Академический Документы

Профессиональный Документы

Культура Документы

1975 BMW Integral Carrier

Загружено:

vixentd0 оценок0% нашли этот документ полезным (0 голосов)

57 просмотров5 страницService manual

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документService manual

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

57 просмотров5 страниц1975 BMW Integral Carrier

Загружено:

vixentdService manual

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

Drive Axles 1

BMW INTEGRAL CARRIER

2002 Series

DESCRIPTION

Differential has hypoid ring and drive pinion geor set and

may hove a clutch pack type limited sip unit. Differential

housing hes removable rear cover. Differential carrier is

retained in the sides of the housing by retaining plates, and is

jpported by roller bearings. Drive pinion gear is supported

by roller bearings, and in addition, along neck housing hos @

ball bearing supporting the drive pinion at the companion

flange. Drive pinion preload is maintained by @ collapsible

in the short neck housing, and by a spacer ond shims in

long neck housing.

AXLE RATIO & IDENTIFICATION

The ring and pinion gear set with Klingelnberg tooth design,

bbe identified by the letter “K" stamped on the head of the

ited by an "H" or "F

pi

th on ring and drive pinion gears is stomped on

left side of differential housing

REMOVAL & INSTALLATION

DRIVE SHAFTS & UNIVERSAL JOINTS.

Remove drive shaft after removing retaining bolts from axle

‘and half shaft flanges. For universal joint or dust boot replace-

ment, use the appropriate procedure below.

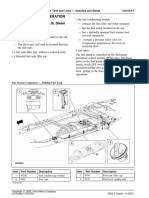

Long Neck Housing

With Limited Slip i

Short Neck Housing

Standard Differential Gear Set

Fig. 1 Exploded View Of BMW 2002 Standard ond Limited Slip Differential Assemblies

‘opr 200

78 Drive Axles

BMW INTEGRAL CARRIER (Cont.)

Constant Velocity Joint — Remove cover trom joint housing,

then remove snap ring from end of driveshaft. Remove clamps

{rom boot then press driveshaft from jint. Remove dust boo.

To install, reverse removal procedure Using euler on book 1o-

joint surfaces and install seal cover after packing joint with

itable greose.

Sliding U-Joint ~ Drain eil from joint, note position of hose

clamps, then remove clamps. Pull off housing ond roller caps

‘and coat needle bearings with grease. Remove dust boot from

spacer ring and then remove boot and ring, To install, reverse

removal procedure, locating hose clomps in original position

Cross and Roller U-Joint - NOTE — It yoke is bent or

‘twisted, complete drive shaft must be replaced. Remove

bearing cup snap rings, then press out beoring cups vsing

suitable orbor press or vise and supporting fools. Remove

cross assembly from yoke. To install, hold cross between ears

‘of drive shaft and partially install two bearing cups. Align

«ross with cups, then using orbor pressor vse, press cups into

yoke uni snap rings con be inserted

AXLE SHAFTS & BEARINGS

Raise and support vehicle. Remove wheel, loosen castellated

rut securing flange to axle shaft, then using a suitable puller,

remove flange. Remove drive shaft, then using a soft headed

mallet, drive axle shaft inward and out of housing. Drive out

bearings and seals, then remove spacer sleeve and shim. To in

stall, reverse removal procedure noting the following: Install

inner bearing, then determine distance between outer races of

inner and ovter bearings. Meature spacer and shim, then in

stall spacer and o suitable shim that will obtain a wheel bear-

ing ploy of .002-.004" (.05..10 mm). Pack bearings and hub

with suitable grease, then using new seals, complete installa

tion procedure,

Spocer

Shim Seal

Fig. 2. Sectional View of Axle Shaft Assembly

DRIVE PINION COMPANION FLANGE OIL SEAL

TE — On short neck differential hovring, complete

jsassembly of differential is required for seal replacement.

Refer to Drive Pinion Ger Removal and Installation

procedures for sal replacement.

19 — Remove propeller shoft,

ing companion flange on drive pinion gear, compa:

rion flange, and seal. To install, reverse removal procedure in-

{uring s00l installed depth is 24" (6 mm) from Front of seal to

front edge of housing.

