Академический Документы

Профессиональный Документы

Культура Документы

Aug 05 Case History Reitz

Загружено:

rahulАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aug 05 Case History Reitz

Загружено:

rahulАвторское право:

Доступные форматы

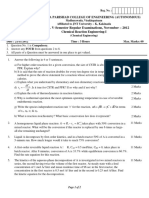

JFAPBC (2005) 4:20-25

DOI:

10.1361/154770205X55126

Failure

Analysis of Brass Bolt

from

ASM International

1547-7029 / $19.00

Mausoleum (continued)

Failure Analysis of Brass Bolt from Mausoleum

W. Reitz

(Submitted June 3, 2005; in revised form June 13, 2005)

Brass is usually considered to be a good candidate material for use in a nonaggressive corrosion

environment. Brass 260 was used in a rural environment (at a mausoleum) as fixturing hardware that

holds etched marble slabs that cover the interment region. After 12 years of service, the bolts began

breaking, and the marble slabs crashed to the ground. Failure analysis investigation showed that

seasonal cracking occurred due to interaction of the bolt with moisture and fertilizer. The company

that designed the mausoleum hardware believed that the bolt manufacturer was at fault. However, the

only specification given to the bolt manufacturer indicated alloy and dimensions. The bolts were

replaced at considerable cost, proving once again that even a seemingly simple component can prove

to be costly if not designed by the proper engineer.

Keywords: brass, corrosion, corrosion failure analysis, failure analysis, residual stress, stress-corrosion cracking

Introduction

A company reported that brass bolts used in two

mausoleums were failing. Failure of these bolts

resulted in crypt-front marble slabs crashing to the

ground. Fortunately, no one was present when the

slabs fell; thus, no injuries were associated with the

failures. However, the probability existed that eventually someone could be injured.

The bolts were manufactured from cartridge

brass (C26000) and were beginning to fail after 8

to 12 years of service. Several failed bolts along with

several unused bolts were examined. Figure 1 shows

an unused bolt with cold-forged nut. Figure 2

shows the assembly drawing.

Results and Discussion

The metallurgical examinations of the bolts included chemical analysis, macroscopic and microscopic examination using optical and scanning

electron microscopy, and both tensile and hardness

testing.

Chemistry results are presented in Table 1. The

bolts P-14 and P-15 were pulled from service, and

chemistry results showed that they were Copper

Development Association (CDA) 260, except that

high iron content was present as compared to the

specification for cartridge brass. It has been shown

that high iron promotes grain refinement and increases resistance to dezincification.[1]

Fig. 1

Unused bolt, 3/8 16 threads per inch by 2 in. (9.5 by

57.2 mm) long, with cold-worked nut integral with

bolt

Several fractured bolts were provided from the

mausoleums that had been in service for 8 to 12

years. They all exhibited the same fracture appearance, and typical bolts are shown in Fig. 3 and 4.

In all instances, the short, threaded end of the bolt

fractured at the top of the nut. Table 2 lists the

hardness of each bolt. These values were obtained

on one end of each bolt. The minimum and maximum values were 82 and 97 RB, respectively. A

sample of blank material was obtained from the bolt

manufacturer. The hardness of the blank material

prior to final forging was softer, as was expected.

Three unused bolts were tensile tested, and the

ultimate tensile strengths were 385, 393, and 394

MPa (55,800, 57,000, and 57,100 psi). These

tensile strengths were considerably lower than the

W. Reitz, Reitz Consulting, Ltd., 96 Meadowlark Lane, Fargo, ND 58102. Contact e-mail: reitzconsulting@cableone.net.

20

Volume 5(4) August 2005

Journal of Failure Analysis and Prevention

equivalent tensile strength for 92 R B hardness

(average hardness). Tensile failures occurred in the

threaded portion of the bolt; the tensile failure

locations were not similar to the failure sites of the

Table 1

Chemistry Results

Cu

Pb

Composition, wt.%

Sn

Fe

Zn

70.10

70.30

0.06

0.04

<0.01

<0.01

0.13

0.09

bal

bal

68.5-71.5

<0.07

<0.05

bal

Material

P-14

P-15

Specification of CDA 260

(cartridge brass)

Fig. 2

used bolts. The low tensile values were related to the

fact that the bolt had threads that acted as regions of

stress concentration, which lowered the performance

of the material.

