Академический Документы

Профессиональный Документы

Культура Документы

10216prdocfi FI

Загружено:

legasu zemeneАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

10216prdocfi FI

Загружено:

legasu zemeneАвторское право:

Доступные форматы

______________________________________________________________________________

E 5/06

Automatic

Winding Machines

______________________________________________________________________________

Manufacturer:

General Distributor:

Schleich GmbH

An der Schleuse 11

58675 Hemer

Germany

Tel: 02372/9498-0 Fax: 02372/9498-99

eMail: info@schleich.com

Internet: http://www.schleich.com

F. W. Scheiing KG

Elektro-Technik

Beratgerstr. 32

44149 Dortmund

Germany

Tel: 0231/958062-0 Fax: 0231/958062-20

eMail: info@scheiing.com

Internet: http://www.scheiing.com

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM3000euroline

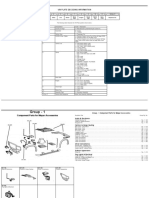

Picture: WM3000euroline with electrical adjustable winding arm and arbour storage facility

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

WM3000euroline

WM4000euroline

WM5000euroline

_______

Technical Data WM 3000 PC

Drive

Motor power-nominal

Motor power max. load

Torque nominal

Torque max. load

Connection voltage

Connection power

Winding speed

Controls

General

Winding counter

Number of windings

Braking

Wire guiding

1.5 kW

2 kW

100 Nm (up to 100 rpm)

160 Nm (up to 100 rpm)

230 V, 50 Hz

3 kVA

25 400 rpm infinitely variable

PC-controlled, Pentium 500 MHz, 80 GB hard disk, TFT-LCD display,

data backup on USB-Stick, keyboard nomenclature according to country,

printer socket, various programmes for standard arbours stored in

memory, easy creation of special winding sequences without programming

knowledge, graphical indication of the arbour shapes and winding

sequences, feasibility checking of various entries, library for motor data

unlimited

0 99999

fully automatic

depending on wire diameter, number of layers, or jumps

Working range for IEC frame sizes

Coil

dimensions

Coil dia.

Coil circum.

(depending on former)

Layer width

56 225

min

max

min

max

max

50 mm

750 mm

160 mm

2355 mm

400 mm

Winding wire No. of parallel wires

8 wires 1.32 mm dia.

1000 mm

Wire entry height

Dimensions

Measurement LxHxW

Height with open cover

Weight

1800 x 1250 x 1200 mm

approx. 2400 mm

approx. 515 kg

Options

Special accessories electrically adjustable winding fixture (by foot switch or software)

attachment for insulation sleeving insertion (1, 2, or 3 times)

adapter mandrel WD10 and arbours 3/12 for the smallest motor coils

four slot arbours 4/11 and 4/24

arbours for lap winding with and without tape slot and tape dispenser unit

manufacture of special arbours according to drawing or sample

strengthened arbour holders for winding without support (only with electrical adjustable

fixture)

arbour storage facility and storage pins for arbours 3/16

wire break monitoring system for as many as desired individual wires

de-reeling and storage units of various types

storage i.e. arbour cupboard

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM3000euroline

Article

Description

WM3000euroline

Basic Equipment:

1.5 kW-drive with 2.2 kW frequency controller

manual adjustable winding fixture

speed: 400 rpm

PC-controlled

wire tension device on layering arm

6 set of formers type: 3/16 no. I, 2, 3, 4, 5, 6

former holder for formers 3/16, 4/11, 4/24

2 slide rails of different lengths

2 sets of spacers for types 3/16, 4/11, 4/24

voltage: 230 V single-phase

colour: grey RAL 7032

weight: approx. 515 kg

comprehensive documentation

Picture: WM3000euroline with electrical adjustment

Software: graphical user interface, database for approx. 10000 motors,

very simple application, various programmes for standard arbours

stored in memory, easy creation of special winding sequences without

programming knowledge, graphical indication of the arbour shapes and

winding sequences, feasibility checking of various entries

Electrically adjustable winding fixture

The arbour distance of the winding fixture is adjusted by an electric

motor. The adjustment is either in accordance with the pre-selected

distance of the formers, or by pressing the double foot pedal. The later

has the functions smaller and larger. Before starting the winding

process, the required coil dimension can easily be adjusted. After the

winding job is finished, the pressure on the winding fixture can quickly

be released in order to ease the take-off of the finished coils. When the

coils have been taken off, the arbour distance returns to the original

winding position by just pressing the foot pedal once.

Picture: Electrical adjustment

Scope of delivery:

1 electrically adjustable winding fixture

2 former holder to take formers type 3/16, 4/11, 4/24

2 slide rails of different lengths

2 sets of spacers for types 3/16, 4/11, 4/24

Former storage facility

The winding machine WM3000 can be delivered with a facility to carry

the storage pins for the winding formers 3/16 no. 1, 2, 3, 4, 5 and 6.

Price for storage facility only (without storage pins)

Picture: Former storage facility with storage pin

Increased torque

140 Nm

Extended speed

500 rpm

Extended speed

600 rpm

Increased torque

The torque is increased to 140 Nm, the max. load torque is increased to

220 Nm. The max. speed is reduced to 300 rpm.

Extended speed without reduced torque

The speed can be increased to 500 rpm without torque reduction.

Extended speed with reduced torque

The speed can be increased to 600 rpm. This causes a reduction of the

torque by approx. 50%.

Automatic opening of the security cover

At the end of the winding cycle the protective cover is opened automatically by a pneumatic cylinder. The user can then directly take off the

wound coil sets. Before the start of the next winding cycle the hood has

to be closed manually again.

Picture: Pneumatic-cylinder to open the security cover

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM3002euroline

Picture: WM3002euroline with two winding arms

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

WM3000euroline

WM4000euroline

WM5000euroline

_______

Technical Data WM 3002 PC

Drive

Motor power-nominal

Motor power max. load

Torque nominal

Torque max. load

Connection voltage

Connection power

Winding speed

Controls

General

Winding counter

Number of windings

Braking

Wire guiding

1.5 kW

2 kW

50 Nm (up to 250 rpm)

80 Nm (up to 250 rpm)

230 V, 50 Hz

3 kVA

50 800 rpm infinitely variable

PC-controlled, Pentium 500 MHz, 80 GB hard disk, TFT-LCD display,

data backup on USB-Stick, keyboard nomenclature according to country,

printer socket, various programmes for standard arbours stored in memory,

easy creation of special winding sequences without programming

knowledge, graphical indication of the arbour shapes and winding

sequences,

feasibility checking of various entries, library for motor data

unlimited

0 99999

fully automatic

depending on wire diameter, number of layers, or jumps

Working range for IEC frame sizes

Coil

dimensions

Coil dia.

Coil circum.

(depending on former)

Layer width

56 132

50 mm

500 mm

160 mm

1300 mm

400 mm

min

max

min

max

max

Winding wire No. of parallel wires

4 wires 1.32 mm dia.

