Академический Документы

Профессиональный Документы

Культура Документы

Tennis Court - CentCom

Загружено:

EppОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tennis Court - CentCom

Загружено:

EppАвторское право:

Доступные форматы

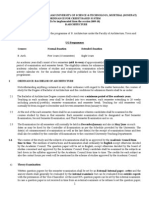

GENERAL STRUCTURAL NOTES AND SPECIFICATIONS

4. WHERE CONSTRUCTION DETAILS ARE NOT SHOWN OR NOTED FOR ANY PART OF THE

WORK, SUCH DETAILS SHALL BE THE SAME AS FOR SIMILAR WORK SHOWN ON THE

DRAWINGS.

5. PIPES, DUCTS, SLEEVES, CHASES, ETC. SHALL NOT BE PLACED IN SLABS, BEAMS, OR

WALLS UNLESS SPECIFICALLY SHOWN OR NOTED NOR SHALL ANY STRUCTURAL

MEMBER BE CUT FOR PIPES, DUCTS, ETC. UNLESS SPECIFICALLY SHOWN. OBTAIN

PRIOR WRITTEN APPROVAL FROM THE ENGINEER FOR INSTALLATION OF ANY

ADDITIONAL PIPES, DUCTS, ETC.

LOCATE AND PROTECT UNDERGROUND OR CONCEALED CONDUIT, PLUMBING OR

OTHER UTILITIES WHERE NEW WORK IS BEING PERFORMED.

6. LOCATE AND PROTECT UNDERGROUND OR CONCEALED CONDUIT, PLUMBING OR

OTHER UTILITIES WHERE NEW WORK IS BEING PERFORMED.

7. TAKE NECESSARY PRECAUTIONS TO MAINTAIN AND INSURE THE INTEGRITY OF THE

STRUCTURE DURING CONSTRUCTION. NEITHER THE OWNER NOR

ARCHITECT/ENGINEER WILL ENFORCE SAFETY MEASURES OR REGULATIONS. IT

SHALL BE THE CONTRACTORS RESPONSIBILITY TO PROVIDE ADEQUATE SHORING

AND BRACING OF THE STRUCTURE FOR ALL THE LOADS THAT MAYBE IMPOSED

DURING CONSTRUCTION. FURTHER, THE CONTRACTOR SHALL DESIGN, CONSTRUCT

AND MAINTAIN ALL SAFETY DEVICES AND SHALL BE SOLELY RESPONSIBLE FOR

CONFORMING TO ALL SAFETY AND HEALTH STANDARDS, LAWS AND REGULATIONS.

8. OBTAIN PRIOR WRITTEN APPROVAL FROM THE ENGINEER IN CASE OF CHANGES TO

THE WORKING DRAWINGS.

28 DAY STRENGTH MAX. SLUMP MAX. SIZE AGG.

20.7 MPa (3,000 PSI)

125MM (5")

25MM (1")

B.

ALL OTHERS (SLABS, BEAMS,

COLUMNS, ETC)

20.7 MPa (3,000 PSI)

100MM (4")

19MM (3/4")

FILL

FILL

SLAB ON GRADE

STAIR LANDINGS AND TREADS

3. ALL REINFORCING STEEL BARS SHALL CONFORM TO ASTM A615 GRADE 33 FOR 12MM

BARS WHILE BARS 16MMM AND ABOVE SHALL BE GRADE 60. GRADE 33 MAY BE

USED FOR 10MM BARS.

100MM THICK GRAVEL BED

SECTION

4. ALL FABRICATION, DETAILING AND PLACING SHALL CONFORM TO THE PROVISIONS

SET BY THE NSCP 2001 EDITION.

