Академический Документы

Профессиональный Документы

Культура Документы

Mech-V-Design of Machine Elements I (10me52) - Solution

Загружено:

Tolbert D'SouzaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mech-V-Design of Machine Elements I (10me52) - Solution

Загружено:

Tolbert D'SouzaАвторское право:

Доступные форматы

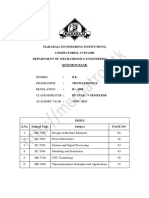

Design of Machine Elements-I

10ME52

V T U - QUESTION PAPERS SOLUTION

UNIT 1

INTRODUCTION

1. Identify the following engineering materials giving specifications:

i) FG350.

ii) FeE300.

iii) C35Mn75.

iv) X20Cr18Ni2.

(June/July 2014)

Solution:

i) FG350:- Grey Cast Iron with an ultimate tensile strength of 350 N/mm2.

ii) FeE300; - Steel with gold strength of 350 N/mm2.

iii) C35Mn75:- Steel with 0.35% carbon & 7.5% Manganese.

iv) X20Cr18Ni2:- Steel with 0.65% Manganese.

2. Point in a structural member is subjected to plane state of stress

Determine the following:

i) Normal and tangential stress intensities at a angle of = 45

ii) Principal stresses 1, and 2 and their directions.

iii) Maximum shear stress and its plane.

(June/July 2014)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 1

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 2

Design of Machine Elements-I

10ME52

3. Draw stress - strain diagram for mild steel subjected to tension. Explain the significance

of salient points.

(Dec/Jan 2015)

Solution: A typical tensile test curve for the mild steel has been shown below,

Salient Points of the Graph:

(A) It is evident from the graph that the strain is proportional to strain or elongation is

proportional to the load giving a straight line relationship, This law of proportionality is

valid upto a point A, or we can say that point A is some ultimate point when the linear

nature. of the graph ceases or there is a deviation from the linear nature, This point is

known as the limit of proportionality or the proportionality limit .

(B) For a short period beyond the point A, the material may still be elastic in the sense that the

deformations are completely recovered when the load is removed. The limiting point B is

termed as Elastic Limit.

(C) and (D) - Beyond the elastic limit plastic deformation occurs and strains are not

totally recoverable. There will be thus permanent deformation or permanent set when load is

removed, these two points are termed as upper and lower yield points respectively, the stress at

the yield Point is called the yield strength.

4. What are the basic requirements of machine elements? Explain briefly. (June/July 2015)

Solution:

The preliminary requirement of machine elements may be

1. Availability of the raw materials.

2. Suitable for the materials for the working condition at its application.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 3

Design of Machine Elements-I

10ME52

3. The cost of the material.

4. Physical properties of the materials such as elasticity, creep, fatigue etc.

5. Chemical composition retention property.

6. Easy manufacturing.

5. What are the factors to be considered for selection of material for a machine component?

(June/July 2015)

Solution:

Selection of material for a machine component can be considered based on strength,

stiffness, rigidity, ductility, toughness, resistance, fatigue resistance, ductile as brittle transition,

creep resistance, wear resistance, oxidation and corrosion resistance. Ductile to brittle transition,

creep resistance, friction characteristics, hardenability, castability, formability, weldability,

machinability and specific weight.

6. A hollow shaft of 40mm diameter and 25mm inner diameter is subjected to a twisting

moment of 118 N-m, a axial thrust of 9806 N and a bending moment of 79 N-m. Calculate

the maximum compressive and shear stresses.

(Dec/Jan 2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 4

Design of Machine Elements-I

10ME52

7. For the stress-element shown in Figure, find the principal stresses and directions.

(June/July 2016)

Solution:

8. Write a note on uniform strength

(Jun/July2016)

Solution:

In many applications such as connecting rods, mechanical presses and power hammers,

bolts are subjected to shock or impact loads. In such cases, bolts are designed to absorb

maximum impact energy and also to resist rupture.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 5

Design of Machine Elements-I

10ME52

UNIT 2

DESIGN FOR STATIC AND IMPACT STRENGTH

1. A round stepped shaft is made of brittle material cast iron FG 260 and subjected to a

bending moment of 15 N-m as shown in Figure. The stress concentration factor at the fillet

is 1.5. Determine the following:

i) Step diameter.

ii) Magnitude of stress at fillet.

iii) Factor of safety.

(June/July 2014)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 6

Design of Machine Elements-I

10ME52

2. Derive an expression for impact stress in a bar of cross section' A' and length 'L' due to

the impact of a load 'W' falling from a height 'h' on the bar, as shown in Fig.

