Академический Документы

Профессиональный Документы

Культура Документы

1 PDF

Загружено:

gavallapalliОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1 PDF

Загружено:

gavallapalliАвторское право:

Доступные форматы

IS : 10124 ( Part

1) - 1988

( Reaffirmed 1998 )

Indian Standard

SPECIFICATIONFOR

FABRICATED PVC FITTINGS FOR POTABLE

WATER SUPPLIES

PART

1 GENERAL

REQUIREMENTS

( First Revision )

Second Reprint NOVEMBER

UDC

1997

621.643.413.062.3[678.743.22]:696.117

@ Copyright 1989

BUREAU

MANAK

Gr3

OF

BHAVAN,

INDIAN

STANDARDS

9 BAHADUR

SHAH

NEW DELHJ 110002

ZAFAR

MARG

Juiy 1989

IS : 10124( Part1) - 1988

Indian Standard

SPECIFICATION FOR

FABRICATED PVC FITTINGS FOR POTABLE

WATER SUPPLIES

PART

GENERAL

First Revision )

0.

FOREWORD

0.1 This Indian Standard (Part 1 ) ( First Revision) was adopted by the Bureau of Indian Standards on 20 June 1988, after the draft finalized

by the Sanitary Appliances and Water Fittings

Sectional Committee had been approved by the

Civil Engineering Division Council.

~0.2 The fabricated PVC fittings are to be used for

jointing to the PVC pipes covered by IS : 49851988*.

0.3 The requirements of fabricated PVC fittings

are covered in following thirteen parts of the

standard :

Part

1 General requirements

requirements

for

sockets

Part 2

Specific

Part 3

Specific requirements

ducers

for straight

Part 4

Specific requirements

for caps

Part 5

Specific requirements

Part 6

Specific requirements for flanged tail

pieces with metallic flanges

Part 7

Specific requirements

adaptors

Part 8

Specific requirements

Part 9

Specific requirements

re-

for equal tees

for

threaded

for 90 bends

for 60 bends

Part 10 Specific requirements

for 45 bends

Part 11 Specific requirements

for 30 bends

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

:REQUlREMENTS

Part 12 Specific requirements, for 22i0 bends

Part 13 Specific requirements

for I 1a0 bends

0.3.1 Part 1 of this series deals with the general

requirements

applicable to all fabricated PVC

fittings and specified requirements of different

types of fittings are covered in separate parts of

the standard.

This part was first published in

1982. The present revision has been taken up

to extend the size of fittings to 630 mm in line

with the sizes of pipes specified in JS : 49851988*.

0.4 In the formulation

of this standard,

due

weightage has been given to international co-ordination among the standards and practices prevailing in different countries in addition to relating it to the practices in the field in this country.

This has been met by deriving assistance from

Draft international

standard

IS0

727-1985

Fittings of

unplasticized

polyvinyl

chloride

( PVC-U ), chlorinated polyvinyl chloride (PVC-C )

or acrylonitrile/butadiene/styrene

( ABS ) with

plain sockets for pipes under pressure - Dimensions of Sockets- Metric series, issued by the

International

Organization

for Standardization

( IS0 ).

0.5 For the purpose of deciding whether a particular requirement of this standard is complied

with, the final value, observed or calculated,

expressing the result of a test or analysis, shall

be rounded off in accordance with IS : 2-19607.

The number of significant places retained in the

rounded off value should be the same as-that of

the specified value in this standard.

*Specification for unplasticized PVC pipes for pot&b

water supplies ( second revision ).

tRules for rounding off numerical values (revised).

Is : 10124 ( Part 1 ) - 1988

1. SCOPE

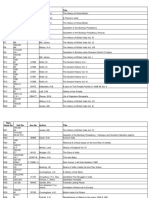

TABLE 1 SOCKET

1.1 This standard

( Part

I ) covers general

requirements

for materials,

sizes, methods of test

and inspection,

and marking of all types of fabricated PVC fittings for jointing with sbivent cement

to the PVC pipes covered in IS : 49851988*

for potable water supplies.