"N1" MATTING BARS

SEE FOOTING SCHEDULE

5. MAINTAIN MINIMUM CONCRETE COVER FOR REINFORCING STEEL AS FOLLOWS:

FOOTINGS (CAST AGAINST & EXPOSED TO EARTH) . . . . . 75MM (3")

COLUMN TIES OR SPIRALS AND BEAM STIRRUPS . . . . . . . 40MM (1 1/2")

SLABS AND WALLS (INTERIOR FACE). . . . . . . . . . . . . . . . . . 20MM (3/4")

6. CLEAR DISTANCE SPACING BETWEEN PARALLED BARS IN A LAYER SHALL NOT BE

LESS THAN 1.50 TIMES THE NOMINAL DIAMETER OF THE BAR, OR 1.33 TIMES MAXIMUM

3. NOTES AND DETAILS ON THE DRAWINGS TAKE PRECEDENCE OVER THE GENERAL

NOTES AND TYPICAL DETAILS IN CASE OF CONFLICT.

TYPE OF CONSTRUCTION

A.

0.075

2. VERIFY ALL DIMENSIONS, ELEVATIONS AND SITE CONDITIONS BEFORE STARTING

WORK. NOTIFY THE ENGINEER IMMEDIATELY OF ANY DISCREPANCIES.

NATURAL GRADE LINE

1. ALL STRUCTURAL MATERIALS AND WORK SHALL CONFORM TO THE REQUIREMENTS

OF THE LATEST EDITION OF THE NATIONAL STRUCTURAL CODE OF THE PHILIPPINES

(NSCP 2001).

2. ALL CONCRETE SHALL DEVELOP A MINIMUM COMPRESSIVE STRENGTH AT 28 DAYS

WITH CORRESPONDING MAXIMUM SLUMP AND MAXIMUM SIZE AGGREGATE AS

FOLLOWS:

EXCAVATION DEPTH

(A) GENERAL REQUIREMENTS

COLUMN VERTICAL BARS

(SEE COLUMN SCHEDULE)

10MM TIES SPACED @:

1@50MM, 20 @ 100MM,

REST @ 150MM O.C. TO CL

SIZE AGGREGATE, NOR LESS THAN 38MM (1 2").

7. SPLICES SHALL BE SECURELY WIRED TOGETHER AND SHALL LAP AT LEAST 40 TIMES

DIAMETER OR 600MM WHICHEVER IS GREATER. STAGGER BOTTOM AT LEAST 1.50M

FROM SPLICES IN OTHER BOTTOM REINFORCEMENT. STAGGER SPLICES FOR TOP

REINFORCEMENT SIMILARLY.

8. ALL ANCHOR BOLTS, DOWELS, AND OTHER INSERTS SHALL BE PROPERLY

POSITION AND SECURED IN PLACE PRIOR TO PLACING OF CONCRETE.

9. ALL CONCRETE SHALL BE KEPT MOIST FOR A MINIMUM OF 7 CONSECUTIVE DAYS

IMMEDIATELY AFTER POURING BY THE USE OF CURING COMPOUNDS, OR OTHER

APPROVED METHODS.

"N2" MATTING BARS

SEE FOOTING SCHEDULE

PLAN

TYPICAL FOOTING DETAILS

(D) MASONRY AND CONCRETE BLOCKS

(B) DESIGN CRITERIA

1. CONCRETE HOLLOW BLOCKS, UNLESS OTHERWISE SPECIFIED SHALL BE 150MM

THICK. LOAD BEARING BLOCKS SHALL HAVE A MINIMUM COMPRESSIVE STRENGTH OF

750 PSI (5.175 MPa) WHILE NON-LOAD BEARING SHALL HAVE A MINIMUM

COMPRESSIVE STRENGTH OF 400 PSI (2.76 MPa).

- - - REFER TO STRUCTURAL COMPUTATIONS

(C) FOUNDATION

1. FOOTINGS SHALL BEAR ON SOLID UNDISTURBED EARTH (CONTROLLED, COMPACTED

STRUCTURAL FILL OR BOTH) AT LEAST 450MM BELOW LOWEST ADJACENT FINISHED

GRADE.

2. FOOTING IS DESIGNED FOR ASSUMED ALLOWABLE SOIL/FOUNDATION PRESSURE OF

100 kPa (2000 psf).

