Академический Документы

Профессиональный Документы

Культура Документы

NS PDF

Загружено:

TarunPatraИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

NS PDF

Загружено:

TarunPatraАвторское право:

Доступные форматы

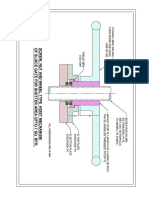

SUBMERSIBLE SEWAGE PUMPS TYPE - NS

C O N S T R U C T I O N A L

These are single stage, single suction pumps with overhung nonclogging impeller. Pumps can be offered in stationary as well as

transportable arrangements. The stationary arrangement is

supplied with pump connector unit and the connector unit is

connected to pump support bracket with rubber diaphragm to make

it leak proof joint.

PUMP CASING

The radially split casing is provided with delivery nozzle cast integral

with it. Suction is axial and delivery nozzle is central and horizontal.

Specially designed semi-concentric casing results in reduced radial

thrust and ensures vibration-free performance. Wide volute

passage ensures non-clogging operation of the pump.

IMPELLER

Impellers are of non-clog type which allow smooth passage of

solids.

Impellers are with single or multi vanes in semi-open, enclosed, or

free flow designs to cater to wide applications.

SHAFT

The high tensile steel shaft accurately machined and ground is

supported by two ball bearings in the motor above the impeller.

Shaft is designed to transmit the power without undue vibrations

and deflections. The shaft is common for pump and motor of

monoblock design.

MECHANICAL SEALS

Two mechanical seals in tandem arrangement are provided to

ensure no ingress of water or sewage in motor.

OPTIONAL FEATURES

a. Pumps can be supplied with "Cutter Fan" arrangement

at suction to agitate the liquid

b. Semi-open impellers can be provided with specially designed

wear plate for cutting and tearing of soft, long fibrous material.

BEARINGS

Bearings are grease lubricated and sealed for life, hence

maintenance free.

F E A T U R E S

DIRECTION OF ROTATION

Clockwise when viewed from motor top.

DRIVE

Motor is dry type submersible and cooled by liquid being handled.

Motors are air tested for leakfree operation.

Degree of protection for motor is IP68 as per IS:2147

Class of insulation : F

Voltage : 415V

10%

Frequency : 50 Hz.

5%

Type of starting : As per requirement (DOL/Star Delta/ATS)

CABLE

A specially designed cable, 1.1 kV grade having annealed tinned

copper conductor, insulated with Electron Beam Irradiated crosslinked elastomeric compound (compatible for continuous operation

at 1200 C) cores laid up with a proof cotton binder tape and sheathed

overall with Electron Beam Irradiated Cross-linked HD HOFR

elastomeric compound and generally conforming to IS 9968 Part l.

The cable with this unique combination of insulating and sheathing

material offers best resistance to acidic or alkaline sewage medium

and to the effluent gases coming out of the sump. The cable is more

flexible than PVC cable making coiling and handling easier and light

in weight compared to PVC cable of the same size.

CONTROL PANEL

Control panel consists of starter, switch, fuse and safety features.

Safety features are:

Single phasing prevention

Overload relays

Moisture sensing unit for detecting ingress of moisture or water

into oil chamber.

Liquid level controllers to avoid dry running.

Under voltage / Reverse phasing

FLANGES

Standard drilling to IS 6392 table 15.

SUBMERSIBLE SEWAGE PUMPS TYPE - NS

C O N S T R U C T I O N A L

These are single stage, single suction pumps with overhung nonclogging impeller. Pumps can be offered in stationary as well as

transportable arrangements. The stationary arrangement is

supplied with pump connector unit and the connector unit is

connected to pump support bracket with rubber diaphragm to make

it leak proof joint.

PUMP CASING

The radially split casing is provided with delivery nozzle cast integral

with it. Suction is axial and delivery nozzle is central and horizontal.

Specially designed semi-concentric casing results in reduced radial

thrust and ensures vibration-free performance. Wide volute

passage ensures non-clogging operation of the pump.

IMPELLER

Impellers are of non-clog type which allow smooth passage of

solids.

