Академический Документы

Профессиональный Документы

Культура Документы

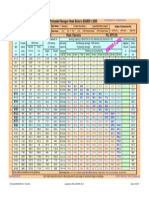

02 Bolt Screw Bs 3692 Gr. 8.8

Загружено:

Asif RazaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

02 Bolt Screw Bs 3692 Gr. 8.8

Загружено:

Asif RazaАвторское право:

Доступные форматы

Manufactured By:

HRC

mm

HARDNESS

PITCH

N-m

PROOF

LOAD

Mpa

PROOF

STRESS

TENSILE

STRESS

KN

HEAD

HEIGHT

PROOF

LOAD

Mpa

ELONGATION #

PROOF

STRESS

mm

HARDNESS

HEAD

HEIGHT

mm

NUT BS 3692 Gr. 8

TORQUE *

WIDTH

ACCROS

FLATS

mm

STRESS

AREA

mm mm mm

BOLT

SIZE

SHANK

DIAMETER

BOLT/SCREW BS 3692 Gr. 8.8

WIDTH

ACCROSS

FLATS

Marketed By:

mm

Mpa

KN

HRC

M6

20.1

5.82~6.00

9.78~10.00

3.85~4.15

580

11.7

800

9.4

22-32

12-

9.78~10.00

4.70~5.00

800

16.1

-30

M8

1.25

36.6

7.78~8.00

12.73~13.00

5.35~5.65

580

21.2

800

22.8

22-32

12-

12.73~13.00

6.14~6.50

800

29.3

-30

M10

1.5

58.0

9.78~10.00

16.73~17.00

6.82~7.18

580

33.7

800

45.8

22-32

12-

16.73~17.00

7.64~8.00

800

47.0

-30

M12

1.75

84.3

11.73~12.00

18.67~19.00

7.82~8.18

600

50.7

830

81.5

23-34

12-

18.67~19.00

9.64~10.00

800

67.4

-30

M14

2.0

115.0

13.73~14.00

21.67~22.00

8.82~9.18

600

69.0

830

129.7

23-34

12-

21.67~22.00

10.57~11.00

800

92.0

-30

M16

2.0

157.0

15.73~16.00

23.67~24.00

9.82~10.18

600

94.5

830

202.3

23-34

12-

23.67~24.00

12.57~13.00

800

125.6

-30

M18

2.5

192.0

17.73~18.00

26.67~27.00 11.785~12.215

600

115.2

830

278.4

23-34

12-

26.67~27.00 14.57~15.00

800

153.6

-30

M20

2.5

245.0

19.67~20.00

29.67~30.00 12.785~13.215

600

147.0

830

394.7

23-34

12-

29.67~30.00 15.57~16.00

800

196.0

-30

M22

2.5

303.0

21.67~22.00

31.61~32.00 13.785~14.215

600

181.8

830

536.9

23-34

12-

31.61~32.00 17.57~18.00

800

242.4

-30

M24

3.0

353.0

23.67~24.00

35.38~36.00 14.785~15.215

600

211.8

830

682.4

23-34

12-

35.38~36.00 18.48~19.00

800

282.4

-30

M27

3.0

459.0

26.67~27.00

40.38~41.00 16.785~17.215

600

275.4

830

998.3

23-34

12-

40.38~41.00 21.48~22.00

800

367.2

-30

M30

3.5

561.0

29.67~30.00

45.38~46.00

18.74~19.26

600

336.6

830

1,356

23-34

12-

45.38~46.00 23.48~24.00

800

448.8

-30

M33

3.5

694.0

32.61~33.00

49.38~50.00

20.74~21.26

600

416.4

830

1,845

23-34

12-

49.38~50.00 25.48~26.00

800

555.2

-30

M36

4.0

817.0

35.61~36.00

54.26~55.00

22.74~23.26

600

490.2

830

2,369

23-34

12-

54.26~55.00 28.48~29.00

800

653.6

-30

M39

4.0

976.0

38.61~39.00

59.26~60.00

24.74~25.26

600

585.6

830

3,066

23-34

12-

59.26~60.00 30.38~31.00

800

780.8

-30

M42

4.5

1,120.0

41.61~42.00

64.26~65.00

25.74~26.26

600

672.00

830

3,789

23-34

12-

64.26~65.00 33.38~34.00

800

896.0

-30

M45

4.5

1,310.0

44.61~45.00

69.26~70.00

27.74~28.26

