Академический Документы

Профессиональный Документы

Культура Документы

OPTALIGNsmart guideNV

Загружено:

marzfieldОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

OPTALIGNsmart guideNV

Загружено:

marzfieldАвторское право:

Доступные форматы

Alignment options

Know your OPTALIGN smart

Context menu

The main operating keys are the oval-shaped data entry keys, the

round functions keys, the 4-way navigation keys, an On/Off/Enter

The context menu can be accessed from any screen by pressing Q.

key, an up key, a clear key and a menu key.

The menu items displayed are relevant to the screen selected. Use

the navigation keys to highlight the required menu items.

The context menu item Configuration is used for configuring device

and regional settings, and licencing applications and features.

Copyright 2007 by PRFTECHNIK Alignment Systems

OPTALIGN smart pocket guide

OPTALIGN smart

Pocket guide

6

7

9

1

2

2

2

3

4

Alignment condition LEDs

USB port

Transducer socket

Charger socket

Function keys

Up/Clear/Menu keys

8

5

6

7

8

9

Navigation keys

On/Off/Enter key

Data entry keys

Bluetooth indicator LED

Battery status LED

Mount system and switch on

Switch on the instrument by pressing

and hold down for a

The scanning process detects

the neighbourhood for

Bluetooth devices

few seconds. The 4 alignment condition LEDs and the Bluetooth

Number 1 in laser precision alignment

indicator LED light up. Shortly afterwards, the splash screen appears,

followed by the machine dimensions screen.

If measurement is carried out using the optional Bluetooth RF

module, the measurement screen context menu item Sensor

Transducer (Laser)

Reflector (Prism)

selection is used to select the communication method.

Machine to be

moved

OPTALIGN smart computer

Printed in Germany ALI 9.122.07.XX.D

Stationary machine

Contact

PRFTECHNIK

Alignment Systems GmbH

Tel +49.89.99616-0

Oskar-Messter-Strasse 15

Fax +49.89.99616-100

85737 Ismaning

info@pruftechnik.com

Germany

www.pruftechnik.com

Voelzow & Company, Inc.

4804 Lawyers Rd E Wingate, NC 28174

704-233-9222 Fax 704-233-9211

E-mail: nvoelzow@perigee.net

Web: www.LaserAlignment.net

OPTALIGN smart pocket guide

1. Enter dimensions

3. Results

Move

Use the data entry keys to directly enter all missing

Press K to view alignment results.

Live MOVE can be performed in either the horizontal or vertical

direction. From the results screen press

dimensions. The editing box appears as soon as a data entry key is

pressed. Confirm entry by pressing either E or ?. The rectangular

Coupling results

highlight box moves to the next dimension.

Vertical gap

Q and then select Move

from the context menu. Press E , and then select the direction of

the MOVE (horizontal or vertical) by pressing F / G.

Vertical offset

Turn shaft to any 45 position and then center the laser beam and

start live MOVE by pressing E

Horizontal gap

Horizontal offset

Coupling results are given in the form of gap and offset. Gap is

positive when open at top or side away from viewer. Offset is positive

when moveable machine is higher or further away from viewer.

Dimensions to be entered include:

Foot results are accessed by pressing K / F / G

Transducer-to-reflector

1

2

Transducer-to-coupling center

Coupling diameter (default is 100 mm)

Transducer-to-front foot (right machine)

Front foot-to-back foot (right machine)

Press

M to proceed with measurement. Center the laser

Direction to move machine

Amount to move machine

Loosen base bolts and move machine following the alignment

values in real-time and the smiley on the display. Tighten anchor

2. Measure

1

2

RPM (default is 1500)

The dimensions screen can always be accessed by pressing M

Horizontal view

Transducer positioned at the

45 arc

1

2

Tolerance symbol

Foot position

bolts and check alignment by taking another set of measurements

1

Direction of corretion

Both vertical and horizontal results show the foot position relative

and viewing results. If within tolerance (indicated by a happy face

smiley), then machines are aligned.