Impellers are with single or multi vanes in semi-open, enclosed, or

free flow designs to cater to wide applications.

SHAFT

The high tensile steel shaft accurately machined and ground is

supported by two ball bearings in the motor above the impeller.

Shaft is designed to transmit the power without undue vibrations

and deflections. The shaft is common for pump and motor of

monoblock design.

MECHANICAL SEALS

Two mechanical seals in tandem arrangement are provided to

ensure no ingress of water or sewage in motor.

OPTIONAL FEATURES

a. Pumps can be supplied with "Cutter Fan" arrangement

at suction to agitate the liquid

b. Semi-open impellers can be provided with specially designed

wear plate for cutting and tearing of soft, long fibrous material.

BEARINGS

Bearings are grease lubricated and sealed for life, hence

maintenance free.

F E A T U R E S

DIRECTION OF ROTATION

Clockwise when viewed from motor top.

DRIVE

Motor is dry type submersible and cooled by liquid being handled.

Motors are air tested for leakfree operation.

Degree of protection for motor is IP68 as per IS:2147

Class of insulation : F

Voltage : 415V

10%

Frequency : 50 Hz.

5%

Type of starting : As per requirement (DOL/Star Delta/ATS)

CABLE

A specially designed cable, 1.1 kV grade having annealed tinned

copper conductor, insulated with Electron Beam Irradiated crosslinked elastomeric compound (compatible for continuous operation

at 1200 C) cores laid up with a proof cotton binder tape and sheathed

overall with Electron Beam Irradiated Cross-linked HD HOFR

elastomeric compound and generally conforming to IS 9968 Part l.

The cable with this unique combination of insulating and sheathing

material offers best resistance to acidic or alkaline sewage medium

and to the effluent gases coming out of the sump. The cable is more

flexible than PVC cable making coiling and handling easier and light

in weight compared to PVC cable of the same size.

CONTROL PANEL

Control panel consists of starter, switch, fuse and safety features.

Safety features are:

Single phasing prevention

Overload relays

Moisture sensing unit for detecting ingress of moisture or water

into oil chamber.

Liquid level controllers to avoid dry running.

Under voltage / Reverse phasing

FLANGES

Standard drilling to IS 6392 table 15.

SUBMERSIBLE SEWAGE PUMPS TYPE - NS

SUBMERSIBLE SEWAGE PUMPS TYPE - NS

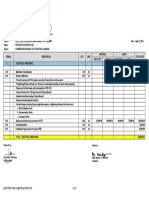

80

50

NS 50/26

65

NS 50/32

II

NS 65/32

J K

L/M

DIA P.C.D

Q

CRS

A1

985 173 491 256 239 225 55 460 165 125 4/18 320 260 200 150 24 560 450

70

320

900

82

50 1085 173 491 256 239 225 55 460 165 125 4/18 320 260 200 150 24 560 450

70

320

900

50

75

50 1020 150 491 256 284 225 55 460 165 125 4/18 320 260 200 150 24 560 450

70

320

900

65

50

65

50 1030 135 491 256 309 225 55 460 165 125 4/18 320 260 200 150 24 560 450

70

320 900

80

65

84

65 1030 140 542 312 309 225 55 460 185 145 4/18 330 270 225 175 24 570 475

80

340

900

NS 65/32

II

80

65

84

65 1130 140 542 312 309 225 55 460 185 145 4/18 330 270 225 175 24 570 475

80

340

900

NS 80/26

100 80

105

80 1035 150 595 350 279 225 60 460 200 160 8/18 360 300 250 200 24 600 500 110 400

900

NS 80/26

II

100 80

105

80 1135 150 595 350 279 225 60 460 200 160 8/18 360 300 250 200 24 600 500 110 400

900

NS 100/26

125 100

130

100 1050 170 468 198 309 225 80 460 220 180 8/18 385 325 280 230 24 625 530 130 440

900

NS 100/26

II

125 100

130

100 1150 170 468 198 309 225 80 460 220 180 8/18 385 325 280 230 24 625 530 130 440 1000