(June/July 2014)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 7

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 8

Design of Machine Elements-I

10ME52

3. The brasses of an automobile engine connecting rod have worn, so as to allow play which

gives shock loading equivalent to a weight of 5886 N falling through a height of 0.2 mm. The

connecting rod is 250 mm long and has a cross sectional area of 3x10 -4 m 2. Determine the

stress induced in the connecting rod. Compare the maximum stress induced with that of a static

load of 5886 N.

(Dec/Jan 2015)

Solution:

4. A bolt is subjected to a direct tensile load of 30kN and a transverse shear force of 15

kN. Material of the bolt has a normal stress of 350 MPa at yield and Poisson's ratio of

0.25. Compute the root diameter of the bolt according to:

i) Maximum shear stress theory of failure and

ii) Von-mises criterion for failure.

Hence suggest suitable size of the bolt. Take a value of 3 for factor of safety. (Dec/Jan 2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 9

Design of Machine Elements-I

10ME52

5. In a plate of C45 steel (y = 353 MPa) subjected to a system of loads, following stresses are

induced at critical point: x =150 N/mm2, y = 100 N/mm2 a nd xy = 50 N /mm2. Find t he

factor of safety according to,

i. Maximum normal stress theory. ii. Maximum shear stress theory.

iii. Distortion energy theory.

(June/July 2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 10

Design of Machine Elements-I

10ME52

6. Determine the safe load that can be carried by a bar of rectangular cross section shown

in Fig. Limiting the maximum stress to 130 MPa taking stress concentration into account.

(Dec/Jan 2016)

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 11

Design of Machine Elements-I

10ME52

Solution:

Safe load P = 20.70 KN

7. An unknown weight falls through 20 mm as to a collar rigidly attached to the lower end of

a vertical bar 2 meter long and 500 sq mm section. If the maximum instantaneous extension

is 2 mm, what is the corresponding stress and the value of unknown weight? Take E = 200

GPa.

(June/July 2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 12

Design of Machine Elements-I

10ME52

8. A weight 600 N drops through a height of 20 mm and impacts the center of 300 mm long

simply supported circular cross section beam. Find the diameter of the beam arid the

maximum deflection, if the allowable stress is limited to 90 MPa. Neglect the inertia effect

and take E = 200 GPa.

(June/July 2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 13

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 14

Design of Machine Elements-I

10ME52

UNIT 3

DESIGN FOR FATIGUE STRENGTH

1. Derive Goodman's equation.

(June/July 2014)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 15

Design of Machine Elements-I

2. Explain cumulative fatigue damage.

10ME52

(Dec 2014)

Solution:

When more than one stress level exists in the working cycle, the load cycle should be

divided into number of intervals in each of which the mean and alternating stress can be

considered as constant. The equivalent completely reversed stress should be calculated for each

position. Let N1 be the number of stress cycles before fatigue failure, if only 1 is acting. One

stress cycle will take 1/N1 of the fatigue life and as there are n1 cycles at the stress level, the

proportional damage is n 1/N1 similarly the proportional damage for stress level 2 will be n2/N2

and so on.

3. A circular bar of 500 mm length is supported freely at its two ends. It is acted upon

by a central concentrated cyclic load having a minimum value of 20 kN and a maximum

value of 50 kN. Determine the diameter of bar by taking a factor of safety of 2, size effect

of 0.85, surface finish factor of 0.9. The material properties of bar are given by: ultimate

strength of 650 MPa, yield strength of 500 MPa and endurance strength of 350 MPa.

(June/July 2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 16

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 17

Design of Machine Elements-I

10ME52

4. A Cantilever beam made of 35C8 steel (ut = 540MPa) is subjected to a completely

reversed load of 1000 N as shown in Figure. The notch sensitivity factor 'q' at the fillet can be

taken as 0.85 and expected reliability is 90%. Determine the diameter of the beam for a life

cycle of 10000 cycles.

(Dec 2015)

Solution:

5. A cantilever beam made of cold drawn C30 steel (= 550 MPa and y = 470

MPa) subjected to load which varied from - F and 3F, as shown in Figure. Determine the

maximum load that these members can withstand for an indefinite life using a factor of

safety '2'. The stress concentration factor effect has to be considered with notch sensitivity of

0.9. Analyze at the fillet section only.

(June/July 2016)

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 18

Design of Machine Elements-I

10ME52

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 19

Design of Machine Elements-I

10ME52

6. A hot rolled steel rod is subjected to a torsional load that varies from 330 N-m, clockwise

to 110 N-m counter clockwise and an applied bending moment varies from + 440 N-m to

-220 N-m. the rod is of uniform cross section. Determine the required rod diameter. The

material has an ultimate tensile strength of 550 MPa and yield strength of 410MPa. Design

based as a factor of safety of 1.5. Take the endurance limit as 1

(June/July 2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 20

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 21

Design of Machine Elements-I

10ME52

UNIT 4

THREDED FASTENERS

1. Write a note on bolt of uniform strength

(Jun/July2014)

Solution:

In many applications such as connecting rods, mechanical presses and power hammers, bolts

are subjected to shock or impact loads. In such cases, bolts are designed to absorb maximum

impact energy and also to resist rupture.