I.2 This specification

from 63 to 315 mm.

covers

the sizes of

All dimensions

NOMINAL Sizt

used for the fabrication

fittings for potable water supplies shall

to IS : 49851988*.

of PVC

conform

MINIMU~Z

SOCKET

LENGTH

(1)

(2)

16

20

25

32

14.0

16.0

19.0

22.0

26.0

31.0

37.5

43.5

51.0

61.0

68.5

76.0

86.0

96.0

106.0

118.5

131.0

146.0

163.5

183.5

206.0

231.0

256.0

286.0

321.0

40

50

3. SIZE OF FITTING

63

75

90

110

125

140

160

180

200

225

250

280

315

355

400

450

500

560

630

3.1 The sizes of fittings

shall be designated

by

diameters of the pipe given in IS :

4985 - 1988* with which they are to be used.

the nominal

4. SOCKET

LENGTH

AND

MID-POINT

OF SOCKET

4.1 The minimum

( see Fig. I ) shall

DIAMETER

LENGTH

socket

be as

length

given

length,

and

AT

of any fitting

by expression:

L=0.5D+6mm

where

L

= socket

D E nominal

inside

diameter

of fitting

(corresponding

to the outside diameter

of the pipe covered in IS : 4985-1988* ).

4.1.1 The socket length is applicable to socket

fittings for pipes of any diameter under pressure.

The minimum socket lengths based on the formula

in 4.1 for socket diameters are given in Table 1.

MEAN SOCKET INTERNAL

DIAMETERAT MID-POINT

OF SOCKET LENGTH

Min

MUX

(3)

16.1

20.1

25.1

32.1

40.1

50.1

63.1

75.1

90.1

110.1

125.1

140.2

160.2

180.2

200.3

225.3

250.4

280.4

315.4

355.4

400.4

450.4

500.4

560.4

630.4

(4)

16.3

20.3

25.3

32.3

40.3

50.3

63.3

75.3

90.3

110.4

125.4

140.5

160.5

180.5

200.6

225.7

250.8

280.9

316.0

356.0

401.0

451.0

501.0

561.0

631.0

4.1.3 Out-of-Roundness

Tolerances of Socket

Inside Diameter -- The maximum

out-of-roundness tolerances

(maximum

diameter-minimum

diameter ) shall be:

4.1.2 The maximum

and minimum

dimensions

of mean inside diameter at mid-point

of socket

depth shall comply with those given in Table 1.

NOTE 1 - The mean inside diameter of the socketed

portion of the fitting is defined as being the arithmetical

mean of two diameters measured at 90 to each other at

the mid-point of socket length using the same crosssection.

The diameter of the socket may be decreased

from mouth to root; for pipe sizes 63 to 75 mm, the total

included angle of taper shall not exceed 0 40. and for

pipe sizes 90 mm and above, the total included angle of

taper shall not exceed o30.

D, or

a) equal

to 0.007

b) equal

mm)

to 0.2 mm (if 0.007 D is less than

0.2

NOTE Out-of-roundness

tolerances of socket inside

diameter shall not apply to fittings of nominal pressure

rating 0.25 MPa (Class 1 ), 0.4 MPa (Class 2 ) and

0.6 MPa ( Class 3 ).

5. TESTS

AND PERFORMANCE

REQUIREMENTS

NOTE 2 - Only the manufacturer

of fabricated PVC

fittings is equipped to measure the socket inside diameter.

Since the socket length is a minimum only (no tolerance

is given to this dimension), it is not practical, other than

for the manufacturer, to establish the exact position of

the mid-point of the socket. He can therefore, tool up

to measure his own fittings but such equipment will not

necessarily give the correct figures for a fitting of other

manufacturer.

5.1 Opacity - When tested by the method described in Appendix A, the wall of the fitting shall

not transmit more than 0.2. percent of the visible

light falling on it.

5.2 Short

Term Hydraulic Test - When tested

by the method given in Appendix B, the fittings

shall withstand

*Specification for unplasticized

water supplies (second revision).

in millimetres.

fittings

2. MATERIAL

2.1 The pipes

DIMENSlONS

( C/UU.WS4.1.1 and 4.1.2, and Fig. I )

PVC pipes for potable

a pressure

of 4.2%

times the

working pressure for one hour without failure.

