Академический Документы

Профессиональный Документы

Культура Документы

Cap KSM72

Загружено:

Jaffer HussainИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cap KSM72

Загружено:

Jaffer HussainАвторское право:

Доступные форматы

Capricorn Controls

Page 1 of 6

KSM72 Key Start Module

Genset Controls - Timers - Monitors - Trips - Battery Charging - Spares & Accessories - Custom Products

Combining the convenience of manual operation with engine

protection for Low Oil Pressure, Coolant Fault and

(optionally) Overspeed, these short Keystart Modules can

be easily mounted into almost any control panel or

switchbox. Set in a compact 72mmsq DIN sized module they

can be used with a wide range of engine driven equipment.

The front panel has up to five High Intensity LEDs

indicating system status. The key switch provides

PREHEAT

(KSM72_J option Only)

Select Pre-Heat if required, just prior to

starting the engine. Use it for the

shortest possible time to preserve charge

in the battery (typically 10sec but

dependant on the ambient temperature).

Do not leave the switch in this position

See page-3 for Timed Pre-Heat options.

KSM72CH

OFF / RESET

Use to stop the engine and resets all Shutdowns. Always ensure that the engine is

stationary before restarting.

RUN

Powers the unit, energises the fuel solenoid and starts the Hold-Off timer (T0). If the

key remains in this position for 25secs or more, the Hold-Off timer will elapse and

the module will latch out on Low Oil Pressure. To start the engine from an alarm

condition, the key must first be turned to the OFF position for at least 1 second

(see above).

START

Hold in this position to crank the engine, releasing it to the Run position as soon as

the engine fires. If the engine fails to start after approx. 10 secs return the key to

the OFF position, wait approx. 10 secs and try again. If the engine fails to start

after three attempts, turn the key to the Off position and consult the engine

manufactures Handbook.

Assuming that the engine fires the Keyswitch is returned to the RUN position, disengaging the Starter,

the engine runs up to normal speed and the Hold-Off timer (T0) is running. The tachometer circuitry

(KSM72B & D) continually monitors for Overspeed. When the hold-off timer has elapsed, the Low Oil

Pressure and Cooling fault circuits are enabled. In the event of a shutdown, the appropriate fault Led is

lit, the Alarm output (if applicable) is activated, the Fuel relay is locked out and the LOP & HET

channels disabled (first-up interlock).

Page 2 of 6

Ordering Information

Model No.

KSM72A

KSM72B

KSM72C

KSM72D

Options

* KSM72 - A (note 3)

KSM72 - - H

* KSM72 - - - - J

**KSM72 - - - - - Y

* KSM72 - - - -Z

Overspeed

No

Yes

No

Yes

Channel 5 = Charge Failure

No

No

Yes

Yes

Channel 5 = 'Lamp Only'

see note 4

see note 4

No

No

Features

Term.

Alarm Output +Ve from the N/C contact on the internal Fuel Control Relay

Integral (LCD) 'Hours Counter'

Switched 'Pre-Heat' +Ve output

Pulsed output for Fuel pull-in coil + Timed Pre-Heat. i.e YANMAR engines.

Timed 'Pre-Heat' +Ve output

7

7

9 & 10

7

Input Phasing

KSM72 - - KSM72 - - - / HR

KSM72 - - - / LR

KSM72 - - - / HLR

Het (Cooling Fault) & Lop (Low Oil Pressure) are both 'closed to ground' (Batt -Ve) on fault

'Het Reversed' - open from ground (Batt -Ve) on fault

'Lop Reversed'- open from ground (Batt -Ve) on fault

'Het & Lop Reversed' - {both of the above} - open from ground (Batt -Ve) on fault

NOTE: 1/ *

These Models & Options are 'Mutually Exclusive' as they all use terminal 7, but for different

functions!

2/ ** Builds with this option (KSM72A & C only) utilise term.9 & 10 for DC outputs and is therefor NOT

compatible with KSM72B & D builds which use these terminals for 115 / 230Vac inputs.

3/

Unless requested otherwise, KSM72AA, BA, CA or DA are now supplied as standard.

4/

Connect term.7 to Batt Ve to light LED 5. Various Over-Stick labels can be supplied from stock.

