Академический Документы

Профессиональный Документы

Культура Документы

Balancer Plan

Загружено:

panosАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Balancer Plan

Загружено:

panosАвторское право:

Доступные форматы

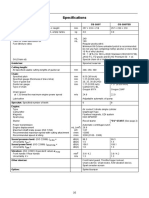

DIY Static Balancer

Drill & tap setscrew holes through

both sides of adaptors & rings. Have a

setscrew in both holes to

maintain balance, especially

on large adaptors.

On large-diameter

adaptors, it may be necessary

to use a pusher rod because you cant

tap to the bottom of a deep hole.

SSA

Adaptor

Standard

Lock

Adaptor

ring

Alan Lapp 12/26/05

Drawing not to scale

Main frame - 1 Sq. Tubing. Round tube will work equally well. How

cool would a DeltaBox-style formed sheet Alu. frame be?

Wheel balancing axle - 5/8 or 1/2 drill rod. If you only plan to

balance modern (90+) wheels, which have large axles, use the larger

drill rod. If youre a perfectionist, hydraulic shafting would be even

better as its hardened, hard chromed and ground true.

Balancing adaptor cones - mild steel, make at least one cone 3 in

diameter to accomodate most single-sided swingarm wheels. Some

SSA wheels require special adaptors. 2 dia. cones will be adequate

for non-SSA wheels.

Bearings - I used ABEC 5 bearings meant for in-line skates.

Bearing axle - size to suit your bearings. Mild steel or drill rod.

DO NOT substitue aluminum as it will surely bend.

Bearing spacers - mild steel, aluminum, delrin. Anything, really.

Bearing house - I used 1.5 .25 wall structural tube with the top

side cut off, which is overkill. A welded assembly works equally well

if care is taken to align the parts.

Setscrew

Note that the cone angle is fairly

steep in order to bypass the seals

and have solid contact with the inner

bearing race on the wheel.

a STOUT close-fitting

spring will ensure the

wheel remains centered

on the balancing axle.**

Leveling feet - any old nuts & bolts will do. Balancer works best

when level.

The only precise part of the job is making sure the bearing axles are

parallel and coplanar, or the balancing axle will walk off the end of

balancer. Extra axle length is good for this reason.

Safety fingers prevent

the balancing axle from

falling out.

Round off

corners and

break edges for

safety.

Bearing axles

should be positioned

so the bearings create

a shallow V for the

balancing axle to

ride in.

Positioning the

bearings too far

apart may bind,

which will cause

unreliable

results.

Stagger bearings so they dont touch.

There will be 4 spacers of each size.

Neat feature: since the base is a rectangular

frame, I enclosed the floor and added a

hinged sheet metal lid for storage of

valve stems, caps, weights & tools.

Fix bearing axles

with circlips, cotter

pins, hitch pins, or

my fav: push-nuts.

They dont need to be

tight, just not fall out.

Size to fit the biggest wheel youll ever want

to balance. I figure Honda made 23 dirtbike

wheels in the 80s, and there are always strange

vintage bike sizes. A tire is maybe 4 thick, so,

somewhere about 14 should accommodate

pretty much any MC tire. Its not critical.

** Added after trying to balance a mysteriously unbalancable wheel. Let the weight of the wheel help compress the spring when assembling the wheel & cones onto the axle.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Foreword Foreword: Warnings, Cautions and Notes CautionДокумент118 страницForeword Foreword: Warnings, Cautions and Notes CautionpanosОценок пока нет

- 1SM-28199-80 Yz250f en 2016Документ356 страниц1SM-28199-80 Yz250f en 2016AndrésОценок пока нет

- Beverly Tourer 400ieДокумент82 страницыBeverly Tourer 400iepanosОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- SRM 520esДокумент1 страницаSRM 520espanosОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- AnДокумент1 страницаAnpanos100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Stirling Engine Reference Guide and CatalogДокумент16 страницStirling Engine Reference Guide and Catalogmutatim hawari85% (13)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- CS 3000 (36) - P014 000440 10Hb - ENДокумент17 страницCS 3000 (36) - P014 000440 10Hb - ENpanosОценок пока нет

