Академический Документы

Профессиональный Документы

Культура Документы

1974 Austin Marina 1973-74

Загружено:

vixentd0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров3 страницыService manual

Оригинальное название

1974_Austin_Marina_1973-74

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документService manual

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров3 страницы1974 Austin Marina 1973-74

Загружено:

vixentdService manual

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

Drive Axles 73

1973-74 AUSTIN MARINA

‘Austin Marina (1973-74)

DESCRIPTION

Rear axles are hypoid design with center line of pinion set

below centerline of ring gear. The axle shafts, pinion ond

differential assemblies can be serviced without removing axle

‘trom vehicle. All differential adjustments are performed using

shims. No adjustment for axle shaft end play is necessary,

AXLE RATIO & IDENTIFICATION

‘Only one basic axle design is used on these models. To

determine axle ratio, divide number of ring gear teeth by

number of pinion gear teeth,

REMOVAL & INSTALLATION

AXLE SHAFTS & BEARINGS

1) With rear of vehicle raised and wheel removed, remove

foxle shaft nut and washer. Remove screws retaining brake

‘drum ond remove drum. Withdraw rear hub from axle shaft

Using suitable tool. Disconnect handbrake cable ond broke

pipe. Remove nuts, washers ond bolts retaining brake

backplate to axle housing

2) Note installed position of drip lip in relation to brake slave

cylinder and remove oil catcher and backplate. assembly

Remove rear hub oil seal and hovsing assembly. Remove ol

seal from housing using suitable tool. Remove axle shatt key

fond ploce container under axle to collect oil spillage

Withdrow oxle shaft from housing, using suitable puller.

Remove inner oil seal and press bearing from oxle shaft

3) Pack beoring with lithium based grease ond dip new oil

Seal in light oil before reassembling, Install new oil seal with

lip of seal facing inwards. Press bearing onto axle shaft until

dimension from bearing to threaded end of axle shaft is to

specifications. Continue assembling in reverse of disossembly

Using @ new rear hub joint washer and using “Loctite LT 270"

for equivalent on axle shoft nut

PINION FLANGE & SEAL

1) Roise ond support rear of vehicle. Mark propeller shaft and

pinion flanges for correct realignment. Disconnect propeller

Shaft ond remove flange nvt split pin. Retain flonge using

suitable tool and remove nut and washer.

2) Place container under flange to collect cil spillage ond

remove flange and oll seal, To install, reverse removol

procedure noting the following: Soak new seal in light oil for

fone hour before installing. Install seal with lip of seal facing

inwards

DIFFERENTIAL CARRIER

Remove both axle shafts and mark differential pinion ond

propeller shoft for proper realignment on assembly

Disconnect propeller shaft. Ploce container under axle

‘ossembly to collect il and remove nuts and washers retaining

carrier to oxle housing. Remove carrer. To reinstall, reverse

removal procedure, ving @ new gasket ond witebe gosket

OVERHAUL

DISASSEMBLY

1) With carrier removed, mount unit upright in @ vise and

mark bearing cops for correct reassembly. Remove bearing

cap bolts, washers and caps, Astemble suitable oxle stretcher

(186-131) on unit casing and stretch unit case by tightening

turnbuckle three or four flats until differential carrier can be

levered out and bearing shims and cops removed. CAUTION

"To aveid damaging case, do not spread any more than

necessary. Maximum stretch is .008" (.20 mm). Do not pry

‘agains stretcher.

2) Remove gear corrier bearing caps and mark ring gear ond

carrier to ensure correct replacement. Remove ring gear

retaining bolts and ring gear. Drive out pinion shaft locking

pin, then drive out pinion shaft. Remove pinion gears and

thrust washers. Remove differential gears ond thrust washers.

Remove drive flange nut cotter pin and drive flange nut. Using

suitable puller, remove drive flange.

3) Press out drive pinion and remove pinion bearing shims ond

‘spacer. Using suitable press tools, remove inner bearing from

Binion, Remove pinion head washer and drift out pinion outer

beoring cup, bearing ond oil seal. Drift out pinion inner beor-

ing cup,

INSPECTION

CClean and inspect all components for wear or damage. Ring

‘and pinion gears, differentiol bearings ond pinion beorings

must be replaced as matched sets.