1000 mm

Wire entry height

Dimensions

Measurement LxHxW

Height with open cover

Weight

1900 x 1250 x 1200 mm

approx. 2400 mm

approx. 550 kg

Options

Special accessories

centric adjustable winding arms with hand crank and spindle

extended winding diameter

attachment for insulation sleeving insertion (1, 2, or 3 times)

adapter mandrels WD10 and arbours 3/12 for the smallest motor coils

adapter mandrels WD19 and three slot arbours 3/16

four slot arbours 4/11 and 4/24

manufacture of special arbours according to drawing or sample

wire break monitoring system for as many as desired individual wires

automatic opening of the security cover (closing manual)

de-reeling and storage units of various types

storage i.e. arbour cupboard

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM3002euroline

Article

Description

WM3002euroline

Basic Equipment:

1.5 kW drive with 2.2 kW frequency controller

2 manual adjustable winding arms (without centric adjustment spindle)

speed: 800 rpm

PC-controlled

wire tension device on layering arm

winding mandrels WD10 (10 mm) or WD19 (19 mm) at your choice

voltage: 230 V single phase

colour: grey RAL 7032

weight: approx. 550 kg

comprehensive documentation

Picture: WM3002euroline with two winding arms

other winding mandrels

Winding mandrels with a different hex bar

The machine will be delivered with either two pairs of 10 mm (WD 10),

or two pairs of 19 mm (WD 19) winding mandrels. The listed price is for

the other two pairs of mandrels when both types are needed.

Fast arbour distance adjustment with

spindle

The arbour distance of each winding arm can be adjusted very fast

using a hand crank and a centric spindle.

Picture: Centric arbour distance adjustment

WM 3003

winding diameter 650 mm

WM3003euroline

(enlarged version of the WM 3002)

The maximum winding diameter is increased to 650 mm; the winding

arms are extended to a length of 550 mm. The speed range is changed

to 25 500 rpm, and the torque nominal is increased to 100 Nm (max.

load torque 150 Nm). The working range is extended to include IEC

frame size 160.

Attention: The scope of delivery includes the centric adjustment of the

winding arms.

Move in and move out by foot pedal

Pneumatic insert and

introduce the swing of the change arm, it has to be released by

release of the change arm To

pressing a button and then is moved out by a pneumatic cylinder. After

swinging the arm it has to be pressed back into position manually.

by foot pedal

This process can be controlled with the help of a foot pedal, so that the

operator has both hands free to handle the load of the swing-out arm. In

contrast to the standard version the move in herewith also occurs

pneumatic, no force effort of the operator when inserting is required.

Automatic opening

of the security hood

WM 3005

winding diameter 750 mm

Automatic opening of the security cover

At the end of the winding cycle the protective cover is opened automatically by a pneumatic cylinder. The operator can then directly swing

over the change arm. Before the start of the next winding cycle the hood

has to be closed manually again.

WM3005euroline

(enlarged version of the WM 3002)

The maximum winding diameter is increased to 750 mm; the speed

range is changed to 25 400 rpm.

Attention: The scope of delivery includes the centric adjustment of the

winding arms as well as pneumatic insert and release of the change

arm by foot pedal.

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM4000euroline

Picture: WM 4000euroline

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

WM3000euroline

WM4000euroline

WM5000euroline

_______

Technical Data WM 4000 PC

Drive

Motor power-nominal

Motor power max. load

Torque nominal

Torque max. load

Connection voltage

Connection power

Winding speed

Controls

General

PC-controlled, Pentium 500 MHz, 80 GB hard disk, TFT-LCD display,

data backup on USB-Stick, keyboard nomenclature according to country,

printer socket, various programmes for standard arbours stored in memory,

easy creation of special winding sequences without programming knowledge,

graphical indication of the arbour shapes and winding sequences,

feasibility checking of various entries, library for motor data

Winding counter

Number of windings

Braking

Wire guiding

unlimited

0 99999

fully automatic

depending on wire diameter, number of layers, or jumps

3 kW

5 kW

200 Nm (up to 130 rpm)

350 Nm (up to 130 rpm)

400 V, N, PE, 50 Hz

7 kVA

25 400 rpm infinitely variable

Working range for IEC frame sizes

Coil

dimensions

Coil dia.

Coil circum.

(depending on former)

Layer width

50 mm

1060 mm

160 mm

3330 mm

400 mm

min

max

min

max

max

Winding wire No. of parallel wires

Wire entry height

Dimensions

56 315

25 wires 1.32 mm dia. at 1000 mm winding diameter

1000 mm

Measurement LxHxW

Height with open cover

Weight

1900 x 1600 x 1200 mm

approx. 2330 mm

approx. 700 kg

Options

Special accessories

attachment for insulation sleeving insertion

adapter mandrel WD10 and arbours 3/12 for the smallest motor coils

four slot arbours 4/11 and 4/24

concentric arbours for lap winding with and without tape slot and tape dispenser unit

storage pins for arbours 3/16

attachment for rectangular and rhombus windings incl. swivelling arbours

manufacture of special arbours according to drawing or sample

strengthened arbour holders for winding without support

mechanical reinforcement of the winding fixture for high tractive force or supportless winding

rapid wire laying shaft for continual winding without stop between slots

wire break monitoring system for as many as desired individual wires

adjustable former with layer winding programme for large DC-fields

de-reeling and storage units of various types

storage i.e. arbour cupboard

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM4000euroline

Article

Description

WM4000euroline with winding motor 3 kW

most common version

Picture: WM 4000 PC with electrical adjustable winding fixture

Standard equipment:

3 kW drive, 4 kW frequency controller

speed: 400 rpm

voltage: 400 V 3-phase with neutral

PC-controlled

electrical adjustable winding fixture

wire tension device on layering arm

6 set of formers type: 3/16 no. I, 2, 3, 4, 5, 6

former holder for formers 3/16, 4/11, 4/24

2 slide rails of different lengths

2 sets of spacers for types 3/16, 4/11, 4/24

colour: grey RAL 7032

weight: 600 kg

complete documentation

Electrically adjustable winding fixture: the arbour distance is

adjusted by an electric motor. The adjustment is either in accordance

with the pre-selected distance of the formers, or by stepping on the

double-foot pedal. The later has the functions smaller and larger.

Before starting the winding process, the required coil dimension can

easily be adjusted. After the winding job is finished, the pressure on the

winding fixture can quickly be released in order to ease the take-off of

the finished coils. When the coils have been taken off, the arbour

distance returns to the original distance by pressing the foot pedal.

WM4000euroline with winding motor 1.5 kW

Standard equipment:

1.5 kW drive, 2.2 kW frequency controller

speed: 400 rpm

voltage: 230 V single phase

Torque nominal 100 Nm, torque max. load 160 Nm

The working range reduces to IEC frame sizes 56 - 225,

the number of parallel wires to 8 x 1.32 mm at 1000 mm coil diameter.

