Tram, AIME (195S) Vol. 213, 236,

6. Alexander, John D., Martin, Willism L. and Dew, John

N.: Factors

Affecttng

FueI Availability

end Cornposition During JrrSitu Combustiont,

Jorw, Pet, Tech

(Ott,

1962) 11S4,

APPENDIX

Martin. st al, 2 in their valuable va~er show

exhaust gas arialyses for their Tests- 1> through

18. They also show values for the volume of air

required and the C/H ratio of the ~burned residuum.

Their exhaust gas analyses were used to determine,

from Eq. 1, the C/H ratios of the fuel for combustion.

of

These ratios were used to make determinations

the air required per pound of fuel for combustion

from Eq. 2. These latter values were multiplied by

1.25, which was taken from Fig. 2 and is the fuel

consumption in pounds of fuel per cubic foot of oil

sartd corresponding to an oil gravity of 21.2 API,

the reported gravity of the in situ oil for their

Tests 13 through 18. Table 6 shows that there is

good agreement between the air requirements which

they report and the air requirements

determined

as above for all but* their Test 1% This single

discrepancy

could probably be explained if more

information were available.

The exhau& gas analyses used for these determinations

were not corrected to an extraneousgas-free basis because the required data were not

in the published report.

***

SOCIETY

.,

OF

PETROl.EllM

l?NC INltERS

JOURNAL

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 00000768Документ50 страниц00000768Bahman MatouriОценок пока нет

- Permeabilities and Po-ItiesДокумент12 страницPermeabilities and Po-ItiesBahman MatouriОценок пока нет

- Proper Selection OF Drill Bits AND Their USE: Sent To The Society ofДокумент12 страницProper Selection OF Drill Bits AND Their USE: Sent To The Society ofBahman MatouriОценок пока нет

- Reservoirs With Gas and Walter: SimpleДокумент6 страницReservoirs With Gas and Walter: SimpleBahman MatouriОценок пока нет

- Su. Ts In: M R12s VДокумент20 страницSu. Ts In: M R12s VBahman MatouriОценок пока нет

- Su. Ts In: M R12s VДокумент20 страницSu. Ts In: M R12s VBahman MatouriОценок пока нет

- Underground Combustion 01L-Rec0Ver% Experiment in The Venango First Sand, Warren County, PaДокумент47 страницUnderground Combustion 01L-Rec0Ver% Experiment in The Venango First Sand, Warren County, PaBahman MatouriОценок пока нет

- A Review of Diffusion and Dispersion in Porous MediaДокумент15 страницA Review of Diffusion and Dispersion in Porous MediaBahman MatouriОценок пока нет

- A. and M. DivisionДокумент17 страницA. and M. DivisionBahman MatouriОценок пока нет

- 00000545Документ8 страниц00000545Bahman MatouriОценок пока нет

- A Mathematical Model For Dispersion in The Direction of Flow in Porous MediaДокумент4 страницыA Mathematical Model For Dispersion in The Direction of Flow in Porous MediaBahman MatouriОценок пока нет

- !pedmical I'?Ote: Some LmlmowДокумент19 страниц!pedmical I'?Ote: Some LmlmowBahman MatouriОценок пока нет

- Pressure Build-Up Analysis, Variable-Rate Case: S+?s - RX' """Документ5 страницPressure Build-Up Analysis, Variable-Rate Case: S+?s - RX' """Bahman MatouriОценок пока нет

- Evaluation of Scale-Up Laws For Two-Phase Flow (Through Porous MediaДокумент13 страницEvaluation of Scale-Up Laws For Two-Phase Flow (Through Porous MediaBahman MatouriОценок пока нет

- A Material-Balance Technique For Undersaturated, Partially Water-Driven ReservoirsДокумент3 страницыA Material-Balance Technique For Undersaturated, Partially Water-Driven ReservoirsBahman MatouriОценок пока нет

- K?I'K TiaДокумент27 страницK?I'K TiaBahman MatouriОценок пока нет

- Some Effects of Pressure Forward and Reverse CombustionДокумент11 страницSome Effects of Pressure Forward and Reverse CombustionBahman MatouriОценок пока нет

- Spes - : Some Experiments On The Flow of Miscible Fluids of Unequal Density Through Porous MediaДокумент4 страницыSpes - : Some Experiments On The Flow of Miscible Fluids of Unequal Density Through Porous MediaBahman MatouriОценок пока нет

- Fi%%no. SPE 340Документ10 страницFi%%no. SPE 340Bahman MatouriОценок пока нет

- Experimental Study of Crater Formation in Plastically Deforming Synthetic RocksДокумент6 страницExperimental Study of Crater Formation in Plastically Deforming Synthetic RocksBahman MatouriОценок пока нет

- Recent Developments in The Interpretation and Application of DST DataДокумент11 страницRecent Developments in The Interpretation and Application of DST DataBahman MatouriОценок пока нет

- 00000330Документ64 страницы00000330Bahman MatouriОценок пока нет

- J. F. Wilson Member Aime Union Oil Co. of California Bi?Ea, CalifДокумент6 страницJ. F. Wilson Member Aime Union Oil Co. of California Bi?Ea, CalifBahman MatouriОценок пока нет

- Numerical Calculation of Multidimensional Miscible DisplacementДокумент13 страницNumerical Calculation of Multidimensional Miscible DisplacementBahman MatouriОценок пока нет

- Factors Affecting Fuel Availability and Composition During in Situ CombustionДокумент11 страницFactors Affecting Fuel Availability and Composition During in Situ CombustionBahman MatouriОценок пока нет