NS 100/32

II

125 100

130

100 1150 170 468 198 344 225 80 460 220 180 8/18 385 325 280 230 24 625 530 130 440 1000

NS 150/26

II

150 150

165

150 1180 185 553 248 390 245 100 510 285 240 8/23 500 420 355 280 30 720 580 205 590 1000

NS 150/32

II

150 150

165

150 1180 190 553 248 435 245 100 510 285 240 8/23 500 420 355 280 30 720 580 205 590 1000

S

CRS

NWD

66/77

51 / 61

32/43

SUC. & DEL. SIZE

PUMP

TYPE

NOMINAL

SIZE

OPENING

SIZE

NWS NWD NWS

80

J

DIA

K

P.C.D

L/M

Q

CRS

S

CRS

W1

A1

NWD

NS 80/40

100

100

80

1305 165 595 350 384 265 60 530 200

160

8/18 360 300

250 200 24 600 500 110 400 1200

NS 100/32

125 100 130

100

1325 170 468 198 344 265 80 530 220

180

8/18 385 325

280 230 24 625 530 130 440 1225

NS 100/40

125 100 125

100

1335 170 468 198 384 265 80 530 220

180

8/18 385 325

280 230 24 625 530 130 440 1235

NS 150/26

150 150 165

150

1355 185 553 248 390 265 100 530 285

240

8/23 500 420

355 280 30 720 580 205 590 1270

NS 150/32

150 150 165

150

1350 190 553 248 435 265 100 530 285

240

8/23 500 420

355 280 30 720 580 205 590 1270

NS 150/40

150 150 160

150

1350 190 553 248 435 285 100 560 285

240

8/23 500 420

355 280 30 720 580 205 590 1270

NS 200/32

200 200 202

200

1360 215 640 300 435 280 110 550 340

295

12/23 560 480

380 300 30 780 600 225 630 1300

NS 200/40

200 200 185

200

1370 210 640 300 435 285 110 560 340

295

12/23 560 480

380 300 30 780 600 225 630 1300

FOUNDATION

BOLT SIZE

II

M24X M24X M24X M24X M24X M20X M20X500 M24X

500L 500L 500L 500L 500L 500L 500L 500L

NS 50/20

GUIDE PIPE

I.D/O.D

50

51/61

82

W1

III

66/77 66/77 66/77 66/77 66/77

50

I N S T A L L A T I O N

FOUNDATION

BOLT SIZE

80

NWS NWD NWS

M20 x 500 L.

OPENING

SIZE

M20 x 500 L.

NS 50/20

NOMINAL

SIZE

M24 x 500 L.

MOTOR UNIT

SUC. & DEL. SIZE

PUMP

TYPE

GUIDE PIPE

I.D/O.D

S T A T I O N A R Y

SUBMERSIBLE SEWAGE PUMPS TYPE - NS

SUBMERSIBLE SEWAGE PUMPS TYPE - NS

80

50

NS 50/26

65

NS 50/32

II

NS 65/32

J K

L/M

DIA P.C.D

Q

CRS

A1

985 173 491 256 239 225 55 460 165 125 4/18 320 260 200 150 24 560 450

70

320

900

82

50 1085 173 491 256 239 225 55 460 165 125 4/18 320 260 200 150 24 560 450

70

320

900

50

75

50 1020 150 491 256 284 225 55 460 165 125 4/18 320 260 200 150 24 560 450

70

320

900

65

50

65

50 1030 135 491 256 309 225 55 460 165 125 4/18 320 260 200 150 24 560 450

70

320 900

80

65

84

65 1030 140 542 312 309 225 55 460 185 145 4/18 330 270 225 175 24 570 475

80

340

900

NS 65/32

II

80

65

84

65 1130 140 542 312 309 225 55 460 185 145 4/18 330 270 225 175 24 570 475

80

340

900

NS 80/26

100 80

105

80 1035 150 595 350 279 225 60 460 200 160 8/18 360 300 250 200 24 600 500 110 400