Further equipment as with 3 kW model.

1.5 kW

WM4000euroline with winding motor 5.5 kW

5.5 kW

Standard equipment:

5.5 kW drive, 7.5 kW frequency controller

speed: 300 rpm with increased torque

voltage: 400 V 3-phase with neutral

Torque nominal 480 Nm, torque max. load 650 Nm

Stronger belt drive using a special Poly-V-Belt.

The main winding arm is replaced by a substantially reinforced version

with stronger profiles, more stable guidance and improved double

bearings (as with WM4500 / WM 5000).

Further equipment as with 3 kW model.

Increased torque

265 Nm

extended speed

500 rpm

extended speed

600 rpm

Automatic opening

of the security hood

Increased torque

Torque is increased by 30% whereas the speed is reduced to 300 rpm

3 kW drive: 265 Nm torque, 465 Nm max. load torque

1.5 kW drive: 130 Nm torque, 210 Nm max. load torque

Extended speed without reduced torque

The speed can be increased to 500 rpm without torque reduction.

Extended speed with reduced torque

The speed can be increased to 600 rpm. This causes a reduction of the

torque by approx. 50%.

Automatic opening of the security cover

At the end of the winding cycle the protective cover is opened automatically by a pneumatic cylinder. The user can then directly take off the

wound coil sets. Before the start of the next winding cycle the hood has

to be closed manually again.

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

10

WM3000euroline

WM4000euroline

WM5000euroline

_______

Machine in Mirror-Imaged Design

It is possible to make the machine in a mirror-imaged version.

That is of importance if a manufacturer has two machines which should

be served by one operator. In this case the machines are placed

opposite to each other and the operator has an easy access to both.

Whilst one machine is winding coils the other is ready for tying and

removing from the machine and visa-versa.

As the operator works between two machines and the wire intake

direction should not be changed, one machine should be designed

mirror-imaged.

Picture: WM4000 in mirror-imaged design

Safety Cover moving

horizontally

Safety Cover Horizontally Slideable

In this design the safety hood is not being opened by lifting up but it is

pushed horizontally to the right. It can be very useful to slide the cover,

e.g. If there are heavy coils which have to be taken off the machine by

means of a hoist.

It should be kept in mind that this design eases the take-off of finished

coils, but is a bit awkward for the operator to thread the wire in as the

cover interferes with his action.

Mechanical reinforcement of the electrical

adjustable winding fixture

The winding fixture has to be mechanically reinforced when taking many

wires in hand or if the front end winding head holder is used with more

than 10 wires 1.32 mm dia. (16 AWG).

(Only applicable for WM 4000 with 1.5 kW and 3 kW drive)

Attention: Mandatory if increased torque is used with 3 kW WM4000.

Picture: Winding fixture (winding arm)

Machine with automatic security curtain

Instead of the normal security cover a large cabinet with an automatic

electrical security curtain is installed.

For production it may be required to use a transfer tool or a hoist to take

of the coils automatically. This can require a lot of space in the cabinet,

as well as the option to automatically open this cabinet when the

winding is done.

The new height of the machine in this version is approx. 2320 mm.

Picture: WM4000 with automatic security curtain

Pressure Sensitive Mat

By means of this mat the winding area can be protected. It is put on the

floor adjacent to the winding machine.

If a person steps on the mat, the machine shuts off immediately. It is

only possible to operate the machine by push buttons. Only if the

pressure is removed, the automatic operation is in use again.

Picture: Pressure sensitive mat

The pressure sensitive mat should avoid an automatic operation if a

person is present in the winding area with closed safety hood for safety

reasons.

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

11

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM4002euroline

2-spindle-version for series production

Picture: WM4002euroline with two layering units for short winding cycles

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

12

WM3000euroline

WM4000euroline

WM5000euroline

_______

Technical Data WM 4002 PC

Drive

Motor power-nominal

Torque nominal

Torque max. load

Connection voltage

Connection power

Winding speed

Controls

General

PC-controlled, Pentium 500 MHz, 80 GB hard disk, TFT-LCD display,

data backup on USB-Stick, keyboard nomenclature according to country,

printer socket, various programmes for standard arbours stored in memory,

easy creation of special winding sequences without programming knowledge,

graphical indication of the arbour shapes and winding sequences,

feasibility checking of various entries, library for motor data

Winding counter

Number of windings

Braking

Wire guiding

unlimited

0 99999

fully automatic

depending on wire diameter, number of layers, or jumps

5.2 kW

150 Nm (up to 340 rpm)

200 Nm (up to 340 rpm)

400 V, N, PE, 50 Hz

10 kVA

25 600 rpm infinitely variable

Working range for IEC frame sizes

56 280

Coil

dimensions

50 mm

850 mm

700 mm

Coil diameter

Layer width

min

max

max

Winding wire No. of parallel wires

Wire monitor

Wire entry height

Dimensions

Measurement LxHxW

Weight

20 wires 1.32 mm

individual wire monitor for 12 wires

1000 mm

3980 x 1600 x 1500 mm (+ 1000 mm for wire entry)

approx. 1200 kg

Standard equipment

Standard equipment

2 parallel layering units for very short winding cycle times

rapid wire laying shaft for continual winding without stop between slots

automatic opening and closing of the security hood

double-spindle revolver to avoid stand-still times when wound coils are removed

winding arms driven from both sides

Colour RAL 7032

Options

Special accessories

attachment for insulation sleeving insertion

three slot arbours 3/16

four slot arbours 4/11 and 4/24

manufacture of special arbours according to drawing or sample

wire break monitoring system for as many as desired individual wires

de-reeling and storage units of various types

storage i.e. arbour cupboard

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

13

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM4010euroline

for automatic insertion technique with many parallel wires

Picture: WM 4010euroline with automatic clamping and cutting for removal of wound coils with a transfer tool with very short handling times

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

14

WM3000euroline

WM4000euroline

WM5000euroline

_______

Technical Data WM 4010 PC

Drive

Motor power-nominal

Motor power max. load

Torque nominal

Torque max. load

Connection voltage

Connection power

Winding speed

Controls

General

PC-controlled, Pentium 500 MHz, 80 GB hard disk, TFT-LCD display,

data backup on USB-Stick, keyboard nomenclature according to country,

printer socket, various programmes for standard arbours stored in memory,

easy creation of special winding sequences without programming knowledge,

graphical indication of the arbour shapes and winding sequences,

feasibility checking of various entries, library for motor data

Winding counter

Number of windings

Braking

Wire guiding

unlimited

0 99999

fully automatic

depending on wire diameter, number of layers, or jumps

4.0 kW

8.0 kW

200 Nm (up to 150 rpm)

400 Nm (up to 150 rpm)

400 V, N, PE, 50 Hz

9 kVA

25 500 rpm infinitely variable

Working range for IEC frame sizes

Coil

dimensions

Coil diameter

Layer width

1000 mm

400 mm

max

max

Winding wire No. of parallel wires

Wire monitor

Wire entry height

Dimensions

56 250

Measurement LxHxW

Weight

16 wires 1.32 mm

individual wire monitor for 16 wires on pedestal with tensioning unit

1000 mm

2600 x 2320 x 1200 mm

approx. 900 kg

Standard equipment

Standard equipment mechanical reinforcement of the electrical adjustable winding fixture for high tractive force and

winding without front support

rapid wire laying shaft for continual winding without stop between slots

automatic clamping and cutting of the wire

automatic former distance adjustment of the layering arm

automatic security curtain

wire monitoring for 16 wires with automatic pneumatic tension device on pedestal

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

15

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM4010euroline

Article

Description

WM 4010euroline

Standard equipment:

4 kW drive, 7,5 kW frequency controller

speed: 500 rpm

voltage: 400 V 3-phase with neutral

PC-controlled

mechanically reinforced electrical adjustable winding fixture

wire monitoring for 16 wires with automatic tension device on pedestal

colour: grey RAL 7032

weight: 900 kg

automatic clamping and cutting of the wire

automatic security curtain

automatic former distance adjustment of the layering arm

complete documentation

Picture: WM4010 with automatic security curtain

The wire or wires are automatically transferred to the former and

clamped. After winding the coil and insertion of the transfer tool the wire

is automatically cut and the arbours are driven together. Now the next

winding cycle can begin.

Picture: Automatic clamping and cutting

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

16

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM4500-PC

Picture: WM 4500euroline

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

17

WM3000euroline

WM4000euroline

WM5000euroline

_______

Technical Data WM 4500-PC

Drive

Motor power-nominal

Motor power max. load

Torque nominal

Torque max. load

Connection voltage

Connection power

Winding speed

Controls

General

3.0 kW

5.0 kW

350 Nm (up to 75 rpm)

610 Nm (up to 75 rpm)

400 V, N, PE, 50 Hz

7 kVA

10 200 rpm infinitely variable

PC-controlled, Pentium 500 MHz, 80 GB hard disk, TFT-LCD display,

data backup on USB-Stick, keyboard nomenclature according to country,

printer socket, various programmes for standard arbours stored in memory,

easy creation of special winding sequences without programming knowledge,

graphical indication of the arbour shapes and winding sequences,

feasibility checking of various entries, library for motor data

Winding counter

Number of windings

Braking

Wire guiding

unlimited

0 99999

fully automatic

depending on wire diameter, number of layers, or jumps

Working range for IEC frame sizes

56 355

Coil

dimensions

50 mm

1260 mm

160 mm

3950 mm

400 mm

Coil dia.

Coil circum.

(depending on former)

Layer width

min

max

min

max

max

Winding wire No. of parallel wires

Wire entry height

Dimensions

Measurement LxHxW

Height with open cover

Weight

35 wires 1.32 mm dia. at 1250 mm winding diameter

1000 mm

2130 x 1700 x 1200 mm

approx. 2430 mm

approx. 650 kg (Transport weight approx. 800 kg)

Options

Special accessories

attachment for insulation sleeving insertion

adapter mandrel WD10 and arbours 3/12 for the smallest motor coils

four slot arbours 4/11 and 4/24, 3 slot formers 3/16

concentric arbours for lap winding with and without tape slot and tape

dispenser unit

storage pins for arbours 3/16

attachment for rectangular and rhombus windings incl. swivelling arbours

manufacture of special arbours according to drawing or sample

strengthened arbour holders for winding without support

rapid wire laying shaft for continual winding without stop between slots

wire break monitoring system for as many as desired individual wires

adjustable former with layer winding program for large DC-fields

de-reeling and storage units of various types

storage i.e. arbour cupboard

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

18

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM 4500-PC

Article

Description

WM4500euroline with winding motor 3 kW

Standard equipment:

3 kW drive, 4 kW frequency controller

speed: 200 rpm

voltage: 400 V 3-phase with neutral

PC-controlled

extra strong electrical adjustable winding fixture

wire tension device on layering arm

colour: grey RAL 7032

weight: approx. 650 kg

complete documentation

Picture: WM 40500 PC with electrical adjustable winding fixture

WM4500euroline with winding motor 5.5 kW

Standard equipment:

5.5 kW drive, 7.5 kW frequency controller

Speed: 200 rpm

Torque nominal 600 Nm, torque max. load 800 Nm

Stronger belt drive using a special Poly-V-Belt.

5,5 kW

Further equipment as with 3 kW model.

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

19

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM5000euroline

Picture: WM 5000euroline

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

20

WM3000euroline

WM4000euroline

WM5000euroline

_______

Technical Data WM 5000 PC

Drive

Motor power-nominal

Motor power max.load

Torque nominal

Torque max. load

Connection voltage

Connection power

Winding speed

Controls

General

PC-controlled, Pentium 500 MHz, 80 GB hard disk, TFT-LCD display,

data backup on USB-Stick, keyboard nomenclature according to country,

printer socket, various programmes for standard arbours stored in memory,

easy creation of special winding sequences without programming knowledge,

graphical indication of the arbour shapes and winding sequences,

feasibility checking of various entries, library for motor data

Winding counter

Number of windings

Braking

Wire guiding

unlimited

0 99999

fully automatic

depending on wire diameter, number of layers, or jumps

4.0 kW

7.0 kW

500 Nm (up to 65 rpm)

1000 Nm (up to 65 rpm)

400 V, N, PE, 50 Hz

9 kVA

25 200 rpm infinitely variable

Working range for IEC frame sizes

Coil

dimensions

Coil dia.

Coil circum.

(depending on former)

Layer width

56 400

50 mm

1450 mm

160 mm

4500 mm

400 mm

min

max

min

max

max

Winding wire No. of parallel wires

30 wires 1.50 mm dia.

1000 mm

Wire entry height

Dimensions

Measurement LxHxW

Weight

2400 x 2300 x 1050 mm

approx. 1000 kg

Options

Special accessories

attachment for insulation sleeving insertion

adapter mandrel WD10 and arbours 3/12 for the smallest motor coils

adapter mandrel WD19 and three slot arbours 3/16

four slot arbours 4/11 and 4/24

concentric arbours for lap winding with and without tape slot and tape dispenser unit

attachment for rectangular and rhombus windings incl. swivelling arbours

storage pins for arbours 3/16

manufacture of special arbours according to drawing or sample

strengthened arbour holders for winding without support

mechanical reinforcement of the winding fixture for high tractive force or supportless winding

rapid wire laying shaft for continual winding without stop between slots

adjustable former with layer winding programme for large DC-fields

wire break monitoring system for as many as desired individual wires

de-reeling and storage units of various types

storage i.e. arbour cupboard

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

21

WM3000euroline

WM4000euroline

WM5000euroline

_______

WM5000euroline

Article

Description

WM 5000euroline

Standard equipment:

4 kW drive, 7.5 kW frequency controller

electrical adjustable winding fixture

speed: 200 rpm

PC-controlled

wire entry height: 1000 mm

wire tensioning device on layering arm

voltage: 400 V, N, PE, 50 Hz

colour: grey RAL 7032

weight: 1000 kg

complete documentation

Picture: WM 5000euroline

Increased torque

1000 Nm

Increased torque

Increased torque

2000 Nm

Increased torque

Winding motor 5.5 kW

Torque is increased by approx. 100% to 1000 Nm, max. load torque to

2000 Nm, whereas the speed is reduced to 100 rpm.

Torque is increased by approx. 200% to 2000 Nm, max. load torque to

3500 Nm, whereas the speed is reduced to 50 rpm.

Winding motor 5.5 kW

For a further increase of the torque a 5.5 kW motor can be used in lieu

of the standard 4 kW drive. Together with a reduction or the maximum

speed to 50 rpm the nominal torque increases to 3000 Nm (up to 16

rpm) and the max. load torque increases to 4500 Nm.

