Академический Документы

Профессиональный Документы

Культура Документы

Tech Audit

Загружено:

RamaKrishna0 оценок0% нашли этот документ полезным (0 голосов)

14 просмотров1 страницаtech

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документtech

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

14 просмотров1 страницаTech Audit

Загружено:

RamaKrishnatech

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

1.

Technical audit of casting cranes

2. About crane:

2.1Make: HEC

2.2Capacity- DF-1 & 3 225T/63T+20T DF-2 200T/63T+20T

2.3Number of crane- 03

2.4Class: VI heavy duty

2.5Year of commission- Crane1- 1991, Crane2- 1990 and Crane3- 1992

2.6Monthly maintenance schedule: crane 1 &3 twice for 8 hours and crane 2

four times in a month for four hours.

2.7Average maintenance hours per year2.8Deflection test for Main grader : Every year

3. Scope:

3.1Inspection of all drives and prediction of healthiness of drives.

3.2Inspection of crane structures and prediction of healthiness of crane

structures

3.3 Inspection of operators cabin and its supporting structures, prediction of

healthiness of operators cabin and supporting structures.

3.4 Prediction of overall healthiness and assessment of crane life based on

technical audit.

3.5Generation and submission of technical audit report.

3.6

4. Major maintenance activity

4.1Crane-1:

I.

May 2000 MH capacity enhanced form 200 T to 225 T. MH trolley

(along with both MH gearboxes, both rope drums and both MCT

gear boxes) replaced.

II.

May 2000 all four LT gear boxes replaced to support enhanced

capacity.

III.

May 2000 MH grader strengthened to support enhanced capacity.

IV.

June 2002 DSL/PP side LT main balancer body along with aux

balancers and wheels replaced.

V.

August 2002 AH rope drum and output shaft assembly changed.

VI.

November 2007 during capital repair, MH both gear boxes internals,

MH both rope drums, MH ladle beam modified (foldable type)

replaced. LT, AH and MCT gear boxes internals revisioned/replaced.

VII.

4.2Crane-2:

I.

January 1994 AH 63 T rope drum and output shaft changed.

II.

July 2005 gear box oil SS 150 replaced with SS 220 on

recommendation of lubrication cell.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 3 Module 1Документ91 страница3 Module 1Divyesh yadavОценок пока нет

- Sausanil: ResumeДокумент1 страницаSausanil: ResumeMagician S C SinhaОценок пока нет

- How to update a crack using pattern search and hex editingДокумент17 страницHow to update a crack using pattern search and hex editingpeterОценок пока нет

- SEFI General Discussion30Документ4 страницыSEFI General Discussion30blisscutest beagleОценок пока нет

- Abm Principles of Marketing Module 6 9Документ10 страницAbm Principles of Marketing Module 6 9Trixie GallanoОценок пока нет

- Viagra vs Garlic Study Comparing EffectsДокумент5 страницViagra vs Garlic Study Comparing EffectsMuhammad AnwerОценок пока нет

- Name - Date - GroupДокумент2 страницыName - Date - GroupAlberto Recio GimenezОценок пока нет

- Mobile heat treatment equipment for preheating and annealing metal objectsДокумент2 страницыMobile heat treatment equipment for preheating and annealing metal objectsAnand SankarОценок пока нет

- Manual Apex Thermal SightsДокумент56 страницManual Apex Thermal SightsGuido Catello0% (1)

- 00 CCSA TestДокумент276 страниц00 CCSA TestPedro CubillaОценок пока нет

- IELTSFEVER ACADEMIC READING PRACTCIE TEST 49 PDF 1 PDFДокумент11 страницIELTSFEVER ACADEMIC READING PRACTCIE TEST 49 PDF 1 PDFŔãvî ŚødãnîОценок пока нет

- Academic Performance of Senior High School Students During Online Classes ImplementationДокумент3 страницыAcademic Performance of Senior High School Students During Online Classes ImplementationJulianne BeltranОценок пока нет

- Iso 20000-1Документ4 страницыIso 20000-1Dr-MohamedLashinОценок пока нет

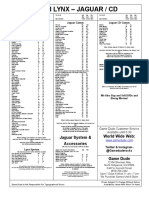

- Atari Lynx - Jaguar / CD: Jaguar System & Accessories World Wide WebДокумент1 страницаAtari Lynx - Jaguar / CD: Jaguar System & Accessories World Wide WebGame DudeОценок пока нет

- Oracle 1Z0-1065-20 Exam Questions & Answers DemoДокумент5 страницOracle 1Z0-1065-20 Exam Questions & Answers DemoSathyanarayananОценок пока нет

- HCL Call Letter PDFДокумент3 страницыHCL Call Letter PDFUtkarsh AnandОценок пока нет

- Код хромаДокумент2 страницыКод хромаМельник МаксимОценок пока нет

- Script For Video InterviewДокумент2 страницыScript For Video InterviewRojakBusukОценок пока нет

- Spare Parts CatalogueДокумент484 страницыSpare Parts CatalogueAlexDorОценок пока нет

- Kam CSM: PER API 8.3, ASTM D5854Документ2 страницыKam CSM: PER API 8.3, ASTM D5854SaputraОценок пока нет

- Blue Coat Authentication Webcast FinalДокумент53 страницыBlue Coat Authentication Webcast FinalriddОценок пока нет

- Homework Assignment #3: EE122: Introduction To Communication Networks (Fall 2007)Документ4 страницыHomework Assignment #3: EE122: Introduction To Communication Networks (Fall 2007)Jack Chen Su-LeeОценок пока нет

- Alineamiento y Perfil 1aupvДокумент3 страницыAlineamiento y Perfil 1aupvingeniero civilОценок пока нет

- Phqaa La-6831pДокумент58 страницPhqaa La-6831pEdovan soto lizcanoОценок пока нет

- Gas Turbine Trip System 2.2.5.3 Trip MatrixДокумент1 страницаGas Turbine Trip System 2.2.5.3 Trip MatrixMohammad Jahangir AlamОценок пока нет

- SWEG3091 Software Architecture DesignДокумент65 страницSWEG3091 Software Architecture Designsibhat mequanintОценок пока нет

- U1 PDFДокумент20 страницU1 PDFFarah AlhamadОценок пока нет

- Megawide Construction CorporationДокумент2 страницыMegawide Construction CorporationKersy Mere FajardoОценок пока нет

- Planning and Monitoring Pilot SystemДокумент10 страницPlanning and Monitoring Pilot SystemDo DothingsОценок пока нет

- Target CoDeSys Reference Manual enДокумент238 страницTarget CoDeSys Reference Manual enShivaperumal.K EEEОценок пока нет