When bolts of the usual form are used in such situations, the maximum part of the energy

is absorbed in the threaded portion. The energy absorbed per unit volume is directly proportional

to the square of the stress developed. If the shank of a bolt is reduced to the core diameter as

shown in Fig.4.S.I, the stress 'developed in the shank increases, which in turn increases the

energy absorption in the shank, thus relieving the material near the threads. Thus, reducing

the shank area corresponding to the thread root area results in a design of a bolt of uniform

strength.

The area of the shank can alternately be reduced by drilling a hole of diameter d, as shown in

Fig. The hole dimension d1 should be such that:

Area of the Root = Area of the Shank

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 22

Design of Machine Elements-I

10ME52

The method of drilling a hole in the shank is relatively more difficult and expensive to

manufacture, that to reduce the outer diameter to the shank.

2. A wall bracket is attached to a wall by means of 4 identical bolts, two at A and two at B,

as shown in Fig. Assuming that the bracket is held against the wall and prevented from

tipping about C, by all four bolts, and using an allowable stress in the bolt as 35 MPa,

determine the size of bolts on the basis of maximum principle stress theory, selecting ISO,

metric threads of not than 1.5 mm pitch.

(Jun/July2014)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 23

Design of Machine Elements-I

10ME52

3. An M20x2 steel bolt of 100mm long is subjected to impact load. The energy absorbed

by the bolt is 2 N-m,

i) Determine the stress in the shank of the bolt if there is no threaded portion between

the nut and bolt head.

ii) Determine the stress in the shank if the entire length of the bolt is threaded.

Assume modulus of elasticity for steel as 206 GPa.

(Dec 2014)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 24

Design of Machine Elements-I

10ME52

4. Determine the size of the bolts for the loaded brackets shown in Fig, if the allowable

Tensile stress in the bolt material is limited to 80 MPa.

(Jun/July2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 25

Design of Machine Elements-I

10ME52

5. A MIO steel bolt of 125 mm- long is subjected to an impact load. The kinetic

energy absorbed by the bolt is 2.5 Joules. Determine (i) Stress in the shank of the bolt if

there is no threaded portion between the nut and the bolt head, (ii) Stress in the shank of

the area of the shank is reduced to that of the root area of the threaded or the entire

length of the bolt is threaded.

(Dec2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 26

Design of Machine Elements-I

10ME52

6. A bolt is subjected to initial loading of 5 kN and final tensile load of 9 kN. Determine

the size of the bolt, if the allowable stress is 80 MPa and K = 0.05.

(Jun/July2016)

Solution:

7. A Flange bearing as shown in Figure is fastened to a frame by means of 4 bolts,

spaced equally on a 500mm bolt circle. The dia of the bearing flange in 650mm and a load

of 400 kN acts at a distance of 250mm from the frame. Determine the size of bolt, taking

allowable tensile stress in the bolt material as 60N/m2. Two dowel pins are provided to

take up the shear load.

(Jun/July2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 27

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 28

Design of Machine Elements-I

10ME52

UNIT 5

DESIGN OF SHAFTS

1. A transmission shaft running at 500 rev/min is supported on bearings 800 mm apart. 20

KW power is supplied to the shaft through a 450 mm dia pulley which is located 400mm

to the further transmits this power to a spur gear of 300 pitch circle diameter, which is

located at 400mm to the right of left bearing. The gear has 20 involute teeth and ratio of

belt tensions is 3:1. The gear drives another gear which is place directly above the shaft. The

gear drives another gear which is places directly above the shaft. The gear and pulley

are keyed to the shaft. Selecting the Material as steel having u,= 700 MPa and yt=

460MPa as per ASME code, determine of shaft. Assume shock factor for bending and torsion

as 1.5.

(June/July 2014)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 29

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 30

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 31

Design of Machine Elements-I

10ME52

2. The standard cross- section of a flat key, which is fitted on a 50 mm diameter shaft is 16 x

10 mm. The key is transmitting 475 N-m torque from the shaft to the hub. The key is

made of commercial steel for which yield strength in both tension and compression may

be taken as 230 N/mm2. Determine the minimum length of key required if the factor of safety

is 3.

Department of Mechanical Engineering, SJBIT, Bengaluru.