3. SUB-GRADE PREPARATION INCLUDING DRAINAGE, EXCAVATION, COMPACTION,

AND FILLING REQUIREMENTS, SHALL CONFORM STRICTLY WITH THE

RECOMMENDATIONS GIVEN IN THE SOILS REPORT OR AS DIRECTED BY THE SOILS

ENGINEER.

4. THE CONTRACTOR SHALL NOTIFY THE ENGINEER AFTER FOOTING EXCAVATION

HAVE BEEN COMPLETED AND PRIOR TO CONCRETING TO CONFIRM THE DESIGN

FOUNDATION CAPACITY.

5. ROOF AND AREA DRAINAGE SHALL BE DIRECTED AWAY FROM THE FOUNDATIONS.

6. EXCAVATIONS SHALL BE PROPERLY BACKFILLED. BACKFILL FOR WALLS SHALL BE

PERVIOUS MATERIAL ACCEPTABLE TO THE GEOTECHNICAL ENGINEER. DO NOT PLACE

BACKFILL BEHIND WALLS BEFORE THEY HAVE ATTAINED THEIR DESIGN STRENGTH.

SHORE AND PROTECT WALLS FROM LATERAL LOADS UNTIL THE SUPPORTING

MEMBERS ARE IN PLACE AND HAVE DEVELOPED SPECIFIED STRENGTHS.

2. PROVIDE 1-16MM VERTICAL BARS AT CORNERS, INTERSECTIONS, END OF WALLS,

EACH SIDE OF OPENINGS.

3. LINTEL BEAMS SHALL BEAR AT LEAST 200MM (8") ON EACH SIDE OF MASONRY WALL

OPENING.

4. WALL REINFORCEMENTS SHALL BE AS FOLLOWS:

WALL THICKNESS

8 IN. (200 mm) . . . . . . . . . .

6 IN (150 mm) . . . . . . . . . . .

4 IN. (100 mm) . . . . . . . . . .

VERTICAL BARS

12MM @ 400 mm

10MM @ 400 mm

10MM @ 400 mm

HORIZONTAL BARS

10MM @ 600 mm

10MM @ 600 mm

10MM @ 600 mm

(E) STRUCTURAL STEEL

1. ALL STRUCTURAL STEELS SUCH AS ANGLES, WIDE FLANGE SECTIONS, PIPES,

STIFFENER PLATES, BASE PLATES, ETC. SHALL CONFORM TO ASTM A-36.

2. ALL STRUCTURAL STEEL SHALL BE DETAILED, FABRICATED AND ERECTED BASED ON

THE SPECIFICATION FOR DESIGN, FABRICATION, AND ERECTION OF STRUCTURAL

STEEL GIVEN BY THE NATIONAL STRUCTURAL CODE OF THE PHILIPPINES (NSCP).

(D) REINFORCED CONCRETE

3. CONNECTION BOLTS (34 ROUND, UNLESS SHOWN OTHERWISE) SHALL CONFORM TO

ASTM A-325. ANCHOR BOLTS (EMBEDDED IN MASONRY OR CONCRETE) SHALL

CONFORM TO ASTM A307 UNLESS NOTED OTHERWISE ON THE DRAWINGS.

1. CONCRETE SHALL BE MIXED, PROPORTIONED, CONVEYED AND PLACED IN

ACCORDANCE WITH THE PROVISIONS SET BY THE NSCP 2001.

4. ALL WELDINGS SHALL BE IN CONFORMANCE WITH NSCP STANDARDS AND SHALL BE

PERFORMED BY CERTIFIED WELDERS USING E70 XX ELECTRODES.