Soft foot

to the stationary machine centerline. Positive values indicate that

right machine is upwards or away from viewer. Negative values

Soft foot can be checked at any time. Access the soft foot function

beam using the reflector thumbwheel and the yellow knob. The

indicate that right machine is downwards or towards the viewer.

by pressing Q. Use the navigation keys to select

default measure mode, continuous sweep, is automatically initiated

The alignment condition is indicated by the tolerance symbol.

3:00 or 9:00 oclock position and then center the laser beam. Press

With blue LED lit values within excellent tolerances

corresponding anchor bolt and wait until the readings stabilize and

With green LED lit values in acceptable tolerances

then press

With red LED lit values out of tolerance

Repeat the procedure for all feet.

by rotating the shafts when the laser beam is centered. Minimum

rotation of at least 60 is required.

Press E to finish measurement.

. Rotate shaft to

E and use H / I to select foot to check. Press E and loosen

E. Tighten bolt and press H / I to select next foot.

Вам также может понравиться

- OPTALIGN Smart Pocket GuideДокумент2 страницыOPTALIGN Smart Pocket GuideMahmoud MohamedОценок пока нет

- AllProductCatalog FDPC 2018Документ105 страницAllProductCatalog FDPC 2018William VillamizarОценок пока нет

- Introducing 810 Vibration Tester: Get Answers NowДокумент60 страницIntroducing 810 Vibration Tester: Get Answers NowluisghernandezjОценок пока нет

- Shaft Alignment ReportДокумент2 страницыShaft Alignment ReportSumner TingОценок пока нет

- GGGGGGGGGGGGGGG: FTF Is The Only One Standing OutДокумент4 страницыGGGGGGGGGGGGGGG: FTF Is The Only One Standing OutsebastianОценок пока нет

- UntitledДокумент161 страницаUntitledAishwaryaОценок пока нет

- Need for Awareness of Environmental Laws and Global WarmingДокумент15 страницNeed for Awareness of Environmental Laws and Global WarmingPooja HansrajaniОценок пока нет

- Detecting Rolling Elements Bearings Faults: February 2020Документ57 страницDetecting Rolling Elements Bearings Faults: February 2020Felipe Andres Figueroa VidelaОценок пока нет

- Two Channel Plot Setup: 8-16 Advanced Analyze FunctionsДокумент13 страницTwo Channel Plot Setup: 8-16 Advanced Analyze FunctionsrfhunterОценок пока нет

- 2130 Ru RefmanualДокумент360 страниц2130 Ru Refmanualz_bryantОценок пока нет

- Machine Condition Monitoring TechnologiesДокумент23 страницыMachine Condition Monitoring Technologiesashraful anikОценок пока нет

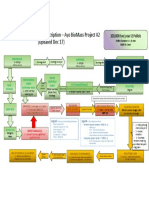

- Process Flow & Equipment Description - Ayo Biomass Project #2 (Updated Dec 17)Документ1 страницаProcess Flow & Equipment Description - Ayo Biomass Project #2 (Updated Dec 17)Nguyên Võ TriệuОценок пока нет

- VibrationДокумент6 страницVibrationAashu PandeyОценок пока нет

- Sample Laser Alignment ReportДокумент7 страницSample Laser Alignment ReportTis TabauОценок пока нет

- Forcing FrequencyДокумент87 страницForcing FrequencybodZkeeОценок пока нет

- ROTALIGN ULTRA Presentation DraftДокумент88 страницROTALIGN ULTRA Presentation DraftAnonymous wIPMQ5rh100% (1)

- FT Pitot Type LДокумент4 страницыFT Pitot Type LThai VoОценок пока нет

- Installation and Introduction PDFДокумент39 страницInstallation and Introduction PDFOscar Daga CaravantesОценок пока нет

- Soft Foot Diagnosis & The Soft Foot WizardДокумент25 страницSoft Foot Diagnosis & The Soft Foot WizardDiego Alejandro100% (1)

- Reactions of flexible bearings and vibrationsДокумент34 страницыReactions of flexible bearings and vibrationsAhmed El-Shafei100% (1)