Other customer specific variations are likewise possible on inquiry.

The scope of delivery includes solely the increased motor performance,

the further increase of the torque must be ordered separately.

Extended winding diameter 2000 mm

The maximum winding diameter is increased to 2000 mm.

Thereby the width of the machine is enlarged by approx. 900 mm to

approx. 3300 mm.

Picture: WM5001 with 2000 mm winding diameter

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

22

WM3000euroline

WM4000euroline

WM5000euroline

_______

Wire Detectors

Wire end detector units on layering arm

The machine comes without wire detector device in the standard scope

of delivery. It is possible to have wire detectors for max. 12 wires

attached to the layering arm before the string tensioning device.

Detector for max 4 parallel wires on layering arm:

Picture: Wire detectors on layering arm

Detector for max 8 parallel wires on layering arm:

Detector for max 12 parallel wires on layering arm:

Pedestal for wire detectors

A pedestal is necessary to hold more detectors for more then 12 wires,

or if automatic sleeve release will be used. The pedestals have 2

sockets to extend the number of monitored wires in units of 12 wires.

A storage cup is attached to the wire detector pedestal which can hold

the unused sensor pins. The pedestal has to be fixed to the floor by 3

screws.

Pedestal with sensors for 12 wires (max. 36):

Pedestal with sensors for 24 wires (max. 48):

Picture: Pedestal with 48 wire detectors

Tensioning assembly for pedestal

If required, it is also possible to attach a string brake type wire

tensioning device to the pedestal (required for use with sleeve release).

The existing wire brake can be disassembled from the layering arm and

attached to the pedestal using the tensioning fixing assembly for the

pedestal. At the layering arm then an entry nozzle or a cross-rolls

assembly must be installed as a substitute to guide the wire. If

necessary, a larger wire brake is also available, e.g. if very many

parallel wires are to be used or shaped (rectangular) wire is to be

wound.

Fixing assembly for string brake (without brake):

Small string tensioning brake for max 18 x 1.18 mm wires:

Picture: Tensioning assembly with brake

Large string tensioning brake for max 50 x 1.50 mm wires:

Entry nozzle small (18 x 1.18 mm wires):

Entry nozzle large (50 x 1.50 mm wires):

Cross-Rolls assembly (for sleeve release):

12 Wire extension for pedestal

The extension of the wire detector device on the pedestal is always

possible by blocks of 12 wires. These can be easily screwed to the

pedestal and plugged in. Each pedestal has 2 free sockets.

If more than 48 wires are to be monitored, several pedestals can be

hooked up one behind the other. The additional pedestal then is simply

plugged into a free socket of the existing pedestal.

Picture: Wire detector extension for 12 wires

Pedestal for wire monitoring device with

integrated Teflon-felt tensioning device

Picture: Open wire tension

device

Picture: Wire

detector pedestal

for 16 wires

Dimensions (W*L*H):

250 * 250 * 1300 mm

9.84" * 9.84" * 51.2"

Alternatively to the standard pedestal a pedestal equipped with a

Teflon-felt wire brake can be supplied.

Detectors to monitor 16 wires are attached to the pedestal. A magazine

attached to the wire detector pedestal can hold the unused sensor pins.

The pedestal has to be fixed to the floor by 4 screws.

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

23

WM3000euroline

WM4000euroline

WM5000euroline

_______

Sleeve Release

Sleeve Release ordered with the Machine

With the automatic sleeve release device it is possible to wind pieces of

insulating sleevings into the coil to protect cross-overs. It is imperative

to thresd the cut pieces on to the magnet wire in advance.

The PC-control releases a sleeve according to the pre-set programme

whenever it is required. The remainder which is stored on the wire are

held back by a clamp. The device works pneumatically. An air-pressure

of at least 6 bar is required. Supplied air must be clean and dry.

Picture: sleeve insertion clamps (delivery)

The software is able to position the sleeves on any spot required. Even

the number of sleeve pieces required during the winding process can be

pre-set. By means of a sleeve numbering counter the exact amount can

be monitored. If there are not enough sleevings left the next winding

job, the machine reports and new pieces may be put on.

Attention: The layering arm is different when sleeve release is used.

The wire monitoring and tensioning unit that usually is attached to the

layering arm cannot be used in conjunction with the sleeve release. For

this reason a pedestal for the wire monitoring units and the wire braking

has to be ordered separately.

Sleeve Release as an Later Option

(only possible with sleeve release preparation installed)

Picture: sleeve insertion fixed at the wire guide

If sleeve insertion is required for an already delivered machine, it is

possible to equip the machine with the unit, but only if the corresponding machine already has the required preparation installed.

To this the layering arm has to be exchanged (scope of delivery), just as

the corresponding clamps are connected.

Attention: The layering arm is different when sleeve release is used.

The wire monitoring and tensioning unit that usually is attached to the

layering arm cannot be used in conjunction with the sleeve release. For

this reason a pedestal for the wire monitoring units and the wire braking

has to be ordered separately.

Scope of delivery: New layering arm, clamps, air-tubes, valves, and

software

Picture: the front sleeve is held back during the

winding

Preparation for Installation as an Later Option

The necessary internal preparations of the machine to be able to use

the sleeve insertion option later on are made. To this the connections

for the valves, the air-tubes, etc. are installed.

Attention: The installation of the sleeve release unit without this

preparation requires a lot of additional work and causes substantial

extra costs!

Picture: for sleeve insertion the front sleeve is now

free and the other sleeves are held back

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

24

WM3000euroline

WM4000euroline

WM5000euroline

_______

Different Options for all Machines

Rapid Wire Laying Shaft

(not for WM 3000 and WM 3002)

On request it is possible to equip the machine with a rapid wire laying

shaft.

In normal cases this is only of importance for manufacturers in order to

shorten the winding time.

By this design the machine does not stop at every finished coil and to

guide the wire into the next winding head slot. The wire laying jumps

very quickly over to the next slot without stopping the wire guide.

Picture: Servo Motor

The speed with the rapid wire laying shaft is approx. 250 mm/sec.

