Академический Документы

Профессиональный Документы

Культура Документы

Failure of Safety Leadership - Case History 03 - PFCDir - Feb16

Загружено:

1mmahoneyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Failure of Safety Leadership - Case History 03 - PFCDir - Feb16

Загружено:

1mmahoneyАвторское право:

Доступные форматы

FROM THE PFC TECHNICAL DIRECTOR

A Normal Accident

The Loss of the RAF Nimrod XV230: A Failure of Leadership, Culture, and Priorities

Howard Duhon, GATE

A few months ago, a friend sent me a link to an hour-long

YouTube video of Charles Haddon-Cave speaking about

his investigation of the Nimrod XV230 crash in 2006. The

presentation was delivered at the Piper 25 Conference

in 2013. It is remarkable. After watching the video, I

downloaded the board of inquiry (BOI) report. This column

is a summary of the video and report.

The Accident and Board of Inquiry Findings

Developed from the de Havilland Comet, the Nimrod aircraft

first entered service in the UK Royal Air Force (RAF) in

1969. A total of 49 Nimrod planes were built. Initially it

served in antisubmarine warfare, maritime reconnaissance,

and marine search-and-rescue operations. In 1982, the planes

were refitted with the air-to-air refueling capabilities needed

for service in the Falklands War. Air-to-air refueling allowed

the planes to remain in the field for extended periods oftime.

More recently, the Nimrod has served as an intelligencegathering platform in Afghanistan and Iraq. It normally

carried a crew of 12 people.

On 2 September 2006, RAF Nimrod XV230 was on

a routine mission over Helmand province in southern

Afghanistan in support of NATO and Afghani ground

forces. Shortly after air-to-air refueling, a fire was detected.

Six minutes later, the plane, engulfed in flame, broke apart

andcrashed.

Fuel escaped during the refueling, either from an

overflow from the No. 1 tank through the blowoff valve,

or from a leaking coupling. The fuel tracked rearward and

accumulated in the starboard No. 7 tank dry bay. The fuel was

ignited by contact with exposed high-temperatureducts.

Because the crew had no access to the No. 7 tank dry

bay, it had no means to fight the fire. After about 5 minutes,

the fire caused the fuel in the tank to boil. The tank ruptured,

and shortly thereafter the plane was engulfed in flames. The

resulting crash killed all 14 crewmen.

Howard Duhon is the systems

engineering manager at GATE and the

SPE technical director of Projects,

Facilities, and Construction. He is a

member of the Editorial Board of Oil

and Gas Facilities. He may be reached

at hduhon@gateinc.com.

A BOI, led by Haddon-Cave, was established to

investigate the crash. It identified several major issues that

contributed to the accident, including the following:

1) Poor initial design and modifications from 1960s

onward led to the potential for fuel to pool and

contact hot piping

2) History of leaks in the 1970s and 1980s did not raise

alarm flagsnormalization of deviance

3) Increase in operational tempo in 1990s and 2000s.

Heavy use in Kosovo, Afghanistan, and Iraq

4) Problems of maintenance of an aged aircraft with

repeated out-of-service date extensions

5) Distractions of major organizational change and cuts

in funding in the UK Ministry Of Defense (MOD)

between 1998 and 2005 resulting in an organization of

Byzantine complexity

6) A shifted focus from airworthiness to business

principles (MBAs over subject matter experts [SMEs])

7) Outsourcing of the Nimrod Safety Case, and pathetic

work by the subcontractors

Design and Modifications

The original Nimrod design incorporated a crossfeed

duct.It enabled engines to be shut down and restarted

inthe air by routing hot bleed air from one engine to

another. The crossfeed duct gave rise to a serious fire

hazard, especially in the No. 7 tank. The duct was in close

proximity to fuel piping and was routed through the

bottom of the bay where fuel could pool. The fuel piping

was congested, contorted, and contained many couplings

subjectto leaks.

The addition of air-to-air refueling capacity increased

the risk of leakage. It created the possibility of the fuel tank

pressure relief valves going off in flight. The valves relieved

overpressure on tank overfilling to the outside of the aircraft.

When refueling on the ground, any vented fuel fell to the

tarmac. In the air, the fuel blew onto the side of the plane, and

some of it entered nonpressurized compartments of the plane

through gaps in the panels.

In addition, air-to-air refueling occurs at a higher flow

rate and higher pressures, thus increasing the likelihood of

the fuel tank overfilling, overpressure, and coupling leaks.