SPECIAL BUILDS

RSM72 - - - / - - / X0? These 'X' numbers, indicate non-standard product, which have been manufactured to suit specific

customers requirements. They do not appear in any catalogues and may only be available to the original customer. When reordering, please quote the full part number together with the 'Serial Number' of the original unit(s).

CUSTOMISED PRODUCTS

If you have a specific requirement that is not listed above; please contact our Sales Desk for a quotation. We can normally

customise a standard product within a matter of days in order to provide a prototype (if not, production) unit.

Note: - For a spare or replacement part, please quote the Serial Number of the original unit if possible.

Capricorn Controls

Page 3 of 6

Connections

Always ensure that the correct wire sizes are used and that all terminals are correctly tightened.

Terminal

Description

Type

Connect To ------

1

2

3

4

5

6

7

8

9

10

Low Oil Pressure

High Engine Temp.

Max. Load 16 Amps (resistive)

Supply +Ve

Max. Load 16 Amps (resistive)

Common DC -Ve supply

(see below)

Charge Failure

Frequency (Speed) sensing

Frequency (Speed) sensing

-Ve Input

-Ve Input

+Ve Output

Low Oil Pressure switch

High Engine Temp. Switch

Solenoid or Solenoid Relay

Battery positive

Solenoid or Solenoid Relay

Battery negative

LOP

HET

Starter

Batt+

Fuel

Batt Exc+

C.F.

AC

AC

NOTE :

+Ve Output

Charging Alternator (WL)

115/230VAC (Main Alternator)

115/230VAC (Main Alternator)

Max. Load 16 Amps (resistive) de-rate to 14% for Inductive Loads (2.2A continuous)

BUILD OPTIONS

KSM72_A

Unless requested otherwise, this option is now fitted on all standard builds. Previously, special

option X069 it provides a +Ve Alarm output (from the N/C contact on the internal Fuel Control

relay). Whenever the engine is shutdown on a fault condition the Fuel Control relay de-energises,

stopping the engine and providing a +Ve ALARM output rated at 16A (resistive) to directly drive a

small sounder or power relay. An external flywheel diode will be required with inductive loads.

Please note:- At switch-on, the Alarm Output pulses for approx. 20mSec.

KSM72__/X06 This special option provides a +Ve Alarm output whenever the engine is shutdown on a fault

condition. Derived from the internal logic, it does not pulse at switch on. The output has an

integral flywheel diode as it is designed to drive an external relay. Continuous output current

must not exceed 150mA.

KSM72__H

An 'LCD' Hours Counter is fitted behind a windowed front label. It is powered in the 'Run' (or

start) mode. An 'hour glass' indicator flashes every 6th second to indicate that counting is in

progress (only while the fuel solenoid is energised). Data retention is in excess of 20 years.

KSM72___J

The standard J option provides a manual Pre-Heat position on the Keyswitch, anti-clockwise

from OFF. This +Ve Output is rated at 15Amps (resistive) and an external flywheel diode is

required if switching a solenoid, relay or other inductive load..

KSM72___Z

(KSM72A & KSM72C only) The standard Z option provides a Timed Pre-Heat function

(typically set to 12secs). An integral flywheel diode is employed as it is designed to drive an

inductive load, such as a relay. Continuous output current must not exceed 150mA.

Please note: A, X06, J & Z Options are Mutually Exclusive as they all use term.7, but for

different purposes.

KSM72____Y

(KSM72A & KSM72C only) this special option is for use with engines (i.e. Yanmar) with twostage fuel solenoids (separate pull-in and hold coils). Terminals 9 & 10 provide drivers for external

relays to operate the 1 sec fuel pulse and Glowplugs. Continuous output current must not exceed

150mA.This option does not include the standard A Option as Exc+ is required.

WARNING: Builds with this option are incompatible with our standard range above as term.9 &

10 are normally reserved for 115/230V Frequency (Speed) sensing of the main alternator.

Page 4 of 6

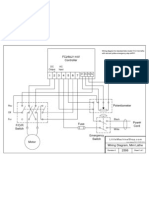

Application Notes

Low Oil Pressure

Standard Builds

KSM72AA

KSM72BA

KSM72CA

KSM72DA

Oil Press.

