Академический Документы

Профессиональный Документы

Культура Документы

Expanding The Column Overhead System: Instructor: Eng. Ahmed Deyab Fares Mobile: 0127549943

Загружено:

TayebASherifОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Expanding The Column Overhead System: Instructor: Eng. Ahmed Deyab Fares Mobile: 0127549943

Загружено:

TayebASherifАвторское право:

Доступные форматы

Expanding the Column Overhead System

Expanding the Column Overhead

System

Instructor:

Eng. Ahmed Deyab Fares

Mobile: 0127549943

1

2004 Aspen Technology. - All Rights Reserved

Expanding the Column Overhead System

re

s

Workshop

Learning Objectives

ey

In this module you will:

ab

Fa

In this module the Overhead Condenser unit operation of the

DePropanizer Column will be replaced by an overhead system

consisting of various pieces of equipment. This comprehensive

condenser configuration is required in instances when you want to

perform detailed Rating Dynamics.

En

g.

Ah

m

ed

Add unit operations and controllers in the Dynamic mode

Replace the standard HYSYS Condenser unit operation with a detailed

overhead system

Make necessary P/F Specs for the overhead system

Implement appropriate control strategies

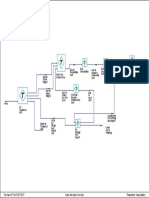

Partial Process Overview

Expanding the Column Overhead System

re

s

Build the Flowsheet

Deleting the Condenser

ab

Fa

In this module, you will construct an expanded, detailed, overhead

system in the Dynamic mode. Up to this point, it was recommended

that users construct simulations in the Steady State mode and then

move them into the Dynamic mode. It is the goal of this module,

however, to teach you how to built simulations in the Dynamic mode.

ey

Open the saved case from Module 6. This case should still be in the

Dynamic mode. If it is not, enter the Dynamic mode and run the

Integrator until Steady State is reached.

In this module, we are going to replace the Condenser Overhead system

for the DePropanizer column.

m

ed

Before the Condenser is deleted in the Column Environment, its

associated product streams and energy streams should be deleted in the

Main Environment.

In the Main Environment, delete the Condenser product streams,

Propane and Cond-Q.

2.

Enter the Column Environment. Create a copy of the Reflux stream.

(Create a new stream and use the Define from Other Stream button

to copy the conditions from the Reflux stream to the new stream).

Give the new stream a Flow specification and connect it as a feed

stream to the top stage.

En

g.

Ah

1.

3.

Delete the Condenser, the Condenser Duty Stream, and both

product streams (Reflux and Propane). Delete the controller (CondLC, and Cond-PC).

4.

Run the integrator.

Expanding the Column Overhead System

Now, once the operations are added, the P/F specs need to be moved to

the boundary streams and the integrator should be run after each

operation is added.

It is recommended that you periodically save your case as equipment is

added to the Flowsheet. You can use different case names if you want to

provide a snapshot at the various stages of building the case.

Save your case!

Adding the Overhead System

Generally it is advisable to build a detailed overhead condenser system

in the Column Environment. However, there are unit operations in

HYSYS that are unavailable in the Column Subflowsheet, such as the Air

Cooler. In these instances, the overhead system must be built in the

Main Environment. This example contains an Air Cooler, so the

overhead system must be built in the Main Environment.

Connecting the Column and Main Environments

The connection between the Column environment and the Main

environment was broken when the streams were deleted. The two

environments must be reconnected before construction can begin on

the expanded overhead system.

On the Design tab, select the Connections page. Enter On the Flowsheet

tab in the Column Property View, enter an appropriate stream name in

the External column, next to the Internal To Condenser stream. Do the

same for the Reflux stream.

Expanding the Column Overhead System

re

s

Adjusting the Pressure Flow Specs

Fa

It is important to keep track of the pressure-flow specifications for the

Flowsheet. If specifications are eliminated by deleting streams, an

equivalent number of specifications must be added to keep the degrees

of freedom at zero. Also, as equipment is added to the Flowsheet, the

pressure-flow specifications will be correspondingly moved to the

boundary streams.

ey

ab

Since product streams and the Condenser have been deleted, the

flowsheet boundary streams have changed and thus, the pressure-flow

specifications must be moved. In this case, one stream that had a

pressure-flow specification was deleted, so you will need to add one

pressure flow spec to the flowsheet.