The BOI concluded that the fuel that collected in No. 7

tank dry bay was released either from the No. 1 tank blowoff

valve or from a leaking coupling.

February 2016 Oil and Gas Facilities

FROM THE PFC TECHNICAL DIRECTOR

Normalization of Deviance

The starboard No. 7 tank dry bay was a spaghetti junction of

fuel pipes and other kit. The fuel pipes in the bay contained

9 couplings. In total, the fuel system on the Nimrod

contained more than 400 couplings, all of which included

elastomericseals.

There were many fuel leaks tolerated to a significant

extent. There was a prevailing belief throughout the military

that the focus should be on eliminating ignition sources.

Also, there was no trend analysis of maintenance, which

may have helped officials notice the large increase in fuel

system leaks from 0.5 per thousand flying hours in 1980

to3.5in2000.

A major finding from the investigation of the US space

shuttle Challenger accident was normalization of deviance.

The Challenger solid fuel boosters had O-ring seals that were

frequently charred. Initially, the seals raised alarm bells, but

as more experience developed, the charred rings came to be

accepted as normal. This happened with the Nimrod as

well. Frequently, leaks did not lead to catastrophe, and that

led to a normalization of deviance; the leaks became accepted

as normal and not a cause ofconcern.

Pressure on the fuel system was higher during air-to-air

refueling because of higher flow rates. Steady-state operating

pressure during air-to-air refueling was 30 to 40 psig, still

well within the systems pressure rating. But the closing of

fuel system valves caused surges in pressure (water hammer).

Modeling suggests that surges may have exceeded the

coupling design pressure of 110 psig. Surge analysis was not

attempted until after the accident.

Operation of the aircraft in Iraq and Afghanistan, and

proximity to the hot crossfeed ducts, exposed the seals

to elevated temperatures, perhaps above 70C. The seal

elastomers experience significant stress relaxation between

70C and 80C.

Maintenance and Organizational Problems

The aircraft was not effectively maintained in the years leading

to the crash. The BOI attributes this to several factors: The

aircraft was old, built in an earlier age without access to good

maintenance technologies, and there were dwindling spares;

the operating budget was cut, and leaks were accepted as a

normality; and continuous delays in the delivery of replacement

aircraft caused a serial extension of the out-of-service date.

The most withering criticism leveled by the BOI was

reserved for organizational changes in the MOD, which

underwent significant organizational changes between 1998

and 2006. The MOD shifted from an organizational structure

built along functional lines to a project-oriented organization.

Also, organizations within the MOD were rolled up to

create larger purple management structures inclusive of all

three military forces (army, navy, and air force). This included

mergers of procurement and service organizations. For

Oil and Gas Facilities February 2016

FROM THE PFC TECHNICAL DIRECTOR

example, teams with the responsibility for airworthiness no

longer had the responsibility for spare parts purchasing and

storing, nor for the maintenance of the aircraft.

Business principles were imposed within the MOD to

the exclusion of sound engineering practices. The ministry

preferred MBAs over SMEs. The imposition of unending

cuts amid a steady stream of other business initiatives

caused deep organizational trauma. A culture developed

with too little appreciation of hard-handed engineering

specialist skills and too great a reverence for young softhandedMBAs.

The cuts and changes within the MOD led to the dilution

of safety and airworthiness cultures and the distraction from

airworthiness as the top priority. In addition, the ministry

outsourced responsibilities to industry as a way to save cost.

Project Delays and Complexity

An important organizational factor that played a role was

the delay in the project that was intended to generate the

replacement aircraft for the Nimrod. The Nimrod 2000

program, which was later renamed the MRA4, began in

1989 with the replacement aircraft originally scheduled for

operation in2000.

According to the BOI report, the current MOD

airworthiness system is of Byzantine complexity. HaddonCave wrote that, in his view, the system lacks sufficient

clarity, simplicity, and transparency. Roles and responsibilities

are diffuse, diluted, and opaque. Lines of authority are often

attenuated, conflicting, and unclear The collection of so

many disparate regulators, each responsible for different

aspects of Airworthiness, and each having different levels

of authority, is an arrangement that is neither effective nor,

frankly, understood by the majority of practitioners in

theService.

An example of this complexity is the process for

purchasing a simple part, the Avimo coupling seal. A

serious manufacturing defect was found on the Avimo seal

elastomer in 2005. Through a convoluted and dysfunctional

purchasing system, the RAF purchased noncompliant seals

beginning in 2000. The seals were incompatible with aircraft

fuel, swelling significantly on contact. Though the problem

was discovered in 2005, working through the bureaucracy

proved too difficult for the mechanics; the purchase spec

had not been correct a year later at the time of the crash.