In special applications the rapid wire laying shaft may be used for a very

precise wire layering of wires below 1 mm dia.

Attention: If this is required, it is imperative to contact the manufacturer

beforehand!

Picture: Ball Rotating Spindle

Supply Voltage 380V - 480V

(only machines with 400V nominal voltage)

If a supply voltage of 400V is not achievable, but a voltage in the range

380V - 480V (3-phase without neutral) is possible, a standard

transformer can be supplied.

Attention: It is mandatory to contact the manufacturer beforehand, if

the local supply voltage is non-standard.

Other Supply Voltages

(all other machines and machines with 230V nominal voltage)

Depending on drive power the machines are operating with different

voltages:

Drive 1.5 kW = 230 V (single phase)

Other drives = 400 V (3-phase plus neutral)

Picture: Transformer 380 V - 480 V

If these supply voltages are not achievable and no standard transformer

can be used, a special step-up transformer can be supplied.

Usage with circuit breaker Transformer for Usage with Earth Leaking

Circuit Breaker

single phase

machines only

Because of CE regulations filters for electromagnetic emissions are

installed in the machine. For this reason the operation of the machine

over an earth leaking circuit breaker is not allowed.

If the supply power is only possible over a circuit breaker, the use of a

transformer with galvanic separation is mandatory.

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

25

WM3000euroline

WM4000euroline

WM5000euroline

_______

Additional Wire Guide with Rolls

The machine can be operated with several parallel wire guides. Here

several groups are wound at the same time and thus the total winding

time is substantially shortened. Up to 3 parallel wire guides are

possible. The price refers to 1 additional wire leader without wire break

monitoring or tensioning.

Fixed distance cross beams for wire guides

Picture: Parallel wire guides with sleeve release

Different Machine Colour

These cross beams are needed for the attachment of the 2nd and/or

2nd and 3rd wire guide. Hereby 2 different not changeable distances of

the wire guides can be realized. These distances are former dependent

and must be indicated at the time of order.

Machine Colour

It is possible to order a different machine colour. The machine is

powder-coated. For this reason it is mandatory to contact the

manufacturer beforehand, since only certain RAL colours where the

required coating-powder is available are possible.

Keyboard Protection

The transparent keyboard protection is put on the PC - keyboard. The

protection conforms exactly to the keys and therefore allows a smooth

operation.

The keyboard protection is resistant to water and diverse chemicals.

Picture: Keyboard protection

Key Switch

The mode select switch "Run"/"Program" is replaced by a key switch.

It is not possible to changed any stored winding data in "Run"-mode.

The key switch prevents that someone unauthorised changes into

"Program"-mode where data can be changed or erased.

Picture: Key switch

Tool Storage Box

(not for WM 3000 and WM 3002)

Within the corner of the winding space below the security cover a tool

box is mounted. Here the frequently used set-up tools, coil fixing

clamps, etc can be stored.

Picture: Tool storage box

Machine Balancing Shoes

In case of uneven floor or floors with limited point pressure these

screws are available for balancing purpose.

Picture: Machine balancing shoe

Diameter: 90 mm (3.55)

Scope of delivery: 4 pieces

Transport Pallet

Every shipment is carried out on a pallet.

WM 3000 WM 4000:

WM 4500 WM 5000:

WM 5001 WM 5002:

Picture: Machine on a transport pallet

ISPM 15 treatment (required for many countries):

Wooden Box:

Wooden Box seaworthy:

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

26

WM3000euroline

WM4000euroline

WM5000euroline

_______

Wire Guide Pulley with Special Groove

If there is a requirement for a special design of the guide pulley, e.g. for

thinner wires or multi-parallel or wire strip, it is possible to make this to

customer's requirement.

The pulley is double-mounted in bearings and the groove is made to

customer's design.

Picture: wire guide pulley

Picture: Example with a slot for rectangular wire

Width-adjustable wire guide pulley

To wind with many different wires in parallel or rectangular wires an

adjustable wire guide pulley in connection with a wide rear pulley can be

used.

of guide pulley: 108 mm inside, 134 mm outside. Width: 0 - 20 mm

of rear pulley: 73 mm inside, 99 mm outside. Width: 24 mm

Attention: Requires supportless winding preparation.

Scope of delivery: adjustable front pulley and wide rear pulley.

Picture: Width-adjustable wire guide pulley

Storage pins with magnetic foot

For an easy storage of winding heads it is possible to take storage pins

with a magnetic foot. Due to the magnet the pins are very stable and

can be stored vertically or horizontally.

On the front side of the pins there is a bore which fits into the thread of

the winding fixture. It is possible to slip the heads onto the winding

fixture which is time-saving.

for winding heads type 3/12 (WD 10)

for winding heads type 3/16, 4/11, and 4/24 (WD 19)

Picture: Storage pin with magnetic foot

The price is for one pin.

Storage pins for winding heads type 3/16

(not for WM 3002, WM 3000 only with optional storage facility)

At the machine there is a facility for storage of the formers. The pins can

be put vertically into holes. The pins can take winding heads type 3/16

only. All other formers (type 3/12, 4/11 and 4/24) cannot be stored.

There are 12 pins necessary to take up all 6 sets of 3/16.

On the front side of the pins there is a bore which fits into the thread of

the winding fixture. It is possible to slip the heads onto the winding

fixture which is time-saving.

Picture: Setting up formers using storage pin

The price is for one pin.

Picture: Storage pin for 6 formers

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

27

WM3000euroline

WM4000euroline

WM5000euroline

_______

Use under special environmental conditions

Filter Fan

for WM 3000

Filter Fan for Controls (only WM 3000 and WM 3002)

If the machine should be used in an environment with warmer

temperatures, it is advisable to aerate the interior of the machine, to

guarantee sufficient heat dissipation for the control and the PC. To this

a special filter fan is available, which can be used also in dust

contaminated environments. The cabinet of the machine, which is

normally open below, has to be closed and sealed by an additional floor

plate.

Cooling unit for WM3000

For the employment in countries with high atmospheric humidity or very

high outside temperatures a cooling unit for the electronic components

of the control and the PC is recommended.

At the WM 3000 and WM 3002 the cabinet of the machine, which is

below open normally, must be sealed. The cooling unit is placed at the

side at the machine and works fully automated and largely selfcontained.

Through the hermetical locking of the cabinet the interior of the machine

is protected in addition against dust and other dirt particles in the

surrounding air.

Picture: Cooling unit WM 3000

Filter Fan

for Controls

WM 4000 + WM 5000

Filter Fan for Controls (only WM 4000 and WM 5000)

If the machine should be used in a dust contaminated environment, the

possibility exists to fit a special filter fan in lieu of the normal aeration of

the interior of the machine and the PC.

Cooling unit for WM4000 + WM5000

For the employment in countries with high atmospheric humidity or very

high outside temperatures a cooling unit for the electronic components

of the control and the PC is recommended.