- T016273e PDFДокумент6 страницT016273e PDFMaxi452Оценок пока нет

- Hammer Mill, Feeder DFZC-0655 / DFZC-400: Pitstop - MaintenanceДокумент4 страницыHammer Mill, Feeder DFZC-0655 / DFZC-400: Pitstop - Maintenanceghazi trikiОценок пока нет

- Bhausaheb Vartak Polytechnic: A Presentation ON Bearing Prepared by Akash Panchal S.Y.P.T - 1429Документ51 страницаBhausaheb Vartak Polytechnic: A Presentation ON Bearing Prepared by Akash Panchal S.Y.P.T - 1429PreethamBAsaravalliMohanОценок пока нет

- Structure Window PDFДокумент78 страницStructure Window PDFOscar Daga CaravantesОценок пока нет

- Troubleshooting Guide For Fan BearingsДокумент11 страницTroubleshooting Guide For Fan BearingsSanjeevi Kumar SpОценок пока нет

- IMD Hammermills GuideДокумент8 страницIMD Hammermills GuideInternational Milling DirectoryОценок пока нет

- Compressor unit performance data over timeДокумент10 страницCompressor unit performance data over timebodZkeeОценок пока нет

- TN 13 Omnitrend ShortcutsДокумент2 страницыTN 13 Omnitrend ShortcutsBrtonОценок пока нет

- SOP Pengujian MCSAДокумент3 страницыSOP Pengujian MCSAHabibie Rahman0% (1)

- OneProD MVP 2C + XPR 300 Specifications ComparisonДокумент4 страницыOneProD MVP 2C + XPR 300 Specifications ComparisonJuanVargasОценок пока нет

- Example Alignment Report PDFДокумент11 страницExample Alignment Report PDFdg_cd7340Оценок пока нет

- CSI 2130 CSI 2130: Machinery Health™AnalyzerДокумент42 страницыCSI 2130 CSI 2130: Machinery Health™Analyzersebastian100% (2)

- SPM Bearing Checker InstructionДокумент42 страницыSPM Bearing Checker Instructionmilos dzinoОценок пока нет

- SKF Bearing Fitting Tool TMFT 33Документ2 страницыSKF Bearing Fitting Tool TMFT 33Nang Dapi100% (1)

- ODS Operating Deflection Shape - PruftechnikДокумент3 страницыODS Operating Deflection Shape - PruftechnikGUSTAVO HOLGUIN RAMIREZОценок пока нет

- Alignment Report PDFДокумент4 страницыAlignment Report PDFmohamadhakim.19789Оценок пока нет

- Analysis ExamplesДокумент53 страницыAnalysis ExamplesAbdelrahman KassmОценок пока нет

- Laser Alignment Systems For Shafts, Turbines, and MachinesДокумент16 страницLaser Alignment Systems For Shafts, Turbines, and MachinesMarcosОценок пока нет

- Balanceo Dinamico de Rotores en VoladizoДокумент2 страницыBalanceo Dinamico de Rotores en VoladizoRepositorio Mantenimiento100% (1)

- Vibxpert Catalog EN 04122014 PDFДокумент78 страницVibxpert Catalog EN 04122014 PDFRizal RivaldiОценок пока нет

- BLC-2017 (Most Updated)Документ125 страницBLC-2017 (Most Updated)Emilius Wahyu NugrohoОценок пока нет

- Daily vibration and temperature report of main equipment at Hatta CementДокумент4 страницыDaily vibration and temperature report of main equipment at Hatta Cementzain140Оценок пока нет

- Documentatie Foamico R3 Uk - Mo 0122 - Mo 0122 D - Mo 0122 FD 22-11-2011Документ26 страницDocumentatie Foamico R3 Uk - Mo 0122 - Mo 0122 D - Mo 0122 FD 22-11-2011Dascalu ValentinОценок пока нет

- TN 7 VibxpertДокумент1 страницаTN 7 VibxpertBahtiar YudhistiraОценок пока нет

- EXPERIMENTAL INVESTIGATION OF BEARING FAULT DETECTION USING VIBRATION ANALYSISДокумент24 страницыEXPERIMENTAL INVESTIGATION OF BEARING FAULT DETECTION USING VIBRATION ANALYSISArkit KabirОценок пока нет

