Академический Документы

Профессиональный Документы

Культура Документы

Job HAzard Analysis Welding Operations Miftah

Загружено:

LukmanElekAeАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Job HAzard Analysis Welding Operations Miftah

Загружено:

LukmanElekAeАвторское право:

Доступные форматы

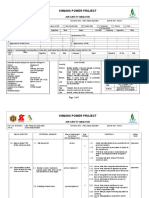

Created:

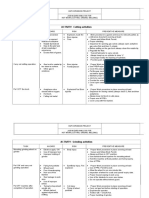

JOB TITLE:

JOB HAZARD ANALYSIS

Welding Operations

OxyAcetylene Welder

WORK LOCATION (ROOM NO.):

Revise Date:

5/15/2007

DEPARTMENT:

Define Activities/Equipment Used (note

frequency/duration)

POTENTIAL HAZARDS

Title:

Beverly Maki

OSHEM Saf Spec

TOOL/MACHINE MAKE AND MODEL:

Oxy-Acetylene welding machine, model xxx

Most welding shops

Task(s)

JHA Creator:

REQUIRED CONTROLS/WORK PRACTICES

REQUIRED PPE

Oxy-Acetylene welding, used on average X

times a day, X days a week by X # of welders.

Spilling water could cause slip/trip. Not cleaning

area could leave dust particles/combustibles that

could flare

Slowly apply small amount of water to cloth and wipe

down work area. Ensure fire extinguishers are available N/A

and charged.

1b. Uncoil and straighten hoses from

cylinders.

Loose hose on floor could cause slip/trip.

Damaged hose could cause leak/fire

Ensure uncoiled hoses will not be a tripping hazard.

Ensure there are no kinks, cracks or damage to hoses. N/A

Ensure all torch valves are closed and inspect for

possible leaks.

1c. Adjust screws on regulators so they are

backed off.

Gas leak could cause fire

Ensure adjustment screws on regulators are backed off N/A

so no tension is present for both acetylene and oxygen.

None

None

None

Know the correct pressure for type equipment

1f. Crack open acetylene valve on torch body.

Potential gas accumulation if not prepared to light

Have striker available

Safety glasses, work

gloves

1g. Use striker to ignite torch

Potential gas accumulation

Spark production (could ignite other material)

Quickly, so not to let gas accumulate, hold torch facing

away from face, body and portable unit. Using other

hand, strike flint approximately 2 inches from tip of

torch.

Safety glasses, work

gloves

1. Turn torch 1a. Wipe down work area with damp cloth

(water)

on

1d. Open cyclinder valve slowly by turning

counterclockwise.

1e. Turn adjustment screw clockwise to

desired pressure

1h. Adjust acetylene torch body valve

1i. Open axygen valve on torch body

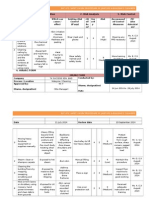

2. Perform

weld

Incorrect adjustment could cause flame out,

undesirable magnitude

Incorrect adjustment could cause flame out,

undesirable magnitude

2a. Have flux and welding rods appropriate for Improper weld due to improper selection of flux

type weld and material being welded

and welding rods

Adjust acetylene torch body valve to desired flame

Slowly open oxygen valve on torch body to achieve

desired flame.

Welding training should cover when and how to use

different fluxes and welding rods. Adhere to the

trianing.

N/A

Safety glasses, work

gloves

Safety glasses, work

gloves

Task(s)

Define Activities/Equipment Used (note

frequency/duration)

REQUIRED CONTROLS/WORK PRACTICES

REQUIRED PPE

2b1. Fire or Explosion

1. Updated (annual) Welding shop burn permit

required.

2. If welding outside shop, Burn Permit from

Authorized Person required.

3. Do not weld near flammable material. Move

flammables at least 35 feet away or protect them with

flame-proof covers.

4. Do not weld on drums, tanks or any closed

containers unless a qualified person has tested it and

declared it or prepared it to be safe.

2b2. Breathing welding fumes

1. Use enough forced ventilation or local exhaust

(forced suction) at the arc to remove fumes from

breathing area.