Cooling Fault

Start

Batt.+Ve

Fuel

Batt.-Ve

Alarm +Ve

Chg.Fail

A.C

A.C

10

Batt -Ve

Slave

Relay

F1

BATT +Ve

See note

Slave

Relay

WL

SOUNDER

AC Frequency

Sensing

KSM72B & D only

Slave

Relay

Y Option

Fuel

Timed Pre-Heat &

Fuel Pulse output

Typically for

YANMAR

Engines

5

IGN

6

Exc.+Ve

Chg.Fail

PreHeat

Fuel Pulse

BATT -Ve

Batt -Ve

J Option : Manual Pre-Heat

Z Option : Timed Pre-Heat

X06 Option : Alarm Output

Cooling Fault

10

WL

Slave

Relay

BATT -Ve

Slave

Relay

Notes

1.

2.

3.

4.

5.

6.

7.

Oil Press. & Cooling Fault inputs are shown as close to ground on fault.

Coolant Fault can be used to indicate High Engine Temperature & / or Low Coolant Level

Fuse F1 = 5A Anti-surge if Slave Relay on Fuel Solenoid, else 10A Anti-surge.

FUEL output = 16A resistive. (De-rate to 14% (2.2A continuous) to allow for 7x inrush into an inductive load)

START output = 16A resistive (direct from Keyswitch contacts).

For Slave Relays see Spares & Accessories section of our latest Price List.

All Slave Relays should have flywheel suppression diodes fitted, to comply with EMC regulations (

)

Capricorn Controls

Page 5 of 6

FAULT FINDING ----- KSM72 BASED SYSTEMS

Always check the obvious first i.e. :

System correctly wired

Correct KSM72 type fitted for the specific application

KSM72 suitably calibrated

All connections use suitably rated cables to comply with all appropriate regulations.

All terminal screw connections tight.

Battery(s) charged, in good condition, clean & tight connections and of the correct voltage

The Module MUST be fitted in a control panel with adequate protection from adverse Temperature, Moisture & Vibration

WARNING - Incorrect wiring might permanently damage the module i.e. 1/

2/

3/

4/

Loss of battery negative (term.6).

Connecting any Active low outputs directly to a positive supply.

Connecting any positive DC outputs (i.e. Starter, Fuel, Exc.+, etc.) directly to a negative supply.

Connecting any DC terminals to an AC supply.

Unit Dead - set will not start

Check for battery supply on term.4(B+) and term.6(B-) of the KSM72 using a DC voltmeter

False tripping of Overspeed shutdown

(a) Module requires calibration

(c) Engine speed overshoots on run-up.

(d) External relays &/or Contactor coils may require noise suppression components.

Low oil pressure shutdown

(b) Faulty oil pressure switch, incorrect type or trip setting

(c) Incorrect KSM72 type for use with oil pressure switch fitted

Cooling Fault (High engine temp.) shutdown

(b) Faulty temperature switch, incorrect type or trip setting

(c) Incorrect KSM72 type for use with temperature switch fitted

Charging Alternator fails to excite because

(a) incorrect type of KSM72 fitted

(b) rear mounted 82r resistor damaged, missing or too high a value (may require 47R on certain 12VDC Alternators).

WARNING : Voltages dangerous to human life

Voltages dangerous to human life may be present at some of the terminal connections of this unit.

Ensure all supplies are de-energised before attempting any connection / disconnection.

MOUNTING

The module must be fitted into a suitable control panel that provides adequate protection from

the extremes of : Temperature, Humidity & Vibration. If this control panel is set-mounted then

suitable Anti-Vibration mounts MUST be used

Page 6 of 6

SPECIFICATION

Supply

12/24V Single range supply, operating from 6V to 30VDC

Drop out : < 4 VDC Absolute maximum input : 40VDC

Burden : 70mA at 12VDC

Speed Sensing

(KSM72B & D versions only)

Main Alternator, sensing 50 Hz to 70 Hz at rated speed. 40V to 280Vac absolute maximum.