REASSEMBLY & ADJUSTMENT

Side Bearing Preload — 1) Instll differential beoring cones

jn geor carrier using suitable tool. Install two differential

‘gears in cartier, ensuring each thrust washer is correctly

positioned. Position two pinion gears, one each side of carrer

fond mesh them with diferentiol gears. Using an oxle shaft in-

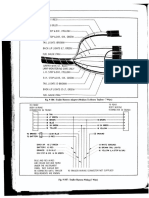

Diol Indicator

CHECKING RUNOUT & TOTAL SIDE FLOAT

‘ipo 200 Rapa ema Campa

14 Drive Axles

1973-74 AUSTIN MARINA (Cont.)

serted in a differential gear, turn gears and ensure two

pinions rotate into mesh and align with pinion shaft hole in

Earrie. Install pinion shaft

2) Press each pinion firmly into mesh with differential gears

fond assess required pinion thrust washer thickness required to

‘ochieve ZERO backlash. Remove pinion shaft ond pinions ond

install thrust washers. Reinstall pinion gears and shafts with

‘thrust washers and check that zero backlash exists. Lubricate

‘components and install pinion shah locking pin and secure by

peening metal of differential carrier

3) Clean ring gear mounting ond carrier face and install ring

‘gear, tighten bolts. Assemble carrier bearing cups to bearings

‘ond position assembly in case; do not install bearing shims

Install bearing cops in correct position. Using diol indicator

‘ond suitable adopters, ensure that ring gear runout does not

‘exceed specifications. Remove bearing cops and press

differential bearing cups onto bearings ond move carrier

‘ossembly to one side of case. Zero dial indicator ond move

corrier assembly fully in opposite direction. The indicator

reading should be noted for future reference as “Total Side

Float”. Remove differential assembly from cate.

Drive Pinion Depth — 1) Install inner and outer pinion

bearing cups to case using suitable tool. Install pinion inner

beating to dummy pinion (186-191 M). NOTE — Dummy

pinion incorporates stondord pinion head washer of .077"

(1.95 mm) thickness. Oil bearing ond install dummy pinion,

outer bearing, tool spacer, washer and nut. Tighten nut

gradually until bearing preload specification is obtained

Clean dummy pinion head ond postion dial indicator gavge

foot of tool 186-191 on dummy head and zero indicator,

Dummy Pinion

CHECKING PINION DEPTH

2) Move dil indicotor over center of one differential bearing

bore and note reading. Repeot for opposite bearing bore.

‘Average these two measurements and perform the following

calevlation:

EXAMPLE

‘Average of bore measurements £002" (.051 mm)

PLUS dummy pinion washer allowance... 077" (1.956 mm)

Required size of pinion head washer... .079" (2.007 mm)

If the etched marking on pinion face is "N" (normal), no

change to above dimension is requried. If etched marking is

postive (+), reduce size of required pinion washer by amount

‘marked. I etched marking is negative (—], increase size of

required pinion washer by amount marked. Remove dummy

pinion and remove inner bearing from dummy pinion.

Pinion Bearing Preload — 1) Place selected pinion head

‘washer on pinion and install inner bearing using suitable tools

Oil bearing ond install pinion in cose. Instoll bearing spacer,

chamfered end towards drive flange, Install shims oll ond in

stall outer bearing. Install drive flange washer ond nut

Gradvally tighten nut, but do not exceed torque specification,

‘ond check preload during tightening operation.

2) Rotate flonge to settle beoring and check preload with

flange aut tightened to specifications. If prelood is high, in-

crease shim thickness. If preload is low, decrease shim

thickness, NOTE — .001" shim thickness equals approximately

4 INCH lbs. (4.8 emkg) preload. Remove drive flange nut and

flange. Soak new oil eal in oil for one hour and then install

seal. Install drive flange, washer ond nut and tighten flange

‘ut, Install new cotter pin

Diol Indicator

Adopter

CHECKING BACKLASH

Adjusting Backlash ~ 1) Place bearing cups on differential

bearing and install carrier in case. Position diol indicator with

svitable adopters on ring gear side of case. Move ring gear

{ully into mesh with pinion and zero indicator on reer of ring

‘gear. Move ring gear ond carrier in opposite direction until

bearing ring gear side is butted in housing. The indicated

‘measurement should be noted os the “In-Out” mesh clearance,

‘ipo 200 Rapa ema Campa

Drive Axles

1973-74 AUSTIN MARINA (Cont.)

Dy

3AS03

Adopter

CHECKING "IN-OUT" MESH CLEARANCE

2) Perform the following coleulation:

EXAMPLE

"In-Out" mesh clearance®. 025" (.63 mm)

MINUS Specified backlash (005" (.13 mm)

Required ring gear side shim pack. 020" (.50 mm)

"Total Side Float" is (060° (1°52 mm)

MINUS ring geor side shim pack. (020° ('50 mm)

Required shim pack opposite ring gear... -040" (1.02 mm)

© — Value from 2) above

© — Volue from 2} under “Side Bearing Prelood”

‘Add @ value of .002" (.51 mm) to each shim pack colculet

‘obove for preload.

3) Stretch cose specified amount and from calculations made

‘above, select required shim pack. Install differential ossembly

jn cate with shim packs. Loosen case stretcher and remove.

Install bearing cops 0: originelly marked and tighten bolts.

