Академический Документы

Профессиональный Документы

Культура Документы

MEHB323 Tutorial Assignment 3 PDF

Загружено:

Nirmal ChandraОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MEHB323 Tutorial Assignment 3 PDF

Загружено:

Nirmal ChandraАвторское право:

Доступные форматы

MEHB323 Heat Transfer

Tutorial Assignment No. 3

1. Consider one-dimensional steady heat conduction in the radial direction of a hollow

cylinder. The thermal conductivity of the cylinder is 0.14 W/mK. The inner wall of the

cylinder has a diameter of 37.5 mm and is subjected to a heat flux of 1.16 kW/m2. The

thickness of the cylinder wall is 5.4 mm. The outer wall of the cylinder is exposed to an

airflow at 25C and convection heat transfer coefficient of 60 W/m2K. Determine the

position and value of maximum temperature within the cylinder.

Tmax = 79.33C

2. Electrical current flows through a long rod with radius rr = 0.01 m generating thermal

energy at a uniform volumetric rate of q = 2 106 W/m3. The rod is concentric with a

hollow ceramic cylinder, creating an enclosure that is filled with air as shown below. The

hollow ceramic cylinder has inner and outer radius of ri = 0.02 m and ro = 0.03 m,

respectively, and the conductivity k = 2 W/mK. The thermal resistance per unit length due

= 0.5 mK/W, and the convection heat

to radiation between the enclosure surfaces is Rrad

transfer coefficient in the enclosure is h = 10 W/m2K. The outer surface of the hollow

cylinder is exposed to cold air at T = 20C and convection coefficient of h = 15 W/m2.K

= 100 W/m2. Under steady condition, construct a

while absorbs a radiant flux of q rad

thermal circuit that can be used to calculate the surface temperature of the rod, Tr.

Tr = 528.92C

3. A proposal to store naturally occurred radioactive materials (NORM) in a spherical vessel

constructed from aluminium alloy 2024-T6 with melting point of 775 K. The vessel has a

storage capacity of 0.3 m3 and wall thickness of 15 cm. In order to protect the vessel from

corrosive environment, the outer surface is wrapped by a stainless steel (AISI 304) lining

with melting point of 1670 K. The NORM generates 0.30 MW/m3 of heat uniformly. The

wrapped vessel is to be submerged in oceanic water that is at an average temperature of

16C and provides a uniform convection coefficient of 50 W/m2K. Evaluate all materials

properties at room temperature (27C).

(a) You are required to design the suitable thickness of the stainless steel lining for safe

storing of the NORM.

(b) What is the outer surface temperature of the lining?

This question has no fixed answers. Any value of thickness less than 0.1616 m (which

provides radius of the lining of no more than 0.7269 m) is acceptable. For radius of the

lining at 0.7269 m, the outer surface temperature of the lining is 287.09C

1

MEHB323 Heat Transfer

Tutorial Assignment No. 3

4. For residential water heating purpose, a chlorinated PVC pipe (kp = 0.14 W/mK) carrying

hot water at an average temperature of 80C is exposed to ambient air at 25C as shown

in figure below. The average convection heat transfer coefficients between the hot water

and the inner wall of the pipe is estimated to be 1500 W/m2K while the average convection

heat transfer coefficients between the outer surface of the pipe and the ambient air is 60

W/m2K. For a unit length of the pipe (L = 1 m), design the pipe dimensions (i.e. diameters

and thickness) in order to ensure the outer surface of the pipe is at safe-to-touch condition,

which is below 40C. (Hint: in common practice, the outer diameter of a household water

heater pipe is within the range of 2.14 to 6 cm).

Hot water

This question has no fixed answers. Some possible combinations of outer diameter and

thickness of the pipe are as following:

(a) Do = 0.0214 m; t = 0.0047 m

(b) Do = 0.0334 m; t = 0.0051 m

(c) Do = 0.04826 m; t = 0.0054 m

5. Given a composite wall as shown below with kB = 1.0W/mK, kC = 1.5W/mK, kD = 2.0

W/mK, L = 1m, T = 25oC, and h = 20 W/m2K. Wall A experiences uniform volumetric

heat generation of q 200W/m 3 . Assuming one-dimensional conduction with constant

properties and steady state condition, determine the surface temperature of wall A labelled

as TA.