Open the property view for the stream Reflux (in the Main

Environment) and examine the Dynamics page. The Reflux stream

should have a Flow Specification. Specify a Molar Flowrate of 1600

kgmole/h (3500 lbmole/hr).

m

ed

1.

Which Pressure-Flow Specification stream was deleted? ___________________

2.

The To Condenser (in the Main Environment) stream should have a

Pressure Specification of 2000 kPa (290 psia).

Adding a Splitter

Ah

A TEE operation will be added to the Flowsheet to separate the overhead

vapour into a vapour bypass stream and an overhead stream which will

be condensed. The overhead bypass stream flows to the flare system.

En

g.

Add a TEE operation with the following information.

In this cell...

Enter...

Connections

Name

Splitter

Feed

To Condenser

Products

Bypass to Valve

Ovhd

Expanding the Column Overhead System

Moving the P-F Specs

With the addition of the Splitter, the pressure-flow specifications must

be adjusted. Stream To Condenser is no longer a boundary stream, thus

it should not contain a Pressure-Flow spec.

1.

Move the Pressure specification from To Condenser to a Molar Flow

specification on Bypass to Valve. Supply a Molar Flow of 100

kgmole/hr (220 lbmole/hr).

2.

Supply a Pressure Specification for stream Ovhd. With no pressure

drop across the Tee, the pressure in this stream should be the same

as the pressure in the feed stream.

3.

Run the Integrator for a few minutes to propagate the values to the

boundary streams.

Adding the Condenser

An Air Cooler operation is used to model the Condenser. The overhead

vapour stream, Ovhd, is fed into the Air Cooler operation.

1.

Add an Air Cooler operation and supply the following information.

In this cell...

Enter...

Connections

Name

Ovhd Cooler

Feed

Ovhd

Product

ToAccumulator

Parameters

Overall UA

1.14e6 kJ/C-h (6.0e5 Btu/F-hr)

Configuration

two tube rows, one pass

Temperature

25C (77F)

Dynamics

Fluid Volume

2.

1.0 m3 (35 ft3)

On the Dynamics tab, activate the delta P spec and enter a value of

70 kPa (10 psi). Click the Calculate K button. Change the pressure

spec from to delta P to the k value specification.

Expanding the Column Overhead System

Calculate the k Value for the Air Cooler and move the Dynamic

Specification from an Overall Delta P spec to an Overall k Value

specification.

re

s

3.

4.

Fa

What overall k value does HYSYS calculate here?________________________

Run the Integrator for a few minutes to propagate the values to the

boundary streams.

ab

Adding the Accumulator

Add a Separator and provide the following information:

In this cell...

1.

ey

A Separator unit operation will be used as the overhead accumulator.

The cooled overhead stream will be used as the feed for the unit. The

size of the Accumulator will be the same as that used for the Condenser

in previous modules.

Enter...

m

ed

Connections

Name

Accumulator

Feed

ToAccumulator

Vapour Outlet

ToPropane

Liquid Outlet

LiquidReturn

Parameters

Ah

Volume

En

g.

Remember the rules for P/F

Specifications. You cannot

place Pressure

Specifications on both

Accumulator product

streams.

15 m3 (530 ft3)

2.

Move the P-F Specifications to the new boundary streams. The

stream Liquid Return will eventually to connect to the Reflux

stream, so use the same flow specification for both streams.

3.

Run the Integrator for a few minutes to propagate the values to the

boundary streams.

Adding the Vapour Product Valve

A Valve unit operation will be added to the flowsheet so adjustments can

be made to the vapour stream from the Accumulator.

Expanding the Column Overhead System

1.

Add a Valve and provide the following information.

In this cell...

Enter...

Connections

You can specify the Cv if you

have a valve of known Cv

that you want to use in the

simulation.

Name

Propane Valve

Inlet

ToPropane

Outlet

Propane

Rating

300

Cv

2.