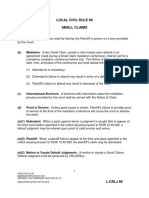

Fig. 1 summarizes the MODs process for purchasing

the Avimo seal.

The Nimrod Safety Case

Safety cases originated from UK regulations following the

Piper Alpha disaster in 1988. The Nimrod was designed

long before that. A safety case was developed for the aircraft

between 2001 and 2005. The safety case took 4 years and cost

GBP 400,000.

The purpose of a safety case is to identify, assess, and

mitigate potentially catastrophic hazards and is defined as a

structured argument, supported by a body of evidence that

provides a compelling, comprehensible, and valid case that a

system is safe for a given application in a givenenvironment.

The No. 7 bay contained eight fuel couplings with

elastomeric seals and an exposed duct operating at a

temperature above the auto-ignition temperature of jet fuel.

One would have thought that it would have been a major

focus of a safety case. But it was missed.

The BOI called the safety case a lamentable job from

start to finish, riddled with errors of fact and opinion, it

was essentially a paperwork exercise, and its production is a

story of incompetence, complacency, cynicism. It was fatally

undermined by the assumption that the Nimrod was safe

anyway, because the fleet had flown successfully for 30 years.

They were merely documenting something they already

knew, according to the BOI report.

Closing Thoughts on Normal Accidents

In her book The Challenger Launch Decision (1996), Diane

Vaughan makes a claim that startled me when I read it.

Toparaphrase:

If you study the engineering design organization of a

project that went badly, you will find chaos (complex

processes, changes and problems not properly

communicated, people using outdated drawings and

data, etc.)

And, if you study the engineering design organization

of a project that went well, you will find chaos (complex

processes, changes and problems not properly

communicated, people using outdated drawings and

data, etc.)

Could it be that the types of problems so well documented

in this case are more or less normal in our projects, and that

we only find out about them following an accident?

Complexity. One of the main themes of the Nimrod BOI

is the Byzantine complexity of the MOD and the effect of

that in making the system ineffective and unsafe. We have the

same problems in our industry.

MBAs vs. SMEs. The focus was on business principles at the

expense of technical expertise. Yeah, we do that. The pipeline

leaks that BP suffered in Alaska were a direct result of costcutting initiatives.

Safety studies: we know it is safe anyway. The Nimrod

safety case was sabotaged by the teams assumption that the

plane was safe anyway. They were just documenting what

they already knew.

Do we suffer from the same normalization of deviance

mentality when we do hazard and operability studies of

Ministry of Defence

Air Command

User Units

Nimrod IPT

Air Commodities IPT

Medical and General

Stores IPT

Spares Requirement

Part Number from

illustrated parts

catalogue

Manufactured part

Contractor A

Depot

Manufactured part

Items for aviation use

ISO 9001:2000,

BS EN 9120:2005

Contractor B

Manufactured part

Taunton

Aerospace Ltd.

IPR holder

(formerly Thales, Avimo)

Detail component

drawing and

specification for part

number required

Manufactured part

IPT: Integrated project team

Cellular

Developments Ltd.

Manufacturer

Material Suppliers

Fig. 1The procurement chain for Avimo couplings and seals.

Source: The Nimrod Review 2009.

familiar systems? Do our safety studies focus too much

effort on the minutia of safety, and not enough on the highly

unlikely, but potentially catastrophic scenarios? OGF

For Further Reading

Haddon-Cave, C. 2009. The Nimrod Review: An Independent

Review Into the Broader Issues Surrounding the Loss of the

RAF Nimrod MR2 Aircraft XV230 in Afghanistan in 2006.

Report, The UK Stationery Office, London, https://www.gov.

uk/government/uploads/system/uploads/attachment_data/

file/229037/1025.pdf (accessed 12 January 2016).

Haddon-Cave, C. 2013. Leadership and Culture, Principles and

Professionalism, Simplicity and SafetyLessons From the Nimrod

Review. Presentation at the Oil and Gas UKs Piper 25 Conference,

a three-day conference held to mark the 25th anniversary year

of the Piper Alpha disaster, Aberdeen, 1820 June, https://www.

youtube.com/watch?v=y99_lhFFCsk (accessed 12 January 2016).

Lustgarten, A. 2012. Run to Failure: BP and the Making of the

Deepwater Horizon Disaster, first edition. W.W. Norton &

Company.