2

Bureau of Indian Standards

institution established under the Bureau of Indian Standards Act, 1986 to promote

harmonious development of the activities of standardizaticq

marking and quality certification of goods and

attending to connected matters in the country.

BIS

is a statutory

Copyright

No part of these publications may be reproduced in any form

BIS has the copyright of all its publications.

This does not preclude the free use, in the course of

without the prior permission in writing of BIS.

implementing the standard, of neeessary de~ils, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publication), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue

of BXS Handbook and Standards Monthly Additions.

This Indian Standard has been developed from Dot: No. CHD 20 ( 96o3 )

Amendments

Issued Since Publication

Date of Issue

Amend No.

BUREAU

Text Affected

OF INDIAN

STANDARDS

Headquarters:

Manak

Bhavan,

Telephones:

9 Bahadur

Shah Zafar Marg, New Delhi

110002

Telegrams:

3230131,3233375,3239402

Manaksans[ha

(Common to all offices)

Regional Offi&s:

Central

: Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern

: 1/14 C.I.T. Scheme VII M, V.I.P. Road, Maniktola

CALCUTTA 700054

Northern

Telephone

3237617,323

3~ 41

3378499,3378561

{ 3378626,33791

: SC(3 335-336, Sector 34-A, CHANDIGARH 160022

2(}

60 M 43

{ 602025

Southern

: C.I.T. Campus, IV Cross Road, CHENNAI 600113

2350216,

2350442

{ 2351519,2352315

Western

Branches

: Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBA3 400093

832 y~ 95,832

7S 58

{ 8327891,8327892

: AHMADABAD.

BANGALORE. BHOPAL. BHUBANESHWAR,

COIMBATORE.

FARIDABAD.

GHAZIABAD.

GUWAHATI.

HYDERABAD.

JAIPUR. KANPUR.

LUCKNOW.

NAGPUR.

PATNA.

PUNE. THIRUVANANTHAPURAM.

Printed hy Reprography Llni[. 111S,Ficw Delhi

Вам также может понравиться

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerОт EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerРейтинг: 5 из 5 звезд5/5 (1)

- Specification For Fabricated PVC Fittings For Potable Water SuppliesДокумент5 страницSpecification For Fabricated PVC Fittings For Potable Water SuppliesgavallapalliОценок пока нет

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- IS8008 8reducing TeeДокумент5 страницIS8008 8reducing TeeAshish TanejaОценок пока нет

- Specificatio-N FOR Fabricatedpvcfittingsfor PotablewatersuppliesДокумент3 страницыSpecificatio-N FOR Fabricatedpvcfittingsfor PotablewatersuppliesgavallapalliОценок пока нет

- Bureau of Indian Standards: For BIS Use OnlyДокумент6 страницBureau of Indian Standards: For BIS Use OnlyanmoljassalОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Specification For Fabricated PVC Fittings For Potable Water SuppliesДокумент5 страницSpecification For Fabricated PVC Fittings For Potable Water SuppliesgavallapalliОценок пока нет

- Is Code-447 - 1988Документ6 страницIs Code-447 - 1988Manas NayakОценок пока нет

- Specification For Fabricated PVC Fittings For Potable Water SuppliesДокумент5 страницSpecification For Fabricated PVC Fittings For Potable Water SuppliesgavallapalliОценок пока нет

- Specification For Fabricated PVC Fittings For ' Potable Water SuppliesДокумент5 страницSpecification For Fabricated PVC Fittings For ' Potable Water SuppliesgavallapalliОценок пока нет

- Is 10238Документ6 страницIs 10238kundank_32Оценок пока нет

- 1 SS PP 007Документ44 страницы1 SS PP 007SURAJ PRSADОценок пока нет

- Wis4 35 01Документ17 страницWis4 35 01swinousОценок пока нет

- Is 4984Документ16 страницIs 4984Joseph Mathew56% (9)

- I S 2328Документ5 страницI S 2328Hariprasad gantyalaОценок пока нет

- 10646Документ6 страниц10646Richa JainОценок пока нет

- Ced50 (7622)Документ19 страницCed50 (7622)anmoljassalОценок пока нет

- Piping Fabrication and InstallationДокумент30 страницPiping Fabrication and InstallationVijay Mohan100% (3)

