Академический Документы

Профессиональный Документы

Культура Документы

5S Audit Checklist - Workplace Evaluation

Загружено:

Nenad DeusicОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

5S Audit Checklist - Workplace Evaluation

Загружено:

Nenad DeusicАвторское право:

Доступные форматы

5S Audit Checklist - Workplace Evaluation

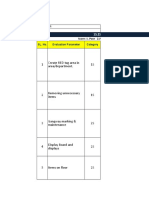

Date:

Time:

Rev 4, 2010

Work Area:

Auditor:

Score (circle one)

# of Problems w

Item

Unneeded equipment, supplies, inventory, tools, furniture, etc. are present anywhere

Items are present in aisle ways, stairways, corners, under equipment, etc.

Sort

( Organize )

Red tag area items are not properly tagged or dispositioned in a timely manner

Subtotal: Distinguish between what is needed and not needed

Correct places for items are not obvious

Items are not in there correct places (check aisle ways, stairways, corners, etc.)

Set In Order

( Orderliness ) Aisle ways, workstations, equipment locations are not indicated

Quality and QTY. Information are not obvious (Docs. & Samples)

Subtotal: A place for everything and everything in its place

Floors, walls, stairs, equipment, surfaces have dirt, oil and grease present

Cleaning materials are not easily accessible

Shine

Lines, labels, signs, etc. are dirty, torn, missing or not readable

( Cleanliness )

Other cleaning problems ( of any kind ) are present

Subtotal: Cleaning, keeping and it clean and organized

Documents & info. are available and controlled (SWS, audits, comm.boards, samples

Checklists not used cleaning and maintenance jobs (if no checklists score zero)

Standardize

Min/max levels or Kanban or visual inventory controls not present / used properly

( Adherence )

How many items, relevant to the work, can't be located in 5 / 30 seconds

Subtotal: Maintain and monitor the first three categories

How many workers have not had 5'S training or are not following 5S rules

Last scheduled 5S audit was not done for this area

Sustain

How many works have personal belongings not neatly stored.

( SelfAudits

are not being preformed effectively (not taken seriously or dealt with)

discipline )

Supervisor is part of the sustaining process (participating in change for the better)

Subtotal: Discipline to maintain and improve

Category

4+

/15

/20

/20

/20

5

/25

Subtotal

Safety item found

Reported to

Date Resolved

/100

Resolution

Safety

(any Safety related

items found during

audit). Subtract 3 points

for each item found)

`-

For each safety issue , subtract 3 points from subtotal

Grand Total

/100

Passing Score is 80

Notes:

file:///var/www/apps/conversion/tmp/scratch_3/342992754.xlsx01/19/2017

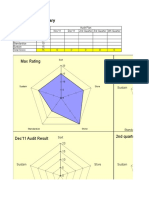

5S Advanced Audit - Workplace Evaluation

Date:

Time:

Rev 1

Work Area:

Auditor:

# of Problems w

Item

Are unneeded items of any sort are present or needed items are not available?

Red tag area items are properly tagged or dispositioned in a timely manner

Correct places for items are obvious, or items are in homes.

Paths, item homes/locations are indicated and labels, signs are not missing/worn

Floors, walls, stairs, equipment, surfaces do not have: debris, dirt, oil and grease, etc.

Cleaning materials are easily accessible (brooms, dustpans, sprays, cloths, vac)

Do operators habitually sweep floors, and wipe equipment without being told?

Su

Im st

pr ain

ov /

e

St

an

da

rd

iz

So

Se rt

,

Sh t-i

n

in

e Or

d

er

,

Category

Subtotal: Essential items only, all in proper place and clean

Job status indicators are displayed: (quality, worksheets, audits, andons, scheduling info)

Are standard procedures clear, documented and actively used?

Checklists are used for cleaning and maintenance jobs (if no checklists score zero)

Min/max levels or Kanban or visual inventory controls are present & used properly

How many items, relevant to the work, can't be located in 5 / 30 seconds?

Workers are showing that they are aware of basics of 5S or job standards

PM schedules are posted and updated for equipment

Subtotal: Monitor and prove Sort, Set-in-Order, Shine & Quality

Audits are being preformed regularly (see 5S matrix) or are not taken seriously by workers

Action plans are posted & updated showing tasked responsibilities and accountability

Follow-up by management is performed effectively and tasks are being completed (PDCA)

Workers are not empowered to suggest and improve and/or recommend line stop

Is the 5S program discussed during key indicator/production meetings?