Vaughan, D. 1996. The Challenger Launch Decision: Risky Technology,

Culture, and Deviance at NASA, first edition. University of

Chicago Press.

February 2016 Oil and Gas Facilities

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Sams DesaltingДокумент23 страницыSams DesaltingJose Montenegro100% (4)

- TSNДокумент16 страницTSNPj Tigniman100% (6)

- Afton Chemical Gear Oil Additives HiTEC-315 - PDSДокумент2 страницыAfton Chemical Gear Oil Additives HiTEC-315 - PDS1mmahoneyОценок пока нет

- Gomez Sept2006Документ48 страницGomez Sept20061mmahoneyОценок пока нет

- Aug2009 ATP Presentation PDFДокумент29 страницAug2009 ATP Presentation PDF1mmahoneyОценок пока нет

- GMF BrochureДокумент4 страницыGMF Brochure1mmahoneyОценок пока нет

- Enercom 022008Документ27 страницEnercom 0220081mmahoneyОценок пока нет

- TelemarkMinDocPlansShuffled 2ndMinDocDeferred 17feb09Документ1 страницаTelemarkMinDocPlansShuffled 2ndMinDocDeferred 17feb091mmahoneyОценок пока нет

- Afton Chemical HiTEC-317 - PDSДокумент2 страницыAfton Chemical HiTEC-317 - PDS1mmahoneyОценок пока нет

- Vacuum Contactor BrochureДокумент16 страницVacuum Contactor Brochure1mmahoneyОценок пока нет

- Quickstart LicensingДокумент6 страницQuickstart Licensing1mmahoneyОценок пока нет

- Ueckerdt Hirth Luderer Edenhofer System LCOE 2013Документ33 страницыUeckerdt Hirth Luderer Edenhofer System LCOE 20131mmahoneyОценок пока нет

- CLAMPSДокумент37 страницCLAMPSRamesh KrishnanОценок пока нет

- Roxtec BG B Description Application GuidelinesДокумент36 страницRoxtec BG B Description Application Guidelines1mmahoneyОценок пока нет

- ESIAДокумент55 страницESIA1mmahoneyОценок пока нет

- Ipst WhitepaperДокумент10 страницIpst Whitepaper1mmahoneyОценок пока нет

- Blast Resistant Equipment CentersДокумент4 страницыBlast Resistant Equipment Centers1mmahoneyОценок пока нет

- HLD Marketing Information 11-04 FinalДокумент1 страницаHLD Marketing Information 11-04 Final1mmahoneyОценок пока нет

- 03-04-01 Offshore Capabilities - PoriДокумент33 страницы03-04-01 Offshore Capabilities - Pori1mmahoneyОценок пока нет

- Argonaut Ics 4Документ7 страницArgonaut Ics 41mmahoneyОценок пока нет

- COMPRESSORtech2 Small Scale MR Vs Big BlockДокумент5 страницCOMPRESSORtech2 Small Scale MR Vs Big Block1mmahoneyОценок пока нет

- Bearing Lubrication With Refrigerant 1996Документ7 страницBearing Lubrication With Refrigerant 19961mmahoneyОценок пока нет

- Sakhalin PsaДокумент37 страницSakhalin Psa1mmahoneyОценок пока нет

- Aug2009 ATP Presentation PDFДокумент29 страницAug2009 ATP Presentation PDF1mmahoneyОценок пока нет

- Seismic Stimulation of Oil Production in Depleted ReservoirsДокумент4 страницыSeismic Stimulation of Oil Production in Depleted Reservoirs1mmahoneyОценок пока нет

- PEI Technical Note BookДокумент2 страницыPEI Technical Note Book1mmahoneyОценок пока нет

- Desalter Upgrade Final - FormattedДокумент2 страницыDesalter Upgrade Final - Formatted1mmahoneyОценок пока нет

- Deshidratacion de CrudoДокумент7 страницDeshidratacion de CrudochirinoslaaОценок пока нет

- 4.1.6 Technology Report Pulsed Combustion Drying KudraДокумент13 страниц4.1.6 Technology Report Pulsed Combustion Drying Kudra1mmahoneyОценок пока нет

- Action Plan Process IntensificationДокумент93 страницыAction Plan Process Intensification1mmahoneyОценок пока нет

- Argyropoulou Christina MSC 2017Документ220 страницArgyropoulou Christina MSC 20171mmahoneyОценок пока нет

