Академический Документы

Профессиональный Документы

Культура Документы

Lifting Analysis Report - Template

Загружено:

Lukman HakimОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lifting Analysis Report - Template

Загружено:

Lukman HakimАвторское право:

Доступные форматы

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

APPROVED FOR

CONSTRUTION

0

B

A

REV.

ISSUED FOR APPROVAL

20/05/05

ANA

ISSUED FOR CLIENT

COMMENTS

DATE

BY

DESCRIPTION

CHECK

APPR.

APPR.

ENGINEER APPROVAL

APPR.

CONTRACTOR

COMPANY

STATUS CODE : A = Issued for comments - B = Issued for approval - C = Approved

TOTAL OR PARTIAL REPRODUCTION AND/OR UTILIZATION OF THIS DOCUMENT ARE FORBIDDEN

WITHOUT PRIOR WRITTEN AUTHORIZATION OF THE OWNER

DOCUMENT NUMBER

AG-03-002

CLASS

REVISION

STATUS

A

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

10/10/10

REVISION:

PAGE:

2 of 31

TABULATION OF REVISED PAGES

REVISIONS

PAGE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

A

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

REMARKS

E

APP

A

B

C

D

E

F

G

EXHI.

ATTACHMENTS

REVISIONS

PAGES

A

B

C

D

8

X

X

22

X

X

2

X

X

2

X

X

16

X

X

10

X

X

2

X

X

PAGES

REVISIONS

B

C

D

REMARKS

E

REMARKS

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

10/10/10

REVISION:

PAGE:

3 of 31

TABLE OF CONTENTS

1 INTRODUCTION.................................................................................................................. 6

1.1 OBJECTIVE OF THE ANALYSIS................................................................................6

2 SUMMARY OF CONCLUSION............................................................................................7

2.1 WEIGHT SUMMARY..................................................................................................7

2.2 CENTRE OF GRAVITY..............................................................................................7

2.3 MAXIMUM SLING LOAD............................................................................................8

2.4 API/AISC MEMBER STRESS RATIOS.......................................................................9

2.5 API/AISC JOINT PUNCHING SHEAR STRESS RATIOS...........................................9

2.6 API/AISC JOINT MINIMUM REQUIRED STRENGTH RATIOS................................10

2.7 JOINT DEFLECTION...............................................................................................10

3 DESIGN PREMISES..........................................................................................................11

3.1 REFERENCE DOCUMENTS....................................................................................11

3.2 MATERIAL................................................................................................................ 11

3.3 COMPUTER PROGRAM.........................................................................................12

3.4 UNIT SYSTEM......................................................................................................... 12

4 COMPUTER MODEL......................................................................................................... 14

4.1 METHOD OF ANALYSIS..........................................................................................14

4.1.1 GENERAL.................................................................................................................... 14

4.1.2 ALLOWABLE STRESS................................................................................................ 14

4.1.3 CONTINGENCY FACTOR........................................................................................... 14

4.1.4 DYNAMIC AMPLIFICATION FACTOR.........................................................................15

4.1.5 CONSEQUENCE FACTOR.......................................................................................... 15

4.1.6 SKEW EFFECT............................................................................................................ 15

4.1.7 RIGGING ARRANGEMENT......................................................................................... 15

4.1.8 COG VARIATION......................................................................................................... 16

4.2 STRUCTURAL MODEL............................................................................................18

4.2.1 GENERAL VIEW.......................................................................................................... 18

4.2.2 DESCRIPTION............................................................................................................. 19

4.3 GLOBAL AXIS SYSTEM...........................................................................................19

4.4 LOCAL AXIS SYSTEM.............................................................................................19

4.5 BOUNDARY CONDITIONS......................................................................................19

4.5.1 HOOK POINT............................................................................................................... 19

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

10/10/10

REVISION:

PAGE:

4 of 31

4.5.2 SLINGS........................................................................................................................ 19

4.5.3 MODEL GLOBAL STABILITY.....................................................................................19

5 LOADING........................................................................................................................... 21

5.1 ELEMENTARY LOAD DEFINITION..........................................................................21

5.2 COG SHIFT FORCE CALCULATION.......................................................................21

5.3 LOADING COMBINATIONS.....................................................................................23

5.3.1 PRE-LOADING COMBINATION..................................................................................23

5.3.2 LOADING COMBINATION WITHOUT CONSEQUENCE FACTOR............................24

5.3.3 LOADING COMBINATION FOR MEMBER CONNECTING TO PADEYE...................24

5.3.4 LOADING COMBINATION FOR MEMBER NOT CONNECTING TO PADEYE..........25

6 ANALYSIS RESULTS......................................................................................................... 26

6.1 LOADING SUMMARY..............................................................................................26

6.1.1 ELEMENTARY LOAD.................................................................................................. 26

6.1.2 PRE-LOADINGS AND LOADING COMBINATION......................................................26

6.1.3 LOADING SUMMARY AND COG................................................................................27

6.2 DEFLECTION PLOTS..............................................................................................28

6.3 SLINGS LOAD......................................................................................................... 28

6.4 MEMBER CODE CHECKS.......................................................................................29

6.4.1 MEMBER CONNECTED TO PADEYE.........................................................................29

6.4.2 MEMBER NOT CONNECTED TO PADEYE................................................................29

6.5 REACTION............................................................................................................... 29

6.6 CONNECTION CODE CHECKS..............................................................................31

ATTACHMENTS

APPENDIX A

PADEYE DESIGN AND CALCULATION

APPENDIX B

STRUCTURAL GEOMETRY

APPENDIX C

JOINT DEFLECTION PLOTS

APPENDIX D

UNITY CHECK RATIO PLOTS

APPENDIX E

SACS INPUT FILE

APPENDIX F

SACS OUTPUT FILE

Appendix F1

Maximum Joint Deflection List

Appendix F2

Member Unity Check Summary

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

APPENDIX G

REFERENCES DRAWING

10/10/10

A

5 of 31

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

INTRODUCTION

1.1

OBJECTIVE OF THE ANALYSIS

10/10/10

A

6 of 31

The purpose of this calculation is to check the adequacy of DIESEL STORAGE to sustain the loads

that may occur during the lifting conditions, which comprise of :

The dead weight of Diesel Storage Platform

The dynamic amplification due to offshore site.

The lifting sling load distribution accounting for CoG variation and sling length inaccuracy.

The design of lifting padeyes

The calculation is based on the design data and the requirements in the Structural Design Basis ,

General Specification, General Specification for Design of Offshore Topside Structure (Ref. 7),

General Specification for Load-out, Sea-fastening, Transportation and Installation of Offshore

Structures (Ref. 10) & API RP2A-WSD 21st 2000 Edition (Ref. 11).

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

SUMMARY OF CONCLUSION

2.1

WEIGHT SUMMARY

10/10/10

A

7 of 31

The detail weight summary of DIESEL lifting condition without contingency as well as with

contingency is given in the following table. Definition and detail of the loading condition is given in

chapter 5.1.

Unit : kN

Structure

Loading Condition

Main Structure Self Weight

Structural Appurtenance

Diesel Storage Tanks Opt.