(Dec 2014)

Page 32

Design of Machine Elements-I

10ME52

Solution:

3. A hollow propeller shaft of 0.6 m outside diameter and 0.3 m inside diameter is used to drive

a propeller of a marine vessel. The shaft is mounted on bearings 5m apart and it transmits 6

MW power at 100rpm. The maximum axial propeller thrust is 600 kN and shaft weighs

60 kN. Determine i) Maximum shear stress developed in the shaft and ii) Angle of twist of

the shaft

(June/July 2015)

Solution:

Do = 600mm

Di= 300mm

L = 5m = 500mm

N = 6000kW, n = 100rpm, F = 600kN, W = 60kN, G = 84GPa = 84 x 103 N/rnrn2

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 33

Design of Machine Elements-I

10ME52

4. If a shaft and key are made of same material, determine the length of the key required in

terms of shaft diameter, taking key width and key thickness. Assume keyway factor as 0.75.

(Dec 2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 34

Design of Machine Elements-I

10ME52

5. A horizontal steel shaft, supported on bearings "A" at the left end and "B" at the right

end, carries two gears "C" & "D", located at distances 250 mm and 400 mm respectively,

'from the center lines of left and right end bearings'. The pitch diameter of gear C is

600mm and that of gear D is 200 mm. The pressure angle is 20. The distance between

the center lines of the bearings is 2400 mm. The shaft transmits 20 kW power at 120 rpm,

The power is delivered to the shaft at gear C and is taken out a gear D in such a manner that

the tooth pressure Ftc and F td are 100 MPa in tension and 56 MPa in shear. The gear C

and D weigh 950 Nand 350 N respectively. Take Cm = 1.5 and CT = 1.2.

(June/July 2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 35

Design of Machine Elements-I

10ME52

Considered vertical load diagram (VLD)

Taking moments about A

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 36

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 37

Design of Machine Elements-I

10ME52

6. Prove that a hollow shaft is stronger and stiffer than a solid shaft of same length, weight

and material.

(June/July 2016)

Solution:

A shaft is a rotating machine element which is used to transmit power from one place to

another. The power is delivered to the shaft by some tangential force and the resultant torque (or

twisting moment) set up within the shaft permits the power to be transferred to various

machines linked up to the shaft. In order to transfer the power from one shaft to another, the

various members such as pulleys, gears etc., are mounted on it.

(i) Strength

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 38

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 39

Design of Machine Elements-I

10ME52

UNIT 6

COTTER AND KNUCKLE JOINTS, KEYS AND COUPLINGS

1. The standard cross- section of a flat key, which is fitted on a 50 mm diameter shaft is 16 x

10 mm. The key is transmitting 475 N-m torque from the shaft to the hub. The key is made

of commercial steel for which yield strength in both tension and compression may be taken

as 230 N/mm. Determine the minimum length of key required if the factor of safety is 3.

(June/July 2014)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 40

Design of Machine Elements-I

10ME52

2. It is required to design a rigid type flange coupling to connect two shafts. The input

shaft transmits 37.5 KW at 180 rev/Min to the output shaft through the coupling. The

starting torque is 50% higher than the rated torque. Select material for flanges as cast iron

FG200 (ut=200MPa) with a factor of safety 6, material for shafts as carbon steel with

(yt=380MPa), with a factor of safety 2.5, material for key and bolts may be taken as steel

with (yt=400MPa in tension) and (yc=600MPa in compression) respectively and a factor of

safety 2.5. Design the coupling and given dimension.

(Dec 2014/Jan 2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 41

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 42

Design of Machine Elements-I

10ME52

3. If a shaft and key are made of same material, determine the length of the key required

in terms of shaft diameter, taking key width and key thickness. Assume keyway factor as 0.75.

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

(Jun/July2015)

Page 43

Design of Machine Elements-I

10ME52

4. Design a rigid flange coupling to transmit 18kW at 1440 rpm. The allowable shear stress

in the cast iron flange is 4 MPa. The shaft and keys are made of AISI 1040 annealed steel

with ultimate strength and yield stress valued as 518.8 MPa and 353.4 MPa, respectively.

Use ASME code to design the shaft and the key.

(Dec2015/Jan2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 44

Design of Machine Elements-I

10ME52

5.

Design a cast iron flanged couplings for a steel shaft transmitting 100 kW at 250 rpm.

Take the allowable shear stress for the shaft as 40 N/mm 2. The angle of twist is not to exceed

1 in a length of 20 diameters. Allowable shear stress for the bolts is 13 N/mm2. The

allowable shear stress in the flange is 14 N/mm2. For the key shear stress is 40 N/mm2 and

compressive stress is 80 N/mm2.

(June/July2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 45

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 46

Design of Machine Elements-I

10ME52

UNIT 7

RIVETED AND WELDED JOINTS

1. Design a double riveted lap joint with zig-zag riveting for 13 mm thick plates. The

working stresses to be used are a = 80 MPa; = 60 MPa; c= 120 MPa. State how the joint

will fail and find the efficiency of the joint.