Functions Overspeed Trip Level

Hold-Off Timer

factory pre-set to 57Hz or 68Hz (unless specified otherwise)

25 sec fixed

Fault Inputs

Low Oil Pressure

Cooling Fault

Outputs

Normally Open, close to Batt.-Ve on fault (unless otherwise stated)

Normally Open, close to Batt.-Ve on fault (unless otherwise stated)

FUEL output

START output

Exc.+Ve output

ALARM output

Fuel Pulse output

Timed Pre-Heat output

General

16A resistive. De-rate to 14% (2.2A) to allow for 7x inrush

16A resistive. De-rate to 14% (2.2A) to allow for 7x inrush

< 1A maximum

16A resistive. De-rate to 14% (2.2A) to allow for 7x inrush

fixed 1 sec pulse to suit fuel solenoids with separate pull-in coil

150mA max. (active low) output to drive an external Slave Relay.

user adjustable 0 25 sec (set at mid-scale)

150mA max.(active high) output to drive an external Slave Relay

Ambient temperature -100C to +550C Operating,

-250C to +700C Storage

Construction

Through panel fitting, 72mm sq. DIN standard case. Reversed screen-printed LEXAN (or similar)

front panel. Printed Circuit Boards varnished as standard.

Dimensions

72

95

Notes :

1/ Not to Scale

2/ all dimensions in

3/ Panel cut-out

68 x 68 mm

mm

72

For a spare or replacement unit, please ensure that the Serial Number of the original unit is quoted.

Вам также может понравиться

- Arduino Upgraded Learning Kit ManualДокумент116 страницArduino Upgraded Learning Kit Manualjohn christian de leonОценок пока нет

- VR6B ManualДокумент53 страницыVR6B ManualJorge EspinozaОценок пока нет

- CIRCUIT DIAGRAM Skoda Octavia IV Workshop Manual 2020Документ3 017 страницCIRCUIT DIAGRAM Skoda Octavia IV Workshop Manual 2020Gábor KISPÉTER100% (1)

- TP 6437Документ34 страницыTP 6437Roberto Sanchez ZapataОценок пока нет

- V28 Rebuild GuidelinesДокумент26 страницV28 Rebuild Guidelinesacere18100% (1)

- Manual Qummins QSL9-G5Документ3 страницыManual Qummins QSL9-G5Carlos Alberto PerdomoОценок пока нет

- Inala Power Wizard 1.0 OlympainДокумент4 страницыInala Power Wizard 1.0 OlympainAntonio MartinОценок пока нет

- Perkins 2206c E13tag2 en ItДокумент20 страницPerkins 2206c E13tag2 en Itganesh_d2k6100% (1)

- DST4602 enДокумент255 страницDST4602 enMarcos BrandãoОценок пока нет

- 6125HF070 PDFДокумент4 страницы6125HF070 PDFKeivinMC50% (2)

- Specsheet 3516 1825 kVA PrimeДокумент6 страницSpecsheet 3516 1825 kVA PrimeYusman EkaОценок пока нет

- Generator MMD SDG25SДокумент63 страницыGenerator MMD SDG25SRobert GardnerОценок пока нет

- Caterpillar C15 FTH000001Документ3 страницыCaterpillar C15 FTH000001Hendra MechanicОценок пока нет

- Guard Evolution: Operation ManualДокумент38 страницGuard Evolution: Operation ManualJaffer HussainОценок пока нет

- CAN HandoutДокумент16 страницCAN HandoutJaffer HussainОценок пока нет

- Guard Evolution: Operation ManualДокумент38 страницGuard Evolution: Operation ManualJaffer HussainОценок пока нет

- Technical Data: @perkinsДокумент6 страницTechnical Data: @perkinsLakshan WeliwattaОценок пока нет

- My 1306 1300 EDi Genset - Data List - 2Документ1 страницаMy 1306 1300 EDi Genset - Data List - 2Khaled Kamel100% (1)

- VOLVO TAD 1341 GE 300 Kva PDFДокумент2 страницыVOLVO TAD 1341 GE 300 Kva PDFluislunar0% (2)

- Diagram LCG2Документ1 страницаDiagram LCG2Edgar De50% (2)

- General: Technical Data TAD721GEДокумент8 страницGeneral: Technical Data TAD721GEbaljeetjatОценок пока нет

- (Lehe0124-00) RTD Module - Emcp 4Документ4 страницы(Lehe0124-00) RTD Module - Emcp 4victor.ciprianiОценок пока нет

- Altronics CD1 IOM 08-1993 PDFДокумент16 страницAltronics CD1 IOM 08-1993 PDFSMcОценок пока нет

- S285 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.1 Rev 2 PDFДокумент1 страницаS285 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.1 Rev 2 PDFfaraidunОценок пока нет