- Polyethylene Pipes For Sewerage and Industrial Chemicals and Effluent - SpecificationДокумент28 страницPolyethylene Pipes For Sewerage and Industrial Chemicals and Effluent - SpecificationVakkanthula SaikarthikОценок пока нет

- 06-Division 2-Section 02205 uPVC Pipelines-Version 2.0Документ16 страниц06-Division 2-Section 02205 uPVC Pipelines-Version 2.0Avaan Ivaan100% (1)

- GHGGFHJДокумент13 страницGHGGFHJAllswell ElleОценок пока нет

- P 1-11 Storm Drainage PDFДокумент11 страницP 1-11 Storm Drainage PDFMahmoud GwailyОценок пока нет

- 2004 A Piping DesignДокумент76 страниц2004 A Piping DesignRudy SuryaОценок пока нет

- Joints in Canal LiningДокумент5 страницJoints in Canal Liningext_a1Оценок пока нет

- GRP Pipelien MaterialДокумент22 страницыGRP Pipelien MaterialSyed Ashfaq100% (1)

- Concreteliningofcanals - Compound - Specification: Indian StandardДокумент5 страницConcreteliningofcanals - Compound - Specification: Indian StandardkkodgeОценок пока нет

- Is 5624Документ9 страницIs 5624jselwyn1980Оценок пока нет

- 3208 - Coriolis Meter - Rev 1Документ7 страниц3208 - Coriolis Meter - Rev 1scribd_thakurОценок пока нет

- Is 3589 - 2001Документ21 страницаIs 3589 - 2001Aara MeghОценок пока нет

- Laying of DWC PipesДокумент56 страницLaying of DWC Pipessatyam50% (2)

- 00102W C G0 G000 PE SPC 0013 Rev 1 Standard Pipe SupportsДокумент119 страниц00102W C G0 G000 PE SPC 0013 Rev 1 Standard Pipe SupportsMurtadda MohammedОценок пока нет

- Is 9523Документ78 страницIs 9523Anonymous XBq5J840% (1)

- 4985 PDFДокумент26 страниц4985 PDFgavallapalliОценок пока нет

- Features of Asme b31.3Документ11 страницFeatures of Asme b31.3Ignacio OñateОценок пока нет

- IS 3589 - 2003-10 - With Amd 1 To 4Документ25 страницIS 3589 - 2003-10 - With Amd 1 To 4hhr2412Оценок пока нет

- 1 ErrrrffДокумент11 страниц1 ErrrrffAllswell ElleОценок пока нет

- D3034 16Документ12 страницD3034 16masoudОценок пока нет

- Instrumentation - Liquid Level: MAY 1994 Page 1 of 8Документ8 страницInstrumentation - Liquid Level: MAY 1994 Page 1 of 8Jhonny Rafael Blanco CauraОценок пока нет

- Specification For Fabricated PVC Fittings For Potable Water SuppliesДокумент5 страницSpecification For Fabricated PVC Fittings For Potable Water SuppliesRitesh kumarОценок пока нет

- Is 49851 ManualДокумент35 страницIs 49851 ManualpaddydhaliwalОценок пока нет

- ENA - 12 - 24 TS For Ducts - Buried Electric CablesДокумент17 страницENA - 12 - 24 TS For Ducts - Buried Electric CablessdvijayОценок пока нет

- Is 4885 Specification For Sewer Bricks R1.182104631Документ5 страницIs 4885 Specification For Sewer Bricks R1.182104631Arvind DhimanОценок пока нет

- 3468 - Pipe Nuts - SpecificationДокумент5 страниц3468 - Pipe Nuts - SpecificationVikash YadavОценок пока нет

- Methods of Test For Unplasticized PVC Pipes For Potable Water SuppliesДокумент20 страницMethods of Test For Unplasticized PVC Pipes For Potable Water SuppliesPerkresht PawarОценок пока нет