Improvement ideas are being generated and are visible (employee and employer)

Subtotal: Discipline to maintain and improve

Subtotal

Safety item found

Reported to

Date Resolved

Resolution

Safety

(any Safety related items

found during the 5S

audit).

Total lost point for safety issues

Previous

Score:

Grand Total:

Passing S

Notes:

file:///var/www/apps/conversion/tmp/scratch_3/342992754.xlsx01/19/2017

file:///var/www/apps/conversion/tmp/scratch_3/342992754.xlsx01/19/2017

t - Workplace Evaluation

Rev 1 2011

Score (circle one)

0

4+

0

/35

0

/35

/30

/100

- 3 points/issue

`-

%

Passing Score is 80%

file:///var/www/apps/conversion/tmp/scratch_3/342992754.xlsx01/19/2017

file:///var/www/apps/conversion/tmp/scratch_3/342992754.xlsx01/19/2017

5 S Checklist - Workplace Evaluation:

Washroom / Change Room

Date:

Time:

Auditor:

Category

Sort

( Organize )

Set In Order

( Orderliness )

Shine

( Cleanliness )

# of Problems w

Item

Unneeded items are on walls, floors, on lockers, etc.

Items are present in aisle ways, corners, etc.

Excess, unneeded items are in lockers (random inspection of 2 lockers)

Subtotal: Distinguish between what is needed and not needed

Correct places for items are not obvious

Items are not in there correct places

Storage areas or locations are not supplied or indicated

Subtotal: A place for everything and everything in its place

Floors, walls, stairs, and surfaces are not free of dirt

Lines, labels, signs, etc. are dirty, torn, missing or not readable

Other cleaning or hygiene problems (of any kind) are present

Subtotal: Cleaning, keeping and it clean and organized

Standardize

( Adherence )

All cleanliness expectations and aids are not known and visible

Hygiene education and information signs are not visible

Subtotal: Maintain and monitor the first three categories

How many times, last week, was 5'S audit not performed

How many times that personal belongings are not neatly stored

Sustain

( Self-discipline Audits are not being preformed effectively (not taken seriously or dealt with)

)

Management is part of the sustaining process

Subtotal: Stick to the rules

Safety item found

Reported

to/Owner

Date Resolved

Score (circle one)

0 1 2 3 4

4 3 2 1 0

4 3 2 1 0

4 3 2 1 0

/12

4 3 2 1 0

4 3 2 1 0

4 3 2 1 0

/12

4 3 2 1 0

4 3 2 1 0

4 3 2 1 0

/12

4 3 2 1 0

4 3 2 1 0

/8

4 3 2 1 0

4 3 2 1 0

4 3 2 1 0

4 3 2 1 0

/16

Resolution

Safety

(any Safety related

items found during

audit)

Subtract 3 points for

each item found)

Subtotal: Safety Items Found X 3 - Subtract from score

Total

/60

Passing Score is 80%+

Notes:

file:///var/www/apps/conversion/tmp/scratch_3/342992754.xlsx01/19/2017

file:///var/www/apps/conversion/tmp/scratch_3/342992754.xlsx01/19/2017

Вам также может понравиться

- Basic 5S Audit ChecklistДокумент1 страницаBasic 5S Audit Checklistbasha1900Оценок пока нет

- 1st S: Sort Through/sort OutДокумент8 страниц1st S: Sort Through/sort OutpaknejadОценок пока нет

- 5S Checklist OfficeДокумент1 страница5S Checklist Officetoxicity23Оценок пока нет

- 5s ChecklistДокумент8 страниц5s ChecklistMohini MaratheОценок пока нет

- MSE507 Lean Manufacturing: 5S and The Visual WorkplaceДокумент85 страницMSE507 Lean Manufacturing: 5S and The Visual WorkplaceSAYFUDDINSG100% (1)

- Audit ChecklistДокумент12 страницAudit Checklistjohnoo7Оценок пока нет

- 5S CFT Audit Checklist-FY 2014-15Документ2 страницы5S CFT Audit Checklist-FY 2014-15arunbiswal100% (1)

- CANDO Pillar Audit Check SheetДокумент2 страницыCANDO Pillar Audit Check SheetharpreetmuditОценок пока нет

- 5s AuditchecklistДокумент15 страниц5s AuditchecklistChristian PaulsenОценок пока нет