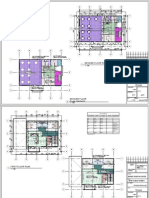

PERSPECTIVE

ej avila architecture

+ engineering

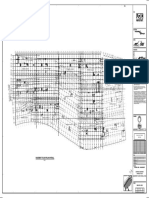

36000

CORRUGATED G.I. SHEET

50mm x 50mm x 4.00mm

2 - ANGLE BARS

INSULATION FOAM

100mm x 100mm x 7.00mm

2 - ANGLE BARS

GUTTER

C1/F1

C1/F1

2" x 6" X 2MM C-PURLIN

6000

20-25 MM ANCHOR BOLT S

2MM THK. BEARING PLATE

ROOF SUPPORT?

C1/F1

C1/F1

C1/F1

C1/F1

C1/F1

2

8000

6000

C1/F1

18000

6000

12969

20mm VERTICAL BARS

SCALE

1:200 M

10MM LATERAL TIES

SPACED @ 1@50, 5&100,

5@150, REST @ 200MM O.C.

2500

N. G. L.

600

14- 20mm VERTICAL

BARS

FILL

550

FILL

2500

2000 X 2500 X 550 MM PLAN

ej avila architecture

+ engineering

20-20 MM

SECTION

S

COLUMN DETAIL

SCALE

1:75 M

1500

27-20 MM

300

FOUNDATION PLAN

2000

A

36.00

18.00

18.00

9.00

9.00

9.00

9.00

MIDSPAN OF

ROOF BEAM

MIDSPAN OF

ROOF BEAM

50mm x 50mm x 4.00mm

2 - ANGLE BARS

PURLINS SPACED @

EVERY 1.00m O.C.

PURLINS SPACED @

EVERY 1.00m O.C.

1.50

1.50

12.40

GUTTER

9.70

11.00

STEEL BEAM

300mm x 600mm

REINFORCED CONCRETE

COLUMN

300mm x 600mm

REINFORCED CONCRETE

COLUMN

INSULATION FOAM

2" x 6" X 2MM C-PURLIN

100mm x 100mm x 7.00mm

2 - ANGLE BARS

STEEL BEAM

8.00

1.70

RB

RB

100mm x 100mm x 7.00mm

2 - ANGLE BARS

9.70

100mm x 100mm x 7.00mm

2 - ANGLE BARS

1.00

50mm x 50mm x 4.00mm

2 - ANGLE BARS

50mm x 50mm x 4.00mm

2 - ANGLE BARS

CORRUGATED G.I. SHEET

8.00

12.40

1.00

1.70

S

5

20-25 MM ANCHOR BOLT S

2MM THK. BEARING PLATE

FRONT ELEVATION

1:200 M

SCALE

600 420

ROOF SUPPORT?

20mm VERTICAL BARS

600

18000

18000

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1700

1700

900

1500

ROOF TRUSS DIAGRAM

SCALE

ej avila architecture

+ engineering

1:100 M

600

SPOT DETAIL

SCALE

1:40 M

12mm - SAG ROD W/

TURNBUCKLE

BOLT SCREWS

C1

C1

T-1

C1

4

0.90

T-1

C1

C1

BOLT SCREWS

6000

T-1

SECTION

18000

6000

12969

6000

C1

C1

C1

T-1

S

3

ROOF FRAMING PLAN

SCALE

ej avila architecture

+ engineering

1:200 M

PLAN

1

S

ROOF TRUSS RIDGE DETAIL

SCALE

1:40 M

Вам также может понравиться

- General Structural NotesДокумент5 страницGeneral Structural NotesreinerОценок пока нет

- Basement Floor Plan-Overall: Partial Plan-2 Partial Plan-3 Partial Plan-4 Partial Plan-5Документ7 страницBasement Floor Plan-Overall: Partial Plan-2 Partial Plan-3 Partial Plan-4 Partial Plan-5abid hamzaОценок пока нет

- Flooding in JapanДокумент25 страницFlooding in JapangefinnaОценок пока нет

- Phoenix Towers PlansДокумент18 страницPhoenix Towers PlansThe Valley IndyОценок пока нет