Assembly drawing

Journal of Failure Analysis and Prevention

Volume 5(4) August 2005

21

Failure Analysis of Brass Bolt from Mausoleum (continued)

Fig. 3

As-received fractured bolt (M-1; M, mausoleum located

in Michigan)

Table 2

Fig. 4

As-received fractured bolt (P-3; P, mausoleum located in

Pennsylvania)

Rockwell Hardness Values

Bolt(a)

Hardness, RB

Bolt(a)

Hardness, RB

Prior to final forge

59, 65

P-5

95

M-1

88

P-6

93

M-2

97

P-7

94

M-3

95

P-8

92

P-1

96

P-9

91

P-2

97

P-10

94

P-3

96

P-11

93

P-4

96

P-12

82

(a) M, mausoleum located in Michigan; P, mausoleum located in Pennsylvania

Bolt(a)

Hardness, RB

P-13

P-14

P-15

P-16

P-17

P-18

P-19

90

83

88

93

97

94

92

Several bolts were sectioned through the forged

nut and evaluated metallographically. Figure 5

shows a typical macroscopic view of the sectioned

bolts. There appeared to be a difference in grain

structure related to the manufacturing process;

heavier cold work and a corresponding higher

strength appeared in the forged nut region.

Figures 6 and 7 show the macroscopic cross

sections of two used bolts that were retrieved from

the mausoleum prior to fracture. (Several bolts were

retrieved at random. Two bolts were severely

cracked, while the remaining bolts were free of cracks

or defects.) These cracks followed the same path as

the bolts that failed in service (Fig. 8). The cracks

22

Volume 5(4) August 2005

Fig. 5

Macroscopic view of forged bolt showing various levels

of cold work

Journal of Failure Analysis and Prevention

in Fig. 6 and 7 followed the interface between the

duplex grain structures. This interface between

large grains and small grains causes the grain

boundaries at the interface to line up, which facilitates crack propagation.

The grain structure in the threaded region of the

bolt, which received less cold work than the forged

nut region, possessed larger grain size and lower

microhardness. The microhardness for two bolts is

tabulated in Table 3.

Intergranular cracking was readily apparent, as

shown in Fig. 9(a) and (b). The main crack is

intergranular, and secondary intergranular cracking

is present in numerous locations. Stress-corrosion

Fig. 6

Table 3

Microhardness (Equivalent RB) of

Two Retrieved, Cracked Bolts

Bolt P-12

Bolt P-4

61

61

60

73

73

Crack

76

82

79

87

89

90

85

79

(a) Broken end missing

(a)

Fracture

67

89

80

82

85

87

84

71

58

Cracked bolt (P-12)

(a)

Fig. 7

Cracked bolt (P-8)

(b)

Fig. 9

Fig. 8

Bolt that failed in service

Journal of Failure Analysis and Prevention

(a) Intergranular cracking via optical microscopy. Scale

marker is 100 m. (b) Intergranular cracking via

scanning electron microscopy. Scale marker is 10 m.

Volume 5(4) August 2005

23

Failure Analysis of Brass Bolt from Mausoleum (continued)

cracking (SCC), also known as seasonal cracking,

occurred on the failed bolts.[2] Seasonal cracking

was first observed in brass cartridge cases in India

that were adjacent to a horse stall during the

monsoon season. This was the first evidence that

ammonia caused SCC in brass. Three criteria are

necessary for SCC to occur: the presence of stress,

a corrosive environment, and a material susceptible

to SCC. Brass is known to be susceptible to SCC

when ammonia is present. Ammonia can be present

in the atmosphere in minute quantities that are

difficult to measure. Bacteria as well as fertilizer

can be sources of ammonia. Another environmental

concern is an alkaline atmosphere (lithium, sodium,

potassium, rubidium, cesium) that may leach from

the concrete during rainy weather. The stress is

present due to residual stress from cold forging and/

or overtorquing of the jam nut during assembly.[3]

Witnessing the retrieval process revealed that a

strong groundskeeper worked hard to loosen the

bolts. This obser vation is consistent with

overtorquing during installation. All of the failed

bolts came from areas of the mausoleum that were

exposed to the environment: for example, wind,

rain, and birds. Overtorquing of the bolts is

completely unnecessary. It may not be obvious from

the assembly drawing (Fig. 2), but the weight of

the marble slab is carried by the brackets underneath. The bolts in question (item 11 in Fig. 2) do

not carry any load; they merely keep the marble

slab in a vertical position.

The assembly page is the extent of the specification for the bolt. Basically, only dimensional

information is specified; strength and environment

are not noted. The bolt manufacturer supplied a

dimensionally correct bolt.