- Training JH PillarДокумент41 страницаTraining JH PillarSelvamОценок пока нет

- 7QC Tools - Training WorkshopДокумент10 страниц7QC Tools - Training Workshopb-consultant960Оценок пока нет

- OPL Knowladge SharingДокумент4 страницыOPL Knowladge SharingRakesh TigadiОценок пока нет

- QC 7tools in EnglishДокумент109 страницQC 7tools in EnglishPunitha PaulОценок пока нет

- 5S Audit Checklist-NewДокумент1 страница5S Audit Checklist-NewArun BiswalОценок пока нет

- 7 Equip Loss Def. by JIPMSДокумент5 страниц7 Equip Loss Def. by JIPMSRanjit BhandariОценок пока нет

- 5s Audit ChecklistДокумент22 страницы5s Audit ChecklistJeevaAJAnanthanОценок пока нет

- 5S Basic Training: Whatis5Sandwhydowewanttodoit?Документ15 страниц5S Basic Training: Whatis5Sandwhydowewanttodoit?Mahdi ZeynОценок пока нет

- 6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1Документ5 страниц6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1stylish eagleОценок пока нет

- BF Area - 5S Check ListДокумент30 страницBF Area - 5S Check ListVi KraОценок пока нет

- l06 MSC Nutra Glass 1Документ32 страницыl06 MSC Nutra Glass 1Prof C.S.PurushothamanОценок пока нет

- Chromatography Solution: 5S AuditДокумент3 страницыChromatography Solution: 5S Auditabhijit612Оценок пока нет

- 5s Training Slides 138Документ60 страниц5s Training Slides 138Farrukh AhmedОценок пока нет

- Question BankДокумент16 страницQuestion BankAman SinghОценок пока нет

- 5S Audit Checklist - Supply StorageДокумент16 страниц5S Audit Checklist - Supply StorageJavier GutierrezОценок пока нет

- Gemba Walk Webinar June 23 2011 FinalДокумент28 страницGemba Walk Webinar June 23 2011 FinalGustavo GtzОценок пока нет

- Compressor ComparisonДокумент1 страницаCompressor ComparisonAsep HermanОценок пока нет

- 5 SДокумент50 страниц5 Sshishunal100% (1)

- One Day Training On KAIZEN: Hilton HotelДокумент74 страницыOne Day Training On KAIZEN: Hilton HotelyinueОценок пока нет

- Basic Kaizen Procedures of LPS Activity XP)Документ4 страницыBasic Kaizen Procedures of LPS Activity XP)Tee Hor ChangОценок пока нет

- 7QC ToolsДокумент62 страницы7QC ToolsRaiham EffendyОценок пока нет

- 5S Over ViewДокумент108 страниц5S Over ViewChethan Nagaraju KumbarОценок пока нет

- 5 S - A PresentationДокумент38 страниц5 S - A Presentationpbalawin43900% (1)

- Poka Yoke ExamplesДокумент7 страницPoka Yoke ExamplesAkshay ZutshiОценок пока нет

- International Business Centre (Ibc) : One Day Training Programme OnДокумент35 страницInternational Business Centre (Ibc) : One Day Training Programme Onanpuselvi125Оценок пока нет

- Another Contribution From Dr. Shigeo Shingo: Poka YokeДокумент23 страницыAnother Contribution From Dr. Shigeo Shingo: Poka Yokekeerti_1984Оценок пока нет

- 5S Thoughts - AllДокумент12 страниц5S Thoughts - Allssk3712Оценок пока нет

- 16 Types of Loss in GembaДокумент5 страниц16 Types of Loss in GembashivendrakumarОценок пока нет

- Final Report TPM PartДокумент16 страницFinal Report TPM PartNikita AwasthiОценок пока нет

- Basic Concepts of 5S-KAIZEN-TQM ApproachДокумент33 страницыBasic Concepts of 5S-KAIZEN-TQM Approachsandeep singhОценок пока нет

- Anand Kumar ResumeДокумент3 страницыAnand Kumar ResumeArun ShishodiaОценок пока нет

- The 5S Number GameДокумент7 страницThe 5S Number GameSaurabh SaoОценок пока нет

- 4 Building A Production System - Step 7-12Документ56 страниц4 Building A Production System - Step 7-12Ngọc Hồ HoàngОценок пока нет

- WAAREE Energies PVT Ltd-LatestДокумент40 страницWAAREE Energies PVT Ltd-LatestJp Gupta100% (2)