2. Use portable smoke eater when out on a job.

3. Use welding helmet that has fresh air supply.

4. Keep your head out of the fumes and do not breathe

fumes.

Welder's cap; safety

glasses, oxygen fed

respirator, if required;

Welder's face shield;

welder's gloves; welder's

apron

2b3. Sparks could burn eyes, hands, clothes

1. Wear welder's cap, eye protection, face shield,

gloves, apron

2. If welding outside with breeze, use wind break and

line of sight barrier to protect passers-by.

Welder's cap, eye

protection, face shield,

gloves, apron

2b4. Arc rays can burn eyes

1. Use welding helmet with correct shade of filter.

2. Use welding curtain to shield other employees and

visitors from arc rays.

Welder's cap, eye

protection, face shield,

gloves, apron

2b5. Smoke may set off smoke alarm or sprinkler

system

Follow procedures/protocols listed in Chapter XX, Fire Welder's cap, eye

Protection Impairment Permit whenever working closer protection, face shield,

than 35 feet from a sprinkler head or smoke detector.

gloves, apron

2c. Weld heating, AC, water, steam,

condensate return lines.

2c1.. Contents of piping could cause burns

Drain piping at welding area, wearing insulated gloves, Welder's cap, eye

eye protection or whatever other PPE based on pipe

protection, face shield,

contents.

gloves, apron

2d. Perform weld on or near electrical devices

2d1. Electical shock, cuts and burns

Use lock-oout/tag-out procedures.

Welder's cap, eye

protection, face shield,

gloves, apron

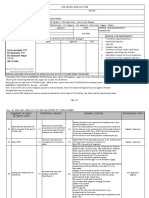

3a. Close acetylene valve on torch body

Valve and stem (pinch points)

Position fingers on acetylene valve ensuring they do

not come in contact with the valve stem. Turn valve

clockwise.

Welder's cap, eye

protection, face shield,

gloves, apron

2b. Perform weld

3c. Perform weld with arc welder

3. Turn off

torch

POTENTIAL HAZARDS

4-22

Task(s)

Define Activities/Equipment Used (note

frequency/duration)

POTENTIAL HAZARDS

REQUIRED CONTROLS/WORK PRACTICES

Position fingers on oxygen valve ensuring they do not

come in contact with the valve stem. Turn valve

clockwise.

REQUIRED PPE

Welder's cap, eye

protection, face shield,

gloves, apron

3b. Close oxygen valve on torch body

Valve and stem (pinch points)

3c. Turn the acetylene valve clockwise

Valve and stem (pinch points)

Position fingers on acetylene valve ensuring they do

not come in contact with the valve stem. Turn valve

clockwise.

Welder's cap, eye

protection, face shield,

gloves, apron

3d. Turn the oxygen valve clockwise

Valve and stem (pinch points)

Position fingers on acetylene valve ensuring they do

not come in contact with the valve stem. Turn valve

clockwise.

Welder's cap, eye

protection, face shield,

gloves, apron

None

N/A

None

None

N/A

None

3e. Close adjustment screws on acetylene

regulator

3f. Close adjustment screws on oxygen

regulator

3g. Slowly open Acetylene valve on the torch

body to bleed lines.

3h. Slowly open oxygen valve on the torch

body to bleed lines.

Gas (potential inhalation, explosion)

Gas (potential explosion)

Position torch nozzle away from personnel and any

heat source. Open valve on torch body.

Position torch nozzle away from personnel and any

heat source. Open valve on torch body.

None

None

3i. Close acetylen valve on torch body

Valve and stem (pinch points)

Position fingers on acetylene valve ensuring they do

not come in contact with the valve stem. Turn valve

clockwise.

None

3j. Close oxygen valve on torch body

Valve and stem (pinch points)

Position fingers on acetylene valve ensuring they do

not come in contact with the valve stem. Turn valve

clockwise.