At the WM 4000 and WM 5000 the floor of the machine is already

closed. The cooling unit is placed on top of the machine and works fully

automated and largely self-contained.

Picture: Cooling unit WM 4000

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

28

WM3000euroline

WM4000euroline

WM5000euroline

_______

Standard winding mandrels

Standard Mandrels with

19 mm Hex bar

Standard WD19 former holders

(Included in the scope of delivery for WM 3000 and WM 4000)

If the below listed standard formers Type 3/16, 4/11, or 4/24 shall be

used in winding, the corresponding winding mandrels with 19 mm hex

bars are required.

Scope of delivery:

2 former holders WD19, 2 sets of spacers,

2 sliding rail front support bars, 2 quick-action locking blocks

Additional blocks for quick locking device

Picture: WD19-Mandrels

Picture: Quick-lockingFront Support

The scope of delivery of the standard former holders contains 3 sliding

rail front support bars, which are fitted according to the winding

diameter. To avoid the time-consuming reconstruction off the locking

blocks at the exchange the front support bar, 4 further quick-action

locking blocks can be used.

Scope of delivery:

4 quick-action locking blocks

Rectangular Winding Heads

Former holder for 4-edge

windings with centric

quick-adjustment

Former holder for 4-edge windings

(1 group)

A special arbour holder with cross-bars for 4-edge formers can be

assembled on the winding arm of the WM 5000. Using these 4-edge

formers one group of can be wound without the need of a front support,

to easily take off the wound coils when the winding cycle is finished.

The cross-bar dimensions can be adjusted very quickly using a centric

spindle and a hand crank.

Standard traverse (cross bar) length is 480 mm, also available with

580 mm for machines with ext. diameter, and 380 mm for WM 4000.

Coil dimensions

(in mm):

Picture: Former holder with formers mounted on winding arm

C = max.

circumference

WM4000

WM5000

380mm

480mm _

NA25: small large small large

A

300 550

400 650

B

870 990 1270 1390

C

2340 3080 3340 4800

Equal Size:

A

420

B

980

C

2800

520

~1380

~3800

WM5001

580mm _

small large

500 750

1770 1890

4540 5000

620

~1880

~5000

4-edge Rectangular Formers

The 4-edge rectangular former have 6 winding slots each are used with

the former holder for 4-edge windings. A set consists of 4 pieces.

4-edge rectangular formers with 6 slots equal size

Picture: 4-edge formers with 6 slots

4-edge rectangular formers with 6 slots for stator slot distance 15 mm

4-edge rectangular formers with 6 slots for stator slot distance 20 mm

4-edge rectangular formers with 6 slots for stator slot distance 25 mm

4-edge rectangular formers with 6 slots for stator slot distance 30 mm

4-edge rectangular formers with 6 slots for stator slot distance 40 mm

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

29

WM3000euroline

WM4000euroline

WM5000euroline

_______

4-edge / 6-edgeWinding Fixture

Arbour holder 4-edge

with WD 19 hex bars

The 4-edge arbour holder can be used to wind rectangular coil forms.

Because the identical 19 mm hex bar is used to hold the arbours, the

same formers as with the standard arbour holders can be utilised.

It consists of the following parts:

1. Two cross bars which mount into the winding arm

2. Four hex bars with mounting plates which are adjustable on the

cross bars to required coil widths

3. Front end supports to hold the fixture in position with quick-release

The following coil dimensions (mm) are possible:

Picture: 4-edge arbour holder, without formers

mounted on WM4000

Min

max

A 100

B 170

370

720

Measured for WM 4000

Extension 6-edge (Diamond)

with WD 19 hex bars, only for equal size

The 4-edge arbour holder can be extended with two additional hex bars

to achieve 6-edge (diamond) coil forms.

Picture: Diamond (6-edge) arbour holder with formers

Mounted on WM4000

It consists of the following parts:

1. 2 hex bars with mounting plates which are adjustable on cross bars

to the required coil widths

2. 2 additional quick release holder blocks for the front support

The following coil dimensions (mm) are possible:

A

B

C

D

min

max

120

170

75

330

370

690

150

1000

measured for WM 4000

Picture: Details of 6-edge arbour holder, with cross bars and formers

mounted on WM4000

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

30

WM3000euroline

WM4000euroline

WM5000euroline

_______

4-/ 6-edge winding unit for lap winding

Winding unit (tetragonal/hexagonal-form)

only for lap winding

This winding unit is suitable for rectangular or diamond-shaped coils of

equal design.

The unit consists out of 2 T-shaped holders with 2 or 3 winding heads

on each holder. The holders are engaged to the winding beam.

The unit can be adjusted to all dimensions.

On the front there is an adjustable support, for holding the winding

heads in position during the winding process.

* Attention *

Special design for

the US market

For availability in

other countries

please ask!

If only large coils are necessary, it is possible to get the two large

holders (see below) instead of the standard holders without additional

price.

Picture: 6-edge-winding unit fixed at the winding arm

Scope of Delivery:

2 standard holders

6 winding heads with 12 slots

6 winding heads with 18 slots

1 universal adjustable front end support

Coil Dimensions with Standard Holders:

A

B

C

D

6-edge-form

4-edge-form

min max

min max

---------------------------------------------------------95 mm 430 mm

55 mm 430 mm

130 mm 579 mm

130 mm 860 mm

50 mm 165 mm

230 mm 900 mm

A

B

C

D

6-edge-form

4-edge-form

min max

min max

-------------------------------------------------------3.74 16.93

2.165 16.93

5.118 22.795

5.118 25.59

1.968 6.496

9.055 35.43

Picture: complete delivery of the winding unit

Measured for WM 4000

Sketch of Coil Shape

Larger holder for the tetragonal/hexagonal

winding unit (only for lap winding)

This holder is used for larger rectangular or diamond coil forms.

It is a supplementary device to the pre-described winding unit for larger

coil circumferences.

Coil dimensions with Larger Holders:

Picture: holders for large coil forms

A

B

C

D

6-edge-form

4-edge-form

min max

min max

-----------------------------------------------------95 mm 430 mm 55 mm 430 mm

270 mm 760 mm 70 mm 760 mm

50 mm 110 mm

370 mm 980 mm

A

B

C

D

6-edge-form

4-edge-form

min max

min max

----------------------------------------------------3.74 16.93

2.165 16.93

10.63 29.92

2.756 29.92

1.968 4.33

14.567 37.795

Measured for WM 4000

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

31

WM3000euroline

WM4000euroline

WM5000euroline

_______

Supportless Winding

Supportless winding device for winding

heads 3/16, 4/11, and 4/24

(only for machines with electrical adjustable winding fixture)

With this device it is possible to wind coils without the front support, i.e.

to fix the time-wasting slide-rails.

This is achieved by a supportless winding device. It can be used for up

to 10 wires of 1.32 mm in parallel.

More than 10 wires will require a mechanical reinforcement of the

winding beam. The limitation goes up to 20 wires 1.32 mm in parallel.