900

NS 80/26

II

100 80

105

80 1135 150 595 350 279 225 60 460 200 160 8/18 360 300 250 200 24 600 500 110 400

900

NS 100/26

125 100

130

100 1050 170 468 198 309 225 80 460 220 180 8/18 385 325 280 230 24 625 530 130 440

900

NS 100/26

II

125 100

130

100 1150 170 468 198 309 225 80 460 220 180 8/18 385 325 280 230 24 625 530 130 440 1000

NS 100/32

II

125 100

130

100 1150 170 468 198 344 225 80 460 220 180 8/18 385 325 280 230 24 625 530 130 440 1000

NS 150/26

II

150 150

165

150 1180 185 553 248 390 245 100 510 285 240 8/23 500 420 355 280 30 720 580 205 590 1000

NS 150/32

II

150 150

165

150 1180 190 553 248 435 245 100 510 285 240 8/23 500 420 355 280 30 720 580 205 590 1000

S

CRS

NWD

66/77

51 / 61

32/43

SUC. & DEL. SIZE

PUMP

TYPE

NOMINAL

SIZE

OPENING

SIZE

NWS NWD NWS

80

J

DIA

K

P.C.D

L/M

Q

CRS

S

CRS

W1

A1

NWD

NS 80/40

100

100

80

1305 165 595 350 384 265 60 530 200

160

8/18 360 300

250 200 24 600 500 110 400 1200

NS 100/32

125 100 130

100

1325 170 468 198 344 265 80 530 220

180

8/18 385 325

280 230 24 625 530 130 440 1225

NS 100/40

125 100 125

100

1335 170 468 198 384 265 80 530 220

180

8/18 385 325

280 230 24 625 530 130 440 1235

NS 150/26

150 150 165

150

1355 185 553 248 390 265 100 530 285

240

8/23 500 420

355 280 30 720 580 205 590 1270

NS 150/32

150 150 165

150

1350 190 553 248 435 265 100 530 285

240

8/23 500 420

355 280 30 720 580 205 590 1270

NS 150/40

150 150 160

150

1350 190 553 248 435 285 100 560 285

240

8/23 500 420

355 280 30 720 580 205 590 1270

NS 200/32

200 200 202

200

1360 215 640 300 435 280 110 550 340

295

12/23 560 480

380 300 30 780 600 225 630 1300

NS 200/40

200 200 185

200

1370 210 640 300 435 285 110 560 340

295

12/23 560 480

380 300 30 780 600 225 630 1300

FOUNDATION

BOLT SIZE

II

M24X M24X M24X M24X M24X M20X M20X500 M24X

500L 500L 500L 500L 500L 500L 500L 500L

NS 50/20

GUIDE PIPE

I.D/O.D

50

51/61

82

W1

III

66/77 66/77 66/77 66/77 66/77

50

I N S T A L L A T I O N

FOUNDATION

BOLT SIZE

80

NWS NWD NWS

M20 x 500 L.

OPENING

SIZE

M20 x 500 L.

NS 50/20

NOMINAL

SIZE

M24 x 500 L.

MOTOR UNIT

SUC. & DEL. SIZE

PUMP

TYPE

GUIDE PIPE

I.D/O.D

S T A T I O N A R Y

Next

Вам также может понравиться

- AVT Ball & Butterfly Brochure 05 Latest 12 PageДокумент12 страницAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyОценок пока нет

- Technical Bulletin: Valtek Mark One Control ValvesДокумент20 страницTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzОценок пока нет

- Ci NLДокумент12 страницCi NLanuraeОценок пока нет

- Automax Valve Automation Systems - Pneumatic Actuators and Accessories - FlowserveДокумент24 страницыAutomax Valve Automation Systems - Pneumatic Actuators and Accessories - FlowserveKakoDaОценок пока нет

- SubmersibleDewateringPumps E10361Документ20 страницSubmersibleDewateringPumps E10361Rolando AlvaradoОценок пока нет

- ACV-12 Adjustable Choke Valves: For Wide Applications in Oil, Gas, and Water ServiceДокумент2 страницыACV-12 Adjustable Choke Valves: For Wide Applications in Oil, Gas, and Water ServiceDeyokeОценок пока нет