(June/July 2014)

Solution: i) Type of Joint

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 47

Design of Machine Elements-I

10ME52

2. A bracket carrying a load of 15 kN is to be welded as shown in Figure. Find the size of

the weld required if the allowable shear stress is not to exceed 80 MPa.

(June/July 2014)

Solution:

i) c.g. of the world

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 48

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 49

Design of Machine Elements-I

10ME52

3. Design a double riveted but joint with two cover plates for the longitudinal seam of a

boiler shell 1.5 M in diameter subjected to a steam pressure of 0.9 MPa. Assume joint

efficiency as 75%. Allowable stress in tension for the plate 83 MPa in compression 138

MPa and stress in rivets may be assumed as 55 MPa. Assume chain riveted joint.

(Dec 2014/Jan 2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 50

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 51

Design of Machine Elements-I

10ME52

4. A circular shaft 50 mm in diameter is welded to a support by means of a fillet weld and

loaded as shown in Figure. Determine the size of weld of the permissible shear stress in

the weld is limited to 100 MPa.

(June/July 2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 52

Design of Machine Elements-I

10ME52

5. A bracket is supported by means of four rivets of dame size as shown in Figure. Determine

the diameter of the rivet if the maximum shear stress in the rivet is 90 N/mm2.

(Dec 2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 53

Design of Machine Elements-I

10ME52

6. Determine the maximum normal stress and the maximum shear stress in the weld shown

in Figure.

(June/July 2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 54

Design of Machine Elements-I

10ME52

7. Design a double riveted butt joint with two cover plates for the longitudinal beam of a

boiler shell 1.5 m in diameter subjected to a steam pressure of 0.95 N/mm 2. Assume an

efficiency of 75%, allowable tensile stress in the plate of 90 N/mm2, allowable crushing stress

of 140 N/mm2 and an allowable shear stress in the rivet of 50 N/mrn2.

(June/July 2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 55

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 56

Design of Machine Elements-I

10ME52

UNIT 8

POWER SCREW

1. Derive the equation for maximum efficiency of square threaded screw. (June2014/June2015)

Solution: Maximum efficiency of square thread screw

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 57

Design of Machine Elements-I

10ME52

Hence efficiency of self-locking is less than 50%. If the efficiency is more than 50%, then it is

said to be overhauling.

2. The cutter of a broaching machine is pulled by square threaded screw of 55 mm

external diameter and 10 mm pitch. The operating nut takes the axial load of 400 N on a flat

surface of 60 mm and 90 mm internal and external diameters respectively. If the coefficient of

friction is 0.15 for all contact surfaces, determine the power required to rotate the not when

the cutting speed is 6m/min. Also find the efficiency of the screw.

(Dec 2014)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 58

Design of Machine Elements-I

10ME52

3. The lead screw of a lathe has single start ISO metric trapezoidal treads of 52mm

nominal diameter and 8mm pitch. The screw is required to exert as axial force of 2kN in

order to drive the tool carriage during turning operation. The thrust is carried on a collar

of 100mm outer diameter and 60mm inner diameter. The values of Coefficient of

friction at the screw threads and collar are 0.15 and 0.12 respectively. The lead screw

rotates at 30 rev/min.

i) The power required to drive the screw

ii) The efficiency of the screw.

(June/July 2015)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 59

Design of Machine Elements-I

10ME52

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 60

Design of Machine Elements-I

10ME52

4. A weight. of 500 kN is raised at a speed of 6 m/min by a two screw rods with square

threads of 50 x 8 cut on them. The the screw rods are driven through level gear drives

by a motor. Determine (i) The torque required to raise the load (ii) The speed of rotation

of the screw rod assuming the threads are double start (iii) The maximum stresses

induced in screw rod. (iv) The efficiency of screw drive. (v) The length of nuts for the

purpose of supporting the load.

(Dec 2015/Jan 2016)

Solution:

T 18.8 for normal series when d = 50 mm, minor dia (d 1) = 42 mm, pitch (p) = 8 mm, core

area Ac=1385mm2

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 61

Design of Machine Elements-I

10ME52

5. A single start square-threaded power screw is used to raise a load of 120 kN. The screw

has a mean diameter of 24 mm and four threads per 24 mm length. The mean collar

diameter is 40 mm. The coefficient of friction is estimated as 0.1 for both the thread and

the collar. (i) Determine the major diameter of the screw. (ii) Estimate the screw torque

required to raise the load. (iii) Estimate overall efficiency. (iv) If collar friction is

eliminated, what minimum value of thread coefficient is needed.