600

786.00

830

4,748

23-34

12-

69.26~70.00 35.38~36.00

800

1,048.0

-30

M48

5.0

1,470.0

47.61~48.00

74.26~75.00

29.74~30.26

600

882.00

830

5,684

23-34

12-

74.26~75.00 37.38~38.00

800

1,176.0

-30

M52

5.0

1,760.0

51.54~52.00

79.26~80.00

32.69~33.21

600

1,056.00

830

7,372

23-34

12-

79.26~80.00 41.38~42.00

800

1,408.0

-30

M56

5.5

2,030.0

55.54~56.00

84.13~85.00

34.69~35.31

600

1,218.00

830

9,157

23-34

12-

84.13~85.00 44.38~45.00

800

1,624.0

-30

M60

5.5

2,360.0

59.54~60.00

89.13~90.00

37.69~38.31

600

1,416.00

830

11,406

23-34

12-

89.13~90.00 47.38~48.00

800

1,888.0

-30

M64

6.0

2,680.0

63.54~64.00

94.13~95.00

39.69~40.31

600

1,608.00

830

13,816

23-34

12-

94.13~95.00 50.26~51.00

800

2,144.0

-30

M68

6.0

3,060.0

67.54~68.00

99.13~100.00

42.69~43.31

600

1,836.00

830

16,761

23-34

12-

800

2,448.0

-30

M72

6.0

3,460.0

600

2,076.00

830

20,067

23-34

12-

800

2,768.0

-30

M76

6.0

3,890.0

600

2,334.00

830

23,814

23-34

12-

800

3,112.0

-30

M80

6.0

4,340.0

600

2,604.00

830

27,967

23-34

12-

800

3,472.0

-30

M85

6.0

4,950.0

600

2,970.00

830

33,891

23-34

12-

800

3,960.0

-30

M90

6.0

5,590.0

600

3,354.00

830

40,525

23-34

12-

800

4,472.0

-30

M95

6.0

6,270.0

600

3,762.00

830

47,980

23-34

12-

800

5,016.0

-30

M100

6.0

6,990.0

600

4,194.00

830

56,304

23-34

12-

800

5,592.0

-30

Dimensions

HEX as per BS 3692

HEX as per BS 3692

Markings

FPI M 8.8

FPI 8

Carbon

0.25-0.55/0.20-0.55

Manganese

Sulfur

-0.58

(<= M16) 0.25- / 0.3- (> M16)

-0.025

(<= M16) -0.15 / -0.056 (> M16)

Silicon

Chromium

Molybdenum

Nickle

Vanadium

Boron

-0.003

Copper

Nitrogen

Phosphorus

-0.025

-0.06 / -0.048

Material

Carbon steel/Alloy steel quenched & tempered

Medium Carbon Steel

Notes:

Left hand side of '-' is minium value

right hand side of '-' is maximam value

Eg. 0.5-0.7 min is 0.5 and max is 0.7

Eg. -0.8 max is 0.8 no minimam value

Eg. 2.0- min is 2.0 no maximam value

* Torque value based on 75% of proof load and nish as received steel

While every care has been taken in preparation of the information, the company accepts no liability for any loss or

damage either direct or consequential, Please refer Original standards for details.

Page: 02

Вам также может понравиться

- 01-Grade 8.8 Bolt & NutДокумент1 страница01-Grade 8.8 Bolt & NutbingminОценок пока нет

- 03-Grade 8.8 Bolt & NutДокумент1 страница03-Grade 8.8 Bolt & NutsualpesenliОценок пока нет

- Properties of Grade 8.8 Bolt & Nut (Iso)Документ1 страницаProperties of Grade 8.8 Bolt & Nut (Iso)Didik RahmadОценок пока нет

- Technical Data Sheet For Mgs and MGSRДокумент3 страницыTechnical Data Sheet For Mgs and MGSRFILID MADОценок пока нет

- Din 931Документ1 страницаDin 931Showkath Ali100% (2)

