Академический Документы

Профессиональный Документы

Культура Документы

Fusion Bonded Epoxy Coated Reinforcing Bars Specification: 1) Surface Preparation

Загружено:

Niraj PrasadОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fusion Bonded Epoxy Coated Reinforcing Bars Specification: 1) Surface Preparation

Загружено:

Niraj PrasadАвторское право:

Доступные форматы

FUSIONBONDEDEPOXYCOATED

REINFORCINGBARSSPECIFICATION

1) SURFACE PREPARATION:a) The surface of the steel reinforcing bars to be coated shall be cleaned by

abrassive blast cleaning to near white metal.

b) The coating shall be applied to the cleaned surface as soon as possible after

cleaning. Any formation of rust blooms on the cleaned bars are to be removed

by blast cleaning before application of the coating. However, in no case shall

the coating be delayed more than eight hours after cleaning unless otherwise

permitted by the purchaser.

2) APPLICATION OF COATING:The coating shall be applied as an electrostatically charged dry powder sprayed

onto the grounded steel bar using an electrostatic spray gun. The powder may be

applied to either a hot or cold bar. The coated bar shall be given a thermal treatment

specified by the manufacturer of the epoxy resin which will provide a fully cured

finish coating.

3) REQUIREMENTS OF COATED BARS:a) Coating Thickness :- For acceptance purposes at Jeast 90 percent of all coating

thickness measurements shall be 0.1 mm to O-3 mm after curing.

b) Continuity of Coating:-The coating and shall be free from holes, voids,

contamination, cracks and damaged areas discernible to the unaided eye. In

addition, there shall be not more than an average of two holidays per 300 cm when

tested.

NOTE - Holiday means a pinhole not discernible to the unaided eye.

4) TEST METHODS:The thickness of the coating shall be measured on the body of reinforcing bar

between deformations and ribs or both, on a straight length. Non-destructive coating

thickness measurements using magnetic gauges shall be used.

5) FREQUENCY OF TEST:a) Coating thickness shall be tested at a frequency of not less than one full length bar

every twenty bars for each size.

b)For testing adhesion of coating, samples shall be selected from each size

according to the frequency given below:

Nominal Size of Bar, mm No. of Samples

Up to 16 1 for every 1 tonnes

Above 16 and up to 25 1 for every 2 tonnes

Above 25 1 for every 4 tonnes

6) HANDLING AND IDENTIFICATION:All systems for handling coated bars shall have padded contact areas. All bundling bands

shall be padded or suitable banding shall be used to prevent damage to the coating. All

bundles of coated bars shall be lifted with a strong back, spreader bar, multiple supports,

or a platform bridge to prevent bar-to-bar abrasion from sags in the bundles of coated

bars. The bars or bundles shall not be dropped or dragged.

7) PERMISSIBLE COATING DAMAGE AND REPAIR AFTER COATING

APPLICATION:a) Coating damage due to fabrication and be traced to the cast from which they are made

handling need not be repaired in case where or the original identification mark of the bars.

the damaged area is 40 mm2 or smaller.

b) All damaged areas larger than 40 mm be suitably marked with the Standard Mark in

shall be repaired with patching material.

c) Maximum amount of damage shall not exceed 2 percent of the surface area of each bar.

Вам также может понравиться

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingОт EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingОценок пока нет

- Section 03210 Epoxy Coated Concrete ReinforcementДокумент7 страницSection 03210 Epoxy Coated Concrete ReinforcementgulzamanОценок пока нет

- Increasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionОт EverandIncreasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionОценок пока нет

- 80080-TCH-0000-SP-003 - SIGNED-Coating ProcedureДокумент7 страниц80080-TCH-0000-SP-003 - SIGNED-Coating ProcedurePaul NieОценок пока нет

- 1055 Attachment 9 - QP GRP Piping SpecifiДокумент8 страниц1055 Attachment 9 - QP GRP Piping SpecifikarunaОценок пока нет