(June/July 2016)

Solution:

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 62

Design of Machine Elements-I

10ME52

Total frictional torque to raise load = Mts + Mtc = 500.654 x 103 Nmm

iii. Overall efficiency (fes sq thread ) E 18.33

iv. Neglecting c value of to prevent the screw for overhauling condition for overhauling

for

SQ. threads tan .

6. Write a note on power screw strength.

(June/July2016)

Solution:

A power screw is a drive used in machinery to convert a rotary motion into. a linear motion

for power transmission. It produces uniform motion and the. design of the power screw may be such

that. Either the screw or the nut is held at rest and the other member rotates as it moves axially.

In many applications such as connecting rods, mechanical presses and power hammers, power

screws are subjected to shock or impact loads. In such cases, screws are designed to absorb

maximum impact energy and also to resist rupture.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 63

Вам также может понравиться

- Mech-V-Design of Machine Elements I (10me52) - AssignmentДокумент10 страницMech-V-Design of Machine Elements I (10me52) - AssignmentArunОценок пока нет

- Design of Machine Element ProblemsДокумент2 страницыDesign of Machine Element Problemsmaxpayne5550% (1)

- Final ExamMDFinal 2016 FinalAnswersДокумент10 страницFinal ExamMDFinal 2016 FinalAnswerskhalil alhatabОценок пока нет

- Final Exam STRESS ANA 2021Документ2 страницыFinal Exam STRESS ANA 2021khalil alhatabОценок пока нет

- Machine Design REE 302: CH 1: Introduction To Mechanical Engineering DesignДокумент26 страницMachine Design REE 302: CH 1: Introduction To Mechanical Engineering DesignDull PersonОценок пока нет

- Finite Element Analysis AE2351Документ5 страницFinite Element Analysis AE2351Aghil BuddyОценок пока нет

- Mech-V-Design of Machine Elements I (10me52) - Notes PDFДокумент242 страницыMech-V-Design of Machine Elements I (10me52) - Notes PDFHari Kiran M PОценок пока нет

- Lecture 1Документ41 страницаLecture 1norhaslina_aa33% (3)

- Subject Metal Cutting and Tool Design de PDFДокумент2 страницыSubject Metal Cutting and Tool Design de PDFBabuli KumarОценок пока нет

- Engineering Mechanics 2 Marks and 11 MarksДокумент89 страницEngineering Mechanics 2 Marks and 11 MarksHemachandran100% (1)

- Machine Design-II Question BankДокумент9 страницMachine Design-II Question BankProf. Avinash MahaleОценок пока нет

- Machine Design Assignment-1Документ2 страницыMachine Design Assignment-1RAJAT RAJОценок пока нет

- SE-Lecture 12 To 14 PDFДокумент21 страницаSE-Lecture 12 To 14 PDFAnonymous WMShhrОценок пока нет

- r05320305 Design of Machine Members IIДокумент9 страницr05320305 Design of Machine Members IISRINIVASA RAO GANTAОценок пока нет

- Som Part B CДокумент16 страницSom Part B CSrini VasanОценок пока нет

- Machine Design Unit 1 Design PhilosophyДокумент12 страницMachine Design Unit 1 Design PhilosophyAnand Babu100% (3)

- Ed9221-Finite Element Methods in Mechanical Design-R8Документ2 страницыEd9221-Finite Element Methods in Mechanical Design-R8Bakkiya RajОценок пока нет

- Univ Lab Set - 1 Me8711 Sa LabДокумент5 страницUniv Lab Set - 1 Me8711 Sa LabAsst.Prof MECH100% (1)

- Machine Drawing-Short Answer QuestionsДокумент3 страницыMachine Drawing-Short Answer QuestionsfatehjitsinghОценок пока нет

- Design For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringДокумент22 страницыDesign For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringjonОценок пока нет

- Design of Machine Elements - Ebook - 03112015 - 063217AM PDFДокумент205 страницDesign of Machine Elements - Ebook - 03112015 - 063217AM PDFArjun ChandraОценок пока нет

- ME6403-Engineering Materials and MetallurgyДокумент10 страницME6403-Engineering Materials and Metallurgykannan100% (1)

- DTS Unit 5Документ20 страницDTS Unit 5Muthuvel MОценок пока нет

- SheetДокумент2 страницыSheetKhaled Gamal EL-SaftawyОценок пока нет

- Design of IC Engine CylinderДокумент2 страницыDesign of IC Engine CylinderSushil Kumar Singh80% (5)

- Cad-Mcq-Question Bank PDFДокумент19 страницCad-Mcq-Question Bank PDFTushar PatelОценок пока нет

- Fem NotesДокумент11 страницFem NotesvenkiteshksОценок пока нет

- Final ExamSOMFinal 2016 FinalДокумент11 страницFinal ExamSOMFinal 2016 Finalkhalil alhatabОценок пока нет