Move the P/F specifications to their proper locations.

3.

Start the Integrator for a few seconds to propagate values to the

boundary stream, Propane.

Adding the Pump

A Pump unit operation will be added to the flowsheet to increase the

pressure of the Reflux stream returning to the tower.

1.

Add a Pump and provide the following information.

In this cell...

Enter...

Connections

Remember to change the

Flow and Head units

BEFORE entering the curve

data.

Name

RefluxPump

Inlet

LiquidReturn

Outlet

To Reflux

Energy

Pump-Q

2.

On the Rating tab, input the following curve for the Pump. The

Pump has been in service for quite some time so the vendor curves

are only in Imperial units. The Speed for the curve is 60 rotations

per min.

Flow (USGPM)

If the Pump speed is

different than the curve

speed, HYSYS will

extrapolate values for head

and efficiency.

Head (ft)

%Efficiency

275

100

260

42

200

235

60

300

190

66

400

150

70

500

140

75

You can only use Speed as

a specification if the Curves

are Active.

Head (ft)

%Efficiency

600

100

69

700

70

65

800

40

60

Move to the Dynamics tab, Specs page to make the dynamic

specifications for the Pump. In general, two specifications should be

selected in the Dynamics Specifications group in order for the

pump operation to fully solve. In this case, we will supply a Speed

and a Curve. Enter a Speed of 85 per min and make that

specification Active.

4.

To propagate information to the To Reflux stream run the integrator

for about 10 seconds.

Fa

3.

ab

If the Pump speed is

different than the curve

speed, HYSYS will

extrapolate values for head

and efficiency.

Flow (USGPM)

re

s

Expanding the Column Overhead System

ey

10

Adding a Reflux Valve

m

ed

A Valve unit operation will be added to the flowsheet to connect the

streams To Reflux and Reflux. This last piece of equipment will close the

overhead condenser loop.

1.

In this cell...

Enter...

Connections

Name

Reflux Valve

Feed

To Reflux

Product

Reflux

Ah

A Recycle Operation is NOT

needed in the Dynamic

mode. this was one of the

reasons for constructing this

simulation in the Dynamic

mode.

Add a Valve and provide the following information.

Parameters

Delta P

70 kPa (10 psi)

En

g.

The pressure-flow relation will be temporarily disabled so that

information can be propagated through the Reflux Valve.

10

2.

Start the Integrator for a few seconds to propagate values to the

boundary stream, Reflux.

3.

Size the Reflux Valve to calculate the Cv.

What Cv does HYSYS calculate for this valve? ____________________________

Expanding the Column Overhead System

4.

Activate the Pressure Flow Relation and deactivate the Total Delta P

specification.

5.

On the Flowsheet tab of the DePropanizer property view, connect

the Reflux stream in the Main Environment to the Reflux stream in

the Column Environment.

6.

Check that your Pressure Flow specifications are all correct and start

the Integrator for a few minutes.

11

Adding the Controllers

Just as with the default Condenser, the overhead system requires

controllers to stabilize the model. Two controllers are going to be added,

one Pressure and one Level Controller for the Accumulator.

Accumulator Pressure Controller

1.

Add the following pressure controller to the flowsheet.

In this cell...

Enter...

Connections

Name

Accumulator-PC

Process Variable Source

Accumulator, Vessel Pressure

Output Target Object

Propane Valve

Parameters - Configurations

Action

Direct

Mode

Auto

PV Minimum

1725 kPa (250 psia)

PV Maximum

2075 kPa (300 psia)

Kc

2.0

Ti

2.0 Minutes

SP

1900 kPa (275 psia)

11

Expanding the Column Overhead System

Accumulator Level Controller

Add the following level controller to the Flowsheet.

In this cell...

Enter...

Connections

Fa

1.

Accumulator-LC

Process Variable Source

Accumulator, Liquid Percent

Level

Output Target Object

Reflux Valve

ab

Name

Parameters - Configurations

Direct

Mode

Auto

PV Minimum

0%

ey

Action

PV Maximum

100 %

Kp

10 Minutes

Ti

SP

re

s

12

50 %

m

ed

Adding Strip Charts

Create strip charts to monitor primary variables in your flowsheet.