- Ceramic Materials for Energy Applications VIОт EverandCeramic Materials for Energy Applications VIHua-Tay LinОценок пока нет

- Method Statement For Roofing & SidingДокумент7 страницMethod Statement For Roofing & SidingJoe_Average88% (8)

- Weld Overlay Procedure For InconelДокумент3 страницыWeld Overlay Procedure For InconelArash Mohamadi100% (2)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesОт EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášОценок пока нет

- BBM Specification (227 229)Документ3 страницыBBM Specification (227 229)mayur_lanjewar100% (4)

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesОт EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghОценок пока нет

- General SpecificationДокумент5 страницGeneral SpecificationDindo CabudbudОценок пока нет

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIIОт EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiОценок пока нет

- Fusion Bonded Epoxy Coated Reinforcing Bars - Specification: Indian StandardДокумент12 страницFusion Bonded Epoxy Coated Reinforcing Bars - Specification: Indian StandardsssmouОценок пока нет

- Technical Specification - FilterДокумент15 страницTechnical Specification - FilterMurli RamchandranОценок пока нет

- Internal Surface Treatment SpecificationДокумент3 страницыInternal Surface Treatment SpecificationaltipatlarОценок пока нет

- External Pipe CoatingsДокумент15 страницExternal Pipe Coatingsupesddn2010100% (3)

- Appendix-8 Painting SpecificationДокумент12 страницAppendix-8 Painting SpecificationVasanthakumarОценок пока нет

- 41537TECH MechДокумент24 страницы41537TECH MechSunilChotaliyaОценок пока нет

- Clamps Specification GeneralДокумент20 страницClamps Specification Generalpiyush_123456789Оценок пока нет

- Specification Cum Compliance Certificate of Earthing SystemДокумент2 страницыSpecification Cum Compliance Certificate of Earthing Systemsbpathi100% (1)

- ISO 2063-Thermal Spray Coating PDFДокумент5 страницISO 2063-Thermal Spray Coating PDFabhibmaneОценок пока нет

- C 36 - C 36M - 99 - Qzm2ltk5rteДокумент3 страницыC 36 - C 36M - 99 - Qzm2ltk5rte2010civ164Оценок пока нет

- 0702 Sound and Vibration ControlДокумент7 страниц0702 Sound and Vibration Controlntt_121987Оценок пока нет

- Shop Painting 411Документ4 страницыShop Painting 411quietdifferentОценок пока нет

- Visual Inspection of Weld Api 650Документ2 страницыVisual Inspection of Weld Api 650amshivОценок пока нет

- A 780Документ3 страницыA 780Gustavo SuarezОценок пока нет

- C 931 - C 931m - 04 Qzkzms9dotmxtqДокумент3 страницыC 931 - C 931m - 04 Qzkzms9dotmxtqHumberto GutierrezОценок пока нет

- Gypsum Wallboard (Hard Metric Sizes) : Standard Specification ForДокумент3 страницыGypsum Wallboard (Hard Metric Sizes) : Standard Specification Forkoushik15Оценок пока нет

- Durashield 110 61Документ6 страницDurashield 110 61huicholeОценок пока нет

- 04200Документ9 страниц04200uddinnadeemОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 09680-1 CarpetДокумент6 страницITCC in Riyadh Residential Complex J10-13300 09680-1 CarpetuddinnadeemОценок пока нет

- Storage Tank API 650Документ20 страницStorage Tank API 650jalison07xОценок пока нет

- Building CodesДокумент15 страницBuilding CodesPikuОценок пока нет

- Amsc N/A FSC 1325Документ5 страницAmsc N/A FSC 1325Mark AinsworthОценок пока нет

- Anticorrosion Reinforcement SpecsДокумент5 страницAnticorrosion Reinforcement SpecsNishan Lulu Muhamed JaleelОценок пока нет