- Why People Do Not Understand The P-F Curve: by Ricky Smith CMRPДокумент7 страницWhy People Do Not Understand The P-F Curve: by Ricky Smith CMRPJoydeep ChakrabortyОценок пока нет

- 6s Evaluation FormДокумент3 страницы6s Evaluation FormDhananjay PatilОценок пока нет

- Implementation & Monitoring: (Work Place Improvement)Документ112 страницImplementation & Monitoring: (Work Place Improvement)Sonika SinghОценок пока нет

- ECRS WorksheetДокумент1 страницаECRS WorksheetShanmugam BalasubramaniamОценок пока нет

- LWMC Final HR ManualДокумент172 страницыLWMC Final HR ManualUsama QayyumОценок пока нет

- The Lean Stack - Part 1Документ15 страницThe Lean Stack - Part 1iNFuT™ - Institute for Future TechnologyОценок пока нет

- Value Stream Mapping, 5S& Visual ManagementДокумент58 страницValue Stream Mapping, 5S& Visual ManagementShrishti GuptaОценок пока нет

- TQM 4th ChapterДокумент31 страницаTQM 4th ChapterWaleed Tahir ChОценок пока нет

- Work StudyДокумент20 страницWork Studyjesus784Оценок пока нет

- Multi SkillДокумент6 страницMulti SkillK.s. RameshОценок пока нет

- QC ToolsДокумент51 страницаQC ToolsMonu SharmaОценок пока нет

- ISE 420 (Quality Improvement Methods) : by Group 6Документ39 страницISE 420 (Quality Improvement Methods) : by Group 6Abdullaziz AbdullahОценок пока нет

- Quality Circle Forum of India: Problem Solving TechniquesДокумент121 страницаQuality Circle Forum of India: Problem Solving TechniquesSamОценок пока нет

- 5S Standard GuideДокумент48 страниц5S Standard GuideRonald Abadi TariganОценок пока нет

- 5S Audit ChecklistДокумент5 страниц5S Audit ChecklistZahid Hussain100% (3)

- 5S Audit Checklist - Workplace EvaluationДокумент5 страниц5S Audit Checklist - Workplace EvaluationDaniel2116Оценок пока нет

- 5S Audit ChecklistДокумент5 страниц5S Audit ChecklistEduardo LugoОценок пока нет

- Of Free-Flowing Powders: Reliable Motor Loader ConveyingДокумент4 страницыOf Free-Flowing Powders: Reliable Motor Loader ConveyingNenad DeusicОценок пока нет

- Of Colorants, Additives: Economical FeedingДокумент4 страницыOf Colorants, Additives: Economical FeedingNenad DeusicОценок пока нет

- Flender FlexibleCouplings FLE10 2 ENДокумент116 страницFlender FlexibleCouplings FLE10 2 ENNenad DeusicОценок пока нет

- Vacuum Pumps and Systems: Air KnifesДокумент3 страницыVacuum Pumps and Systems: Air KnifesNenad DeusicОценок пока нет

- Century Extrusion ShaftДокумент2 страницыCentury Extrusion ShaftNenad DeusicОценок пока нет

- SKF Training866966Документ34 страницыSKF Training866966Nenad DeusicОценок пока нет

- Panasonic AAA3000CE7Документ4 страницыPanasonic AAA3000CE7Nenad DeusicОценок пока нет

- CRE Workshop 20150411aДокумент4 страницыCRE Workshop 20150411aNenad DeusicОценок пока нет

- By: Chan Dy, TPM Team Leader Cambodia Brewery LimitedДокумент25 страницBy: Chan Dy, TPM Team Leader Cambodia Brewery LimitedNenad DeusicОценок пока нет

- G2 Rust Grades USA PDFДокумент2 страницыG2 Rust Grades USA PDFNenad DeusicОценок пока нет

- 20 Korrosionsschutz enДокумент4 страницы20 Korrosionsschutz enNenad DeusicОценок пока нет

- Corrosion Protection of Steel Following ISO 12944-5 - 2007 PDFДокумент5 страницCorrosion Protection of Steel Following ISO 12944-5 - 2007 PDFNenad DeusicОценок пока нет

- Top CMMS Software - Reviews of 2015's Best SystemsДокумент8 страницTop CMMS Software - Reviews of 2015's Best SystemsNenad DeusicОценок пока нет

- CMMS Software ListДокумент2 страницыCMMS Software ListNenad Deusic100% (1)

- LCE Hierarchy Guidelines 261Документ1 страницаLCE Hierarchy Guidelines 261Nenad Deusic100% (1)