Diesel Fuel Transfer Pump

Piping Dry

Electrical/Instrumentations

DIESEL

STORAGE

Actual Weight

Cont's

Precog: saclst.1000ta , keyword : basic load

2.2

CENTRE OF GRAVITY

The centre of gravity and origin co-ordinates are shown below :

Platform North

8.40 m

PL09

1

PL12

Diesel

Storage

DIESEL STORAGE

Deck Center

(-0.000, 0.000)

11.75 m

X

DIESEL CoG

(-0.90,0.34)

2

PL05

PL06

Actual Weight

with

Contingencies

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

10/10/10

A

8 of 31

The centre of gravity from SACS calculation are as follow :

CoG (m)

Structure

DIESEL STORAGE

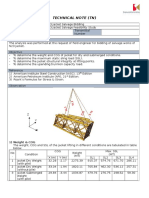

2.3 MAXIMUM SLING LOAD

The maximum sling loads is performed with considering the 1.30 dynamic amplification factor and

shifted of centre of gravity location. The slings angles are measured between slings and the

horizontal plane (degree) see sketch below.

HOOK

POINT

Point

No.

1

2

3

4

Point

Diesel Storage

Vertical Angle (

Member

Degree

The maximum sling loads are shown in the table below:

Padeye on the DIESEL STORAGE:

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

Lifting Point Type

Attached to:

Load Case

10/10/10

Member

9 of 31

Load (kN)

Padeye

Padeye

Padeye

Padaye

From the above member sling load table, the maximum sling load DIESEL STORAGE is 728.75 kN.

Thus, this load will be used for pad-eyes design. The pad-eye design and calculation will be

explained in Appendix A in this report.

File dari pltlst.LPA, keyword : member forces

2.4

API/AISC MEMBER STRESS RATIOS

Maximum stress ratios obtained for members are :

Members connected to padeye :

The maximum interaction ratio below is checked with the consequence factor of 1.35.

Location

Member

Properties

Load

Case

UC

DIESEL

STORAGE

Pstlst.NLP, key word : r than 1

Members not connected to padeye :

These member below are not connected to the lift points. These members are checked with the

consequence factor of 1.15.

Location

Member

Properties

Load

Case

UC

DIESEL

STORAGE

Pstlst.FLP, key word : r than 1

All member have satisfied the API RP2A WSD 21 st Edition / AISC 9th Edition code checking

requirements in lifting condition.

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

2.5

10/10/10

A

10 of 31

API/AISC JOINT PUNCHING SHEAR STRESS RATIOS

No tubular intersection is found during structure lifting analysis. Therefore, punching shear check is

not performed in the analysis.

2.6

API/AISC JOINT MINIMUM REQUIRED STRENGTH RATIOS

No tubular intersection is found during structure lifting analysis. Therefore, joint minimum required

strength ratios is not resulted in the analysis.

2.7

JOINT DEFLECTION

The maximum joint deflection occurred on the lifting analysis (included lifting in shifted position) are

shown below :

Displacements given are relative displacements with regard to the extremities of span (mm).

Location

Member

Span

(l)

Properties

Deflection

Relative (d)

Load

Case

d/l

DIESEL

STORAGE

All deflections are acceptable, which are less than 1/360 for main beam and 1/300 for other beam

(for cantilever l design value is twice the cantilever length).

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

DESIGN PREMISES

3.1

REFERENCE DOCUMENTS

10/10/10

A

11 of 31

The present analysis is carried out based on the design criteria described in the following documents

1) Document no. Design of Offshore Topside Structure

2) Document no. MTO -Structural

3) Document no. Equipment List

4) Drawings References:

a.

DIESEL STORAGE Platform Deck Framing Sheet 1

b.

DIESEL STORAGE Platform Deck Framing Sheet 1

3.1.1 Project Specification and Reports

1) Document No. Structural Design Basis

2) Document No. Platforms Weight Control Report

3.1.2 Company General Specification

3) Document No. Weight Monitoring and Weighing Offshore Units, Rev. 02.

4) Document No. Design of Offshore Topsides Structures, Rev. 02.

5) Document No. Material for Offshore Steel Structures, Rev. 01.

6) Document No. Fabrication of Offshore Steel Structures, Rev. 02.

7) Document No. Load-out, Sea-Fastening, Transportation and Installation of Offshore Structures,

Rev.01.

3.1.3 Codes and Standards

8) API RP2A-WSD. 21st Edition, Recommended Practice for Planning, Designing and Construction

Fixed Offshore Platforms 2000.

9) AISC 9th Edition/ASD, American Institute of Steel Construction/Allowable Stress Design 1989.

3.2

MATERIAL

All structures will be made of steel, using the following properties:

Steel density

: 7.850 t/m3

Elastic modulus

: 205000 MPa

Poisson's ratio

: 0.3

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

10/10/10

REVISION:

12 of 31

PAGE:

Steel grades are per basic engineering drawings with the following corresponding yield stresses:

for grade S355

for grade S235

Fy = 355 MPa

thk 16 mm

Fy = 345 MPa

16 mm < thk 40 mm

Fy = 335 MPa

40 mm < thk

Fy = 235 MPa

thk 16 mm

Fy = 225 MPa

16 mm < thk 40 mm

Fy = 215 MPa

40 mm < thk

Material strength refer to general COMPANY specification of reference GS-STR-201.

See hereunder the steel category specification and yield stress.

SPECIAL CATEGORY

FIRST CATEGORY

SECOND CATEGORY

Piles

S355

Tubular OD < 12

S235

Deck leg

S355

Tubular OD > 12

S355

Tubular

S235

WPG

S355

(Web height > 600mm) (*)

WPG

S235

(Web height > 600mm) (*)

Padeyes

S355

Rolled section

S235

(Web height < 600mm) (*)

Rolled section

S235

Plates

S355

Plates

Plates

S235

S235

(*) Welded plate girder shall be preferred for web height is superior to 600mm, else rolled section

shall be used.

3.3

COMPUTER PROGRAM

The following software will be used for modelling and designing of structures :

SACS version 5.2.

This software is developed and produced by EDI (Engineering Dynamics Inc.)

The analysis uses the following co-ordinates :

X : Plant east

3.4

Y : Plant north

Z : Vertical up

UNIT SYSTEM

The following unit system shall be adopted in the SACS analysis files and design documents:

-

Great length

: in meter (member length, joint co-ordinates)

Small length

: in mm or inches (tube diameter, tube wall thickness, etc)

Forces and moments

: in kN or kNm

Masses

: in kg or metric tons

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

Stresses

: in kN/cm2

Angles

: in degree

10/10/10

A

13 of 31

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

COMPUTER MODEL

4.1

METHOD OF ANALYSIS

10/10/10

A

14 of 31

4.1.1 General

The lifting analysis to be carried out are classical static linear analysis of a three dimensional space

frame computer model comprising the Diesel Storage main structure.

Each loading case, an equivalent linear stiffness matrix simulating the behaviour of the structure

automatically computed by the software before the structural analysis of the whole frame proceeds.

The lift arrangement is based on a hook position above the deck CoG and such that the minimum

sling angle with the horizontal is 60 (+/-) 5.

In addition to the nominal CoG position, 2 extreme positions of the CoG are investigated in a

variation along X ans 2 other positions in a variation along Y, which are equal to 10% of the Diesel

Storage dimensions, but not less than within a 2.0 m.