En

g.

Ah

Start the Integrator and allow the model to stabilize. Once the model has

reached steady state, create a disturbance to test your model.

12

Save your case!

Expanding the Column Overhead System

13

Exercises

When the DePropanizer was originally built in the Steady State mode, it

was specified that the mole fractions of Ethane and Propane would sum

to a value of 0.95. Once the column was run in the Dynamic mode, this

specification did not apply. Now, lets change the control strategy

around the column to reintroduce this specification.

1.

First, use a Spreadsheet in HYSYS to calculate the specification

value. Import both mole fractions into the Spreadsheet and use an

addition equation (+a1+a2) to add the two values.

What is the current value of the sum? ___________________________________

2.

Next, set the mode of the Accumulator-PC as Off. The new control

strategy will vary the Accumulator pressure in an effort to control

the Propane composition.

3.

Add another Controller to the simulation with the following data:

What action should this controller have? _______________________________

In this cell...

Enter...

Connections

Process Variable Source

SPRDSHT-1, B3

Output Target Object

Propane Valve

If you choose the wrong

action, the system will have

no chance of being stable.

Parameters - Configuration

Mode

Auto

The Process Variable that

you choose may vary

depending on which cell

contains your addition

equation.

PV Minimum

0.8

PV Maximum

1.0

Kp

Ti

10 Minutes

SP

0.95

4.

Add the Accumulator pressure to the current strip chart and run the

Integrator.

At what Accumulator pressure does the system eventually flat line? ______

13

Expanding the Column Overhead System

En

g.

Ah

m

ed

ey

ab

Fa

re

s

14

14

Вам также может понравиться

- Sr. Process Engineer CVДокумент6 страницSr. Process Engineer CVTayebASherif50% (2)

- Introduction To Electrical EngineeringДокумент2 страницыIntroduction To Electrical EngineeringTayebASherif100% (1)

- Control Valves FekerДокумент180 страницControl Valves FekerTayebASherifОценок пока нет

- TUTORIAL DE COMPRESI Ôn - HYSYS PDFДокумент18 страницTUTORIAL DE COMPRESI Ôn - HYSYS PDFShirley Hernandez JimenezОценок пока нет

- Column For New OnesДокумент8 страницColumn For New OnesSpicyОценок пока нет

- Advanced Recycle Operations 1Документ44 страницыAdvanced Recycle Operations 1Kajer quemarОценок пока нет

- D. Reactions in HYSYS - NewДокумент12 страницD. Reactions in HYSYS - NewRafael FaioliОценок пока нет

- A-Extensions in HYSYSДокумент4 страницыA-Extensions in HYSYSSyed Muzamil AhmedОценок пока нет

- Hysys TascДокумент10 страницHysys TascMariano PodestáОценок пока нет

- Aspen Hysys Activated AnalysisДокумент21 страницаAspen Hysys Activated AnalysisAlexandra RomeroОценок пока нет

- Getting Started With Relative Economics in Aspen PlusДокумент20 страницGetting Started With Relative Economics in Aspen PlusAndrés Esteban Granada ZapataОценок пока нет

- The HYSYS SpreadsheetДокумент10 страницThe HYSYS SpreadsheetSyed Muzamil AhmedОценок пока нет

- 04 NGLFractionationTrainДокумент20 страниц04 NGLFractionationTraingerbasio100% (1)

- EHY2511 Flare Network Design and RatingДокумент2 страницыEHY2511 Flare Network Design and Ratingdeion29Оценок пока нет

- 08 - Column Pressure ReliefДокумент10 страниц08 - Column Pressure ReliefjeedanОценок пока нет

- AspenProcessEconAnalyzerV9 0 UsrДокумент506 страницAspenProcessEconAnalyzerV9 0 UsrivanОценок пока нет

- Event Scheduler & Spreadsheet 1Документ18 страницEvent Scheduler & Spreadsheet 1Kajer quemarОценок пока нет

- Introduction To HYSYS Steady StateДокумент22 страницыIntroduction To HYSYS Steady StatebehnamhfОценок пока нет