None

4-23

Вам также может понравиться

- Safetyin Welding Gas Cutting OperationsДокумент12 страницSafetyin Welding Gas Cutting OperationsSantanu Kumar SahuОценок пока нет

- JSA 08 Gas WeldingДокумент1 страницаJSA 08 Gas Weldingmuthuswamy77Оценок пока нет

- Civil JSA Form Application of Protective Coating On Sump PitsДокумент1 страницаCivil JSA Form Application of Protective Coating On Sump PitsdrmuhsinОценок пока нет

- Pha ExcavationДокумент13 страницPha ExcavationirshadОценок пока нет

- Jsa SKДокумент10 страницJsa SKEngr Tahir UL Haq100% (2)

- JHA Cutting of Asphalt Road For Replacement of Protection SlabsДокумент5 страницJHA Cutting of Asphalt Road For Replacement of Protection SlabsNasrullah JanОценок пока нет

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSДокумент2 страницыProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Jsa For The Installation of I EamДокумент5 страницJsa For The Installation of I EamMohammed MinhajОценок пока нет

- Gas Welding and Cutting Safety PDFДокумент55 страницGas Welding and Cutting Safety PDFGnanasekaran MОценок пока нет

- Job Safety AnalysisДокумент4 страницыJob Safety AnalysisDedi Apriadi71% (7)

- JSA Forklift PDFДокумент2 страницыJSA Forklift PDFfauziОценок пока нет

- JSA Cable Pulling and Laying WorksДокумент6 страницJSA Cable Pulling and Laying Workskabir100% (1)

- Akk Jha Installation of Diesel TankДокумент3 страницыAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Shifting of Material & Equipment.: Job Safety Analysis JobДокумент6 страницShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariОценок пока нет

- EVT471Документ3 страницыEVT471Nurul AqielaОценок пока нет

- Manual Tig Welding (RRC) - Job ProcedureДокумент3 страницыManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Crane JSAДокумент5 страницCrane JSAKritsada Tiwutanon100% (1)

- Jsa Pipe Cutting at Fire PumpДокумент5 страницJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdОценок пока нет

- JSA Formet New Hot WorkДокумент6 страницJSA Formet New Hot Worksakthi venkat100% (1)

- Jha RebarsДокумент7 страницJha RebarsJaycee QuinОценок пока нет

- NWC Corporate Projects Risk Assessment Forms: Job / TaskДокумент3 страницыNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebОценок пока нет

- JSA WeldingДокумент2 страницыJSA WeldingSigint Sides0% (3)

- Jsa For Mechanical Activity: H/M/L H/M/LДокумент1 страницаJsa For Mechanical Activity: H/M/L H/M/Ljithin shankarОценок пока нет

- Operating The Man LiftДокумент1 страницаOperating The Man LiftEllecer anthony Permejo67% (3)

- JSA HandToolsДокумент2 страницыJSA HandToolsCristina Rican100% (3)

- Duqm Refinery Project EPC Package One: JSA For Confined Space Rev.0Документ8 страницDuqm Refinery Project EPC Package One: JSA For Confined Space Rev.0balasubramaniamОценок пока нет

- Crane JHA OKДокумент4 страницыCrane JHA OKAbu Maaz100% (1)

- 7-Block Work Risk Assessment ReportДокумент7 страниц7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- JSA 04 Confined Sapce EntryДокумент1 страницаJSA 04 Confined Sapce EntryalekyaОценок пока нет

- Daily JSAДокумент4 страницыDaily JSAumn_mlkОценок пока нет

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisДокумент2 страницыBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechОценок пока нет

- Job Safety Analysis Risk Assess Restricted Spaces v1 290311Документ9 страницJob Safety Analysis Risk Assess Restricted Spaces v1 290311Anto MaryadiОценок пока нет

- Demolition PDFДокумент2 страницыDemolition PDFvinothОценок пока нет

- Jsa-Jha For Using of Hand ToolsДокумент2 страницыJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Activity Hazard AnalysisДокумент4 страницыActivity Hazard AnalysisGerrard Singh100% (1)

- 14 - Job Safety Analysis-loading and Offloading Materials装卸料Документ5 страниц14 - Job Safety Analysis-loading and Offloading Materials装卸料Jayvee Baradas Valdez100% (1)

- Incident Report: Proj. N. Unit Document Code Serial NДокумент1 страницаIncident Report: Proj. N. Unit Document Code Serial NSyed Ali HassanОценок пока нет