- Specification Sheet (Template) CUMMINS QSL9 G5Документ3 страницыSpecification Sheet (Template) CUMMINS QSL9 G5Ricardo La CruzОценок пока нет

- TAD1343GEДокумент8 страницTAD1343GEGeorge BarsoumОценок пока нет

- K Series 750-1010 (K38)Документ4 страницыK Series 750-1010 (K38)sameer_ponnadaОценок пока нет

- Wiring Diagram Dse 7320 Amf PDF FreeДокумент1 страницаWiring Diagram Dse 7320 Amf PDF FreeSemih GençОценок пока нет

- M2000Документ7 страницM2000kylegazeОценок пока нет

- Perkins 2306c-E14tag1Документ2 страницыPerkins 2306c-E14tag1Patricia J Ángeles100% (2)

- 1506a E88tag3 - 250 KvaДокумент12 страниц1506a E88tag3 - 250 Kvajean sanchezОценок пока нет

- Performance: Rebuilds For Your KTA50 G3Документ4 страницыPerformance: Rebuilds For Your KTA50 G3Sopian PianОценок пока нет

- Vta 28 TorsДокумент1 страницаVta 28 Torstonielhage100% (1)

- DYNS 30000 CalibratorДокумент4 страницыDYNS 30000 Calibratorgolu201100% (2)

- Cat Electronic Technician 2019A v1.0 Product Status ReportДокумент32 страницыCat Electronic Technician 2019A v1.0 Product Status ReportMohamed Mohamed100% (1)

- Perkins Fault Finding GuideДокумент13 страницPerkins Fault Finding GuideMksreekanthMk100% (2)

- 6M33 Maintain ManualДокумент116 страниц6M33 Maintain Manualteknisijarummas1Оценок пока нет

- Parts Catalog - Option Detail: Option Group Graphic Film Card DateДокумент3 страницыParts Catalog - Option Detail: Option Group Graphic Film Card DateagvassОценок пока нет

- 3306 164-200KW PRДокумент4 страницы3306 164-200KW PRvanaselvan vpОценок пока нет

- SG17V08EДокумент2 страницыSG17V08EAndres HuertasОценок пока нет

- WOODWARD - Product Manual - EPG Electrically Powered Governor-Models 512-524 & 1712-1724 PDFДокумент37 страницWOODWARD - Product Manual - EPG Electrically Powered Governor-Models 512-524 & 1712-1724 PDFsebastian aleОценок пока нет

- Deep Sea Controller 4410 Drawing PDFДокумент3 страницыDeep Sea Controller 4410 Drawing PDFjorge andres yanez quezada100% (2)

- MTU 18V2000 DS1250: Diesel Generator SetДокумент4 страницыMTU 18V2000 DS1250: Diesel Generator SetSidali KilardjОценок пока нет

- TWD1643GE: Volvo Penta Genset EngineДокумент2 страницыTWD1643GE: Volvo Penta Genset Enginemohsen_cumminsОценок пока нет

- KP-C500P (KTA19-G3A) Generating Set Technical Data SheetДокумент5 страницKP-C500P (KTA19-G3A) Generating Set Technical Data SheetMario CastroОценок пока нет

- 1306C E87tag6 PDFДокумент2 страницы1306C E87tag6 PDFMarran Almarrani100% (1)

- KG6 04 PDFДокумент4 страницыKG6 04 PDFAhmed Sherif CupoОценок пока нет

- NT855 G6 PDFДокумент2 страницыNT855 G6 PDFnaveed100% (1)

- Iveco N45 Tm2aДокумент3 страницыIveco N45 Tm2aDave Wallace100% (2)

- S287 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.2 Rev 2Документ1 страницаS287 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.2 Rev 2Parinya0% (1)

- 3012Tag3A 3000 Series: Diesel Engine - ElectropakДокумент2 страницы3012Tag3A 3000 Series: Diesel Engine - ElectropakMounir Yousfi100% (1)

- ETR Junction Box-Switchgear Not Required (OP, WT)Документ17 страницETR Junction Box-Switchgear Not Required (OP, WT)Richard Chua0% (1)

- Perkins Generating Set Power SelectorДокумент2 страницыPerkins Generating Set Power SelectorHanson LiuОценок пока нет