Perfect insulation

TA

Wall B

Wall A

Wall

D

Air, T, h

H

Wall C

0.5H

0.5L

TA = 245C

2

MEHB323 Heat Transfer

Tutorial Assignment No. 3

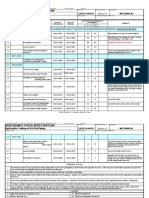

6. A commercial grade cubical freezer, 4 m on a side, has a composite wall consisting of an

exterior sheet of 5.0-mm thick plain carbon steel (kst = 60.5 W/mK), an intermediate layer

of 100-mm thick polyurethane insulation (kins = 0.02 W/mK), and an inner sheet of 5.0mm thick aluminium alloy (kal = 177 W/mK). Adhesive interfaces between the

polyurethane insulation and both metallic sheets are each characterized by a thermal

contact resistance of Rt",c = 2.5 10-4 m2K/W.

(a) What is the steady-state cooling load that must be maintained by the refrigerator under

conditions for which the outer and inner surface temperatures are 25C and -5C,

respectively?

(b) For power saving purpose, which wall material should be increased/reduced in

thickness in order to reduce 50% of the cooling load found in part (a)? Redesign the

thickness of the proposed material.

(a) Q = 575.93 W

7. A 5 m internal-diameter spherical tank made of 1.5 cm thick stainless steel (k = 15 W/mK)

is used to store iced water at 0C. The tank is located in a large room whose temperature

is 30C. The walls of the room are also at 30C. Heat transfer between the outer surface of

the tank and the surroundings is by natural convection and radiation. The convection heat

transfer coefficients at the inner and the outer surfaces of the tank are 80 W/m2K and 10

W/m2K, respectively. The outer surface of the tank is black ( = 1) and hence the radiation

heat transfer coefficient is approximated to be hr = 5.57 W/m2K. Determine:

(a) The rate of heat transfer to the iced water in the tank.

q = 30581 W

(b) The amount of ice at 0C that melts during a 24-hour period. The heat of fusion of

water (the energy needed for 1 kg of ice to melt down) at atmospheric pressure is hif

= 333.7 kJ/kg.

m = 7918 kg

2

(c) Evaluate whether hr = 5.57 W/m K is an acceptable approximation for the surface

radiation convection coefficient in this problem.

Вам также может понравиться

- MEHB323 Tutorial Assignment 6 PDFДокумент3 страницыMEHB323 Tutorial Assignment 6 PDFNirmal ChandraОценок пока нет

- MEHB323 Tutorial Assignment 3Документ2 страницыMEHB323 Tutorial Assignment 3Hanis Che Husain100% (1)

- Solutions Manual to accompany Engineering Materials ScienceОт EverandSolutions Manual to accompany Engineering Materials ScienceРейтинг: 4 из 5 звезд4/5 (1)

- MEHB323 Tutorial Assignment 6Документ2 страницыMEHB323 Tutorial Assignment 6SattishZeeОценок пока нет

- 4 Thermal Resistance ExercisesДокумент5 страниц4 Thermal Resistance ExercisesNurmachda BachmidОценок пока нет

- Tutorial 5-1Документ2 страницыTutorial 5-1chandan rajОценок пока нет

- HT Tutorial1Документ2 страницыHT Tutorial1daabgchiОценок пока нет

- Assignment IДокумент6 страницAssignment IPrerna JainОценок пока нет

- Cadabadi - T1 - Taller ConduccionДокумент5 страницCadabadi - T1 - Taller ConduccionAndres FigueroaОценок пока нет

- Tutorial 2-1Документ4 страницыTutorial 2-1chandan rajОценок пока нет

- MEEG 306 Tutorial Revised May 2019Документ30 страницMEEG 306 Tutorial Revised May 2019sagar100% (1)

- Work Sheet 1 2022Документ6 страницWork Sheet 1 2022Fikadu GonfaОценок пока нет

- HT Notes For ESEДокумент25 страницHT Notes For ESEM BhurleОценок пока нет

- Che 342 Practice Set I IДокумент4 страницыChe 342 Practice Set I IDan McОценок пока нет

- Sheet 3Документ5 страницSheet 3Yasmin RedaОценок пока нет

- Assignment OneДокумент3 страницыAssignment OneAfif Samsun BaharunОценок пока нет

- Prob. Sheet Basic ConceptsДокумент3 страницыProb. Sheet Basic ConceptsAnonymous mXicTi8hBОценок пока нет

- 1,2,3 ProblemsДокумент25 страниц1,2,3 ProblemsWild BotОценок пока нет

- HTДокумент14 страницHTJai MehtaОценок пока нет

- Tutorial 1 Process Heat TransferДокумент4 страницыTutorial 1 Process Heat TransferSuraya JohariОценок пока нет