Stress-corrosion cracking initiated at the heavily

cold-worked transition region between the forged

nut and the outside diameter of the threaded bolt,

as shown in Fig. 10. This region possesses high

residual stress. The cracking continued along the

interface between the high-cold-worked and lowcold-worked regions. The amount of ammonia in

the atmosphere to cause seasonal cracking is not

known.[4] The amount may be very small, and cracking may occur after prolonged exposure. Intergranular cracking is prevalent.[5]

Conclusions/Recommendations

Conclusions/recommendations from this failure

analysis are:

Stress-corrosion cracking occurred in the subject

bolts. Three criteria are required for SCC: corrosive environment, stress, and susceptible material.

Removing any one of these three criteria will

prevent SCC from occurring.

Minimize residual stress: Reduce torque values

used in assembly at the mausoleum; perform

stress-relief annealing after cold forming of the

bolt.

Minimize the presence of a corrosive environment

(rainwater leaching concrete chemicals and carrying fertilizer residue and bird droppings).

Change the bolt material: Consider low-zinc

brass, tough-pitch copper, or oxygen-free highconductivity copper.

Some of the remaining bolts in service will continue to fail due to SCC, especially those that

are exposed to rain.

Fig. 10 Heavily cold-worked grains. Scale marker is approximately 100 m.

24

Volume 5(4) August 2005

The bolts were manufactured without any specifications and without the bolt supplier knowing

the end use (true for most of the hardware). In

this particular case, hindsight is once again

perfect. The company should have provided a

detailed specification for critical components, but

Journal of Failure Analysis and Prevention

this component was not considered critical until

unexplained failures occurred.

References

1.

U. Borggren and M. Selleby: A Thermodynamic Database

for Special Brass, J. Phase Equilibria, 2003, 24(2), pp.11021.

2.

G. Pantazopoulos: A Review of Defects and Failure in

Brass Rods and Related Components, Prac. Fail. Anal.,

2003, 3(4), pp. 1-22.

3.

R.G. Baggerly: Evaluating the Effects of Overtorque in

Bolts, Prac. Fail. Anal., 2001, 1(1), pp. 41-46.

4.

T. Rakich: Copper Development Association, private

communication, Sep 11, 2003.

5.

J.M. Popplewell and T.V. Gearing: Stress Corrosion

Resistance of Some Copper Based Alloys in Natural

Atmospheres, Corrosion, 1975, 31(8), pp. 279-86.

Final Note

The company has had to replace most of the

retaining bolts at these two sites, at great expense.

A review of the drawings prior to ordering these

components may have prevented these failures and

the replacement expense, but it would have taken

a very experienced metallurgist to have predicted

this outcome. Nevertheless, obtaining the services

of mechanical engineers for loading evaluations and

metallurgists for materials property knowledge can

minimize cost down the road.

ASM Handbook of Case Histories in Failure Analysis,

Edited by Khlefa A. Esaklul ASM Publication

Vol. 1 and Vol. 2

Learn how others have solved common and uncommon failures in various industries

such as automotive, aerospace, utilities, oil and gas, petrochemical, biomedical,

ground transportation, off-highway vehicles, and more. Each case history

adheres to a standard format that guides you step-by-step through the failure

investigation.

Volume 1

Volume 2

1992 504 pages

ISBN: 0-87170-453-6

1993 583 pages

ISBN: 0-87170-495-1

Contains 115 never-before-published case

studies conducted by experts worldwide.

Presents more than 120 case histories.

Order #06340G-RPADPFAJ

Order #06410G-RPADPFAJ

Price: $195.00

ASM Member $156.00

Price: $195.00

ASM Member $156.00

Ordering Information:

Call ASM Customer Service Center, toll-free 800/336-5152, ext. 5900 OR

440/338-5151, ext. 5900. Fax: ASM International, Attn: Customer Service Center:

440/338-4634. Online: Visit the ASM website at: www.asminternational.org.