- Basement Floor Plan: Extraction Room 130 SQ.MДокумент1 страницаBasement Floor Plan: Extraction Room 130 SQ.MRichaОценок пока нет

- 12th and Red River HotelДокумент20 страниц12th and Red River Hoteldali yangОценок пока нет

- ShopDrawings - Part 1Документ51 страницаShopDrawings - Part 1YapОценок пока нет

- 24 Harman St. - DOB SUBMISSION PLANS PDFДокумент18 страниц24 Harman St. - DOB SUBMISSION PLANS PDFmgdrivenОценок пока нет

- 01 Site Planning Site Analysis - 1Документ44 страницы01 Site Planning Site Analysis - 1Ma. Jeanne Elyza MuñizОценок пока нет

- Myron's PlansДокумент7 страницMyron's PlansIrvin KleinОценок пока нет

- 405 ColoradoДокумент10 страниц405 Coloradodali yangОценок пока нет

- Hotel Bella Vista PanchkulaДокумент48 страницHotel Bella Vista PanchkulaAnas KhanОценок пока нет

- 1500 15th St. Project PlansДокумент19 страниц1500 15th St. Project PlansMissionLocalОценок пока нет

- 00-Flash Flood Risk Assessment For Kyushu Island, JapanДокумент20 страниц00-Flash Flood Risk Assessment For Kyushu Island, JapanAdly Al-SaafinОценок пока нет

- 5.0 Site Concept1Документ18 страниц5.0 Site Concept1ianyanОценок пока нет

- Urban Design Brief 131 & 135 Trafalgar Road Mixed Residential/Commercial DevelopmentДокумент12 страницUrban Design Brief 131 & 135 Trafalgar Road Mixed Residential/Commercial DevelopmentMehreen IftikharОценок пока нет

- Nijaga RoofДокумент23 страницыNijaga RoofMomie MarquezОценок пока нет

- Case Study - ArДокумент35 страницCase Study - ArUllas MurugeshОценок пока нет

- 1650 E Olive Way: Proposed Mixed-Use Development DPD # 3002133 January 19, 2011 Design Review RecommendationДокумент29 страниц1650 E Olive Way: Proposed Mixed-Use Development DPD # 3002133 January 19, 2011 Design Review RecommendationChs BlogОценок пока нет

- Boys Toilet: W.C 1000x1600 W.C 1000x1600 W.C 1000x1600 W.C 1000x1600Документ1 страницаBoys Toilet: W.C 1000x1600 W.C 1000x1600 W.C 1000x1600 W.C 1000x1600yash ayreОценок пока нет

- ThesisДокумент17 страницThesisAr Raymar Balisi Arabes0% (1)

- Centex Gas Station:Starbucks ProposalДокумент2 страницыCentex Gas Station:Starbucks ProposalnewsroomОценок пока нет

- Its 2008 IRR: Revised Rules and StandardsДокумент32 страницыIts 2008 IRR: Revised Rules and StandardsErika RafaelОценок пока нет

- Lac Session Complete TemplateДокумент4 страницыLac Session Complete TemplateRilyn Limbaro CantaОценок пока нет

- Chapter 1 HousingДокумент97 страницChapter 1 HousingMaDonna ZabalaОценок пока нет

- Micro-Climate Analysis of Bhopal for Passive DesignДокумент5 страницMicro-Climate Analysis of Bhopal for Passive DesignDrishti AgarwalОценок пока нет

- Boutique Fitness Studio Construction SetДокумент11 страницBoutique Fitness Studio Construction SethannahchiaroniclarkeОценок пока нет

- Architectural School Design Study CasesДокумент117 страницArchitectural School Design Study CasesRazan KhrisatОценок пока нет

- Alamainos Waterfront Conclusion Chapter 9Документ3 страницыAlamainos Waterfront Conclusion Chapter 9John Kevin Maddatu SorianoОценок пока нет

- Unit 5Документ42 страницыUnit 5ashok Pradhan0% (1)