- Using Calc LevelsДокумент16 страницUsing Calc LevelsSyed Muzamil Ahmed100% (1)

- 11-4567 JS Activation Tifs RefreshДокумент14 страниц11-4567 JS Activation Tifs Refreshedgardiaz5519Оценок пока нет

- AspenHYSYSRefiningV7 2 OpsДокумент478 страницAspenHYSYSRefiningV7 2 Opsnguyennha1211100% (1)

- Safeti NL: Tutorial ManualДокумент55 страницSafeti NL: Tutorial ManualmelancholicОценок пока нет

- APLUS 111 Input Language PDFДокумент810 страницAPLUS 111 Input Language PDFmehranlnjdОценок пока нет

- Aspen Tech Compressor Modeling in AspenДокумент16 страницAspen Tech Compressor Modeling in AspenIgnacio ChaparroОценок пока нет

- Nagpal Fine Tune The Design of Sour-Water Strippers Using Rate-Based Simulation PDFДокумент6 страницNagpal Fine Tune The Design of Sour-Water Strippers Using Rate-Based Simulation PDFRajendraОценок пока нет

- Aspen Flare System Analyzer: Getting Started GuideДокумент57 страницAspen Flare System Analyzer: Getting Started GuideHaris ShahidОценок пока нет

- Aspen Tech Compressor Modeling in AspenДокумент16 страницAspen Tech Compressor Modeling in AspenDesiree MolinaОценок пока нет

- Transitioning From Steady State To Dynamics 1Документ24 страницыTransitioning From Steady State To Dynamics 1Roger Jhosmar Soliz ArispeОценок пока нет

- Chemical Engineering 422 Simulation With Hysys: NotesДокумент9 страницChemical Engineering 422 Simulation With Hysys: NotesNoor Ul HaqОценок пока нет

- Assay BachaqueroДокумент12 страницAssay BachaqueroGinis MrcОценок пока нет

- Dynamic Depressuring PDFДокумент16 страницDynamic Depressuring PDFAsimОценок пока нет

- 11-4005 HYSYS Acid Gas Cleaning JSG RefreshДокумент16 страниц11-4005 HYSYS Acid Gas Cleaning JSG Refresh1youb tvОценок пока нет

- Pipesys TutorialДокумент62 страницыPipesys TutorialNatalia Prieto JimenezОценок пока нет

- Workshop: 2 The OptimizerДокумент20 страницWorkshop: 2 The OptimizerEshai EsMaОценок пока нет

- 01 GettingStartedДокумент34 страницы01 GettingStartedRyan GonzalesОценок пока нет

- Model A Refrigerated Gas Plant Workshop: ObjectiveДокумент25 страницModel A Refrigerated Gas Plant Workshop: Objectivemiri-256Оценок пока нет

- Brunet (Dynamic Simulation and Process Control)Документ79 страницBrunet (Dynamic Simulation and Process Control)Camilo Diaz100% (1)

- 1.3.10 Optimization Crude ColumnДокумент12 страниц1.3.10 Optimization Crude ColumnflowealthОценок пока нет

- Aspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACДокумент13 страницAspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACRavi Kant TripathiОценок пока нет

- Jump Start - Multiple Valve Analysis in Aspen HYSYS and Aspen Plus - TempДокумент16 страницJump Start - Multiple Valve Analysis in Aspen HYSYS and Aspen Plus - TempphantanthanhОценок пока нет

- Acid Gas Sweetening With DEAДокумент20 страницAcid Gas Sweetening With DEAEfer Cuadros BОценок пока нет

- Sulphur Recovery, HYSYS, GPSA-Conversion ReactorsДокумент3 страницыSulphur Recovery, HYSYS, GPSA-Conversion ReactorsBindu joglekarОценок пока нет

- 09 NaturalGasDehydrationWithTEGДокумент20 страниц09 NaturalGasDehydrationWithTEGGustavo ValleОценок пока нет

- Compressor and Pump Curves 1Документ14 страницCompressor and Pump Curves 1Francis Londoño CarrizoОценок пока нет