- Stamtec Corporate CatalogДокумент8 страницStamtec Corporate CatalogNenad DeusicОценок пока нет

- Filing SystemsДокумент47 страницFiling SystemsThanThanscc0% (1)

- Ikea Kitchen Planning GuideДокумент12 страницIkea Kitchen Planning Guideissaki23Оценок пока нет

- OGM Lilac TowerДокумент28 страницOGM Lilac TowerDantes Manuel Jr.100% (2)

- Ikea AssignmentДокумент5 страницIkea AssignmentFaisal JalalОценок пока нет

- Professional Practices INTA306: Week 5 Assignment 2 Pro. Kerdasha Jesse Rotz 2/1/2018Документ14 страницProfessional Practices INTA306: Week 5 Assignment 2 Pro. Kerdasha Jesse Rotz 2/1/2018Jesse RotzОценок пока нет

- Christina Erickson Sample PortfolioДокумент5 страницChristina Erickson Sample PortfolioChristina Marie EricksonОценок пока нет

- A. Match The Words With The Pictures:-: Learnenglish Kids Print and DoДокумент1 страницаA. Match The Words With The Pictures:-: Learnenglish Kids Print and DoOky DaysОценок пока нет

- Historic Styles Furniture - 1916Документ222 страницыHistoric Styles Furniture - 1916Gisele Vieira Duarte100% (3)

- How Long Does It Take To Clean A Movie TheaterДокумент6 страницHow Long Does It Take To Clean A Movie TheateredwynaОценок пока нет

- GPAC Purple Roadshow Presentation 01.07.18Документ41 страницаGPAC Purple Roadshow Presentation 01.07.18Ala BasterОценок пока нет

- Calibre IndustriesДокумент18 страницCalibre IndustriesjamesОценок пока нет

- Invoice: Al Fateh Skills and Training CentreДокумент1 страницаInvoice: Al Fateh Skills and Training CentreHelmi HashimОценок пока нет

- Global Business Strategy of IKEAДокумент15 страницGlobal Business Strategy of IKEAlutfun nahar dona100% (1)

- Types of Racks For Pharmacy Store by Instor IndiaДокумент11 страницTypes of Racks For Pharmacy Store by Instor IndiaRoshni SharmaОценок пока нет

- Lotus Garden HotelДокумент62 страницыLotus Garden Hotelpaulriqs100% (3)

- Maxima E-Brochure V1Документ26 страницMaxima E-Brochure V1Aditya D TanwarОценок пока нет

- Project-Visits 1303 PDFДокумент14 страницProject-Visits 1303 PDFFacundo BenitezОценок пока нет

- Executive HousekeeperДокумент2 страницыExecutive HousekeeperMalay SarkerОценок пока нет

- Client QuestionnaireДокумент7 страницClient QuestionnaireAndreea CrihanОценок пока нет

- Dissertation Report - Siddharth MisraДокумент59 страницDissertation Report - Siddharth MisraSiddharth MisraОценок пока нет

- Bidding GuidelineДокумент5 страницBidding GuidelineBianca CezarОценок пока нет

- AArado - Simplex Method QuizДокумент3 страницыAArado - Simplex Method QuizAdelson AradoОценок пока нет

- RLB Hotels BrochureДокумент9 страницRLB Hotels BrochureVikas RaoОценок пока нет

- Flyer Brochure - KeewahДокумент1 страницаFlyer Brochure - KeewahDonna Elaine OrdoñezОценок пока нет

- Chapter 3 IllustrationsДокумент6 страницChapter 3 IllustrationsShaila Marcelo100% (1)

- Office Chair Quotation Sheet 1Документ8 страницOffice Chair Quotation Sheet 1LarsenTwil100% (1)

- Bathroom + Kitchen Today 04.06 2019Документ84 страницыBathroom + Kitchen Today 04.06 2019Anonymous v2MqAXI100% (1)

- The Complete Idiot's Guide To - Karen, Reed - 5489Документ368 страницThe Complete Idiot's Guide To - Karen, Reed - 5489Catalin100% (2)

- Google's Plan For The Future of Work: Privacy Robots and Balloon WallsДокумент4 страницыGoogle's Plan For The Future of Work: Privacy Robots and Balloon WallsoktaОценок пока нет

- Kitchen Bath Design News 01 02 2024Документ92 страницыKitchen Bath Design News 01 02 2024MySTicO_CОценок пока нет