The reinforcement of the winding beam is not retrofitable and has to be

ordered in beforehand with the machine.

If more than 10/20 wires are required, it is essential to fix an end

support slide-rail fixture (optional, not in the scope of delivery).

Picture: Supportless Winding Device.

Top: With Winding Heads

Bottom: Without Winding Heads

The price includes the winding head holders (without the winding

heads) and the machining of the complete set winding heads of type

3.16 consisting of No. I, 2, 3, 4, 5, and 6.

Winding Heads for Supportless Winding

The winding heads have to be machined for the application with the

supportless winding device, i.e. a groove has to be cut underneath by a

milling machine.

Picture: machined winding head for supportless winding device

The price is to be understood for a complete set of each winding heads

(6 pairs 4/11 or 3 pairs 4/24).

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

32

WM3000euroline

WM4000euroline

WM5000euroline

_______

Winding Heads Type 3/12

Small winding beam for small coil

To wind small coils the small winding beam is essential.

It consists of the following components:

1. two winding fixtures with a 10 mm hexagonal bore with ground plate

2. one face plate (slide rails) with fixing levers

3. three sets of formers type 3/12 No. 1, 2, 3 eccentric

4. one set of formers type 3/12 No. I concentric

Winding heads type 3/12 equal size

One pair always consists of 2 heads.

The winding fixture can take max. 6 pairs.

Picture: Small Winding Beam

Type

a

mm

e

mm

f

mm

Windingshaft

3/12.I 35

12

52

WD10

Winding heads type 3/12 concentric

One pair always consists of 2 heads.

The winding fixture can take max. 6 pairs.

Picture: Scope of Delivery

Type

a

mm

b

mm

c

mm

e

mm

f

mm

Windingshaft

3/12.1 35

3/12.2 35

3/12.3 35

43

46

49

51

57

63

12

12

12

52

52

52

WD10

WD10

WD10

Winding Heads Type 3/16

Winding heads type 3/16 equal size

One pair always consists of 2 heads.

The winding fixture can take max. 6 pairs (or 12 pairs with the 4-edge

winding fixture, 18 pairs with the 6-edge fixture).

Type

a

mm

e

mm

f

mm

Windingshaft

3/16.I 60

16

64

WD19

Picture: Former Type 3/16 No. I

Winding heads type 3/16 concentric

One pair always consists of 2 heads.

The winding fixture can take max. 6 pairs (or 12 pairs with the 4-edge

winding fixture).

Picture: Former Type 3/16 No. 6

Type

a

mm

b

mm

3/16.2

3/16.3

3/16.4

3/16.5

3/16.6

60

60

60

60

60

71

74

77

80

83

c

mm

82

88

94

100

106

e

mm

16

16

16

16

16

f Windingmm shaft

64

64

64

64

64

WD19

WD19

WD19

WD19

WD19

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

33

WM3000euroline

WM4000euroline

WM5000euroline

_______

Winding Heads Type 4/11

Winding heads type 4/11 equal size

One pair always consists of 2 heads.

The winding fixture can take max. 6 pairs.

Type

a

mm

e

mm

f

mm

Windingshaft

4/11.I 60

11

64

WD19

Picture: Former Type 4/11 No. I

Winding heads type 4/11 concentric

One pair always consists of 2 heads.

The winding fixture can take max. 6 pairs.

Type a

b

c

mm mm mm

Picture: Former Type 4/11 No. 6

4/11.2

4/11.3

4/11.4

4/11.5

4/11.6

60

60

60

60

60

71

74

77

80

83

d

mm

82

88

94

100

106

e

f Windingmm mm shaft

93

102

111

120

129

11

11

11

11

11

64

64

64

64

64

WD19

WD19

WD19

WD19

WD19

Winding Heads Type 4/24

Winding heads type 4/24 equal size

One pair always consists of 2 heads.

The winding fixture can take max. 3 pairs (6 pairs with the 4-edge

winding fixture, 9 pairs with the 6-edge fixture).

Picture: Former Type 4/24 No. II

Type

a

mm

e

mm

f

mm

Windingshaft

4/24.I

4/24.II

4/24.III

4/24.IV

60

120

90

200

24

24

24

24

116

116

116

116

WD19

WD19

WD19

WD19

Winding heads type 4/24 concentric

One pair always consists of 2 heads.

The winding fixture can take max. 3 pairs (6 pairs with 4-edge

winding fixture).

Type

Picture: Former Type 4/24 No. 10

a

mm

b

mm

c

mm

d

mm

e

f Windingmm mm shaft

4/24.2 60

4/24.3 60

4/24.4 60

4/24.5 60

4/24.6 60

4/24.7 60

4/24.8 60

4/24.9 60

4/24.10 60

4/24.12 95

4/24.14 95

71

74

77

80

83

86

89

92

95

136

142

82

88

94

100

106

112

118

124

130

177

189

93

102

111

120

129

138

147

156

165

218

236

24

24

24

24

24

24

24

24

24

24

24

116

116

116

116

116

116

116

116

116

116

116

WD19

WD19

WD19

WD19

WD19

WD19

WD19

WD19

WD19

WD19

WD19

___________________________________________________________________

Manufacturer: Schleich Antriebs- und Steuerungstechnik GmbH * An der Schleuse 11 * 58675 Hemer * Germany * !+49 2372 9498-0 * "+49 2372 9498-99

Distributor: F.W. Scheiing KG * Beratgerstrae 32 * 44149 Dortmund * Germany * !+49 231 958062-0 * "+49 231 958062-20

34

WM3000euroline

WM4000euroline

WM5000euroline

_______

Collapsible Formers

Collapsible Formers Type 3/15-4/GW

Picture: Collapsible Former (powder-coated aluminium)

These winding heads can be folded e.g. by 180 for a fast and easy

removal of wound coils. The full winding head has a hole which takes a

shaft. The shaft clicks into place at the winding beam. For the winding

process the formers are placed such that all slots are showing outside.

After the wound coils are ready to be taken off the slots, the winding

arm should be driven together electrically in order to take the strain off

the coil and all two or four collapsible winding heads can be snapped

inwards to a prepared position and the tied-up coils can be slit over the

round edges.

There is no need to take the winding heads off the machine for

releasing the finished coils.

Winding Head Data:

Concentric (lap) winding

Number of slots = 18, Slot width = 15 mm, Web = 5 mm

Total length of winding head = 435 mm, Coil width = 35 mm

The formers are placed in 4 or 6 corners of the coil. Therefore a

minimum of 4 collapsible winding heads is required.

Collapsible Winding Heads Type 4/23

Type

Picture: Collapsible Formers Type 4/23-4

Width Width Width Width Slot1

2

3

4

width

4/23-4/15

4/23-4/20

4/23-4/22,5

4/23-4/25

4/23-4/30

35

35

35

35

35

50

55

57,5

60

65

65

75

80

85

95

80

95

102,5

110

125

23

23