- 855 (1400)Документ6 страниц855 (1400)Harman Singh NagpalОценок пока нет

- Centrifugal Slurry Pump RangeДокумент16 страницCentrifugal Slurry Pump Rangecitramuara100% (4)

- Product Bulletin - Optima Series eДокумент8 страницProduct Bulletin - Optima Series eeeОценок пока нет

- Large Dia. Butterfly ValveДокумент15 страницLarge Dia. Butterfly ValvepntripathiОценок пока нет

- Grundfos Axial Flow Pumps BrochureДокумент7 страницGrundfos Axial Flow Pumps Brochurefg_111307359Оценок пока нет

- CopperalloybrakeДокумент4 страницыCopperalloybrakeReinaldo Side JuniorОценок пока нет

- En Daten MS-MFДокумент20 страницEn Daten MS-MFcazan93Оценок пока нет

- Max Air PDFДокумент8 страницMax Air PDFKNIGHTHAGENОценок пока нет

- HSCДокумент12 страницHSCSuhas Natu100% (1)

- Gardner Denver Industrial Blowers TF 140L K202Документ8 страницGardner Denver Industrial Blowers TF 140L K202Aleksandar JočićОценок пока нет

- Product Range: Gate Valve / Sluice ValveДокумент6 страницProduct Range: Gate Valve / Sluice ValveTanmoy DuttaОценок пока нет

- Valvula YarwayДокумент12 страницValvula YarwayRobert VillavicencioОценок пока нет

- Catalog Mud Pump 25864Документ24 страницыCatalog Mud Pump 25864agus100% (1)

- 5600 Swing Flex Check ValveДокумент16 страниц5600 Swing Flex Check ValveMahmoud Abd ElnaeimОценок пока нет

- 10.piston CylinderДокумент19 страниц10.piston Cylinderprihartono_diasОценок пока нет

- Neumax QT Series Quarter Turn Electric ActuatorДокумент5 страницNeumax QT Series Quarter Turn Electric Actuatornvhoang0185Оценок пока нет

- Leader PPV Positive Pressure Ventilation FanДокумент6 страницLeader PPV Positive Pressure Ventilation Fandonald_wilson4741Оценок пока нет

- Kirloskar Non Cloging NsДокумент5 страницKirloskar Non Cloging Nsedward baskaraОценок пока нет

- Grundfosliterature 146014Документ12 страницGrundfosliterature 146014Mario Daniel MoreiraОценок пока нет

- KDS CatalogueДокумент4 страницыKDS CataloguechandrakishoreharsheОценок пока нет

- Series 767FR Specification SheetДокумент4 страницыSeries 767FR Specification SheetFEBCOОценок пока нет

- Mueller Resilient Wedge Gate Valves: For Reliable Performance and Long Service Life-Certified To NSF 61Документ4 страницыMueller Resilient Wedge Gate Valves: For Reliable Performance and Long Service Life-Certified To NSF 61gad30Оценок пока нет

- KBLДокумент16 страницKBLRamKS80100% (1)

- Fisa Tehnica Pompe MultifreeДокумент10 страницFisa Tehnica Pompe MultifreeOčtáv VátčoОценок пока нет

- Control Choke Valve 9000Документ8 страницControl Choke Valve 9000sabi_shi100% (2)

- Series 3 & 4 U BonnetedДокумент9 страницSeries 3 & 4 U BonnetedBaskaran RathinamОценок пока нет

- C LineДокумент16 страницC LineSunil Kumar VishwakarmaОценок пока нет

- Válvulas Bola SegmentadaДокумент12 страницVálvulas Bola SegmentadarehynaldoОценок пока нет

- Steering GearДокумент32 страницыSteering GearkindbagusОценок пока нет

- Type 2600 FlowstarДокумент2 страницыType 2600 FlowstartakenoveraccountОценок пока нет

- Silent Check Valve - Wafer and Globe Style - 2012Документ8 страницSilent Check Valve - Wafer and Globe Style - 2012james_chan2178Оценок пока нет