- Jsa forOperatingAForkliftДокумент2 страницыJsa forOperatingAForkliftsupahing supahingОценок пока нет

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerДокумент4 страницыDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustОценок пока нет

- JSA Template 5 - Plumbing and Wastewater System InspectionsДокумент13 страницJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- Confine Space at Water TankДокумент7 страницConfine Space at Water TanknaraОценок пока нет

- JOB HAZARD ANALYSIS - Cable TrayДокумент10 страницJOB HAZARD ANALYSIS - Cable TrayJayson Escamillan100% (1)

- Job Hazard Analysis TemplateДокумент12 страницJob Hazard Analysis TemplateMarvin Arinuelo100% (3)

- Jha RoofingДокумент4 страницыJha Roofingahmadhatake100% (1)

- Permit To Work ProceduceДокумент4 страницыPermit To Work ProceduceQuý Hoàng ChuОценок пока нет

- Heat Stress Assessment Checklist: Section IДокумент3 страницыHeat Stress Assessment Checklist: Section IninisaisОценок пока нет

- Jha of PaintingДокумент3 страницыJha of PaintingAllan Camacho Regalado100% (1)

- JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility RelayДокумент9 страницJSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relayfrancis_e_tan100% (2)

- Tie in Hot Work JHAДокумент4 страницыTie in Hot Work JHAmalik jahan100% (2)

- Jsa For Piping and Erection RevisedДокумент1 страницаJsa For Piping and Erection RevisedDr AnwarОценок пока нет

- 11 - JSA (Tower Crane) 12-9-06Документ11 страниц11 - JSA (Tower Crane) 12-9-06sattiОценок пока нет

- JSA For Working at HeightДокумент2 страницыJSA For Working at HeightXUE JIANОценок пока нет

- JHA General Maintenance Activity PDFДокумент5 страницJHA General Maintenance Activity PDFdede SinbadОценок пока нет

- JSA For MobilizationДокумент3 страницыJSA For MobilizationHossain amjad Hossain100% (1)

- CH 4 Att4Документ6 страницCH 4 Att4akhilakaОценок пока нет

- SWP 013 Oxy Acetylene WeldingДокумент4 страницыSWP 013 Oxy Acetylene WeldingBajaj NitinОценок пока нет

- Safety in Work Place Safety in WeldingДокумент25 страницSafety in Work Place Safety in WeldingRahul SiwakotiОценок пока нет

- Manual Operacion Aas 100 SeriesДокумент104 страницыManual Operacion Aas 100 Seriesdéborah_rosalesОценок пока нет

- Standard Operating Procedure: 1) Synthesis With Gaseous Ammonia 2) Condensing Ammonia 3) Quenching/Evaporating AmmoniaДокумент6 страницStandard Operating Procedure: 1) Synthesis With Gaseous Ammonia 2) Condensing Ammonia 3) Quenching/Evaporating AmmoniagouthamsaiОценок пока нет

- Rizky 1Документ9 страницRizky 1LukmanElekAeОценок пока нет

- Format Resume NersДокумент3 страницыFormat Resume NersLukmanElekAeОценок пока нет

- Anatomy and Fisiology of Liver Hampir JadiДокумент7 страницAnatomy and Fisiology of Liver Hampir JadiLukmanElekAeОценок пока нет

- Keerangka Konsep Teori ADAPTASIДокумент1 страницаKeerangka Konsep Teori ADAPTASILukmanElekAeОценок пока нет

- The Effectiveness of Teaching Writing Descriptive Text by Using Circ at Tenth Grader of Ma Al Bairuny SambongДокумент12 страницThe Effectiveness of Teaching Writing Descriptive Text by Using Circ at Tenth Grader of Ma Al Bairuny SambongLukmanElekAeОценок пока нет

- AbstractionДокумент1 страницаAbstractionLukmanElekAeОценок пока нет

- Work Method Statement AgbaraДокумент28 страницWork Method Statement Agbaravictor egharevbaОценок пока нет