Rotote pinion to setile differential bearings and position dial

indicator using suitable adapters to measure ring gear

backlash, Measure backlash af several locations, it must be to

specifications. If not, interchange shims from side to side to

‘achieve specified backlash. NOTE — A movement of .002"

{.05 mm) shim thickness from one bearing fo the other will vary

backlash by about .002" (.05 mm). Reinstall differential

‘ossembly in tear axle housing

‘AXLE ASSEMBLY SPECIFICATIONS

Bearing-to-Threaded End of Axle Shaft. 2.84" (69.94 mm)

Ring Gear Runou (003" (.076 mm)

Pinion Bearing Preload.... 15-18 INCH tbs. (17-21 emkg)

Ring Gear Backlash (005+.001" .13:4.02 mm)

TIGHTENING SPECIFICATIONS

Application Fr. Lbs. (mkg)

Brake Backplate Nuts 223)

Axle Shatt Nut 105 (14.5),

Carrier Mounting Nuts 23)

Pinion Flange Not... 90(12.4)

‘ipo 200 Rapa ema Campa

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- CK30 WM 00 GeneralДокумент54 страницыCK30 WM 00 GeneralvixentdОценок пока нет

- B44, B25, C25 Series 1967 Workshop Manual 00-4136 X PDFДокумент158 страницB44, B25, C25 Series 1967 Workshop Manual 00-4136 X PDFvixentdОценок пока нет

- CK30 WM 02 EngineДокумент62 страницыCK30 WM 02 EnginevixentdОценок пока нет

- BSA InstructionДокумент55 страницBSA InstructionvixentdОценок пока нет

- CK30 WM 03 ClutchДокумент16 страницCK30 WM 03 ClutchvixentdОценок пока нет

- 1977 BMW Integral CarrierДокумент3 страницы1977 BMW Integral CarriervixentdОценок пока нет

- 1975 BMW Integral CarrierДокумент5 страниц1975 BMW Integral CarriervixentdОценок пока нет

- 1976 BMW Split HousingДокумент5 страниц1976 BMW Split HousingvixentdОценок пока нет

- 1977 BMW Split HousingДокумент5 страниц1977 BMW Split HousingvixentdОценок пока нет

- 1975 BMW CourierДокумент3 страницы1975 BMW CouriervixentdОценок пока нет

- 1975 BMW Split HousingДокумент5 страниц1975 BMW Split HousingvixentdОценок пока нет

- 1976 BMW Integral CarrierДокумент5 страниц1976 BMW Integral CarriervixentdОценок пока нет

- 1974 BMW Capri 1971-74Документ3 страницы1974 BMW Capri 1971-74vixentdОценок пока нет

- 1972 American Motors 1968-74 All Models PDFДокумент2 страницы1972 American Motors 1968-74 All Models PDFvixentdОценок пока нет

- 1974 Al All ModelsДокумент1 страница1974 Al All ModelsvixentdОценок пока нет

- 1972 All Manufacturers 1971-73 All Models PDFДокумент3 страницы1972 All Manufacturers 1971-73 All Models PDFvixentdОценок пока нет

- 78 Olds CSMCHPT 08Документ94 страницы78 Olds CSMCHPT 08vixentdОценок пока нет

- 1974 Austin Sprite 1968-70Документ3 страницы1974 Austin Sprite 1968-70vixentdОценок пока нет

- 1982 All Others LiftgateДокумент2 страницы1982 All Others LiftgatevixentdОценок пока нет

- 1972 American Motors 1968-74 All Models PDFДокумент2 страницы1972 American Motors 1968-74 All Models PDFvixentdОценок пока нет

- 05 NCFДокумент12 страниц05 NCFvixentdОценок пока нет

- 78 Olds CSMCHPT 07Документ325 страниц78 Olds CSMCHPT 07vixentdОценок пока нет

- 8A6-12 TORONADO INSTRUMENT PANEL AND SPEEDOMETER GEAR CHARTДокумент64 страницы8A6-12 TORONADO INSTRUMENT PANEL AND SPEEDOMETER GEAR CHARTvixentdОценок пока нет

- 1982 All Others Multiplex TypeДокумент2 страницы1982 All Others Multiplex TypevixentdОценок пока нет

- 1972 All Manufacturers 1974 All ModelsДокумент4 страницы1972 All Manufacturers 1974 All ModelsvixentdОценок пока нет

- 78 Olds CSMCHPT 07Документ325 страниц78 Olds CSMCHPT 07vixentdОценок пока нет

- 1972 All Manufacturers 1972-73 All ModelsДокумент3 страницы1972 All Manufacturers 1972-73 All ModelsvixentdОценок пока нет

- 78 Olds CSMCHPT 10Документ10 страниц78 Olds CSMCHPT 10vixentdОценок пока нет

- 78 Olds CSMCHPT 11Документ8 страниц78 Olds CSMCHPT 11vixentdОценок пока нет