- Heat Transfer - 012110043920 - 1Документ8 страницHeat Transfer - 012110043920 - 1shweta_770587Оценок пока нет

- ME5101 2020 Assignment 01Документ2 страницыME5101 2020 Assignment 01palash_shrivastava6282058Оценок пока нет

- HT Important Questions For End ExamДокумент10 страницHT Important Questions For End ExamSandeepKattaОценок пока нет

- 4th Sem.-ME 1251-HMTДокумент18 страниц4th Sem.-ME 1251-HMTPon ShanmugakumarОценок пока нет

- Tutorial 1 Conduction by Prince KhanДокумент8 страницTutorial 1 Conduction by Prince KhanPrince KhanОценок пока нет

- T-MEET312 PS SurnameДокумент9 страницT-MEET312 PS Surnamekimbenedictaguilar19Оценок пока нет

- ALL Problems - 230918 - 120556Документ8 страницALL Problems - 230918 - 120556Priyojit GhoshОценок пока нет

- Assignment OneДокумент3 страницыAssignment Onekefiyalew agegnОценок пока нет

- HMT16 MarksДокумент12 страницHMT16 MarkstagoreboopathyОценок пока нет

- MEHB323 Tutorial Assignment 1Документ3 страницыMEHB323 Tutorial Assignment 1anirudhОценок пока нет

- Process Heat Transfer Question BankДокумент10 страницProcess Heat Transfer Question BankMadhuОценок пока нет

- HT Tutorial 1 QuestionsДокумент7 страницHT Tutorial 1 QuestionssairamОценок пока нет

- Practice Set 1 (Basic Questions) (1 Copy)Документ3 страницыPractice Set 1 (Basic Questions) (1 Copy)TutuОценок пока нет

- 1492Документ15 страниц1492_Anggyaa_Оценок пока нет

- Heat and MassДокумент2 страницыHeat and Masssmg26thmayОценок пока нет

- HT Practice QuestionsДокумент3 страницыHT Practice QuestionsVivek SharmaОценок пока нет

- Department of Chemical Engineering, NITK Assignment - 1: Heat Transfer (CH250)Документ6 страницDepartment of Chemical Engineering, NITK Assignment - 1: Heat Transfer (CH250)UdayОценок пока нет

- Tutorial 1Документ4 страницыTutorial 1Unta Di PadAng PaSirОценок пока нет

- Tutorial 1& 2 - SolДокумент10 страницTutorial 1& 2 - SolAli ZaghloulОценок пока нет

- 9A03505 Heat TransferДокумент4 страницы9A03505 Heat TransfersivabharathamurthyОценок пока нет

- 4.tutorial HMTДокумент5 страниц4.tutorial HMTdearsaswatОценок пока нет

- HT AssignmentДокумент12 страницHT AssignmentCollano M. Noel RogieОценок пока нет

- Heat Transfer - Sheet Two ConductionДокумент4 страницыHeat Transfer - Sheet Two ConductionMichael EmadОценок пока нет

- Tarea 3 CalorДокумент3 страницыTarea 3 CalorLuis AngelОценок пока нет

- Home Assignment - 3: Chapter-3Документ3 страницыHome Assignment - 3: Chapter-3AkhilОценок пока нет

- Problems: Heat TransferДокумент7 страницProblems: Heat TransferKinna VnezhОценок пока нет

- Tutorial 1 Conduction - CompressДокумент8 страницTutorial 1 Conduction - CompressFeolo Riel TarayОценок пока нет

- Unsolved Numericals of HTДокумент4 страницыUnsolved Numericals of HTShailendra WaniОценок пока нет

- Heat and Mass Transfer: "Solved Problems"Документ16 страницHeat and Mass Transfer: "Solved Problems"qiritical99Оценок пока нет

- Tutorial One Heat Conduction: 5 2. A P M º N 0Документ7 страницTutorial One Heat Conduction: 5 2. A P M º N 0kookoОценок пока нет

- Tutorial 3Документ3 страницыTutorial 3meansaminОценок пока нет

- Heat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D EДокумент4 страницыHeat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D ERotten AppleОценок пока нет

- Ch3 HeatTransfer 2Документ27 страницCh3 HeatTransfer 2abubackersiddieq0% (1)

- HMT Unit-1 PDFДокумент3 страницыHMT Unit-1 PDFAnkita MishraОценок пока нет

- Heat and Mass Transfer Practice Questions 1Документ2 страницыHeat and Mass Transfer Practice Questions 1Lucky 230503Оценок пока нет