- Is.3600.8.1985 0 PDFДокумент6 страницIs.3600.8.1985 0 PDFSukalpa ChowdhuryОценок пока нет

- Draughtsman (Mechanical)Документ28 страницDraughtsman (Mechanical)Umang SoniОценок пока нет

- Reaction VesselДокумент4 страницыReaction VesselArunkumar MyakalaОценок пока нет

- Weld 3Документ1 страницаWeld 3canettijОценок пока нет

- Collection Catalogue en CejnДокумент36 страницCollection Catalogue en CejnThura AungОценок пока нет

- 6m60 Engine-Sm-Mitsubishi Fd100n Fd120n Fd135n Fd150an Fd160an Forklift Trucks Service RДокумент40 страниц6m60 Engine-Sm-Mitsubishi Fd100n Fd120n Fd135n Fd150an Fd160an Forklift Trucks Service Rfilesonic100% (1)

- M4 For Steel StackДокумент25 страницM4 For Steel Stackksshashidhar100% (1)

- Precommissioning of Pipelines: Technical SpecificationДокумент40 страницPrecommissioning of Pipelines: Technical SpecificationLizeth RamirezОценок пока нет

- Aws-D17.1 PDFДокумент60 страницAws-D17.1 PDFssОценок пока нет

- Welding Journal 1960 10Документ155 страницWelding Journal 1960 10AlexeyОценок пока нет

- Mechanical Project Pump StationДокумент146 страницMechanical Project Pump StationDragan Medojevic100% (1)

- Welder Management Spreadsheet (Metric)Документ4 страницыWelder Management Spreadsheet (Metric)Goutham RathinamОценок пока нет

- Ur P2feb2021Документ40 страницUr P2feb2021nafrisqsОценок пока нет

- Welbee English Web PDFДокумент10 страницWelbee English Web PDFekopujiantoeОценок пока нет

- Bedienungsanleitung BMK-8U 12W 01.08.2015 EnglischДокумент70 страницBedienungsanleitung BMK-8U 12W 01.08.2015 EnglischRaksangob LiveОценок пока нет

- SM Bomag BW218 4dДокумент1 446 страницSM Bomag BW218 4dKevine Khaled100% (3)

- MBE JST Product Flyer 2022 Stabilizer enДокумент2 страницыMBE JST Product Flyer 2022 Stabilizer enEddieОценок пока нет

- PQR Editable SampleДокумент2 страницыPQR Editable SampleKoya ThangalОценок пока нет

- Aisi T 192 Steel Plate Engineering Vol 1 Vol 2Документ132 страницыAisi T 192 Steel Plate Engineering Vol 1 Vol 2Ali MkawarОценок пока нет

- ElectrodesДокумент1 страницаElectrodesnagaraj0710Оценок пока нет

- PE Lecture 3Документ53 страницыPE Lecture 3Fauzaan KhanОценок пока нет

- Rust Bullet AI & GuideДокумент32 страницыRust Bullet AI & GuideImam SitumeangОценок пока нет

- Introduction To Bhel PDFДокумент41 страницаIntroduction To Bhel PDFturpati sai kumarОценок пока нет

- Butt Fusion and Electrofusion EquipmentДокумент83 страницыButt Fusion and Electrofusion EquipmentSoares CardosoОценок пока нет

- Student Work Experience Programme (SWEP 1) Technical Report by Michael AgwulonuДокумент35 страницStudent Work Experience Programme (SWEP 1) Technical Report by Michael AgwulonuMichael C. Agwulonu86% (7)

- 6-81-0001 Rev 3-PMIДокумент8 страниц6-81-0001 Rev 3-PMIravi2007Оценок пока нет

- QAP Rubberlining PDFДокумент6 страницQAP Rubberlining PDFn.s.patkarОценок пока нет

- Chem-Wps - PQR - WPQ-004 CS-SS 08-08 GtawДокумент5 страницChem-Wps - PQR - WPQ-004 CS-SS 08-08 Gtawvijay padaleОценок пока нет

- Method Statement of Heavy Schedule Piping FabricationДокумент6 страницMethod Statement of Heavy Schedule Piping FabricationMohamedОценок пока нет