Member stress checking and joint check are performed according to API RP2A WSD 21 st edition

4.1.2 Allowable Stress

Code checking is done using basic allowable stresses

4.1.3 Contingency Factor

4.1.3.1 Provisions

Gravity loads :

equipment dry weights,

piping dry weight,

structural dead weight,

Instrumentation & Electrical bulk,

live loads,

are calculated based upon the Loading Diagrams, Equipment List and also taking into account the

latest up-dated equipment weight including the following provision:

10 %

provision on equipment dry weight is accounted for supporting structure accesses &

walkways,

15 %

provision on piping dry weight is accounted for pipe supports,

5%

provision on structural weight is accounted for stiffening & welding,

5%

provision on pile weight is accounted for welding,

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

10/10/10

REVISION:

PAGE:

15 of 31

4.1.3.2 Weight Contingencies

Contingencies are covered by applying where appropriate in the load combinations the following

contingency factors.

15 %

on main structural weight,

15 %

on secondary structural weight,

25 %

on mechanical weight,

20 %

on dry piping weight,

25 %

on bulk electrical weight,

25 %

on bulk instrumentation weight,

25 %

on itemised electrical weight,

25 %

on itemised instrumentation weight,

25 %

for safety items,

0%

on environmental loads,

0%

on live loads.

The weight contingency factor as specified above are applied on dry weight plus provision.

4.1.4 Dynamic Amplification Factor

The dynamic amplification factor is 1.30 for lifted weight less than 100 tonnes.

4.1.5 Consequence Factor

A consequence factor of 1.35 is applied for the code checking of any member attached to lifting

points, as well as joints to which these members are connected for punching shear verification.

A consequence factor of 1.15 is applied for the other members and joints.

4.1.6 Skew Effect

The skew effect is applied to take into account shortening or stretching of slings. The load is factored

by 1.33 as a skew load factored (SKL) for flexible object (module) as per GS-STR-401 Section

6.2.2.5 skew load distribution for Single Hook Lifts and 1.15 skew load factored for lifting using

spreader bar

4.1.7 Rigging Arrangement

Diesel Storage is lifted with 4-off slings from a single hook point to padeyes. The hook point is

managed to locate above the centre of gravity of structure. The slings are modeled by tubular

3ODX1.25WT with a Youngs modulus of 100000 Mpa, in order to take into account slings stiffness

for analysis. The minimum angle for the all slings is 60 (+/-) 5 degree. The slings arrangement is

shown below.

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

10/10/10

A

16 of 31

4.1.8 CoG Variation

The effect of the variation of the position of the centre of gravity is investigated. The 4-off positions

are investigated in a variation along X and Y equal to 10% of the structure dimensions, but not less

than within a 2.0 m. The minimum 2.0 m CoG variations along X and Y to be used for this lifting

analysis.

CoG positions are given in the table :

Diesel Storage

CoG shifts

Longitudinal

Transversal

X (m)

Y (m)

5%

5%

X.XX < 1.00

X.XX < 1.00

Deck dimension

Shift +/- (%)

Shifts +/- (m)

Shifts to be used

1.00

COG THEORITICAL POSITION

CoG Original

1.00

COG SHIFTED POSITIONS

CoG 1 (-,-)

CoG 2 (+,-)

CoG 3 (-,+)

CoG 4 (+,+)

The sketch showing the variation of CoG are shown in figure below :

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

10/10/10

A

17 of 31

4

Platform

North

CoG

3

1

4

2

2

CoG shifted (4 Location)

2 m x 2 m Box

The shifts of centre of gravity are obtained by applying dummy forces with zero resultant at four

joints. Dummy forces calculations are presented in Section 5.2 CoG Shift Force Calculation.

The loaded joints at Diesel Storage are node 001L, 002L, 003L and 004L. Those loaded joints are

located at pile heads of the structures.

This is illustrated by figure below :

Diesel Storage SHIFT X

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

Diesel Storage SHIFT Y

4.2

STRUCTURAL MODEL

The computer structural model plot are shown in the Appendix B.

4.2.1 General View

The following plot shows the general model of the Diesel Storage

10/10/10

A

18 of 31

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

4.2.2

10/10/10

A

19 of 31

Description

The different elements included in the structural model are defined here below:

-

Structural part

Primary and secondary structures together with flooring (including the deck plating, grating, handrail,

stringers and joists) are in the structural section. Only the main structure is modelled in this report,

the other structural components will be input as uniform member load or joint load.

4.3

GLOBAL AXIS SYSTEM

Nodes of the structural model are described in a global axis system defined as follows:

4.4

The origin of the global axis system is taken at the Chart Datum/LAT and comes up to the centre

of the main deck legs.

Z is vertical from the Chart Datum/LAT

Y is horizontal parallel to the platform north

X is horizontal parallel to the platform east

LOCAL AXIS SYSTEM

Each member of the structural model has its own local axis system in which calculated internal

forces and moments are expressed. It can also be used to introduce loads on the members.

4.5

BOUNDARY CONDITIONS

4.5.1 Hook Point

The hook point is modelled using 1-off node, as explained in section 4.1.6 Skew Effect. Basically,

this node is fixed for the 6 degrees of freedom.

4.5.2 Slings

All slings are released in local moment Y and Z at hook end point an in moment X, Y, and Z at the

other end, to present the shear force and moment generation.

4.5.3 Model Global Stability

To avoid the numerical instability, joint 001L of Diesel Storage is fixed in horizontal X and Y-axis

displacement, however, joints 004L of Diesel Storage is fixed in horizontal X-axis displacement.

Hook point is fixed in 6 degree of freedom. See figure below.

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

10/10/10

A

20 of 31

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

10/10/10

A

21 of 31

LOADING

The loading diagram shown in the Appendix A has been used to establish the loading.

5.1

ELEMENTARY LOAD DEFINITION

Elementary loads to be considered are summarised in the table below. Description of each loading

type is detailed thereafter.

Discipline of loads

Structure

Loading

name

Structural

Diesel Storage

Equipment

Balancing Forces (couple)

5.2

Description

Structural Self Weight

Structural Appurtenance

Diesel Storage Tank Operation

Diesel Fuel Transfer Pump

Piping Dry

Electrical/Instrumentations

+X

Enforce loads along X direction

+Y

Enforce loads along Y direction

COG SHIFT FORCE CALCULATION

Diesel Storage Platform

The CoG shift forces are applied at the joints connecting slings to boat landing. Those forces allow

for enforced shifting of CoG.

The load +X causes the shift of the CoG along X :

2 x F+x x Lx = Fz x x

F+x = (Fz x x) / (2 x Lx)

F+x = (xxx.xx 1.00) / (2 x xx) = xx.xxx kN

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

10/10/10

REVISION:

PAGE:

22 of 31

These load are applied at :

Node 001L

Node 003L

Node 002L

Node 004L

-xx.xxx kN

-xx.xxx kN

xx.xxx kN

xx.xxx kN

The load +Y causes the shift of the CoG along Y:

2 x F+y x Ly = Fz x y

F

+y

= (Fz x y) / (2 x Ly)

F+y = (xx.xxx x 1.00) / (2 x 11.75) = xx.xxx kN

These load are applied at :

Node 001L

Node 003L

Node 002L

Node 004L

-xx.xxx kN

xx.xxx kN

-xx.xxx kN

xx.xxx kN

This is illustrated by figure below :

Load Condition +X Enforce Loads along X Direction

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

10/10/10

A

23 of 31

Load Condition +Y Enforce Loads along Y Direction

The resultants of these forces are equal to zero in order to keep the same weight of the boat landing.

5.3

LOADING COMBINATIONS

5.3.1 Pre-loading Combination

Prior to make a load combination, the pre-loading combination is required to easier to make load

combination.