- Is 13592 2013Документ17 страницIs 13592 2013Saravanan KcОценок пока нет

- Iwozizcfyr Oaqøhv Ikbi (Fo'Ks"K LGK Dkax LFGR) Fof'Kf"V: HKKJRH EkudДокумент38 страницIwozizcfyr Oaqøhv Ikbi (Fo'Ks"K LGK Dkax LFGR) Fof'Kf"V: HKKJRH EkudPratik KharmateОценок пока нет

- I.S 5624-1993 Foundation BoltsДокумент8 страницI.S 5624-1993 Foundation Boltssandeepgupta202Оценок пока нет

- B729Документ3 страницыB729LambertWayneОценок пока нет

- Induction Bends - COPIДокумент12 страницInduction Bends - COPIAdvis100% (1)

- Sclairpipe MS r12072011Документ10 страницSclairpipe MS r12072011Daniel Cisterna BilbaoОценок пока нет

- 01 Samss 035 API LinepipeДокумент28 страниц01 Samss 035 API Linepipemdsazidalam100% (2)

- Disclosure To Promote The Right To InformationДокумент8 страницDisclosure To Promote The Right To InformationCst WclОценок пока нет

- 5504Документ10 страниц5504hhr2412Оценок пока нет

- D 2729 - 96 - Rdi3mjktukve PDFДокумент6 страницD 2729 - 96 - Rdi3mjktukve PDFAndre CasteloОценок пока нет

- A Pi 13706 SummaryДокумент4 страницыA Pi 13706 SummaryNakkolopОценок пока нет

- 6.2.2.section - 2 - Standard - Spe: Tender SpecificationДокумент8 страниц6.2.2.section - 2 - Standard - Spe: Tender SpecificationMangesh KoliОценок пока нет

- Water MetersДокумент3 страницыWater MetersRashedОценок пока нет

- Rare Books PDFДокумент49 страницRare Books PDFgavallapalliОценок пока нет

- Discusion Forum Nov 2006Документ2 страницыDiscusion Forum Nov 2006gavallapalliОценок пока нет

- Reaffirmed 1995Документ14 страницReaffirmed 1995gavallapalliОценок пока нет

- CountryReport IndiaДокумент39 страницCountryReport IndiagavallapalliОценок пока нет

- 4985 PDFДокумент26 страниц4985 PDFgavallapalliОценок пока нет

- Flltration Equipment: I'dian StandardДокумент10 страницFlltration Equipment: I'dian Standardnimm1962Оценок пока нет

- Specification FOR Fabricated PVC Fittings For Potable Water SuppliesДокумент7 страницSpecification FOR Fabricated PVC Fittings For Potable Water SuppliesgavallapalliОценок пока нет

- Specification For Fabricated PVC Fittings For ' Potable Water SuppliesДокумент5 страницSpecification For Fabricated PVC Fittings For ' Potable Water SuppliesgavallapalliОценок пока нет

- Specification For Fabricated PVC Fittings For Potable Water SuppliesДокумент5 страницSpecification For Fabricated PVC Fittings For Potable Water SuppliesgavallapalliОценок пока нет

- Laws of UX: Using Psychology to Design Better Products & ServicesОт EverandLaws of UX: Using Psychology to Design Better Products & ServicesРейтинг: 5 из 5 звезд5/5 (9)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneОт EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneРейтинг: 4.5 из 5 звезд4.5/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОт EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОценок пока нет

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionОт EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionРейтинг: 3 из 5 звезд3/5 (1)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessОт EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessОценок пока нет

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tОт EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tРейтинг: 4.5 из 5 звезд4.5/5 (27)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionОт EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionОценок пока нет

- Waste: One Woman’s Fight Against America’s Dirty SecretОт EverandWaste: One Woman’s Fight Against America’s Dirty SecretРейтинг: 5 из 5 звезд5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchОт EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchРейтинг: 4 из 5 звезд4/5 (10)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableОт EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableОценок пока нет

- 507 Mechanical Movements: Mechanisms and DevicesОт Everand507 Mechanical Movements: Mechanisms and DevicesРейтинг: 4 из 5 звезд4/5 (28)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsОт EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsРейтинг: 5 из 5 звезд5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontОт EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontРейтинг: 4.5 из 5 звезд4.5/5 (18)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesОт EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesОценок пока нет

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsОт EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsОценок пока нет