- ArchitectureДокумент104 страницыArchitecturePrerna Bhatt100% (1)

- CCTV Installation Gulayan Sa Paaralan Internet ConnectionДокумент13 страницCCTV Installation Gulayan Sa Paaralan Internet ConnectionPhoebe JaeОценок пока нет

- Case Study Heriot WattДокумент62 страницыCase Study Heriot Watt2021827922Оценок пока нет

- Item Analysis and Evaluation of Test Results: May 24, 2017, 1:00 - 3:00pmДокумент27 страницItem Analysis and Evaluation of Test Results: May 24, 2017, 1:00 - 3:00pmdulce garciaОценок пока нет

- Ee9al Ee5d Ballesteros Mariano PDF File 1Документ3 страницыEe9al Ee5d Ballesteros Mariano PDF File 1jenixson tamondongОценок пока нет

- 2524 8 Chifley Sustainable Structural and Fire EngineeringДокумент8 страниц2524 8 Chifley Sustainable Structural and Fire EngineeringJulio MzpОценок пока нет

- Proposed Jamiyah Nursing HomeДокумент25 страницProposed Jamiyah Nursing HomeZafirah ZulfakharОценок пока нет

- Daylighting in Architectural Design.Документ209 страницDaylighting in Architectural Design.Himanshu SainiОценок пока нет

- Tagum City Climate Policy Review and Urban Design Project Brief Draft ProposalДокумент33 страницыTagum City Climate Policy Review and Urban Design Project Brief Draft ProposalLuis S Alvarez JrОценок пока нет

- Types of Roofing SystemДокумент6 страницTypes of Roofing SystemDev SharmaОценок пока нет

- Basement Construction Methods and TechnologiesДокумент10 страницBasement Construction Methods and TechnologiesMadhu KiniОценок пока нет

- Standard Hotel Spatial RequirementsДокумент13 страницStandard Hotel Spatial RequirementsAISHОценок пока нет

- Lecture HallДокумент32 страницыLecture HallkwongyawОценок пока нет

- APartment and Restuarant SINGLE FILEДокумент4 страницыAPartment and Restuarant SINGLE FILEAkela RichardОценок пока нет

- CeilingConnex InstructionsДокумент2 страницыCeilingConnex InstructionsRyan RusherОценок пока нет

- Literature 1-Hong Kong Design InstituteДокумент25 страницLiterature 1-Hong Kong Design InstituteNarmatha KamalОценок пока нет

- Case Study: Shirley Das 1BQ12AT053 Sem: Viii B.Arch, BmssaДокумент1 страницаCase Study: Shirley Das 1BQ12AT053 Sem: Viii B.Arch, BmssaShirley DasОценок пока нет

- Case Study Toranomon Hills Mori Tower, Tokyo ENДокумент4 страницыCase Study Toranomon Hills Mori Tower, Tokyo ENSathiish Kumar100% (1)

- Ad Case Study Sem6Документ18 страницAd Case Study Sem6sakshi meherОценок пока нет

- Mixed Use Development 2Документ3 страницыMixed Use Development 2AKASH DAYAL0% (1)

- Site Analysis Studio 3Документ61 страницаSite Analysis Studio 3Nyzem NasirОценок пока нет

- Luxury Hotel Offers Mountain Views and SpaДокумент44 страницыLuxury Hotel Offers Mountain Views and SpaEphrem HailuОценок пока нет

- Hotel Thesis ProposalДокумент4 страницыHotel Thesis ProposalSupria JanvejaОценок пока нет

- Report on elementary school designs in AsiaДокумент12 страницReport on elementary school designs in AsiaAmina AhmedОценок пока нет

- MG University - Barch - Semester Three - Structure DesignДокумент28 страницMG University - Barch - Semester Three - Structure Designakshay babuОценок пока нет

- BOC Tower Structural DesignДокумент32 страницыBOC Tower Structural DesignSushant GuptaОценок пока нет