- Catalogues Au MyДокумент28 страницCatalogues Au MyChu Hữu LạcОценок пока нет

- SAPAG Butterfly ValvesДокумент22 страницыSAPAG Butterfly ValvespawelzakОценок пока нет

- Series 825YD Specification SheetДокумент2 страницыSeries 825YD Specification SheetFEBCOОценок пока нет

- Howell Bunger Valve 05. HBGR - Text New CoverДокумент4 страницыHowell Bunger Valve 05. HBGR - Text New CovermuazeemKОценок пока нет

- Ebara PumpДокумент14 страницEbara PumpSujanto WidjajaОценок пока нет

- Hydroo Motors For Submersible Pumps - 6"Документ2 страницыHydroo Motors For Submersible Pumps - 6"BearingmanОценок пока нет

- SwingClamp BottomFlangeДокумент4 страницыSwingClamp BottomFlangePeter CusimanoОценок пока нет

- WallДокумент0 страницWallgks6043Оценок пока нет

- Butterfly ValveДокумент14 страницButterfly ValveSingSareblakKanaManahОценок пока нет

- Valvula WW-820Документ4 страницыValvula WW-820Anonymous Iic1fi49uEОценок пока нет

- VekTek Miniature CylindersДокумент13 страницVekTek Miniature CylindersMike von BertouchОценок пока нет

- SF6 GCB 24 - 36 KVДокумент4 страницыSF6 GCB 24 - 36 KVMichael Parohinog GregasОценок пока нет

- P6 Limit SwitchДокумент3 страницыP6 Limit SwitchABCdude1Оценок пока нет

- AVK ValveДокумент2 страницыAVK Valvemih4iОценок пока нет

- Power Steering System ComponentsДокумент10 страницPower Steering System ComponentsAbraham PejovésОценок пока нет

- Bevel Gear Operators: Manual & MotorizableДокумент8 страницBevel Gear Operators: Manual & MotorizablezvblimeОценок пока нет

- S100Документ2 страницыS100letrongvu_tk07Оценок пока нет

- F6 Series, 2-Way, HDU Butterfl y Valve Resilient Seat, 304 Stainless DiscДокумент4 страницыF6 Series, 2-Way, HDU Butterfl y Valve Resilient Seat, 304 Stainless DiscJosephОценок пока нет

- Catalogo 13 - 2016 EditionДокумент12 страницCatalogo 13 - 2016 EditionHector Manuel Calvo MejiaОценок пока нет

- Butterfly ValveДокумент20 страницButterfly Valvenazar750Оценок пока нет

- Geotextiles and Geomembranes HandbookОт EverandGeotextiles and Geomembranes HandbookT.S. IngoldРейтинг: 5 из 5 звезд5/5 (1)

- SKF Latest Price List 2021Документ148 страницSKF Latest Price List 2021nitesh mulhallОценок пока нет

- Ranichak - Scheme - 1200 23.05.2018Документ40 страницRanichak - Scheme - 1200 23.05.2018TarunPatraОценок пока нет

- Estimate For 2500 Cusec BagjolaДокумент12 страницEstimate For 2500 Cusec BagjolaTarunPatraОценок пока нет

- Irjet V2i822 PDFДокумент6 страницIrjet V2i822 PDFTarunPatraОценок пока нет

- Puru LiaДокумент1 страницаPuru LiaTarunPatraОценок пока нет

- Bus Bar DesignДокумент5 страницBus Bar DesignRamadhar Sharma100% (1)

- 06 - Pert CPMДокумент24 страницы06 - Pert CPMManinee Bhojraj DholeОценок пока нет

- ManualДокумент2 страницыManualTarunPatraОценок пока нет

- Schedule-II General Instructions For Filling Up The Self Appraisal Report For Group A OfficersДокумент4 страницыSchedule-II General Instructions For Filling Up The Self Appraisal Report For Group A OfficersTarunPatraОценок пока нет

- FS - Vol 3 - TECH - SPECДокумент31 страницаFS - Vol 3 - TECH - SPECTarunPatraОценок пока нет