- Dynamics Split 1Документ100 страницDynamics Split 1chantran90Оценок пока нет

- 1.3.9 Rating Heat ExchangerДокумент18 страниц1.3.9 Rating Heat ExchangerMelva NainggolanОценок пока нет

- AspenFLARENET2006 StartДокумент61 страницаAspenFLARENET2006 Startapi-3750488100% (1)

- Simple Dew Point Control (HYSYS v10)Документ35 страницSimple Dew Point Control (HYSYS v10)digeca100% (1)

- WP UniSim Design Blowdown Utility PDFДокумент21 страницаWP UniSim Design Blowdown Utility PDFMinh Hoàng NguyễnОценок пока нет

- Simulation Reciprocating Compressor in HYSYSДокумент4 страницыSimulation Reciprocating Compressor in HYSYSLenaldy Nuari GarnokoОценок пока нет

- Self Guided Demo - Aspen Shell and Tube Exchanger V8.8Документ45 страницSelf Guided Demo - Aspen Shell and Tube Exchanger V8.8HarySetiyawanОценок пока нет

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsОт EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahОценок пока нет

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979От EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonОценок пока нет

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОт EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОценок пока нет

- HYSYS Tutorial PDFДокумент607 страницHYSYS Tutorial PDFsalman hussainОценок пока нет

- 04 ColumnDynamicsДокумент18 страниц04 ColumnDynamicsabhmarsОценок пока нет

- Compressor CurvesДокумент10 страницCompressor CurvesSyed Muzamil AhmedОценок пока нет

- Hydronic BalanceДокумент46 страницHydronic BalanceRamadan RashadОценок пока нет

- Workbook: Vent Gas Recover Compression Unit (TPL2) : StreamsДокумент3 страницыWorkbook: Vent Gas Recover Compression Unit (TPL2) : StreamsTayebASherifОценок пока нет

- Flash Gas Compression: Tue Nov 07 19:07:07 2017 Case: The Last R & M.HSC Flowsheet: Case (Main)Документ1 страницаFlash Gas Compression: Tue Nov 07 19:07:07 2017 Case: The Last R & M.HSC Flowsheet: Case (Main)TayebASherifОценок пока нет

- HYSYS Petroleum Refining Ops-V9Документ822 страницыHYSYS Petroleum Refining Ops-V9TayebASherif50% (2)

- Strategic Account Plan e BookДокумент22 страницыStrategic Account Plan e BookTayebASherif100% (1)

- DRW 1Документ3 страницыDRW 1TayebASherifОценок пока нет

- LLEXДокумент1 страницаLLEXTayebASherifОценок пока нет

- Trouble Shooting CourseДокумент4 страницыTrouble Shooting CourseTayebASherifОценок пока нет

- Electrical Materials Sizing CalculationДокумент3 страницыElectrical Materials Sizing CalculationTayebASherifОценок пока нет

- Oil & Gas Technologies Overview CVДокумент2 страницыOil & Gas Technologies Overview CVTayebASherifОценок пока нет

- Introductory Session To Process Engineering in The Oil & GasДокумент1 страницаIntroductory Session To Process Engineering in The Oil & GasTayebASherifОценок пока нет

- Cover Letter: Jerry VargheseДокумент1 страницаCover Letter: Jerry VargheseTayebASherifОценок пока нет

- Tanks CalculationsДокумент102 страницыTanks CalculationsTayebASherifОценок пока нет

- STF Kemim ValveДокумент3 страницыSTF Kemim ValveTayebASherifОценок пока нет

- Instrumetation Report ClarificationДокумент10 страницInstrumetation Report ClarificationTayebASherifОценок пока нет

- KaibelДокумент2 страницыKaibelTayebASherifОценок пока нет

- Nfpa 58 2011 Compliance PackageДокумент29 страницNfpa 58 2011 Compliance PackageTayebASherifОценок пока нет

- Numerical and Experimental Invstigation of The Bell Mouth Inlet Design of A Centrifugal Fan For Higher Internal Flow RateДокумент12 страницNumerical and Experimental Invstigation of The Bell Mouth Inlet Design of A Centrifugal Fan For Higher Internal Flow Ratearvind srinvasОценок пока нет