The pre-loading combination definition are shown below:

Load Label

WGHT

Description

Lift weight with contingencies

DAF

Lift weight with contingencies and dynamic amplification factor

NLP

Lift weight with contingencies, DAF and 1.35 consequence factor

FLP

Lift weight with contingencies, DAF and 1.15 consequence factor

The pre-loading combination factor are shown in the table below:

Loading

Description

WGHT

Structural Self Weight

1.1500

Structural Appurtunances

1.1500

Loading

DAF

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

WGHT

1.20

Loading

PAD

NPAD

DAF

1.350

1.150

10/10/10

A

24 of 31

The loading combination for CSF (common solution file) module will be explained below:

The loading definition:

Loading Type

Definition

Loading 0

Origin position with 1.33 skew load factor

Loading 1

Shift 1 with 1.33 skew load factor

Loading 2

Shift 2 with 1.33 skew load factor

The final result will be a combination of all shifted condition and origin position both for 1.15

consequence factor, 1.35 consequence factor and no consequence factor.

5.3.2 Loading Combination without Consequence Factor

The load factors to be used in the load combination are as follows:

Diesel Storage module

Loading

LPA0

LPA1

LPA2

LPA3

LPA4

DAF

1.330

1.330

1.330

1.330

1.330

+X

1.330

1.330

-1.330

-1.330

+Y

1.330

-1.330

-1.330

1.330

5.3.3 Loading Combination for Member Connecting to Padeye

Diesel Storage module

The corresponding factors to be applied for maximum slings load are:

For +X = 1.33 x 1.35

= 1.7955

For +Y = 1.33 x 1.35

= 1.7955

Loading combination with contingencies, DAF, consequence factor have 1.35 and skew effect

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

Loading

NLP0

NLP1

NLP2

NLP3

NLP4

DAF

1.330

1.330

1.330

1.330

1.330

+X

1.7955

1.7955

-1.7955

-1.7955

+Y

1.7955

-1.7955

-1.7955

1.7955

5.3.4 Loading Combination for Member not Connecting to Padeye

Diesel Storage module

The corresponding factors to be applied for maximum slings load are:

For +X = 1.33 x 1.15

= 1.5295

For +Y = 1.33 x 1.15

= 1.5295

Loading combination with contingencies, DAF, consequence factor of 1.15 and skew effect

Loading

FLP0

FLP1

FLP2

FLP3

FLP4

DAF

1.330

1.330

1.330

1.330

1.330

+X

1.5295

1.5295

-1.5295

-1.5295

+Y

1.5295

-1.5295

-1.5295

1.5295

10/10/10

A

25 of 31

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

ANALYSIS RESULTS

6.1

LOADING SUMMARY

10/10/10

A

26 of 31

6.1.1 Elementary Load

LOAD

CASE

LOAD

LABEL

1

2

3

4

5

6

7

8

1

2

4

6

7

8

+X

+Y

****** SEASTATE BASIC LOAD CASE SUMMARY ******

RELATIVE TO MUDLINE ELEVATION

FZ

MX

MY

FX

FY

(KN)

(KN)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

(KN)

(KN-M)

-250.760

-121.691

-403.081

-9.808

-29.200

-45.112

0.000

0.000

-61.036

-109.679

-143.094

46.833

0.000

-21.204

0.000

-1021.310

(KN-M)

-161.756

-212.862

-322.465

-25.501

-11.538

-33.256

1021.305

0.000

MZ

DEAD LOAD

(KN-M)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

Didapar dari saclst cog 1, keyword : basic load

6.1.2 Pre-Loadings and Loading Combination

G0 Position

LOAD

CASE

LOAD

LABEL

FX

(KN)

7

8

9

10

11

12

13

WGHT

DAF

PAD

NPAD

FLP0

NLP0

LPA0

0.000

0.000

0.000

0.000

0.000

0.000

0.000

***** SEASTATE COMBINED LOAD CASE SUMMARY *****

RELATIVE TO MUDLINE ELEVATION

FY

FZ

MX

MY

(KN)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

(KN)

-1021.301

-1225.561

-1654.507

-1409.395

-1874.495

-2200.494

-1629.996

(KN-M)

-343.823

-412.588

-556.994

-474.476

-631.053

-740.802

-548.742

(KN-M)

MZ

(KN-M)

-914.429

-1097.315

-1481.375

-1261.912

-1678.343

-1970.229

-1459.429

0.000

0.000

0.000

0.000

0.000

0.000

0.000

Dari saclst.cog0 , keyword : combined load

G1 Position

LOAD

CASE

LOAD

LABEL

***** SEASTATE COMBINED LOAD CASE SUMMARY *****

RELATIVE TO MUDLINE ELEVATION

FY

FZ

MX

MY

FX

(KN)

9

10

11

12

13

14

15

WGHT

DAF

PAD

NPAD

FLP1

LPA1

NLP1

0.000

0.000

0.000

0.000

0.000

0.000

0.000

(KN)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

(KN)

-1021.301

-1225.561

-1654.507

-1409.395

-1874.495

-1629.996

-2200.494

(KN-M)

677.486

812.984

1097.528

934.931

1243.458

1081.268

1459.712

(KN-M)

-1935.734

-2322.881

-3135.890

-2671.313

-3552.847

-3089.432

-4170.733

MZ

(KN-M)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

Keyword : relative

G2 Position

LOAD

CASE

LOAD

LABEL

FX

(KN)

9

10

11

12

13

14

15

WGHT

DAF

PAD

NPAD

FLP2

LPA2

NLP2

G3 Position

0.000

0.000

0.000

0.000

0.000

0.000

0.000

***** SEASTATE COMBINED LOAD CASE SUMMARY *****

RELATIVE TO MUDLINE ELEVATION

FY

FZ

MX

MY

(KN)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

(KN)

-1021.301

-1225.561

-1654.507

-1409.395

-1874.495

-1629.996

-2200.494

(KN-M)

677.486

812.984

1097.528

934.931

1243.458

1081.268

1459.712

(KN-M)

106.876

128.251

173.139

147.489

196.160

170.574

230.275

MZ

(KN-M)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

(KN)

250.760

0.000

0.000

0.000

0.000

0.000

0.000

0.000

BUOYANCY

(KN)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

10/10/10

REVISION:

27 of 31

PAGE:

LOAD

CASE

LOAD

LABEL

***** SEASTATE COMBINED LOAD CASE SUMMARY *****

RELATIVE TO MUDLINE ELEVATION

FY

FZ

MX

MY

FX

(KN)

9

10

11

12

13

14

15

WGHT

DAF

PAD

NPAD

FLP3

LPA3

NLP3

(KN)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

(KN)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

-1021.301

-1225.561

-1654.507

-1409.395

-1874.495

-1629.996

-2200.494

(KN-M)

(KN-M)

-1365.133

-1638.160

-2211.516

-1883.884

-2505.565

-2178.752

-2941.316

-1935.734

-2322.881

-3135.890

-2671.313

-3552.847

-3089.432

-4170.733

MZ

(KN-M)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

G4 Position

LOAD

CASE

LOAD

LABEL

FX

***** SEASTATE COMBINED LOAD CASE SUMMARY *****

RELATIVE TO MUDLINE ELEVATION

FY

FZ

MX

MY

(KN)

9

10

11

12

13

14

15

WGHT

DAF

PAD

NPAD

FLP4

LPA4

NLP4

0.000

0.000

0.000

0.000

0.000

0.000

0.000

(KN)

(KN)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

(KN-M)