- Heat Transfer AssinmentДокумент4 страницыHeat Transfer AssinmentbaruaoleОценок пока нет

- EjerciciosДокумент24 страницыEjerciciosMarjorieОценок пока нет

- 1.0 (Apr 2017) Course Outline (Memb483) MQFДокумент7 страниц1.0 (Apr 2017) Course Outline (Memb483) MQFNirmal ChandraОценок пока нет

- MEHB323 Tutorial Assignment 4 PDFДокумент3 страницыMEHB323 Tutorial Assignment 4 PDFNirmal ChandraОценок пока нет

- MEHB323 Tutorial Assignment 7 PDFДокумент2 страницыMEHB323 Tutorial Assignment 7 PDFNirmal Chandra0% (1)

- MEHB323 Tutorial Assignment 2Документ3 страницыMEHB323 Tutorial Assignment 2Amzar Aizad100% (1)

- MEHB323 Tutorial Assignment 5 (Transient) PDFДокумент2 страницыMEHB323 Tutorial Assignment 5 (Transient) PDFNirmal ChandraОценок пока нет

- Coeb 442 Course Outline L Sem 2 11516Документ8 страницCoeb 442 Course Outline L Sem 2 11516Nirmal ChandraОценок пока нет

- MEHB323 Tutorial Assignment 1Документ3 страницыMEHB323 Tutorial Assignment 1anirudhОценок пока нет

- Lecture No1Документ21 страницаLecture No1Anonymous pe40cVMrHОценок пока нет

- Answers To Selected Haomework ProblemsДокумент32 страницыAnswers To Selected Haomework ProblemsAzam RoslanОценок пока нет

- Hello WorldДокумент1 страницаHello WorldNirmal ChandraОценок пока нет

- COEB442 - Sem - 2 - 2015-2016 RevisionДокумент37 страницCOEB442 - Sem - 2 - 2015-2016 RevisionNirmal ChandraОценок пока нет

- Lecture No1Документ21 страницаLecture No1Anonymous pe40cVMrHОценок пока нет

- Hello WorldДокумент1 страницаHello WorldNirmal ChandraОценок пока нет

- COEB442 Engineering Economics Assignment 2Документ1 страницаCOEB442 Engineering Economics Assignment 2Nirmal ChandraОценок пока нет

- Torsion Test (Experiment 2)Документ19 страницTorsion Test (Experiment 2)Nirmal Chandra0% (3)

- Cable - XLPE-LSHF-SWB-LSHF-AT-AR 3GX 2.5MMДокумент2 страницыCable - XLPE-LSHF-SWB-LSHF-AT-AR 3GX 2.5MMavanz7173Оценок пока нет

- BOQ Weligama PDFДокумент3 страницыBOQ Weligama PDFMuhammadWazimAkramОценок пока нет

- Dril-Flex® Structural Self-Drilling FastenersДокумент4 страницыDril-Flex® Structural Self-Drilling FastenersPaulОценок пока нет

- Puranmal Lahoti Government Polytechnic Latur: Name of The StudentsДокумент11 страницPuranmal Lahoti Government Polytechnic Latur: Name of The Studentsshankar biradarОценок пока нет

- Codex Tapered Roller BearingsДокумент4 страницыCodex Tapered Roller BearingsAnonymous Cpe6vcОценок пока нет

- Mann Automotive Filter Stock List19052021Документ3 страницыMann Automotive Filter Stock List19052021B Sathish BabuОценок пока нет

- Technical ManualДокумент375 страницTechnical ManualmmediboyinaОценок пока нет

- Advances in ASME Section VIII Division 2 Pressure Vessel Design and Analysis PDFДокумент10 страницAdvances in ASME Section VIII Division 2 Pressure Vessel Design and Analysis PDFVitor Rigueira de GodoyОценок пока нет

- Bubble Diagram: Zona PenerimaanДокумент1 страницаBubble Diagram: Zona Penerimaananon_545295732Оценок пока нет

- ASTM - 706 60 and 80 Grade Specifications & Standards Use of High-Strength ReinforcementДокумент231 страницаASTM - 706 60 and 80 Grade Specifications & Standards Use of High-Strength ReinforcementTasvir A R ChowdhuryОценок пока нет

- HFY-PIP-SP-00009 X Specification For BNS Seamless Piping Material - A-CommentedДокумент10 страницHFY-PIP-SP-00009 X Specification For BNS Seamless Piping Material - A-CommentedVignesh PanchabakesanОценок пока нет