Journal of Failure Analysis and Prevention

SET SALE

Order #06391G-RPADPFAJ

2-Volume Set $343.00

ASM Member $275.00

Volume 5(4) August 2005

25

Вам также может понравиться

- Drawing 1Документ1 страницаDrawing 1rahulОценок пока нет

- CL 651 A Measurement Systems-SET 1Документ1 страницаCL 651 A Measurement Systems-SET 1rahulОценок пока нет

- APC c1-20Документ1 страницаAPC c1-20rahulОценок пока нет

- CL 651 A Measurement Systems-SET - 2Документ1 страницаCL 651 A Measurement Systems-SET - 2rahulОценок пока нет

- AI SyllabusДокумент1 страницаAI SyllabusrahulОценок пока нет

- CL 651 A Measurement Systems-SET 1Документ1 страницаCL 651 A Measurement Systems-SET 1rahulОценок пока нет

- Best and Last Rank Details 16-17 PortraitДокумент1 страницаBest and Last Rank Details 16-17 PortraitrahulОценок пока нет

- Blindness Power PointДокумент128 страницBlindness Power PointmanognaaaaОценок пока нет

- Chemical Engineering & Process TechnologyДокумент8 страницChemical Engineering & Process TechnologyrahulОценок пока нет

- Tara Gum - A Safe and Natural Biopolymer: AbstractДокумент1 страницаTara Gum - A Safe and Natural Biopolymer: AbstractrahulОценок пока нет

- Modelling and Simulation of Saponification Reaction in Different Type of ReactorДокумент9 страницModelling and Simulation of Saponification Reaction in Different Type of ReactorrahulОценок пока нет

- Ach - 1117 - Industrial Pollution and Control, 01-12-2011, Nov - 2011 PDFДокумент1 страницаAch - 1117 - Industrial Pollution and Control, 01-12-2011, Nov - 2011 PDFrahulОценок пока нет

- Modelling and Simulation of Saponification Reaction in Different Type of ReactorДокумент9 страницModelling and Simulation of Saponification Reaction in Different Type of ReactorrahulОценок пока нет

- Safety and Hazard AnalysisДокумент2 страницыSafety and Hazard AnalysisrahulОценок пока нет

- Chemical Plant Design and Economics - R2009 - 11!12!2012Документ1 страницаChemical Plant Design and Economics - R2009 - 11!12!2012rahulОценок пока нет

- 0419-GVP - Wanted-8 X 5Документ1 страница0419-GVP - Wanted-8 X 5rahulОценок пока нет

- 7-Ode Ivp1Документ12 страниц7-Ode Ivp1rahulОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- CH 6sp06Документ20 страницCH 6sp06rahulОценок пока нет

- Chemicals Prices ListДокумент1 страницаChemicals Prices ListrahulОценок пока нет

- Chemical Plant Design and Economics - R2009 - 20!05!2013Документ2 страницыChemical Plant Design and Economics - R2009 - 20!05!2013rahulОценок пока нет

- Ach - 1115 - Chemical Reaction Engineering-I, 21-11-2012, Nov - 2012 PDFДокумент2 страницыAch - 1115 - Chemical Reaction Engineering-I, 21-11-2012, Nov - 2012 PDFrahulОценок пока нет

- r05420801 Industrial Pollution Control EngineeringДокумент4 страницыr05420801 Industrial Pollution Control EngineeringrahulОценок пока нет

- Modelling and Simulation of Saponification Reaction in Different Type of ReactorДокумент9 страницModelling and Simulation of Saponification Reaction in Different Type of ReactorrahulОценок пока нет

- Chemical Plant Design and Economics - R2009 - 29!05!2014Документ2 страницыChemical Plant Design and Economics - R2009 - 29!05!2014rahulОценок пока нет

- Chemical Reaction Engineering-I - R2012 - 20-11-2014 PDFДокумент2 страницыChemical Reaction Engineering-I - R2012 - 20-11-2014 PDFrahulОценок пока нет

- Industrial Pollution and Control - R2009 - 24!11!2014Документ1 страницаIndustrial Pollution and Control - R2009 - 24!11!2014rahulОценок пока нет

- Ach - 1115 - Chemical Reaction Engineering-I, 29-05-2013, May-2013Документ2 страницыAch - 1115 - Chemical Reaction Engineering-I, 29-05-2013, May-2013rahulОценок пока нет

- Chemical Reaction Engineering-I R2009 20-11-2014Документ2 страницыChemical Reaction Engineering-I R2009 20-11-2014rahulОценок пока нет

- Chemical Reaction Engineering-I R2009 20-11-2014Документ2 страницыChemical Reaction Engineering-I R2009 20-11-2014rahulОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Introduction To Software TestingДокумент42 страницыIntroduction To Software TestingRoxanaОценок пока нет

- 10023890ifu Cedia Csa Low Range DXC 700 Au enДокумент4 страницы10023890ifu Cedia Csa Low Range DXC 700 Au enRodas GetachewОценок пока нет