- The Coriolis Effect - Uche UmekweДокумент14 страницThe Coriolis Effect - Uche UmekwemrtrixsОценок пока нет

- Cavitation in Pumps and TurbinesДокумент34 страницыCavitation in Pumps and TurbinesBen100% (6)

- Airfoil Terminology Airfoil TerminologyДокумент17 страницAirfoil Terminology Airfoil Terminologymani567Оценок пока нет

- AGARDAG325Документ257 страницAGARDAG325becool_bcn75Оценок пока нет

- Flashcards - 1.2 Materials - Edexcel IAL Physics A-LevelДокумент35 страницFlashcards - 1.2 Materials - Edexcel IAL Physics A-LevelNikitha SomaratneОценок пока нет

- Classes and Comparisons Between CompressorsДокумент48 страницClasses and Comparisons Between CompressorsVijay MeenaОценок пока нет

- KSB MultitecДокумент128 страницKSB MultitecMiguel Delgado100% (1)

- WP Dealing With Water Surge in Fire Protection Piping Systems 2018Документ16 страницWP Dealing With Water Surge in Fire Protection Piping Systems 2018Ahmed AlmaghrbyОценок пока нет

- Flexitray Valve TraysДокумент12 страницFlexitray Valve TraysNkakak KkakakОценок пока нет

- Present LabДокумент15 страницPresent LabAnaОценок пока нет

- IC CFD AnalysisДокумент6 страницIC CFD Analysispuyang48Оценок пока нет

- Part2 - Exercise ChokeДокумент4 страницыPart2 - Exercise ChokeGustavo ChacónОценок пока нет

- Me2204 Unit Wise QuestionsДокумент18 страницMe2204 Unit Wise QuestionsMohanraj Subramani0% (1)

- Sim - Phy 205L - College Physics 2 For Engineering - Week1-3 PDFДокумент50 страницSim - Phy 205L - College Physics 2 For Engineering - Week1-3 PDFJayvon Suaybaguio Trytyphoon0% (1)

- AdvHyd02 - 2020 OLC NotesДокумент28 страницAdvHyd02 - 2020 OLC NotesAhmad Khairi Abd WahabОценок пока нет

- Duct DesignДокумент32 страницыDuct DesignsupportLSMОценок пока нет

- CFD Paper ReferenceДокумент2 страницыCFD Paper ReferenceBlue FlameОценок пока нет

- Series Das Dirt & Air Separ Ator: InformationДокумент2 страницыSeries Das Dirt & Air Separ Ator: InformationVikrant GargОценок пока нет

- Chapter 4 Stokes LawДокумент32 страницыChapter 4 Stokes LawAndi FaesalОценок пока нет

- A Study of A Skirtless Hovercraft DesignДокумент71 страницаA Study of A Skirtless Hovercraft DesignSunil Kumar P GОценок пока нет

- Rule of ThumbДокумент8 страницRule of ThumbHima Bindu Kolli100% (1)

- Qestion 3: Ѱ (r) = Γ Γ x−x y − yДокумент8 страницQestion 3: Ѱ (r) = Γ Γ x−x y − yCarlos PalominoОценок пока нет

- Light PresentationДокумент35 страницLight PresentationMichael Steven AlferezОценок пока нет

- Fluid FoundamentalsДокумент12 страницFluid FoundamentalsMoisè AstaОценок пока нет

- Chapter 2Документ27 страницChapter 2hailegebreselassie24Оценок пока нет

- Lesson 5: Mathematical Models of Electrical Control System ComponentsДокумент15 страницLesson 5: Mathematical Models of Electrical Control System ComponentsHasan AljabaliОценок пока нет

- Contoh Excel HAZOP Berdasarkan NODEДокумент58 страницContoh Excel HAZOP Berdasarkan NODEHandyОценок пока нет

- Condensate Line SizingДокумент2 страницыCondensate Line Sizingemmanuilmoulos6339100% (1)

- Om355 Paper PDFДокумент9 страницOm355 Paper PDFArman Hamidi50% (2)