- Kg16-04+Sfbg Speed Control BoxДокумент4 страницыKg16-04+Sfbg Speed Control Boxehsan haleemОценок пока нет

- Service Manual Pcc2100Документ2 страницыService Manual Pcc2100ibrahemОценок пока нет

- EGCP 2 Installation and Operation Manual en TechManДокумент234 страницыEGCP 2 Installation and Operation Manual en TechManRigoberto Lozano100% (2)

- General Information: Drilling Template (MM)Документ4 страницыGeneral Information: Drilling Template (MM)Bruno MarianoОценок пока нет

- Diesel Engine MitsubishiДокумент4 страницыDiesel Engine MitsubishiMarbun Benny100% (1)

- Wiring Diagram 2506Документ1 страницаWiring Diagram 2506alkharashyОценок пока нет

- KSM72 Key Start Module: PreheatДокумент6 страницKSM72 Key Start Module: Preheatdargom salamanОценок пока нет

- EPM72 Engine Protection ModuleДокумент8 страницEPM72 Engine Protection Moduleandy habibiОценок пока нет

- Capricorn RSM72 ASДокумент16 страницCapricorn RSM72 ASarturobatallasОценок пока нет

- BerniniДокумент13 страницBerniniPanagiotis KarafillisОценок пока нет

- Atm 72Документ8 страницAtm 72muhammad arifОценок пока нет

- Amf Controller Device PDFДокумент9 страницAmf Controller Device PDFSirish ShresthaОценок пока нет

- OEM/Dealer Manual: Lcs Itb LC-50Документ80 страницOEM/Dealer Manual: Lcs Itb LC-50Jaffer HussainОценок пока нет

- Parameter and Error List Zanotti GM-Uniblock Zanotti GS-SplitДокумент16 страницParameter and Error List Zanotti GM-Uniblock Zanotti GS-SplitJaffer HussainОценок пока нет

- GT - Eng Visa Touch Guard For Volvo PantaДокумент80 страницGT - Eng Visa Touch Guard For Volvo PantaJaffer Hussain100% (1)

- User's Manual: Multi-Functionable Digital Voltage ControllerДокумент1 страницаUser's Manual: Multi-Functionable Digital Voltage ControllerJaffer HussainОценок пока нет

- Attachment Perkins 1500 & 1600 Series DrwingДокумент6 страницAttachment Perkins 1500 & 1600 Series DrwingJaffer Hussain67% (3)

- CAN Network Trouble ShootingДокумент7 страницCAN Network Trouble ShootingJaffer Hussain100% (1)

- Emko 9FДокумент14 страницEmko 9FJaffer HussainОценок пока нет

- Global CE Help Calibration and Control Help Form: Choose An Item. Choose An Item. Choose An ItemДокумент1 страницаGlobal CE Help Calibration and Control Help Form: Choose An Item. Choose An Item. Choose An ItemJaffer HussainОценок пока нет

- Instruction Sheet: Installation Instructions For InpowerДокумент5 страницInstruction Sheet: Installation Instructions For InpowerJaffer Hussain100% (1)

- Nehs1032 7Документ16 страницNehs1032 7Jaffer HussainОценок пока нет

- Apresentacao PCC1301 DisplayДокумент32 страницыApresentacao PCC1301 DisplayJaffer HussainОценок пока нет

- Auto-Start Digital Controller CEM6 IngДокумент12 страницAuto-Start Digital Controller CEM6 IngJaffer Hussain50% (2)

- Wwi Ms User InstructionsДокумент38 страницWwi Ms User InstructionsJaffer HussainОценок пока нет

- For All DSE Modules UPS Master Guard 80 KVAДокумент3 страницыFor All DSE Modules UPS Master Guard 80 KVAJaffer HussainОценок пока нет

- Phase3 WWIMSUserInstructionsДокумент41 страницаPhase3 WWIMSUserInstructionsJaffer HussainОценок пока нет

- Dse7560 DiagramДокумент2 страницыDse7560 DiagramJaffer HussainОценок пока нет

- EE SymbolsДокумент6 страницEE SymbolsAnupam BanerjeeОценок пока нет

- Catalyst Characterization XPS and TPRДокумент45 страницCatalyst Characterization XPS and TPRDesai Deep IshvarbhaiОценок пока нет