AXLE FLANGE & OI SEAL

Removal ~ Remove drive shaft. Hold oxle flange using

suitable tools (604 wrench; 6040 Spacer) then remove flange

fetaining bolt. Using a suitable puller (20/10) and support

bracket (7011-1) remove axle flange. Remove oil seal

Fig. 3 Removing Axle Drive Flange

Installation — Fill between seoling lips of seal with greose,

then install seal in retaining plate to a depth of 16” (4 mm).

Thoroughly clean flange and carrier splines ond if any

backlash between splines exists, apply small amount of lock-

ing compound to flange splines. Install flange and retaining

bolt

DIFFERENTIAL ASSEMBLY

Remove propeller shaft and drive shafts, tie drive shafts up out

‘of way. Support differential ond remove four frame-to-

housing attaching bolts, two differential cover-to-bracket nuts,

‘and two bracket-to-frame bolts. Remove differential assembly.

To install, reverse removal procedure, insuring rear bracket is

stress free when insolled.

OVERHAUL

DISASSEMBLY

Differential Housing ~ Remove differential ossembly os

previously outlined, and mount assembly in suitable holding

fixture. Drain oil and mark drive pinion shaft and companion

flange for reosiembly reference. Remove rear cover plate.

Remove both oxle flanges, os previously described, keeping

right and let side parts separated. Mount o diol indicotor to

housing, and check ring gear runout for reference at time of,

Drive Axles 79

BMW INTEGRAL CARRIER (Cont.)

reastembly. Make @ gear tooth pattern check. NOTE — Refer

fe Rear Axle Gear Tooth Patterns in this section. Mark and

remove carrier bearing retainer plates and shims. Turn hous-

ing rear opening upward, move carrier to right side, tit and

remove cartier from housing. Proceed as follows for standard

‘oF limited sip differential carrer disassembly.

Fig.4 Checking Ring Gear Backlash

Standard Differential Carrier — Remove carrier beorings

Using suitable puller (Rollex LMS03349). Remove bolts secur-

ing ring gear to corrier, then remove ring gear. Drive out pi-

rion shaft lock pin, remove pinion gears shaft and pinion

(gears. Remove side gears with shims and thrust washers.

Fig. 5 View of Assembled Limited Slip Unit

With Case Removed

Limited Slip Differential Carrier ~ Remove car

‘using suitable puller (HM 89449). Remove bolts

cover fo ring gear flange, invert case and lift case off clutch

‘ond geor assembly. Separate ring gear from flange. Remove

clutch components, lif off hub, remove side gear and one set

of pinion geors. Repeat procedure for other half of case.

‘ipo 0 200 a Rea

Hyb

Spacer

Inner Disc Thrust Washer

(Oil Grooves Up)

Outer Dise

Fig. 6 View of Disassembled Clutch Pack

Side Gear

ey

Pinion Geors ~

Fig. 7 View of Limited Slip Side and Pinion Gear Assembly

Drive Pinion Gear — 1) Remove differential carrier as

previously outlined, then using an inch pound torque wrench,

check preload on drive pinion gear. Hold companion flange

‘ond remove retaining nut. Press drive pinion from flange ond

housing, then remove beotings. NOTE — On long neck

housing, first eemove flange nut, flange, cover and shim. Using

{2 suitable too! (6046) remove drive pinion lock nut, then press

gear out

Componion

Tene" Cover Shim

as) Cd

oy

ci

Fig. 8 Sectional View of Long Neck Housing

Pinion Shalt Front Bearing Assembly

7-10

Drive Axles

BMW INTEGRAL CARRIER (Cont.)

2) Remove drive pinion shaft oil seal then using suitable tools

($109 '& 5120) press drive pinion outer bearing cones from

housing. NOTE — On short neck housing, remove rear bearing

cone first. On long neck housing, remove forward bearing

cone fist.