- Diffie Hellman AlgorithmДокумент11 страницDiffie Hellman Algorithmjoxy johnОценок пока нет

- L-CRLJ 66 Eff 9.1.19Документ2 страницыL-CRLJ 66 Eff 9.1.19Kevin SuitsОценок пока нет

- Form 2Документ1 страницаForm 2Ola Wale100% (1)

- Book ReviewДокумент3 страницыBook ReviewMandeep BatraОценок пока нет

- 15 Days Story - The Grouchy LadybugДокумент2 страницы15 Days Story - The Grouchy LadybugGEETHA NARAYANAN HOMEROOM - PRIMARY-SLM-MAINОценок пока нет

- G.R. No. 252578 - Concurring and Dissenting Opinion Caguioa, (J)Документ94 страницыG.R. No. 252578 - Concurring and Dissenting Opinion Caguioa, (J)Mariaanna ReyesОценок пока нет

- OligarchyДокумент4 страницыOligarchyPiotr KlimaszewskiОценок пока нет

- Application For Compensatory Time Day-OffДокумент1 страницаApplication For Compensatory Time Day-Offjerick16Оценок пока нет

- Psychiatric History 1Документ6 страницPsychiatric History 1Stephen Jao Ayala UjanoОценок пока нет

- TwoconversationsДокумент4 страницыTwoconversationsapi-547131624Оценок пока нет

- The Fading Light of DemocracyДокумент10 страницThe Fading Light of DemocracySaumya ModiОценок пока нет

- Zulhairy KamaruzamanДокумент17 страницZulhairy KamaruzamanLavernyaОценок пока нет

- Pettit EtteillaДокумент6 страницPettit EtteillaMauricio ZecaОценок пока нет

- Significance of Therapy For Mothers With BPDДокумент1 страницаSignificance of Therapy For Mothers With BPDraytalianaОценок пока нет

- English HL EssayДокумент6 страницEnglish HL Essaykhushbir kaur basraОценок пока нет

- Facts:: Class 1aa (Ay 11-12) Statcon Case Digest Resubal at Regis: Mga Alagad NG KabutihanДокумент5 страницFacts:: Class 1aa (Ay 11-12) Statcon Case Digest Resubal at Regis: Mga Alagad NG KabutihanJeiel Jill TajanlangitОценок пока нет

- 7/25/13 Letter From Rep. Rob Woodall To CDC COO Sherri Berger Re: Claimed Investigation of CDC Executive Who Moonlighted As Corporate Treasurer For The Save-A-Life Foundation (SALF)Документ4 страницы7/25/13 Letter From Rep. Rob Woodall To CDC COO Sherri Berger Re: Claimed Investigation of CDC Executive Who Moonlighted As Corporate Treasurer For The Save-A-Life Foundation (SALF)Peter M. HeimlichОценок пока нет

- Native Tribes of Britain The CeltsДокумент3 страницыNative Tribes of Britain The Celtsmaría joséОценок пока нет

- Middle Earth Adventure LocationsДокумент26 страницMiddle Earth Adventure LocationsRafael Praia FiuzaОценок пока нет

- What Is An Amulet or A TaweezДокумент4 страницыWhat Is An Amulet or A TaweezAli AdamОценок пока нет

- Passenger Details: Changes To Seat RequestsДокумент3 страницыPassenger Details: Changes To Seat RequestsSarwar SalamОценок пока нет

- The Analysis of Inaugural Address by President Barack Hussein ObamaДокумент3 страницыThe Analysis of Inaugural Address by President Barack Hussein ObamaSînziana Elena MititeluОценок пока нет

- The Anti-Commandeering Doctrine: States Don't Have To ParticipateДокумент4 страницыThe Anti-Commandeering Doctrine: States Don't Have To ParticipateTenth Amendment CenterОценок пока нет

- Mact MatterДокумент5 страницMact MatterADIL ABBASОценок пока нет

- Agreement Offer AcceptanceДокумент2 страницыAgreement Offer AcceptanceEshaan ChadhaОценок пока нет

- Paradox and Challenges in Military Leadership An Israelian ApproachДокумент30 страницParadox and Challenges in Military Leadership An Israelian Approachdorupara718747100% (1)

- Social Science Part 1 of 3Документ73 страницыSocial Science Part 1 of 3Himank BansalОценок пока нет

- USTerms For AP ExamДокумент16 страницUSTerms For AP ExammrsaborgesОценок пока нет

- Sienes vs. EsparciaДокумент1 страницаSienes vs. EsparciasamontedianneОценок пока нет