- Specification For Pre Stressed Cement Concrete PolesДокумент10 страницSpecification For Pre Stressed Cement Concrete PolesNagabhushanam PayapalleОценок пока нет

- Standard Design Basis - Fire Proofing of Steel StructuresДокумент4 страницыStandard Design Basis - Fire Proofing of Steel Structuresnirmal sutharОценок пока нет

- RECo Abbreviated MSE Spec 7-20-2018Документ5 страницRECo Abbreviated MSE Spec 7-20-2018Faten Abou ShakraОценок пока нет

- BOQ (Society) PDFДокумент7 страницBOQ (Society) PDFAnkita Baban Gavade100% (1)

- Project: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle OrinaДокумент7 страницProject: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle Orinatyn de guzmanОценок пока нет

- Iacs 69 - NDTДокумент15 страницIacs 69 - NDTRicky WCKОценок пока нет

- Storage Tank (API 650)Документ20 страницStorage Tank (API 650)sbmmla83% (6)

- 2007 Section ViiiДокумент3 страницы2007 Section ViiiMiriam LopezОценок пока нет

- Masonry Works: HEO Architects Technical SpecificationДокумент6 страницMasonry Works: HEO Architects Technical SpecificationDk MariОценок пока нет

- Division Iii-Concrete & MasonryДокумент31 страницаDivision Iii-Concrete & MasonryClive Aaron GuanzonОценок пока нет

- WP 11 Corrosion Protection Tape CoatingДокумент3 страницыWP 11 Corrosion Protection Tape CoatingKarthikОценок пока нет

- WP 11 Corrosion Protection Tape Coating123Документ3 страницыWP 11 Corrosion Protection Tape Coating123KarthikОценок пока нет

- Scope of JobДокумент6 страницScope of JobSHIVAM JOHRIОценок пока нет

- ConstructionДокумент8 страницConstructionGaspar Lig-ang TolomiaОценок пока нет

- Techspec Smart Pylon Part 1Документ7 страницTechspec Smart Pylon Part 1shubham sehgalОценок пока нет

- Brick Masonry SpecificationДокумент14 страницBrick Masonry SpecificationHeak Hor100% (1)

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLДокумент13 страницDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikОценок пока нет

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsДокумент11 страниц4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- ITCC in Riyadh Residential Complex J10-13300 07150-1 DampproofingДокумент3 страницыITCC in Riyadh Residential Complex J10-13300 07150-1 DampproofinguddinnadeemОценок пока нет

- Cathodic Protection 2015Документ21 страницаCathodic Protection 2015ainunОценок пока нет

- Standard Test Method For Impact Resistance D2794Документ3 страницыStandard Test Method For Impact Resistance D2794vasu_suvaОценок пока нет

- RDSO - Metalization With AluminumДокумент2 страницыRDSO - Metalization With AluminumPraveen Varma VОценок пока нет

- SSC JeДокумент41 страницаSSC JeHimanshuKashyapОценок пока нет

- Short Title, Extent and Commencement - (1) These Rules May Be Called TheДокумент10 страницShort Title, Extent and Commencement - (1) These Rules May Be Called TheLaksh ManОценок пока нет

- Faq'S - Indigo Cadet Pilot Program - L3HarrisДокумент4 страницыFaq'S - Indigo Cadet Pilot Program - L3HarrisSОценок пока нет

- About - Egovernance of Civil AviationДокумент9 страницAbout - Egovernance of Civil AviationSiddharth ShuklaОценок пока нет

- Fare Details:: Indian Railways GST DetailsДокумент3 страницыFare Details:: Indian Railways GST DetailsNiraj PrasadОценок пока нет

- Medical Certificate of Fitness FormatДокумент1 страницаMedical Certificate of Fitness FormatSheshu BabuОценок пока нет

- Short Title, Extent and Commencement - (1) These Rules May Be Called TheДокумент10 страницShort Title, Extent and Commencement - (1) These Rules May Be Called TheLaksh ManОценок пока нет