-1021.301

-1225.561

-1654.507

-1409.395

-1874.495

-1629.996

-2200.494

-1365.133

-1638.160

-2211.516

-1883.884

-2505.565

-2178.752

-2941.316

(KN-M)

106.876

128.251

173.139

147.489

196.160

170.574

230.275

MZ

(KN-M)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

6.1.3 Loading Summary and CoG

G0 Position

LOAD

CASE

1

2

3

4

5

6

7

8

9

10

11

12

13

LOAD

LABEL

1

2

4

6

7

8

WGHT

DAF

PAD

NPAD

FLP0

NLP0

LPA0

************* SEASTATE LOAD CASE CENTER REPORT *************

RELATIVE TO STRUCTURAL ORIGIN

********* Y - DIRECTION *********

********* Z - DIRECTION *********

FORCE

X

Y

Z

FORCE

X

Y

Z

(KN)

(M)

(M)

(M)

(KN)

(M)

(M)

(M)

********* X - DIRECTION *********

FORCE

X

Y

Z

(KN)

(M)

(M)

(M)

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

-250.76

-121.69

-403.08

-9.81

-29.20

-45.11

-1021.30

-1225.56

-1654.51

-1409.39

-1874.49

-2200.49

-1630.00

-0.65

-1.75

-0.80

-2.60

-0.40

-0.74

-0.90

-0.90

-0.90

-0.90

-0.90

-0.90

-0.90

0.24

0.90

0.35

-4.78

0.00

0.47

0.34

0.34

0.34

0.34

0.34

0.34

0.34

7.36

7.48

7.30

7.67

7.33

7.49

7.36

7.36

7.36

7.36

7.36

7.36

7.36

Pada saclst cogota, keyword relative

G1 Position

LOAD

CASE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

LOAD

LABEL

1

2

4

6

7

8

+X

+Y

WGHT

DAF

PAD

NPAD

FLP1

LPA1

NLP1

************* SEASTATE LOAD CASE CENTER REPORT *************

RELATIVE TO STRUCTURAL ORIGIN

********* Y - DIRECTION *********

********* Z - DIRECTION *********

FORCE

X

Y

Z

FORCE

X

Y

Z

(KN)

(M)

(M)

(M)

(KN)

(M)

(M)

(M)

********* X - DIRECTION *********

FORCE

X

Y

Z

(KN)

(M)

(M)

(M)

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

Pada saclst cog1, keyword relative

Harga x y z harus sama dengan xyz rencana

G2 Position

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

-250.76

-121.69

-403.08

-9.81

-29.20

-45.11

COUPLE

COUPLE

-1021.30

-1225.56

-1654.51

-1409.39

-1874.49

-1630.00

-2200.49

-0.65

-1.75

-0.80

-2.60

-0.40

-0.74

0.00

0.00

-1.90

-1.90

-1.90

-1.90

-1.90

-1.90

-1.90

0.24

0.90

0.35

-4.78

0.00

0.47

0.00

0.00

-0.66

-0.66

-0.66

-0.66

-0.66

-0.66

-0.66

7.36

7.48

7.30

7.67

7.33

7.49

0.03

0.03

7.36

7.36

7.36

7.36

7.36

7.36

7.36

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

10/10/10

REVISION:

28 of 31

PAGE:

LOAD

CASE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

************* SEASTATE LOAD CASE CENTER REPORT *************

RELATIVE TO STRUCTURAL ORIGIN

********* Y - DIRECTION *********

********* Z - DIRECTION *********

FORCE

X

Y

Z

FORCE

X

Y

Z

(KN)

(M)

(M)

(M)

(KN)

(M)

(M)

(M)

LOAD

LABEL

********* X - DIRECTION *********

FORCE

X

Y

Z

(KN)

(M)

(M)

(M)

1

2

4

6

7

8

+X

+Y

WGHT

DAF

PAD

NPAD

FLP2

LPA2

NLP2

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

-250.76

-121.69

-403.08

-9.81

-29.20

-45.11

COUPLE

COUPLE

-1021.30

-1225.56

-1654.51

-1409.39

-1874.49

-1630.00

-2200.49

-0.65

-1.75

-0.80

-2.60

-0.40

-0.74

0.00

0.00

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.24

0.90

0.35

-4.78

0.00

0.47

0.00

0.00

-0.66

-0.66

-0.66

-0.66

-0.66

-0.66

-0.66

7.36

7.48

7.30

7.67

7.33

7.49

0.03

0.03

7.36

7.36

7.36

7.36

7.36

7.36

7.36

G3 Position

LOAD

CASE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

LOAD

LABEL

1

2

4

6

7

8

+X

+Y

WGHT

DAF

PAD

NPAD

FLP3

LPA3

NLP3

************* SEASTATE LOAD CASE CENTER REPORT *************

RELATIVE TO STRUCTURAL ORIGIN

********* Y - DIRECTION *********

********* Z - DIRECTION *********

FORCE

X

Y

Z

FORCE

X

Y

Z

(KN)

(M)

(M)

(M)

(KN)

(M)

(M)

(M)

********* X - DIRECTION *********

FORCE

X

Y

Z

(KN)

(M)

(M)

(M)

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

-250.76

-121.69

-403.08

-9.81

-29.20

-45.11

COUPLE

COUPLE

-1021.30

-1225.56

-1654.51

-1409.39

-1874.49

-1630.00

-2200.49

-0.65

-1.75

-0.80

-2.60

-0.40

-0.74

0.00

0.00

-1.90

-1.90

-1.90

-1.90

-1.90

-1.90

-1.90

0.24

0.90

0.35

-4.78

0.00

0.47

0.00

0.00

1.34

1.34

1.34

1.34

1.34

1.34

1.34

7.36

7.48

7.30

7.67

7.33

7.49

0.03

0.03

7.36

7.36

7.36

7.36

7.36

7.36

7.36

G4 Position

LOAD

CASE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

LOAD

LABEL

1

2

4

6

7

8

+X

+Y

WGHT

DAF

PAD

NPAD

FLP4

LPA4

NLP4

************* SEASTATE LOAD CASE CENTER REPORT *************

RELATIVE TO STRUCTURAL ORIGIN

********* Y - DIRECTION *********

********* Z - DIRECTION *********

FORCE

X

Y

Z

FORCE

X

Y

Z

(KN)

(M)

(M)

(M)

(KN)

(M)

(M)

(M)

********* X - DIRECTION *********

FORCE

X

Y

Z

(KN)

(M)

(M)

(M)

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

6.2 DEFLECTION PLOTS

See Appendix C Deflection Output Plots

6.3

SLINGS LOAD

Ambil di pstlst.lpa, keyword : member forces

-250.76

-121.69

-403.08

-9.81

-29.20

-45.11

COUPLE

COUPLE

-1021.30

-1225.56

-1654.51

-1409.39

-1874.49

-1630.00

-2200.49

-0.65

-1.75

-0.80

-2.60

-0.40

-0.74

0.00

0.00

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.24

0.90

0.35

-4.78

0.00

0.47

0.00

0.00

1.34

1.34

1.34

1.34

1.34

1.34

1.34

7.36

7.48

7.30

7.67

7.33

7.49

0.03

0.03

7.36

7.36

7.36

7.36

7.36

7.36

7.36

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

10/10/10

REVISION:

29 of 31

PAGE:

SACS-IV SYSTEM

MEMBER

NUMBER

6.4

MEMBER

END

MEMBER FORCES AND MOMENTS

******************** KN *********************

FORCE(X)