- Shorings and Bracings of The Structure For All Loads That Maybe Imposed During ConstructionДокумент7 страницShorings and Bracings of The Structure For All Loads That Maybe Imposed During ConstructionNatalie WrightОценок пока нет

- Retrofitting Recommendations and SpecificationsДокумент3 страницыRetrofitting Recommendations and SpecificationsJoseph Cloyd LamberteОценок пока нет

- Structural Notes 1Документ1 страницаStructural Notes 1missiklein3Оценок пока нет

- 01 90 00arcДокумент1 страница01 90 00arcEppОценок пока нет

- Memorial Parks CemeteriesДокумент36 страницMemorial Parks CemeteriesChiradee Barillo GarrovilloОценок пока нет

- 03 05 00xpxДокумент5 страниц03 05 00xpxEppОценок пока нет

- 01 30 00arcДокумент2 страницы01 30 00arcEppОценок пока нет

- Architectural Services ContractДокумент21 страницаArchitectural Services Contractgiuseppe_dicaroОценок пока нет

- 01 60 00arcДокумент1 страница01 60 00arcEppОценок пока нет

- 01 10 00arcДокумент2 страницы01 10 00arcEppОценок пока нет

- 01 35 00wenДокумент3 страницы01 35 00wenEppОценок пока нет

- 01 80 00arcДокумент2 страницы01 80 00arcEppОценок пока нет

- 01 56 00ramДокумент4 страницы01 56 00ramEppОценок пока нет

- 01 70 00arcДокумент2 страницы01 70 00arcEppОценок пока нет

- Board of Architecture-SBДокумент8 страницBoard of Architecture-SBarki_clintОценок пока нет

- 01 20 00arcДокумент3 страницы01 20 00arcEppОценок пока нет

- 01 50 00arcДокумент2 страницы01 50 00arcEppОценок пока нет

- Selective Demolition ProceduresДокумент3 страницыSelective Demolition ProceduresEppОценок пока нет

- Structure Demolition PlanДокумент3 страницыStructure Demolition PlanEppОценок пока нет

- 2016 Sylvanian Family CatalogueДокумент55 страниц2016 Sylvanian Family CatalogueEppОценок пока нет

- EJA Overview DraftДокумент1 страницаEJA Overview DraftEppОценок пока нет

- Conception TropicaleДокумент46 страницConception TropicaleEppОценок пока нет

- Intérieurs ArchitecturauxДокумент135 страницIntérieurs ArchitecturauxEppОценок пока нет

- BP 344Документ58 страницBP 344Ultrabuilders Const100% (14)

- Architectural Color Line Weight (MM) DescriptionДокумент10 страницArchitectural Color Line Weight (MM) DescriptionBagusBudiОценок пока нет

- Enquête ApprentiДокумент1 страницаEnquête ApprentiEppОценок пока нет

- TermsДокумент8 страницTermsEppОценок пока нет

- Olympic StructuresДокумент12 страницOlympic StructuresEppОценок пока нет

- Types of Arches PDFДокумент1 страницаTypes of Arches PDFEppОценок пока нет

- NBC PD1096 Rule VIII AnnotatedДокумент47 страницNBC PD1096 Rule VIII Annotatedraegab93% (69)

- Guidelines For Land-Use PlanningДокумент142 страницыGuidelines For Land-Use PlanningEppОценок пока нет

- Guidelines For Land-Use PlanningДокумент132 страницыGuidelines For Land-Use PlanningEppОценок пока нет

- 1902 - BirДокумент2 страницы1902 - BirLilian Laurel Cariquitan50% (2)

- HP Color Laserjet Pro MFP M477 Series: Stunning Speed. Solid SecurityДокумент5 страницHP Color Laserjet Pro MFP M477 Series: Stunning Speed. Solid Securitygem lihanshОценок пока нет

- Chapter 6 Plate GirderДокумент23 страницыChapter 6 Plate GirderolomuОценок пока нет