REASSEMBLY & ADJUSTMENT

Differential Assembly — Reverse disassembly procedure

‘noting the following checks ond adjustments

Shim

‘Companion

Flange

Fig. 9 Sectional View of Short Neck Housing

Drive Pinion Gear Assembly

ing o

is being installed determine correct size of shim to use

following manner: Drive pinion gears may be stamped

“E123, ete", oF "1.2.3, ete”. Compare marks on topered

tends of old and new gears. Subtract the two numbers. In rela

tion to original shim, © plus remainder means a thinner shim is

required; @ minus remainder means a thicker shim is required.

Bearing Shim

Fig. 10 Sectional View of Long Neck Housing Drive Pinion

Gear and Rear Bearing Assembly

2) Remove then reinstall drive pinion, bearings, and cones, as

required, s0 new shim(s), collapsable spacer, and seal can be

installed. NOTE — On long neck housing, preload must be es:

tablished with pinion lock nut before installing front housing

cover.

‘ipo 0 200 a Rea

3) Install companion flange and nut (short neck housing), or

pinion lock nut (long neck housing) and tighten nut to obtain

Specified preload. NOTE ~ If preload is exceeded, new

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 1955 56 57 SpecsДокумент9 страниц1955 56 57 SpecsvixentdОценок пока нет

- 1982 All Others Multiplex TypeДокумент2 страницы1982 All Others Multiplex TypevixentdОценок пока нет

- CK30 WM 03 ClutchДокумент16 страницCK30 WM 03 ClutchvixentdОценок пока нет

- BSA InstructionДокумент55 страницBSA InstructionvixentdОценок пока нет

- CK30 WM 00 GeneralДокумент54 страницыCK30 WM 00 GeneralvixentdОценок пока нет

- 78 Olds CSMCHPT 08Документ94 страницы78 Olds CSMCHPT 08vixentdОценок пока нет

- 78 Olds CSMCHPT 07Документ325 страниц78 Olds CSMCHPT 07vixentdОценок пока нет

- B44, B25, C25 Series 1967 Workshop Manual 00-4136 X PDFДокумент158 страницB44, B25, C25 Series 1967 Workshop Manual 00-4136 X PDFvixentdОценок пока нет

- 78 Olds CSMCHPT 07Документ325 страниц78 Olds CSMCHPT 07vixentdОценок пока нет

- 78 Olds CSMCHPT 09Документ64 страницы78 Olds CSMCHPT 09vixentdОценок пока нет

- F-Super Duty/Excursion 2004 - Early Build 6.0L Power Stroke Diesel Engine Performance Diagnostic GuideДокумент1 страницаF-Super Duty/Excursion 2004 - Early Build 6.0L Power Stroke Diesel Engine Performance Diagnostic GuidevixentdОценок пока нет

- 6.0 Late 2004 Hardstart - Nostart - DiagnosticsДокумент1 страница6.0 Late 2004 Hardstart - Nostart - DiagnosticsvixentdОценок пока нет

- Vehicle Name Component Global Tool Number NA Number DescriptionДокумент1 страницаVehicle Name Component Global Tool Number NA Number DescriptionvixentdОценок пока нет

- Superduty 6.0L Powerstroke Engine: Removal/Installation Service TipsДокумент21 страницаSuperduty 6.0L Powerstroke Engine: Removal/Installation Service Tipsvixentd100% (1)

- 6.0 PSD E-Van Fuel PumpДокумент3 страницы6.0 PSD E-Van Fuel PumpvixentdОценок пока нет

- 6.0 E-Van Fuel Pump and LinesДокумент2 страницы6.0 E-Van Fuel Pump and LinesvixentdОценок пока нет

- Electrical Wiring Power Take-Off Circuit Installation: Return To Body Builders Layout Book INDEXДокумент1 страницаElectrical Wiring Power Take-Off Circuit Installation: Return To Body Builders Layout Book INDEXvixentdОценок пока нет

- W123 716 Manual Transmission ManualДокумент163 страницыW123 716 Manual Transmission ManualvixentdОценок пока нет

- 337 and 341 EXCAVATOR Wiring Schematic: Left Hand Console Harness - 6806191Документ6 страниц337 and 341 EXCAVATOR Wiring Schematic: Left Hand Console Harness - 6806191vixentd100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)