- SKF Crusher SolutionsДокумент32 страницыSKF Crusher SolutionsLLОценок пока нет

- CM3152 en SKF Idler Sound MonitorДокумент4 страницыCM3152 en SKF Idler Sound MonitorLuisSilvaОценок пока нет

- Principle of Acceleration SensorsДокумент7 страницPrinciple of Acceleration SensorsEr Vijay MamoriaОценок пока нет

- Pitfalls in The Analysis of Machinery Vibration MeasurementsДокумент7 страницPitfalls in The Analysis of Machinery Vibration MeasurementsTheerayoot PoomchaiОценок пока нет

- Milltronics MFA 4p en-USДокумент57 страницMilltronics MFA 4p en-USRavenShieldXОценок пока нет

- Ultraprobe 550 2000 ManualДокумент34 страницыUltraprobe 550 2000 ManualAnonymous V6y1QL6hn0% (1)

- Milling MachineДокумент21 страницаMilling MachineAron Olivera WabelОценок пока нет

- Vib Software OmnitrendДокумент2 страницыVib Software Omnitrendabel100% (1)

- Vibration Analysis For Machinery Health DiagnosisДокумент12 страницVibration Analysis For Machinery Health Diagnosiskoniks519Оценок пока нет

- 07 CouplingsДокумент22 страницы07 CouplingsSachith Praminda RupasingheОценок пока нет

- Nico International: Hazards Identification & Risk AssessmentДокумент4 страницыNico International: Hazards Identification & Risk AssessmentkazishahОценок пока нет

- ROTALIGN-Ultra - Pocket-Guide - ALI 209.844 - 07-08 - 2.06 - G PDFДокумент2 страницыROTALIGN-Ultra - Pocket-Guide - ALI 209.844 - 07-08 - 2.06 - G PDFDon FreemanОценок пока нет

- Terratrip 101 Manual English PDFДокумент5 страницTerratrip 101 Manual English PDFSunnyDreОценок пока нет

- RotorkДокумент4 страницыRotorkEmmanuel MJ Hos AchieverОценок пока нет

- Quick Guide LTL - XL-UKДокумент2 страницыQuick Guide LTL - XL-UKarrahmanzaОценок пока нет

- The Efficiency Improvement of Belt Conveyor Intermediate Drive Traction EffortДокумент5 страницThe Efficiency Improvement of Belt Conveyor Intermediate Drive Traction EffortmarzfieldОценок пока нет

- PK EN 60HzДокумент4 страницыPK EN 60HzmarzfieldОценок пока нет

- Ludecacom 3Документ4 страницыLudecacom 3marzfieldОценок пока нет

- Pengaruh Kualitas Udara Dalam Ruangan Ber-AC Terhadap Gangguan KesehatanДокумент11 страницPengaruh Kualitas Udara Dalam Ruangan Ber-AC Terhadap Gangguan KesehatanAgeng HidayatullahОценок пока нет

- C1e 009Документ24 страницыC1e 009marzfieldОценок пока нет

- Visual Basic 6 Error Handling: Our Program BombsДокумент9 страницVisual Basic 6 Error Handling: Our Program BombsMohammad FaisalОценок пока нет

- Physometric Chart SIДокумент1 страницаPhysometric Chart SIsuathayriОценок пока нет

- Visual Basic 6 Error Handling: Our Program BombsДокумент9 страницVisual Basic 6 Error Handling: Our Program BombsMohammad FaisalОценок пока нет

- Other Hardware: Packages For InstallДокумент2 страницыOther Hardware: Packages For InstallmarzfieldОценок пока нет

- Atlas Copco Tensor DLДокумент16 страницAtlas Copco Tensor DLDutertre théoОценок пока нет

- 64cc7d3e2b60ad241835f230 - Marshall 8 - EN - Web - 0804Документ2 страницы64cc7d3e2b60ad241835f230 - Marshall 8 - EN - Web - 0804ahmed gazzarОценок пока нет