- Comparative Study of Occlusal Contact Marking Indicators: Tanya P. BozhkovaДокумент5 страницComparative Study of Occlusal Contact Marking Indicators: Tanya P. BozhkovaMrinmayee ThakurОценок пока нет

- Method IvivcДокумент15 страницMethod IvivcHari Krishnan100% (1)

- Сравнит. лингвистикаДокумент22 страницыСравнит. лингвистикаАнастасия ДобровольскаяОценок пока нет

- Pre - Mid Term Exam Review Class - Fa'18: Michael E. Odigie, PHD, Pe, Cmq/OeДокумент89 страницPre - Mid Term Exam Review Class - Fa'18: Michael E. Odigie, PHD, Pe, Cmq/OemichaelodigieОценок пока нет

- 3681 113533 1 SM - , mutasiCVKaroseriLaksanaДокумент14 страниц3681 113533 1 SM - , mutasiCVKaroseriLaksanataufiq hidayatОценок пока нет

- What Is A Philosophical Problem - HackerДокумент12 страницWhat Is A Philosophical Problem - Hackersnain1Оценок пока нет

- Design of Adaptive Headlights For AutomobilesДокумент5 страницDesign of Adaptive Headlights For AutomobilesEditor IJRITCCОценок пока нет

- Coding Bobol ExcelДокумент4 страницыCoding Bobol ExcelMuhammad IsmunandarsyahОценок пока нет

- Digital Image ProcessingДокумент71 страницаDigital Image ProcessingPratibha SharmaОценок пока нет

- MATLAB Modeling of SPT and Grain Size Data in Producing Soil-ProfileДокумент5 страницMATLAB Modeling of SPT and Grain Size Data in Producing Soil-Profileicv.xaviОценок пока нет

- DWSIM Training-V02-30dec17Документ58 страницDWSIM Training-V02-30dec17Zanariah HashimОценок пока нет

- Physics 01-Introduction and Kinematics (2018) LabДокумент91 страницаPhysics 01-Introduction and Kinematics (2018) LabcedОценок пока нет

- M2-Exam 2Документ13 страницM2-Exam 2youngturtlevibesОценок пока нет

- Fabry PerotДокумент11 страницFabry PerotG. P HrishikeshОценок пока нет

- Aviation Service ManualДокумент28 страницAviation Service ManualArmo MoralesОценок пока нет

- Neraca energiATK-2Документ29 страницNeraca energiATK-2MauliyaLailaОценок пока нет

- Lesson 5 Appraising Diagnostic Research StudiesДокумент23 страницыLesson 5 Appraising Diagnostic Research StudiesProject MedbooksОценок пока нет

- 06a Consolidation and Settlement in ClayДокумент10 страниц06a Consolidation and Settlement in ClayAlly KhooОценок пока нет

- Quality Control Tests For Emulsions, Syrups, Tinctures, Elixirs, Ointments and OthersДокумент11 страницQuality Control Tests For Emulsions, Syrups, Tinctures, Elixirs, Ointments and OthersMuhammad Masoom Akhtar100% (2)

- LUXEN SERIES 5 182 144cells 530-550w MONOFACIALДокумент2 страницыLUXEN SERIES 5 182 144cells 530-550w MONOFACIALOscar DuduОценок пока нет

- Kolkata and North-East Centre at Tezpur: Indian Statistical InstituteДокумент1 страницаKolkata and North-East Centre at Tezpur: Indian Statistical InstitutePoonam NaiduОценок пока нет

- Jj503 - Mechanical Workshop Practise 4Документ2 страницыJj503 - Mechanical Workshop Practise 4jayadarsini2113Оценок пока нет

- MKT4419 Final ReportДокумент28 страницMKT4419 Final ReportGlenn HengОценок пока нет

- Industrial Organization (Theory and Practice) - 184-189Документ6 страницIndustrial Organization (Theory and Practice) - 184-189kurniaОценок пока нет

- Maya Dynamics Basics:: MEL and ExpressionДокумент33 страницыMaya Dynamics Basics:: MEL and ExpressionNguyễn HuỳnhОценок пока нет

- The Basics of Thread Rolling: Tools, Tips & Design ConsiderationsДокумент108 страницThe Basics of Thread Rolling: Tools, Tips & Design ConsiderationsVictor ParvanОценок пока нет

- Isothermal Heat Treatment PDFДокумент6 страницIsothermal Heat Treatment PDFsmani170Оценок пока нет

- Correlational ResearchДокумент10 страницCorrelational ResearchSari100% (1)