- Echo Parts Look-Up 2009Документ4 страницыEcho Parts Look-Up 2009panosОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- DS62Документ1 страницаDS62panosОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- SKF ConCentra Ball Bearings Units - 6107 - I - ENДокумент28 страницSKF ConCentra Ball Bearings Units - 6107 - I - ENfcrosa100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- JNTUK-DAP-Course Structure and Syllabus-B.tech (Mechanical Engineering) - II YEAR.R10 StudentsДокумент25 страницJNTUK-DAP-Course Structure and Syllabus-B.tech (Mechanical Engineering) - II YEAR.R10 StudentsAnusha MylavarapuОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Howard B (1) - Petroleum Engineers Handbook, Part 4Документ331 страницаHoward B (1) - Petroleum Engineers Handbook, Part 4yayОценок пока нет

- Motion Canada - Bearing CatalogДокумент212 страницMotion Canada - Bearing CatalogEric Lafrance100% (1)

- Mech ANM 2019R1 WS04D-Anisotropic HyperelasticityДокумент14 страницMech ANM 2019R1 WS04D-Anisotropic HyperelasticityDong LIОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Parker 2H CylindersДокумент26 страницParker 2H CylindersnitinjainmechОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- National Foam ManualДокумент4 страницыNational Foam ManualRiky AyalaОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Fatigue Process in Beams of Reinforced Concrete Bridges - A Literature ReviewДокумент8 страницFatigue Process in Beams of Reinforced Concrete Bridges - A Literature ReviewFernandoОценок пока нет

- Internship Report On Suzuki Gujranwala MotorsДокумент108 страницInternship Report On Suzuki Gujranwala MotorsAbdulrehman Butt87% (15)

- Irjet - Speed Breaker Power Generation PDFДокумент7 страницIrjet - Speed Breaker Power Generation PDFJohn Jeren DawinanОценок пока нет

- Physics Project: Topic: To Study Simple Harmonic MotionДокумент7 страницPhysics Project: Topic: To Study Simple Harmonic Motiongorilla soupОценок пока нет

- WSS - 071 Scour Valve Installations - General Arrangement and DetailsДокумент1 страницаWSS - 071 Scour Valve Installations - General Arrangement and DetailsMyrahma Love100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 15780Документ16 страниц15780uddinnadeemОценок пока нет

- AISC Night School 9 Session 2Документ49 страницAISC Night School 9 Session 2LCS100% (1)

- A4-L 2.0 enДокумент194 страницыA4-L 2.0 enAtiq Ur RehmanОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- IVECO StralisДокумент40 страницIVECO StralismicakojicОценок пока нет

- Manual de Partes de Daytona 350Документ66 страницManual de Partes de Daytona 350MariaNuceraОценок пока нет

- Catalogos BombasДокумент12 страницCatalogos BombasJose NavarreteОценок пока нет

- Dimensions of Spades and Ring Spacers ASME B16.48Документ11 страницDimensions of Spades and Ring Spacers ASME B16.48Angs TazОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- ME3252 Chapter 2 NotesДокумент5 страницME3252 Chapter 2 NotesAsffaq MuhdОценок пока нет

- Ash HandlingДокумент3 страницыAsh HandlingAi VietОценок пока нет

- Pipe Jacking Force PDFДокумент417 страницPipe Jacking Force PDFSajjad AnwarОценок пока нет

- PN1949 Perkins Irrigation Engine Ratings GuideДокумент16 страницPN1949 Perkins Irrigation Engine Ratings GuideMd ShОценок пока нет

- Repair of A Hull 15 M Below The WaterlineДокумент8 страницRepair of A Hull 15 M Below The WaterlineRonny De La CruzОценок пока нет

- Manual MERCRUISER QSD 2.0L DIESEL ENGINE Service Repair Manual SN 88200000 and AboveДокумент100 страницManual MERCRUISER QSD 2.0L DIESEL ENGINE Service Repair Manual SN 88200000 and AboveWallace Ferlim100% (6)

- Structural Mechanics NotesДокумент6 страницStructural Mechanics NotesAiden A. CunninghamОценок пока нет

- Panasonic Servisni Manual SXC 9-12 KWДокумент136 страницPanasonic Servisni Manual SXC 9-12 KWzimroviОценок пока нет

- Pneumatic HammerДокумент7 страницPneumatic HammerShlok PatelОценок пока нет

- Structures Module 3 Notes FullДокумент273 страницыStructures Module 3 Notes Fulljohnmunjuga50Оценок пока нет