- Caja de Piso Ref 25249-FBAДокумент4 страницыCaja de Piso Ref 25249-FBACristianDuarteSandovalОценок пока нет

- Classless Inter-Domain Routing (CIDR) (192.168.100.0/29)Документ2 страницыClassless Inter-Domain Routing (CIDR) (192.168.100.0/29)MCTCOLTDОценок пока нет

- CS 152 Numeric Types, Math Operators and Assignment StatementsДокумент12 страницCS 152 Numeric Types, Math Operators and Assignment StatementsCKОценок пока нет

- Digital Communication Using GNU Radio - Unit 3 - Week 0Документ3 страницыDigital Communication Using GNU Radio - Unit 3 - Week 0rensiОценок пока нет

- Greener Energy With Syntek SolarДокумент21 страницаGreener Energy With Syntek SolarirvanОценок пока нет

- BCP EjorДокумент25 страницBCP EjorSitraka Fitia Rosanna RaharizoОценок пока нет

- Technical Blogs on Compiling Qualcomm MSM8909 Chipset FirmwareДокумент4 страницыTechnical Blogs on Compiling Qualcomm MSM8909 Chipset FirmwareSaurabh GuptaОценок пока нет

- Guru Nanak Dev UniversityДокумент17 страницGuru Nanak Dev UniversityAnimesh salhotraОценок пока нет

- Looking at The Future of Manufacturing Metrology R PDFДокумент7 страницLooking at The Future of Manufacturing Metrology R PDFAdven BrilianОценок пока нет

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceДокумент8 страницStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceAmanОценок пока нет

- Orifice Catalogue EnglishДокумент11 страницOrifice Catalogue Englishrahman ariwibowoОценок пока нет

- Monique MariscalДокумент2 страницыMonique Mariscalapi-459378045Оценок пока нет

- IISc Postdoc Application FormДокумент3 страницыIISc Postdoc Application FormBineshОценок пока нет

- Predict Commute Times with Decision TreesДокумент38 страницPredict Commute Times with Decision TreesAbilashini jayakodyОценок пока нет

- 3rd Generation BWC Technical SheetДокумент4 страницы3rd Generation BWC Technical SheetOmar Santiago AvalosОценок пока нет

- Geii2 Internship Report ManglaДокумент22 страницыGeii2 Internship Report ManglaNeel ChayetunОценок пока нет

- MULTEMP PS No. 2 - TDSДокумент1 страницаMULTEMP PS No. 2 - TDSVishal AmleОценок пока нет

- MSV Edan M50 MS PDFДокумент48 страницMSV Edan M50 MS PDFDaniel Felipe Bello TorresОценок пока нет

- SPE 26515 Overbalance Perforating and Stimulation Method For WellsДокумент10 страницSPE 26515 Overbalance Perforating and Stimulation Method For WellsSebastián PavónОценок пока нет

- Background Verification ServicesДокумент14 страницBackground Verification Servicesmohitgarg08Оценок пока нет

- Sonu Kumar Final Updated FormДокумент12 страницSonu Kumar Final Updated FormVeeraj SinghОценок пока нет

- Safe Transportation System: A Project Submitted byДокумент29 страницSafe Transportation System: A Project Submitted byshahinОценок пока нет

- The Root DirectoryДокумент5 страницThe Root DirectoryInbaSaaharanОценок пока нет

- Deanonymisation of Clients in Bitcoin P2P NetworkДокумент15 страницDeanonymisation of Clients in Bitcoin P2P NetworkGary ShenОценок пока нет

- 3 Module 1Документ91 страница3 Module 1Divyesh yadavОценок пока нет

- ICON Tutorial 2019 Time Series ForecastingДокумент129 страницICON Tutorial 2019 Time Series Forecastingkiran gollaОценок пока нет

- Homework Assignment #3: EE122: Introduction To Communication Networks (Fall 2007)Документ4 страницыHomework Assignment #3: EE122: Introduction To Communication Networks (Fall 2007)Jack Chen Su-LeeОценок пока нет

- Ug01 Add Form-TqbДокумент1 страницаUg01 Add Form-TqbMuhd AmirulОценок пока нет