FORCE(Y)

FORCE(Z)

GROUP LOAD

ID

CASE

******************* KN-M ********************

MOMENT(X)

MOMENT(Y)

MOMENT(Z)

PL05-

HD

PL05

SLG

LPA0

LPA1

LPA2

LPA3

LPA4

530.06

692.79

495.41

567.24

358.72

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

PL06-

HD

PL06

SLG

LPA0

LPA1

LPA2

LPA3

LPA4

340.81

306.77

510.94

158.54

375.24

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

PL09-

HD

PL09

SLG

LPA0

LPA1

LPA2

LPA3

LPA4

568.27

605.02

400.40

728.75

534.45

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

PL12-

HD

PL12

SLG

LPA0

LPA1

LPA2

LPA3

LPA4

393.31

215.47

427.47

359.91

560.10

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

MEMBER CODE CHECKS

6.4.1 Member Connected to Padeye

Di pstlst.nlp

* * *

M E M B E R

G R O U P

S U M M A R Y

* * *

API RP2A 21ST/AISC 9TH

GRUP CRITICAL LOAD

ID

MEMBER

COND

MAX.

DIST

UNITY

FROM

CHECK

END

EFFECTIVE

* APPLIED STRESSES *

AXIAL BEND-Y BEND-Z

N/MM2

N/MM2

*** ALLOWABLE STRESSES ***

CRIT

AXIAL

COND

N/MM2

EULER BEND-Y BEND-Z

N/MM2

N/MM2

N/MM2

N/MM2

CM

LENGTHS

* VALUES *

KLY

KLZ

B01 D005-PL05 NLP3

0.33

0.2

-0.04 -41.60 -32.73

174.151774.56 234.30 266.25

C<.15

5.3

0.2

0.85

0.85

B02 D072-D073 NLP3

0.61

0.8

-1.30 -36.49

63.75

133.431914.79 155.10 176.25

C<.15

2.1

0.8

0.85

0.85

G01 D030-D044 NLP3

0.56

0.0

-8.49

98.22

13.99

175.28 463.73 213.00 266.25

C<.15

7.6

4.6

0.85

0.85

G02 D050-D051 NLP3

0.27

0.2

-0.49

54.81

-8.31

149.795116.35 234.30 266.25

C<.15

3.4

0.9

0.85

0.85

P02 004L-PL12 NLP1

0.03

0.0

-4.82

0.00

0.00

184.86 954.13 258.75 258.75

C<.15

7.0

1.5

0.85

0.85

6.4.2 Member Not Connected to Padeye

Di pstlst.flp

* * *

M E M B E R

G R O U P

S U M M A R Y

* * *

API RP2A 21ST/AISC 9TH

GRUP CRITICAL LOAD

ID

MEMBER

COND

MAX.

DIST

UNITY

FROM

CHECK

END

M

EFFECTIVE

* APPLIED STRESSES *

AXIAL BEND-Y BEND-Z

N/MM2

N/MM2

N/MM2

*** ALLOWABLE STRESSES ***

CRIT

AXIAL

COND

N/MM2

EULER BEND-Y BEND-Z

N/MM2

N/MM2

N/MM2

LENGTHS

KLY

KLZ

CM

* VALUES *

Y

B01 D005-PL05 FLP3

0.28

0.2

-0.04 -35.43 -27.88

174.151774.56 234.30 266.25

C<.15

5.3

0.2

0.85

0.85

B02 D072-D073 FLP3

0.52

0.8

-1.11 -31.08

54.31

133.431914.79 155.10 176.25

C<.15

2.1

0.8

0.85

0.85

G01 D030-D044 FLP3

0.48

0.0

-7.23

83.67

11.91

175.28 463.73 213.00 266.25

C<.15

7.6

4.6

0.85

0.85

G02 D050-D051 FLP3

0.23

0.2

-0.42

46.69

-7.08

149.795116.35 234.30 266.25

C<.15

3.4

0.9

0.85

0.85

P02 004L-PL12 FLP1

0.02

0.0

-4.10

0.00

0.00

184.86 954.13 258.75 258.75

C<.15

7.0

1.5

0.85

0.85

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

6.5 REACTION

Reaction force without consequence factor

Dari pstlst.LPA

SACS-IV SYSTEM

JOINT LOAD

NUMBER CASE

REACTION FORCES AND MOMENTS

********************* KN ********************

FORCE(X)

FORCE(Y)

FORCE(Z)

******************** KN-M *******************

MOMENT(X)

MOMENT(Y)

MOMENT(Z)

HD

LPA0

LPA1

LPA2

LPA3

LPA4

-0.490

-0.490

-0.489

-0.490

-0.489

0.351

0.350

0.351

0.353

0.351

1629.991

1629.984

1629.984

1629.984

1629.984

-0.027

-0.039

-0.029

-0.010

-0.034

-0.002

-0.002

0.002

-0.006

0.000

0.000

-0.003

-0.001

0.004

-0.002

001L

LPA0

LPA1

LPA2

LPA3

LPA4

0.132

0.204

0.144

0.120

0.060

-0.351

-0.350

-0.351

-0.353

-0.351

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

004L

LPA0

LPA1

LPA2

LPA3

LPA4

0.358

0.286

0.345

0.370

0.428

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

SACS-IV SYSTEM

REACTION FORCES AND MOMENTS SUMMARY

*** MOMENTS SUMMED ABOUT ORIGIN ***

LOAD

CASE

LPA0

LPA1

LPA2

LPA3

LPA4

********************* KN ********************

FORCE(X)

FORCE(Y)

FORCE(Z)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

1629.991

1629.984

1629.984

1629.984

1629.984

******************** KN-M *******************

MOMENT(X)

MOMENT(Y)

MOMENT(Z)

548.747

548.753

548.753

548.741

548.741

1459.433

1459.423

1459.444

1459.423

1459.444

0.000

0.840

0.138

-0.137

-0.840

Reaction force with consequence factor of 1.15

Dari pstlst.flp

SACS-IV SYSTEM

JOINT LOAD

NUMBER CASE

REACTION FORCES AND MOMENTS

********************* KN ********************

FORCE(X)

FORCE(Y)

FORCE(Z)

******************** KN-M *******************

MOMENT(X)

MOMENT(Y)

MOMENT(Z)

HD

FLP0

FLP1

FLP2

FLP3

FLP4

-0.564

-0.567

-0.559

-0.566

-0.559

0.404

0.397

0.398

0.410

0.408

1874.515

1874.502

1874.502

1874.502

1874.502

-0.032

-0.045

-0.033

-0.012

-0.039

-0.002

-0.003

0.003

-0.007

0.000

0.000

-0.004

-0.001

0.005

-0.002

001L

FLP0

FLP1

FLP2

FLP3

FLP4

0.152

0.238

0.165

0.138

0.067

-0.404

-0.397

-0.398

-0.410

-0.408

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

004L

FLP0

FLP1

FLP2

FLP3

FLP4

0.411

0.329

0.394

0.428

0.492

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

ACS-IV SYSTEM

REACTION FORCES AND MOMENTS SUMMARY

*** MOMENTS SUMMED ABOUT ORIGIN ***

LOAD

CASE

FLP0

FLP1

FLP2

FLP3

FLP4

********************* KN ********************

FORCE(X)

FORCE(Y)

FORCE(Z)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

1874.515

1874.502

1874.502

1874.502

1874.502

Reaction force with consequence factor of 1.35

******************** KN-M *******************

MOMENT(X)