- Boarding Pass: Pune To Patna Vishal/Divya MsДокумент3 страницыBoarding Pass: Pune To Patna Vishal/Divya MsNiraj PrasadОценок пока нет

- BE 2008 Result Nov-Dec 14Документ176 страницBE 2008 Result Nov-Dec 14Niraj PrasadОценок пока нет

- Rennovation of Toilet Blocks in R.O, Pune: Department of Posts, IndiaДокумент2 страницыRennovation of Toilet Blocks in R.O, Pune: Department of Posts, IndiaNiraj PrasadОценок пока нет

- APPLICATION FORM FOR Short Service Commission Executive (GS (Hydro) ) JUN 16 BATCHДокумент1 страницаAPPLICATION FORM FOR Short Service Commission Executive (GS (Hydro) ) JUN 16 BATCHNiraj PrasadОценок пока нет

- TGC 121 NotificatisonДокумент1 страницаTGC 121 NotificatisonNiraj PrasadОценок пока нет

- Notes On Sensitivity AnalysisДокумент12 страницNotes On Sensitivity AnalysisNikhil KhobragadeОценок пока нет

- Water Tank DesignДокумент37 страницWater Tank DesignWrishad Zia95% (98)

- StaircaseДокумент3 страницыStaircaseNiraj PrasadОценок пока нет

- Climate: Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Year Average High °C (°F)Документ1 страницаClimate: Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Year Average High °C (°F)Niraj PrasadОценок пока нет

- Retaining Wall DesignДокумент168 страницRetaining Wall DesignAlfonso PatuktokОценок пока нет

- 17216Документ7 страниц17216Niraj PrasadОценок пока нет

- Sem 2 PracticalДокумент60 страницSem 2 PracticalNiraj PrasadОценок пока нет

- Niraj (Registration-Id 51150048158)Документ4 страницыNiraj (Registration-Id 51150048158)Niraj PrasadОценок пока нет

- S 1Документ2 страницыS 1Niraj PrasadОценок пока нет

- 8.ISCA RJEngS 2013 065Документ8 страниц8.ISCA RJEngS 2013 065Niraj PrasadОценок пока нет

- 158-Calculation of Short Circuit CurrentsДокумент24 страницы158-Calculation of Short Circuit Currentsgeorgel1980100% (2)

- Wifisky Wireless AdapterДокумент9 страницWifisky Wireless AdapterVan HusenОценок пока нет

- Sect1 Network FunctionalityДокумент50 страницSect1 Network FunctionalityIulian StanОценок пока нет

- 3 Lifeline CPVC Hot and Cold Plumbing SystemДокумент4 страницы3 Lifeline CPVC Hot and Cold Plumbing SystemNikita KadamОценок пока нет

- Islplesson 1Документ2 страницыIslplesson 1api-279509605Оценок пока нет

- TLD01 GB PDFДокумент80 страницTLD01 GB PDFLademir FerreiraОценок пока нет

- Economic Thickness of InsulationДокумент16 страницEconomic Thickness of InsulationSomnath RangrejОценок пока нет

- RAN18.1 Capacity Monitoring Guide (BSC6910-Based) (02) (PDF) - EN PDFДокумент78 страницRAN18.1 Capacity Monitoring Guide (BSC6910-Based) (02) (PDF) - EN PDFUmar MirОценок пока нет

- RF 2022 (Jan) v6Документ3 страницыRF 2022 (Jan) v6mozha pradityaОценок пока нет

- NT 664Y6400 B E-Tech-S ENДокумент24 страницыNT 664Y6400 B E-Tech-S ENHugo CarvalhoОценок пока нет

- Anuj Project FileДокумент38 страницAnuj Project FileamaranandminzОценок пока нет

- Network Security Policy: PurposeДокумент17 страницNetwork Security Policy: Purposeamir_saheedОценок пока нет