- Cost Plus Percentage AgreementДокумент12 страницCost Plus Percentage AgreementAnton Cornel100% (4)

- Satip A 004 02Документ10 страницSatip A 004 02mohammadОценок пока нет

- Shear and MomentДокумент17 страницShear and MomentARIANNE GAILE CLARIANESОценок пока нет

- Flare Line Failure CaseДокумент20 страницFlare Line Failure CaseHitesh PanchalОценок пока нет

- HLX 5T TabancaДокумент137 страницHLX 5T TabancaOzan SahinОценок пока нет

- Company Profile - UpdatedДокумент48 страницCompany Profile - Updatedorlando fiel jrОценок пока нет

- Continue: Architectural Design Brief Sample PDFДокумент2 страницыContinue: Architectural Design Brief Sample PDFarjun kumarОценок пока нет

- PC VRF Systems 2Документ50 страницPC VRF Systems 2pallavОценок пока нет

- Eton West Wing Residences at North Belton Communities Quezon CityДокумент20 страницEton West Wing Residences at North Belton Communities Quezon CityEvelyn L. AguinaldoОценок пока нет

- Acoplamentos Sitex PDFДокумент4 страницыAcoplamentos Sitex PDF3DLAB CAD/CAMОценок пока нет

- Joints in Steel Construction - Simple Connections - Part 20 PDFДокумент4 страницыJoints in Steel Construction - Simple Connections - Part 20 PDFkakem61Оценок пока нет

- Group F NBCДокумент48 страницGroup F NBCsaravanan ssОценок пока нет

- Work Schedule For ReferenceДокумент9 страницWork Schedule For Referencekevinmathew27Оценок пока нет

- Performance-Based Seismic Design of Bridges: A Global Perspective and Critical Review of Past, Present and Future DirectionsДокумент25 страницPerformance-Based Seismic Design of Bridges: A Global Perspective and Critical Review of Past, Present and Future DirectionsYati TankОценок пока нет

- HVAC Split Unit Installation Procedure - Method Statement HQДокумент7 страницHVAC Split Unit Installation Procedure - Method Statement HQEngineer ZiaОценок пока нет

- Flanagan e Bennett (2001)Документ7 страницFlanagan e Bennett (2001)Adauto Cezar NascimentoОценок пока нет

- Manual WiloДокумент25 страницManual Wilocarr123Оценок пока нет

- Spool Lift and Loadout ProcedureДокумент75 страницSpool Lift and Loadout ProcedurePhani Kumar G SОценок пока нет

- 1.6 Design Example-Simple Span Precast-Pretensioned I-Girder BridgeДокумент32 страницы1.6 Design Example-Simple Span Precast-Pretensioned I-Girder BridgeglaydelleОценок пока нет

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceОт EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceОценок пока нет

- Introduction to Power System ProtectionОт EverandIntroduction to Power System ProtectionРейтинг: 5 из 5 звезд5/5 (1)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesОт EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Workbook to Accompany Maintenance & Reliability Best PracticesОт EverandWorkbook to Accompany Maintenance & Reliability Best PracticesРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersОт EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersРейтинг: 4.5 из 5 звезд4.5/5 (2)

- A Complete Guide to Safety Officer Interview Questions and AnswersОт EverandA Complete Guide to Safety Officer Interview Questions and AnswersРейтинг: 4 из 5 звезд4/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridОт EverandShorting the Grid: The Hidden Fragility of Our Electric GridРейтинг: 4.5 из 5 звезд4.5/5 (2)

- A Pathway to Decarbonise the Shipping Sector by 2050От EverandA Pathway to Decarbonise the Shipping Sector by 2050Оценок пока нет

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsОт EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!От EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Оценок пока нет

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successОт EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsОт EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsОценок пока нет

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemОт EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemОценок пока нет

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsОт EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsОценок пока нет

- Practical Reservoir Engineering and CharacterizationОт EverandPractical Reservoir Engineering and CharacterizationРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977От EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Оценок пока нет

- Guidelines for Auditing Process Safety Management SystemsОт EverandGuidelines for Auditing Process Safety Management SystemsОценок пока нет

- Global Landscape of Renewable Energy FinanceОт EverandGlobal Landscape of Renewable Energy FinanceОценок пока нет

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerОт EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerОценок пока нет

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОценок пока нет

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsОт EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsРейтинг: 4 из 5 звезд4/5 (11)