- Design of Transmission System Question BankДокумент18 страницDesign of Transmission System Question BankAravind50% (2)

- Question Paper Code:: (10×2 20 Marks)Документ2 страницыQuestion Paper Code:: (10×2 20 Marks)jastraОценок пока нет

- Lec 5 (Welded Joint)Документ38 страницLec 5 (Welded Joint)Ahmed HassanОценок пока нет

- Advance Manufacturing Processes MCQ S 1 PDFДокумент18 страницAdvance Manufacturing Processes MCQ S 1 PDFmhd slmnОценок пока нет

- Ch-4 Design of RivetДокумент15 страницCh-4 Design of RivetTadesse AyalewОценок пока нет

- 4363 111 Machine Design IДокумент6 страниц4363 111 Machine Design Iyogesh_b_k100% (2)

- Lecture 2A Macro Mechanics Stress Strain Relations For Material TypesДокумент15 страницLecture 2A Macro Mechanics Stress Strain Relations For Material TypesHarish ShridharamurthyОценок пока нет

- P Seshu BookДокумент32 страницыP Seshu BookShridhar SrinivasanОценок пока нет

- Tutorial Sheet No 1 On Spur GearДокумент3 страницыTutorial Sheet No 1 On Spur GearChirayuОценок пока нет

- Spring DesignДокумент26 страницSpring DesignNeelkanth BenadeОценок пока нет

- Unit IV Theories of Failure: Introduction: Due To Large Numbers of Examples of Compound Stresses MetДокумент23 страницыUnit IV Theories of Failure: Introduction: Due To Large Numbers of Examples of Compound Stresses MetMohtasham NaeemОценок пока нет

- HES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDFДокумент18 страницHES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDFrisirarocksОценок пока нет

- Design II MDE 221 Mott CH 8 and CH 9 Spur GearsДокумент42 страницыDesign II MDE 221 Mott CH 8 and CH 9 Spur GearsThieroy PelendaОценок пока нет

- A1. Examples: Belt Drives Examples and WorksheetДокумент3 страницыA1. Examples: Belt Drives Examples and WorksheetAb_AlizadehОценок пока нет

- Design and Analysis of Crankshaft With Different CompositeДокумент9 страницDesign and Analysis of Crankshaft With Different CompositeSAI CHARANОценок пока нет

- Computer Aided Machine Drawing Lab KTU Lab QPДокумент3 страницыComputer Aided Machine Drawing Lab KTU Lab QPDrKim J SeelanОценок пока нет

- Mechatronics AssignmentДокумент20 страницMechatronics AssignmentPrashant KumarОценок пока нет

- Exam Paper RGPV MMPD First SemДокумент45 страницExam Paper RGPV MMPD First Semmayuresh_6767Оценок пока нет

- ME 2303 - Design of Machine Elements PDFДокумент14 страницME 2303 - Design of Machine Elements PDFThirumalaimuthukumaranMohan100% (1)

- Hw1 Sol Fall 2015Документ8 страницHw1 Sol Fall 2015Ong Kok Meng100% (1)

- Assignment No. 1 Materials Science and MetallurgyДокумент2 страницыAssignment No. 1 Materials Science and MetallurgySamruddhi MirganeОценок пока нет

- Lecture 4 Theory of Chips FormationДокумент53 страницыLecture 4 Theory of Chips Formationnickokinyunyu11Оценок пока нет

- Assignments Machine Tool DesignДокумент7 страницAssignments Machine Tool Designabdullah 3mar abou reashaОценок пока нет

- Iii MTSДокумент91 страницаIii MTSmagesh.mxОценок пока нет

- ME6503 DME Question PapersДокумент27 страницME6503 DME Question PapersSaravanan KumarОценок пока нет

- Ass Mtech QBДокумент12 страницAss Mtech QBravirainbowОценок пока нет

- Important Questions For Weak StudentsДокумент1 страницаImportant Questions For Weak StudentsDhanabal Palanisamy PОценок пока нет

- Assignment MD IIДокумент6 страницAssignment MD IIRupali PatilОценок пока нет

- Structure Analysis of Cast Iron For Dry Clutch of Amphibious VehicleДокумент4 страницыStructure Analysis of Cast Iron For Dry Clutch of Amphibious VehicleseventhsensegroupОценок пока нет

- Module Title: Mechanical Materials (3D) : MECH8012Документ4 страницыModule Title: Mechanical Materials (3D) : MECH8012Maurício SouzaОценок пока нет

- Dme Model Key 2019Документ25 страницDme Model Key 2019Siva RamanОценок пока нет

- Dynamic Damage and FragmentationОт EverandDynamic Damage and FragmentationDavid Edward LambertОценок пока нет

- Decathlon Prep Material JavaДокумент1 страницаDecathlon Prep Material JavaTolbert D'SouzaОценок пока нет