MOMENT(Y)

MOMENT(Z)

631.075

631.154

631.153

630.997

630.997

1678.364

1678.302

1678.426

1678.302

1678.426

0.000

0.964

0.161

-0.157

-0.967

10/10/10

A

30 of 31

DATE:

DIESEL STORAGE PLATFORM

LIFTING ANALYSIS

REVISION:

PAGE:

10/10/10

A

31 of 31

Dari pstlst.nlp

SACS-IV SYSTEM

JOINT LOAD

NUMBER CASE

REACTION FORCES AND MOMENTS

********************* KN ********************

FORCE(X)

FORCE(Y)

FORCE(Z)

******************** KN-M *******************

MOMENT(X)

MOMENT(Y)

MOMENT(Z)

HD

NLP0

NLP1

NLP2

NLP3

NLP4

-0.660

-0.662

-0.657

-0.662

-0.657

0.474

0.470

0.471

0.477

0.475

2200.502

2200.490

2200.490

2200.490

2200.490

-0.037

-0.053

-0.038

-0.014

-0.046

-0.002

-0.003

0.003

-0.008

0.001

-0.001

-0.005

-0.001

0.006

-0.002

001L

NLP0

NLP1

NLP2

NLP3

NLP4

0.178

0.277

0.193

0.162

0.080

-0.474

-0.470

-0.471

-0.477

-0.475

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

004L

NLP0

NLP1

NLP2

NLP3

NLP4

0.482

0.386

0.464

0.500

0.577

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

SACS-IV SYSTEM

REACTION FORCES AND MOMENTS SUMMARY

*** MOMENTS SUMMED ABOUT ORIGIN ***

LOAD

CASE

NLP0

NLP1

NLP2

NLP3

NLP4

********************* KN ********************

FORCE(X)

FORCE(Y)

FORCE(Z)

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

2200.502

2200.490

2200.490

2200.490

2200.490

******************** KN-M *******************

MOMENT(X)

MOMENT(Y)

MOMENT(Z)

740.823

740.858

740.858

740.788

740.788

1970.257

1970.216

1970.297

1970.217

1970.297

0.000

1.132

0.186

-0.185

-1.132

6.6 CONNECTION CODE CHECKS

Since no tubular intersection is found during lifting analysis, joint can analysis is not

performed in this calculation.

Вам также может понравиться

- Design of Padeye CalcДокумент3 страницыDesign of Padeye CalcBolarinwa89% (9)

- NODE PLATE STRESS CALCULATIONДокумент14 страницNODE PLATE STRESS CALCULATIONparvej0% (1)

- Jacket Weighing ProcedureДокумент14 страницJacket Weighing ProcedureBolarinwaОценок пока нет

- SACS Lifting AnalysisДокумент2 страницыSACS Lifting AnalysisBolarinwa100% (4)

- Padeye CalculationДокумент6 страницPadeye CalculationKarun DasОценок пока нет

- SACS Checklist Latest VersionДокумент9 страницSACS Checklist Latest VersiontaddeoОценок пока нет

- Padeye Calculation For Lifting AnalysisДокумент3 страницыPadeye Calculation For Lifting AnalysisNelson Panjaitan100% (6)

- Seafastening Design CalculationsДокумент82 страницыSeafastening Design CalculationsInhake AutechreОценок пока нет

- 17 TON PADEYE STRENGTH CHECKДокумент12 страниц17 TON PADEYE STRENGTH CHECKoluomo1Оценок пока нет

- Sample Design Calculations of Foundation For Vertical VesselДокумент23 страницыSample Design Calculations of Foundation For Vertical VesselonlyikramОценок пока нет

- Concorde Battery Component Maintenance ManualДокумент40 страницConcorde Battery Component Maintenance Manualrav0% (1)

- The Big Bang Never HappenedДокумент3 страницыThe Big Bang Never HappenedIvan Vule Fridman100% (1)

- TR2400 HF SSB Transceiver FeaturesДокумент4 страницыTR2400 HF SSB Transceiver FeaturesAravind VinduОценок пока нет

- Science8 Q2 Module3 (Week6)Документ30 страницScience8 Q2 Module3 (Week6)Mary Grace Lemon100% (1)

- Testing of Semifinished Products of Thermoplastics Bases - Indications Directive DVS 2201-1Документ4 страницыTesting of Semifinished Products of Thermoplastics Bases - Indications Directive DVS 2201-1OscarОценок пока нет

- 05-1 - EPC-SV-ALE-N-CA-10006 - Rev B2 Barge Deck Strength Check PDFДокумент63 страницы05-1 - EPC-SV-ALE-N-CA-10006 - Rev B2 Barge Deck Strength Check PDFBill BenОценок пока нет

- PP00011 Pdi DS Cal 00007 - C03Документ96 страницPP00011 Pdi DS Cal 00007 - C03Olanrewaju Tope100% (1)

- Lifting Analysis Report - Mahadi KurniawanДокумент31 страницаLifting Analysis Report - Mahadi KurniawanDian SasОценок пока нет

- Lifting Analysis Report - Rev BДокумент31 страницаLifting Analysis Report - Rev BDicky Pramono100% (1)

- Lifting Lug AnalysisДокумент3 страницыLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Sacs-Basics PDFДокумент113 страницSacs-Basics PDFanilОценок пока нет

- Shift of Centre of Gravity (C.o.G.) during LiftingДокумент6 страницShift of Centre of Gravity (C.o.G.) during LiftingLit Phen TuОценок пока нет

- 3423Документ12 страниц3423Tran Van DaiОценок пока нет

- Skew Load Lift AnalysisДокумент3 страницыSkew Load Lift AnalysisBolarinwadeОценок пока нет

- Pile Cap Design - ColumnsДокумент7 страницPile Cap Design - Columnsfeiz asgarОценок пока нет

- DANA-Technical Note (TN)Документ8 страницDANA-Technical Note (TN)Samsul Imran BahromОценок пока нет

- Dog Plate & Tubular Support Subsea Template DesignДокумент4 страницыDog Plate & Tubular Support Subsea Template DesignAkhmad Syahroni100% (1)

- SACS Advanced Offshore Structure Design AnalysisДокумент2 страницыSACS Advanced Offshore Structure Design Analysisspyji99Оценок пока нет

- Cargo acceleration calculation sheetДокумент2 страницыCargo acceleration calculation sheetiw2fualОценок пока нет

- Sea TransportationДокумент8 страницSea TransportationMark Samsel RohanОценок пока нет

- Lift (Skew & Cog Shift) MethodsДокумент18 страницLift (Skew & Cog Shift) MethodsManoj Kumar Pal100% (1)

- Strength Calculation For PlatformДокумент2 страницыStrength Calculation For PlatformRaghОценок пока нет

- Jacket Launching AnalysisДокумент7 страницJacket Launching Analysisiw2fualОценок пока нет

- Miscellaneous Calculations: 1 Sea Transport Forces On CargoДокумент4 страницыMiscellaneous Calculations: 1 Sea Transport Forces On CargoAgarry EmmanuelОценок пока нет

- SEAFASTENING DESIGN CALCULATION FOR TRANSPORT LOADSДокумент1 страницаSEAFASTENING DESIGN CALCULATION FOR TRANSPORT LOADSlkc 8100% (1)

- Spreader Beam BLOCK EДокумент26 страницSpreader Beam BLOCK ESteve MoonОценок пока нет