- Rtu Panel With 2.2 KW X 5 VFD NewДокумент29 страницRtu Panel With 2.2 KW X 5 VFD NewTarunPatraОценок пока нет

- Document From JohannДокумент48 страницDocument From JohannTarunPatraОценок пока нет

- Axial Flow or Propeller PumpДокумент4 страницыAxial Flow or Propeller PumpTarunPatraОценок пока нет

- Incone TechnologiesДокумент6 страницIncone TechnologiesTarunPatraОценок пока нет

- Dam Automation Case StudyДокумент6 страницDam Automation Case StudyTarunPatraОценок пока нет

- D - Est. For Satpukuria Lifting Winch - Worm Gear Drive Lifting Winch MC Model (1Документ1 страницаD - Est. For Satpukuria Lifting Winch - Worm Gear Drive Lifting Winch MC Model (1TarunPatraОценок пока нет

- D - 20 and 16 Vent Sluce at Ghusighata - Draw Shutter 20 and 16 Vent - Pedestal Stool Model (1Документ1 страницаD - 20 and 16 Vent Sluce at Ghusighata - Draw Shutter 20 and 16 Vent - Pedestal Stool Model (1TarunPatraОценок пока нет

- Trash Rack at Forebay BridgeДокумент1 страницаTrash Rack at Forebay BridgeTarunPatraОценок пока нет

- System Head Ranichak P SДокумент8 страницSystem Head Ranichak P STarunPatraОценок пока нет

- Drawing - Pumphouse Pinjarapole Khal HWHДокумент1 страницаDrawing - Pumphouse Pinjarapole Khal HWHTarunPatraОценок пока нет

- The Illustration Is That of A "Power Unit" Which Includes The ReservoirДокумент30 страницThe Illustration Is That of A "Power Unit" Which Includes The ReservoirTarunPatraОценок пока нет

- D - Drawing - Foundation Details 2nd Ups Model (1Документ1 страницаD - Drawing - Foundation Details 2nd Ups Model (1TarunPatraОценок пока нет

- K Lite Products Portfolio 2016 V 0Документ56 страницK Lite Products Portfolio 2016 V 0TarunPatra100% (2)

- Canal System L.D.I. Old A3Документ1 страницаCanal System L.D.I. Old A3TarunPatraОценок пока нет

- Schedule of Rates Building Works Vol I 2017Документ407 страницSchedule of Rates Building Works Vol I 2017TarunPatra0% (1)

- L&T Panel Accessories Price List 01JUL2017Документ44 страницыL&T Panel Accessories Price List 01JUL2017TarunPatraОценок пока нет

- D - Drawing - Screw Nut Wheel Type Hoist 650mm ScrewДокумент1 страницаD - Drawing - Screw Nut Wheel Type Hoist 650mm ScrewTarunPatraОценок пока нет

- SKF Industrial PricelistApril2017 Edition2Документ140 страницSKF Industrial PricelistApril2017 Edition2shekar_991985346Оценок пока нет

- Unbrako Fasteners Price List 2Документ70 страницUnbrako Fasteners Price List 2TarunPatraОценок пока нет

- 2.5 Technical Specifications For Hydro Mechanical WorksДокумент62 страницы2.5 Technical Specifications For Hydro Mechanical WorksAbhishek PandeyОценок пока нет

- PANTERRA 50cc Street Scooter Service Manual PDFДокумент188 страницPANTERRA 50cc Street Scooter Service Manual PDFjoe100% (1)

- Landers PMS Cost Proposalrev01 - Electric Pro 04apr2023Документ1 страницаLanders PMS Cost Proposalrev01 - Electric Pro 04apr2023IVM PhilsОценок пока нет

- 03 - Statron Technical Datasheet - Item 3.0-DikonversiДокумент16 страниц03 - Statron Technical Datasheet - Item 3.0-DikonversiteleangОценок пока нет

- 1 SINGER Panoramic (Mod. 650 - 670G) PDFДокумент89 страниц1 SINGER Panoramic (Mod. 650 - 670G) PDFmaria brito100% (2)