- An Analysis For Predicting The Performance of Cone-Shaped Reservoirs Receiving Gas or Water InjectionДокумент5 страницAn Analysis For Predicting The Performance of Cone-Shaped Reservoirs Receiving Gas or Water InjectionBahman MatouriОценок пока нет

- Energia Hazel Webinar 4 Hydrogen in A Net Zero Energy System Oct 20Документ12 страницEnergia Hazel Webinar 4 Hydrogen in A Net Zero Energy System Oct 20Mohamed IbrahimОценок пока нет

- Running On Waste OilДокумент13 страницRunning On Waste OilJorge OsunaОценок пока нет

- Summative Test Science 4th GradingДокумент4 страницыSummative Test Science 4th GradingSibalom Paradise SpaОценок пока нет

- Biomass For H&P - Lecture 2-2006Документ51 страницаBiomass For H&P - Lecture 2-2006Leonardo Nanjar100% (1)

- Eadsm NotesДокумент135 страницEadsm Noteskypa meenendranathreddyОценок пока нет

- Tribhuvan University Institute of Engineering Pulchowk Campus, Lalitpur, Nepal M. Sc. Engineering in Renewable Energy EngineeringДокумент7 страницTribhuvan University Institute of Engineering Pulchowk Campus, Lalitpur, Nepal M. Sc. Engineering in Renewable Energy EngineeringMovie MasalaОценок пока нет

- Kaj Portin - Wartsila FinlandДокумент11 страницKaj Portin - Wartsila FinlandSenthil KumarОценок пока нет

- Boiler EfficiencyДокумент24 страницыBoiler EfficiencyAmit ChauhanОценок пока нет

- Transportation Research Part D: Tasos Nikoleris, Gautam Gupta, Matthew KistlerДокумент7 страницTransportation Research Part D: Tasos Nikoleris, Gautam Gupta, Matthew KistlerRaniero FalzonОценок пока нет

- Coal Gasification PDFДокумент8 страницCoal Gasification PDFmrizalygani99Оценок пока нет

- BFF Manual InglesДокумент74 страницыBFF Manual InglesLuisPazPerdomoОценок пока нет

- ĐỀ thi HSG nghi lộc (2019 - 2020 N6Документ8 страницĐỀ thi HSG nghi lộc (2019 - 2020 N6Nguyen Khanh BinhОценок пока нет

- PAS Bahasa Dan Sastra Inggris KELAS XI IPS 2020-2021Документ8 страницPAS Bahasa Dan Sastra Inggris KELAS XI IPS 2020-2021Nopan Al AzizОценок пока нет

- Vale Day 2022Документ82 страницыVale Day 2022Gatot WinotoОценок пока нет

- CB-8494 C-B NATCOM Brochure - 2020-WEBДокумент9 страницCB-8494 C-B NATCOM Brochure - 2020-WEBjacquesstrappe06Оценок пока нет

- R11. EnergyДокумент13 страницR11. EnergyarsyadmdzОценок пока нет

- DLL - English 5 - Q3 - W4Документ12 страницDLL - English 5 - Q3 - W4mariaviktoria.aquinoОценок пока нет

- FFVII PowerPoint TemplateДокумент6 страницFFVII PowerPoint TemplateAurora Hsu Eaindra ZawОценок пока нет

- The Future of Energy PDFДокумент297 страницThe Future of Energy PDFJoao MinhoОценок пока нет

- HythaneДокумент2 страницыHythaneJames McGrathОценок пока нет

- Fire HeatДокумент231 страницаFire HeatprabhuarunkumarОценок пока нет

- Speech English Contest Save Our EarthДокумент4 страницыSpeech English Contest Save Our EarthWahyuni Teresia SijabatОценок пока нет

- Lecture 9 Principles of CombustionДокумент5 страницLecture 9 Principles of CombustionArih FadiОценок пока нет

- Envr-S335 U2Документ88 страницEnvr-S335 U2Peter LeeОценок пока нет

- Socio-Economic Determinants of Energy Consumption in Nigeria: Evidence From Household DataДокумент12 страницSocio-Economic Determinants of Energy Consumption in Nigeria: Evidence From Household DatayuniОценок пока нет

- Jenbacher Type 6: Cutting-Edge TechnologyДокумент2 страницыJenbacher Type 6: Cutting-Edge TechnologysxturboОценок пока нет

- Ecolizer 2.0 LCA TablesДокумент89 страницEcolizer 2.0 LCA Tableshieu dongОценок пока нет

- Engine Ratings and Fuel Consumption Iso Standard (Continuous) Ratings For Model L5794Gsi With Esm 130 F (54 C) Auxiliary Water Temperature 180 F (82 C) Jacket Water TemperatureДокумент1 страницаEngine Ratings and Fuel Consumption Iso Standard (Continuous) Ratings For Model L5794Gsi With Esm 130 F (54 C) Auxiliary Water Temperature 180 F (82 C) Jacket Water TemperatureAlfredoОценок пока нет

- Pemilihan Sistem Cadcam Dalam Industri Manufaktur Studi Kasus Brake DrumДокумент5 страницPemilihan Sistem Cadcam Dalam Industri Manufaktur Studi Kasus Brake DrumnanangОценок пока нет

- Energy: Murat Kadir Yesilyurt, Tanzer Eryilmaz, Mevlüt ArslanДокумент20 страницEnergy: Murat Kadir Yesilyurt, Tanzer Eryilmaz, Mevlüt Arslancrisian camilo rojas jimenezОценок пока нет