- P4M800 Pro m7Документ31 страницаP4M800 Pro m7rarahimОценок пока нет

- Pueblo Revival Transitional Housing: Tucson ArizonaДокумент51 страницаPueblo Revival Transitional Housing: Tucson ArizonaJermaine FoxxОценок пока нет

- SAE J551-13 Suface Vehicle StandardДокумент10 страницSAE J551-13 Suface Vehicle StandardLê Đình ĐiềuОценок пока нет

- (BS EN 932-5 - 2000) - Tests For General Properties of Aggregates. Common Equipment and CalibrationДокумент18 страниц(BS EN 932-5 - 2000) - Tests For General Properties of Aggregates. Common Equipment and CalibrationAdelОценок пока нет

- QC General NotesДокумент21 страницаQC General NotesBilly Kurniawan100% (2)

- Mechanical Design Engineer-ZainДокумент5 страницMechanical Design Engineer-ZainSyedZainAliОценок пока нет

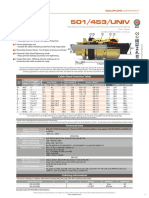

- 501/453/UNIV: Cable Gland Selection TableДокумент1 страница501/453/UNIV: Cable Gland Selection TableAkmalОценок пока нет

- PQP Vs ISO 9001 Clauses List PDFДокумент1 страницаPQP Vs ISO 9001 Clauses List PDFVpln Sarma100% (1)

- Elite IPK II Programming ManualДокумент617 страницElite IPK II Programming Manualvamez2012Оценок пока нет

- Usability Test Form (Customer) : Spelling, Grammar, MechanicsДокумент6 страницUsability Test Form (Customer) : Spelling, Grammar, MechanicsKok Yong ShunОценок пока нет

- R133-E02 Thermometer GlassДокумент24 страницыR133-E02 Thermometer GlasslailiОценок пока нет

- W20PGДокумент147 страницW20PGAnup MishraОценок пока нет

- Elm 327 DSHДокумент76 страницElm 327 DSHekysperОценок пока нет

- Strategic Management Control (Best Summary)Документ2 страницыStrategic Management Control (Best Summary)Laura Lo PrioreОценок пока нет

- Unit 5Документ3 страницыUnit 5rcpascОценок пока нет

- Bender IR485 486 DB UpdatedДокумент4 страницыBender IR485 486 DB UpdatedUrsula JohnsonОценок пока нет

- Title Block in Engineering Drawing and Data Field Arrangement in ISO ExamplesДокумент10 страницTitle Block in Engineering Drawing and Data Field Arrangement in ISO ExamplesGustavo GamezОценок пока нет

- Ports and Protocols - JabberДокумент3 страницыPorts and Protocols - JabberCinthya Rocasalvo PerezОценок пока нет

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionОт EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1От EverandBuilding Construction Technology: A Useful Guide - Part 1Рейтинг: 4 из 5 звезд4/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideОт Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideРейтинг: 3.5 из 5 звезд3.5/5 (7)

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (242)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseОт EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseРейтинг: 5 из 5 звезд5/5 (3)

- Field Guide for Construction Management: Management by Walking AroundОт EverandField Guide for Construction Management: Management by Walking AroundРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesОт EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesОценок пока нет

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEОт EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEРейтинг: 4 из 5 звезд4/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftОт EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftРейтинг: 5 из 5 звезд5/5 (5)

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishОт EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishРейтинг: 4 из 5 звезд4/5 (3)

- Shipping Container Homes: How to build a shipping container home, including plans, cool ideas, and more!От EverandShipping Container Homes: How to build a shipping container home, including plans, cool ideas, and more!Оценок пока нет

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyОт EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyРейтинг: 4 из 5 звезд4/5 (1)

- Civil Engineer's Handbook of Professional PracticeОт EverandCivil Engineer's Handbook of Professional PracticeРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingОт EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingРейтинг: 5 из 5 звезд5/5 (2)