- Rapid Prototyping VTU Question PapersДокумент2 страницыRapid Prototyping VTU Question PapersTolbert D'Souza100% (1)

- 22-Book Reviews - Operations Management PDFДокумент9 страниц22-Book Reviews - Operations Management PDFTolbert D'SouzaОценок пока нет

- Operations ManagementДокумент290 страницOperations Managementrockon60594% (104)

- Geosynthetic Encased ColumnДокумент10 страницGeosynthetic Encased Columnakdce01Оценок пока нет

- Materials Science & Engineering A: Georg B. Rathmayr, Anton Hohenwarter, Reinhard PippanДокумент8 страницMaterials Science & Engineering A: Georg B. Rathmayr, Anton Hohenwarter, Reinhard PippanEidelsayedОценок пока нет

- Pressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon SteelДокумент3 страницыPressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon SteelSakarin WaiyakulОценок пока нет

- Design and Analysis of Magnetic Suspension SystemДокумент8 страницDesign and Analysis of Magnetic Suspension SystemPaul deshmukhОценок пока нет

- Fatigue MechanicsДокумент155 страницFatigue MechanicsWaqar Mahmood100% (2)

- Annex A: (Normative)Документ6 страницAnnex A: (Normative)calvente27Оценок пока нет

- Test Method For Metallic Fibre Concrete - Measuring The Flexural Tensile Strength (Limit of Proportionality (LOP), Residual)Документ20 страницTest Method For Metallic Fibre Concrete - Measuring The Flexural Tensile Strength (Limit of Proportionality (LOP), Residual)Oscar Nieto100% (1)

- Welding Product Range SummaryДокумент28 страницWelding Product Range SummaryFilipe CoelhoОценок пока нет

- Certification: Bill of MaterialДокумент7 страницCertification: Bill of MaterialNinaОценок пока нет

- Specification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsДокумент4 страницыSpecification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsJolettitoОценок пока нет

- Astm A 975Документ7 страницAstm A 975Carlos Américo100% (1)

- QQ-C-320 - Chrome PlatingДокумент18 страницQQ-C-320 - Chrome PlatingEtienne Houle100% (1)

- Properties of Spider SilkДокумент9 страницProperties of Spider SilkArifah PujiatiОценок пока нет

- EOS Ti64 9011-0039 M400-MDS FlexLine 02-17 en PDFДокумент4 страницыEOS Ti64 9011-0039 M400-MDS FlexLine 02-17 en PDFRaj RajeshОценок пока нет

- PCS-1004E HT Frequency of TestsДокумент6 страницPCS-1004E HT Frequency of TestsRobyn NashОценок пока нет

- Ansys Report PDFДокумент9 страницAnsys Report PDFHakimОценок пока нет

- Study of The Microstructure and Mechanical CharactДокумент14 страницStudy of The Microstructure and Mechanical CharactRenuОценок пока нет

- Calcium Carbonate Filled PolyethyleneДокумент7 страницCalcium Carbonate Filled PolyethyleneXuân Giang NguyễnОценок пока нет

- D2000-2018 Standard Classification System For Rubber Products in Automotive ApplicationsДокумент53 страницыD2000-2018 Standard Classification System For Rubber Products in Automotive ApplicationsLuisDupuy67% (3)

- Experiment of Reinforce Concrete Beams at Different Loading RatesДокумент8 страницExperiment of Reinforce Concrete Beams at Different Loading RateskapolaОценок пока нет

- Project: Project No: AuthorДокумент37 страницProject: Project No: Authorabdullah_23320666Оценок пока нет

- W5W6 Chapter 3 Properties Materials Part 1Документ26 страницW5W6 Chapter 3 Properties Materials Part 1Hakim ShahmiОценок пока нет

- D 2936 - 95 R01 Rdi5mzy - PDFДокумент3 страницыD 2936 - 95 R01 Rdi5mzy - PDFLupita CarelyОценок пока нет

- Impact Testing: of TextilesДокумент9 страницImpact Testing: of Textilesരജീഷ് വി എംОценок пока нет

- 1 s2.0 S0020740306001846 MainДокумент15 страниц1 s2.0 S0020740306001846 Mainisraaahmed12Оценок пока нет

- CMT Reviewer Part 2Документ26 страницCMT Reviewer Part 2erwinandal9Оценок пока нет

- KN KN KN: Design As Per Bs en 1999 1 1Документ1 страницаKN KN KN: Design As Per Bs en 1999 1 1Giri DharanОценок пока нет

- ElasticityДокумент37 страницElasticityTetsuya OkazakiОценок пока нет

- Aluminium AlloyДокумент14 страницAluminium AlloyDanu MamlukatОценок пока нет