- Ipstar Satellite Antenna: FeaturesДокумент1 страницаIpstar Satellite Antenna: FeaturesAriОценок пока нет

- Compensator BTechДокумент25 страницCompensator BTechAkash RoyОценок пока нет

- Genie 105739 Battery Charger Generation2 PDFДокумент12 страницGenie 105739 Battery Charger Generation2 PDFJose Gerardo Valencia CОценок пока нет

- Diagnostic Trouble: CodesДокумент17 страницDiagnostic Trouble: CodesAhmed NahrawyОценок пока нет

- Datasheet Mosfet Final RF PDFДокумент4 страницыDatasheet Mosfet Final RF PDFVenkatesh KarriОценок пока нет

- Mos FabricationДокумент35 страницMos FabricationNhật HoàngОценок пока нет

- Design and Implementation of Cosine Control Firing Scheme For Single Phase Fully Controlled Bridge RectifierДокумент7 страницDesign and Implementation of Cosine Control Firing Scheme For Single Phase Fully Controlled Bridge RectifierNishith DhinoraОценок пока нет

- 4.6. Schematic - Bus Riser-J1.10 - RДокумент13 страниц4.6. Schematic - Bus Riser-J1.10 - RMèo Mập Ú NuОценок пока нет

- Nema 34 Stepper Motor SpecsДокумент9 страницNema 34 Stepper Motor Specsm95.hidalgoОценок пока нет

- Harness Draft - Product Knowledge - 16th Dec 2016Документ42 страницыHarness Draft - Product Knowledge - 16th Dec 2016manohar rajuОценок пока нет

- Zelio Control RM17TU00Документ6 страницZelio Control RM17TU00Anas BasarahОценок пока нет

- Science 10 ReviewДокумент3 страницыScience 10 ReviewMarl Rina EsperanzaОценок пока нет

- Battery SOC Estimation PDFДокумент6 страницBattery SOC Estimation PDFAndres LeonОценок пока нет

- Idea ΔΙΑΚΟΠΤΕΣДокумент28 страницIdea ΔΙΑΚΟΠΤΕΣΙΩΑΝΝΗΣ ΔΟΜΙΝΙΚΟΣОценок пока нет

- Uee Unit-1 Electrical DrivesДокумент99 страницUee Unit-1 Electrical Drivessaharsha surviОценок пока нет

- 3.3-Phase IM Motor Using 1-Phase Supply6.Документ9 страниц3.3-Phase IM Motor Using 1-Phase Supply6.SriSruthi KolliparaОценок пока нет

- Manual Planta Electrica PGKT110Документ5 страницManual Planta Electrica PGKT110andresmvargas1984Оценок пока нет

- Installation Manual DPC-411 CabinetsДокумент16 страницInstallation Manual DPC-411 CabinetsalternativblueОценок пока нет

- ABB Monitoring System SAM 3.0 - Data Sheet 1HC0076312 E01 ABДокумент4 страницыABB Monitoring System SAM 3.0 - Data Sheet 1HC0076312 E01 ABlatifОценок пока нет

- NRL VFD Datasheet FormatДокумент3 страницыNRL VFD Datasheet Formatmdnadim42Оценок пока нет

- Technical Data - HVR International - Resistors For Compact CircuitryДокумент2 страницыTechnical Data - HVR International - Resistors For Compact CircuitryNuma LumaОценок пока нет

- Legrand Inter Detector Dual 048806Документ4 страницыLegrand Inter Detector Dual 048806FranciscoOlivaОценок пока нет

- Fig 1 - GE Optima CT660 CT ScannerДокумент4 страницыFig 1 - GE Optima CT660 CT Scannerarwa zeglamОценок пока нет

- TV and CRT Display Vertical Output IC With Bus Control SupportДокумент5 страницTV and CRT Display Vertical Output IC With Bus Control Supportelgollo_33Оценок пока нет

- Service Manual: Chassis No. GA-7SДокумент29 страницService Manual: Chassis No. GA-7SErry Kusuma WardanaОценок пока нет

- Simotras HD FaultДокумент600 страницSimotras HD FaultsantoshОценок пока нет

- This Answer Was Provided by CS Place, Click To Join The DiscordДокумент2 страницыThis Answer Was Provided by CS Place, Click To Join The DiscordMetin KorkutОценок пока нет