- Kms-Iv enДокумент104 страницыKms-Iv enRob VerhagenОценок пока нет

- Dwva (7,700-18,000 CFM)Документ2 страницыDwva (7,700-18,000 CFM)Yutt WattОценок пока нет

- ALU 9500 MPR Product InformationДокумент76 страницALU 9500 MPR Product InformationbigjohnbundyОценок пока нет

- Structural Steel Inspection Report PDF FreeДокумент2 страницыStructural Steel Inspection Report PDF FreeAliОценок пока нет

- BLD-ELEC Standard Data For Electrical Items In BuildingsДокумент115 страницBLD-ELEC Standard Data For Electrical Items In BuildingsrokiahhassanОценок пока нет

- S7 200 CommunicationДокумент34 страницыS7 200 CommunicationsyoussefОценок пока нет

- Kamal Sagar: A Contemporary Indian ArchitectДокумент9 страницKamal Sagar: A Contemporary Indian ArchitectAshanur RahmanОценок пока нет

- PolyView User Guide N6.7 PDFДокумент165 страницPolyView User Guide N6.7 PDFAnonymous DiYsCrAJHtОценок пока нет

- FDT Form PDFДокумент1 страницаFDT Form PDFGenevieve GayosoОценок пока нет

- Materi Erg - 2 PDFДокумент45 страницMateri Erg - 2 PDFMuhamad Farid GeonovaОценок пока нет

- Wireless Security Design PDFДокумент8 страницWireless Security Design PDFIanRahmadiОценок пока нет

- Ds 8 K Tool Announcement PresentationДокумент17 страницDs 8 K Tool Announcement PresentationAshish KuvawalaОценок пока нет

- 6 Sat Plumbing QuestionДокумент2 страницы6 Sat Plumbing QuestionMons DelmendoОценок пока нет

- Contemporary Architecture in Different Areas of The Arab World: Redefining Identity Through A New Built EnvironmentДокумент11 страницContemporary Architecture in Different Areas of The Arab World: Redefining Identity Through A New Built EnvironmentakshiОценок пока нет

- UMTS RAN Dimensioning GuidelinesДокумент31 страницаUMTS RAN Dimensioning GuidelinesAzer TyuiopОценок пока нет

- Cleanroom Design in 10 Easy StepsДокумент5 страницCleanroom Design in 10 Easy StepsWerner SchrammelОценок пока нет

- BN-DS-C01 Overview of The Piping Design StandardsДокумент4 страницыBN-DS-C01 Overview of The Piping Design Standardsyulianus_srОценок пока нет

- Architectural Design-Vi Literature Study of MallДокумент38 страницArchitectural Design-Vi Literature Study of Malldevrishabh72% (60)

- Modern Construction Technology MethodsДокумент17 страницModern Construction Technology MethodsASWIN GEORGE100% (1)

- 2279B Mod07la PDFДокумент6 страниц2279B Mod07la PDFJosé MarquesОценок пока нет

- Concrete Mix Design M20 GradeДокумент4 страницыConcrete Mix Design M20 GradeSyerifaizal Hj. MustaphaОценок пока нет

- Information SheetДокумент4 страницыInformation SheetHarold AguinaldoОценок пока нет

- Design of Staircase 1 Staicase DatasДокумент3 страницыDesign of Staircase 1 Staicase Datasmeenu100% (1)

- CC Marine 2013-14 Catalogue - SailingДокумент8 страницCC Marine 2013-14 Catalogue - SailingGregGGHОценок пока нет

- (Gui To Learn and Use Calculix) : Table 1 Main Calculix CGX CardsДокумент3 страницы(Gui To Learn and Use Calculix) : Table 1 Main Calculix CGX CardsXavier SandovalОценок пока нет

- Citrix Virtual Desktop Handbook (7x)Документ220 страницCitrix Virtual Desktop Handbook (7x)sunildwivedi10Оценок пока нет

- Three Storey Commercial BuildingДокумент2 страницыThree Storey Commercial Buildingrichard romasantaОценок пока нет