- Part 6 - Spectral FatigueДокумент14 страницPart 6 - Spectral FatigueenglandboyОценок пока нет

- Lifting Analysis GuideДокумент3 страницыLifting Analysis GuideNwosu Augustine100% (1)

- Lifting AnalysisДокумент14 страницLifting Analysisruhul72Оценок пока нет

- Noble Denton Guidelines For LoadoutsДокумент36 страницNoble Denton Guidelines For LoadoutsBoyОценок пока нет

- Sacs Analysis Main PointsДокумент2 страницыSacs Analysis Main PointsAndhityaPutraMahardhikaОценок пока нет

- SACS AdvancedTrainingДокумент5 страницSACS AdvancedTrainingTita Permata SariОценок пока нет

- PE-PP-10-1-F3 Rev. 7.0 PLNG SSI Check List Confirmation ListДокумент22 страницыPE-PP-10-1-F3 Rev. 7.0 PLNG SSI Check List Confirmation ListLuis Enrique LavayenОценок пока нет

- OFD5 JACKET IN-PLACE ANALYSIS BOAT IMPACT CALCULATIONДокумент5 страницOFD5 JACKET IN-PLACE ANALYSIS BOAT IMPACT CALCULATIONBolarinwaОценок пока нет

- Stopperwith-Face-Plate-Rev-1.0-SI-Units-www.thenavalarch.com_Документ6 страницStopperwith-Face-Plate-Rev-1.0-SI-Units-www.thenavalarch.com_Karthik36100% (2)

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveДокумент5 страницCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaОценок пока нет

- SL-ELT-AN-WPS1-4114-C2-S1 Topside Lift Analysis & Report PDFДокумент633 страницыSL-ELT-AN-WPS1-4114-C2-S1 Topside Lift Analysis & Report PDFsaeed ghafoori100% (1)

- SACS Training in AbudhabiДокумент4 страницыSACS Training in AbudhabiΈνκινουαν Κόγκ Αδάμου0% (1)

- Lifting COG Shift DDTL-IfR SouthДокумент6 страницLifting COG Shift DDTL-IfR Southvovancuong8Оценок пока нет

- 2L5x3x1/2LLBB: #N/A #N/A #N/AДокумент1 страница2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanОценок пока нет

- (WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGДокумент36 страниц(WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGsholehamikОценок пока нет

- SDA Primary Structure of Passenger Ships-Guidance On Direct Calculations PDFДокумент48 страницSDA Primary Structure of Passenger Ships-Guidance On Direct Calculations PDFhiginio.moro6182Оценок пока нет

- FPSO - Technical Specification For Marine TransportationДокумент11 страницFPSO - Technical Specification For Marine Transportationdndudc100% (1)

- Delta proposes changes to oxygen cylinder valve AD reporting requirementsДокумент3 страницыDelta proposes changes to oxygen cylinder valve AD reporting requirementsKevin PangilinanОценок пока нет

- DOT InterpretationДокумент48 страницDOT Interpretationarbor02Оценок пока нет

- Zau 74 102017 CS 8180 00034 PDFДокумент200 страницZau 74 102017 CS 8180 00034 PDFvasudhaОценок пока нет

- Chilled Water PumpДокумент6 страницChilled Water PumpphilipyapОценок пока нет

- MM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With InternalДокумент9 страницMM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With Internalpragatheesk100% (1)

- SRV Detaisl Awa Salawas PDFДокумент222 страницыSRV Detaisl Awa Salawas PDFdiwakarngm100% (1)

- Stepped Channel DesignДокумент6 страницStepped Channel DesignVivek GuptaОценок пока нет

- PHP MVZe RLДокумент14 страницPHP MVZe RLinfo1639Оценок пока нет

- SAIC-D-2007 Rev 2Документ4 страницыSAIC-D-2007 Rev 2ரமேஷ் பாலக்காடுОценок пока нет

- Code of Construction Practice Part B: Site Speci C Requirements - Greenwich Pumping Station (Comparite Against 23 September 2013)Документ14 страницCode of Construction Practice Part B: Site Speci C Requirements - Greenwich Pumping Station (Comparite Against 23 September 2013)info1639Оценок пока нет

- Eee f111 Electrical Sciences1Документ3 страницыEee f111 Electrical Sciences1aryan mittalОценок пока нет

- Ford Eectch98Документ79 страницFord Eectch98jockerОценок пока нет

- Bio Inorganic ChemistryДокумент2 страницыBio Inorganic ChemistryMeghna KumarОценок пока нет

- AC Assingment 2Документ3 страницыAC Assingment 2Levi Deo BatuigasОценок пока нет

- General Physics1 Q2 W8 Module8 ThermodynamicsДокумент23 страницыGeneral Physics1 Q2 W8 Module8 ThermodynamicsRegine Ann ViloriaОценок пока нет

- Excerpt From Surely Youre Joking, Mr. FeynmanДокумент4 страницыExcerpt From Surely Youre Joking, Mr. FeynmanElbis Santos CardosoОценок пока нет

- Financial Accounting IIДокумент16 страницFinancial Accounting IIMiguel BuenoОценок пока нет

- SE 2003&2008 Pattern PDFДокумент799 страницSE 2003&2008 Pattern PDFBenigno Tique Jonasse100% (1)

- Design of Weirs and BarragesДокумент42 страницыDesign of Weirs and BarragesDivyaSlp100% (2)

- AminesДокумент31 страницаAminesJoseph YayenОценок пока нет

- BIOLOGY Paper 1 Marking Scheme Asumbi Girls Final Prediction 2022Документ4 страницыBIOLOGY Paper 1 Marking Scheme Asumbi Girls Final Prediction 2022balozi training InstituteОценок пока нет

- Welding Machine CatalogueДокумент12 страницWelding Machine CatalogueRodney LanagОценок пока нет

- SamplingДокумент12 страницSamplingΔημητρηςΣαρακυρουОценок пока нет

- L - 1 - INTRO - Well LoggingДокумент47 страницL - 1 - INTRO - Well LoggingSaaeed Ali100% (1)

- Mechanical Engineering Conference ProgramДокумент40 страницMechanical Engineering Conference Programirinuca12Оценок пока нет

- FT 539G Eng 01Документ4 страницыFT 539G Eng 01lmw_arunОценок пока нет

- Proportional Chopper Amplifier VB-3A: Min MaxДокумент5 страницProportional Chopper Amplifier VB-3A: Min MaxryujoniОценок пока нет

- SteganographyДокумент13 страницSteganographyIgloo JainОценок пока нет

- Refinery TankagesДокумент4 страницыRefinery Tankagesmayuresh1101100% (1)

- Active Heating and CoolingДокумент16 страницActive Heating and Coolinga_j_sanyal2590% (1)

- Cylindrical Plug Gage DesignsДокумент3 страницыCylindrical Plug Gage DesignskkphadnisОценок пока нет

- Failure Mode For Gas CHromatographДокумент2 страницыFailure Mode For Gas CHromatographardi-Оценок пока нет

- Binder Modul WMS 10Документ52 страницыBinder Modul WMS 10sandhiakhmadОценок пока нет

- (It Bus) Computer HistoryДокумент6 страниц(It Bus) Computer HistoryRica Elaine LubasanОценок пока нет

- Clone Steps RmanДокумент10 страницClone Steps RmanKishore AdikarОценок пока нет

- Hospital Managemen T System: Oose LAB FileДокумент62 страницыHospital Managemen T System: Oose LAB FileAASHОценок пока нет