- Step by Step Guide Brochure in Sharpening Hand SawДокумент2 страницыStep by Step Guide Brochure in Sharpening Hand Sawivil Jean ocoОценок пока нет

- SPP2 - Siemens TXP HW ManualДокумент293 страницыSPP2 - Siemens TXP HW ManualMiguel CarpioОценок пока нет

- Symbols of Transistors MOSFET and IGFET: Go To WebsiteДокумент2 страницыSymbols of Transistors MOSFET and IGFET: Go To Websitemhs madiunОценок пока нет

- Iom-Ball ValveДокумент10 страницIom-Ball ValveMohamadIbnuHassanОценок пока нет

- Technical Specification Simba S7 D Atlas CopcopДокумент4 страницыTechnical Specification Simba S7 D Atlas CopcopPedro Espinoza HuahuacondoriОценок пока нет

- 2391 Revision 2000 V6.0Документ118 страниц2391 Revision 2000 V6.0mpendleton100% (1)

- Ta-30 - 8281 Manual PartsДокумент484 страницыTa-30 - 8281 Manual PartsAntonio Carrion100% (1)

- Sistem Pengoperasian PltuДокумент21 страницаSistem Pengoperasian PltuNizar AlfianОценок пока нет

- AC Voltage Single Function Transducer TAV-311DG/TAV-321DG: Data SheetДокумент7 страницAC Voltage Single Function Transducer TAV-311DG/TAV-321DG: Data Sheetflash_90697638Оценок пока нет

- CX2032MM Rev1Документ301 страницаCX2032MM Rev1totalofficesupportОценок пока нет

- Donghwa Tanabe H SeriesДокумент95 страницDonghwa Tanabe H Seriesjohn smith0% (1)

- PO No. 536 - OTTO - CTC No. CEPD-2018.73Документ4 страницыPO No. 536 - OTTO - CTC No. CEPD-2018.73mandi bahauddin associatesОценок пока нет

- Service Experience 2023Документ37 страницService Experience 2023신영호Оценок пока нет

- 2015 F150 SpecsДокумент2 страницы2015 F150 SpecsSufian MahadinОценок пока нет

- Fluid-Manual Transmission 48-25859 A: ScopeДокумент1 страницаFluid-Manual Transmission 48-25859 A: ScopeJOSE MIGUELОценок пока нет

- General Engine Info Aircraft Information Limiting Part InformationДокумент1 страницаGeneral Engine Info Aircraft Information Limiting Part InformationAHAMEDОценок пока нет

- ATX Power Supply Pinout TablesДокумент4 страницыATX Power Supply Pinout TablesElectrical EEEОценок пока нет

- VEG2000 - Manual - ENG - V4.6Документ49 страницVEG2000 - Manual - ENG - V4.6ahmed morsyОценок пока нет

- B.Tech. Computer Science Engineering Effective For The Batches Admitted From Session 2022-23-38Документ1 страницаB.Tech. Computer Science Engineering Effective For The Batches Admitted From Session 2022-23-38rajat.20223200Оценок пока нет

- Qy160v633 Opertaion ManualДокумент299 страницQy160v633 Opertaion ManualИванОценок пока нет

- Television HistoryДокумент5 страницTelevision HistoryJaider Mercado López100% (1)

- DC220 Catalogue 4th EditionДокумент70 страницDC220 Catalogue 4th EditionMuchammatAlvinurОценок пока нет

- Micronote #101Документ2 страницыMicronote #101eng,amОценок пока нет

- Kompaktkatalog EN Web Low PDFДокумент324 страницыKompaktkatalog EN Web Low PDFChristopher SkelleyОценок пока нет

- Lenovo Azure HCI Configure GuideДокумент38 страницLenovo Azure HCI Configure GuideMoezОценок пока нет

- Testing, Design For Testability: Mah, Aen EE271 Lecture 16 1Документ28 страницTesting, Design For Testability: Mah, Aen EE271 Lecture 16 1suyog kalaniОценок пока нет