- HSA Stud AnchorДокумент11 страницHSA Stud AnchorWin ThanОценок пока нет

- 934 2Документ2 страницы934 2simpatico131Оценок пока нет

- BAPP-Preload-Assem-BS EN 14399HR-3-HRASS PDFДокумент4 страницыBAPP-Preload-Assem-BS EN 14399HR-3-HRASS PDFrjtcostaОценок пока нет

- Bapp Preload Assem Bsen14399hr 3 HrassДокумент4 страницыBapp Preload Assem Bsen14399hr 3 HrasspolpositionОценок пока нет

- Hilti Manual For BoltДокумент11 страницHilti Manual For Boltcsengineer20% (1)

- Astm A490m InnerДокумент7 страницAstm A490m InnermaekalgОценок пока нет

- 23-Grade 8.8 Bolt & Nut (Iso)Документ1 страница23-Grade 8.8 Bolt & Nut (Iso)anoordheen100% (2)

- Bolt Manufacturing DataДокумент1 страницаBolt Manufacturing Datasyazwan_ramli_1Оценок пока нет

- Tension RodДокумент4 страницыTension RodMarkОценок пока нет

- Thread SizesДокумент4 страницыThread SizesgokulahbОценок пока нет

- Astm A325m InnerДокумент7 страницAstm A325m InnerNgiuyen Viet TienОценок пока нет

- Dimensiones Y Pesos Nominales:: Diametro (D) Diametro Doblado MMДокумент1 страницаDimensiones Y Pesos Nominales:: Diametro (D) Diametro Doblado MMJes Jes SaavordОценок пока нет

- Support RollersДокумент4 страницыSupport Rollersprashant mishra0% (1)

- Table of Bolt SizesДокумент5 страницTable of Bolt Sizesnagaraj108Оценок пока нет

- Astm A325mДокумент8 страницAstm A325mChitra Devi100% (1)

- Metric Bolt Torque Table NM - CNCexpo PDFДокумент1 страницаMetric Bolt Torque Table NM - CNCexpo PDFninatenaОценок пока нет

- Metric Bolt Torque Table NM - CNCexpoДокумент1 страницаMetric Bolt Torque Table NM - CNCexponate anantathat100% (1)

- 22-Stainless Steel Aisi 316 (A4)Документ1 страница22-Stainless Steel Aisi 316 (A4)Paul OnionsОценок пока нет

- Beam DesignДокумент8 страницBeam DesignSelva kumarОценок пока нет

- Iso 7040Документ1 страницаIso 7040serzo75Оценок пока нет

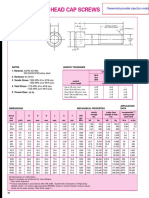

- Metric Socket Head Cap ScrewsДокумент2 страницыMetric Socket Head Cap ScrewsImam MulyonoОценок пока нет

- BoltsДокумент3 страницыBoltsbaburaogtrwОценок пока нет

- Multifix All Mechanical Anchor - Design GuideДокумент28 страницMultifix All Mechanical Anchor - Design GuideConstantino L. Ramirez III0% (1)

- Table of Bolt SizesДокумент8 страницTable of Bolt SizesAbdul Aziz Julkarnain ZulkifliОценок пока нет

- Stainless StudsДокумент4 страницыStainless StudsNestramiОценок пока нет

- Stud Bolt SpecificationДокумент8 страницStud Bolt SpecificationsantoshblonkarОценок пока нет

- 67697425-Bolt-Design 23Документ1 страница67697425-Bolt-Design 23pawkomОценок пока нет

- Welding Bosses - BS 3799: Threaded Fitting Socket Weld FittingДокумент1 страницаWelding Bosses - BS 3799: Threaded Fitting Socket Weld Fittingsj_scribdОценок пока нет

- Tightening Torque1Документ1 страницаTightening Torque1EngrMuhammadAzizОценок пока нет

- Group 2 Tightening Torque: 1. Major ComponentsДокумент3 страницыGroup 2 Tightening Torque: 1. Major ComponentsDenОценок пока нет

- BS en 14399-3 PDFДокумент7 страницBS en 14399-3 PDFClaudia Dutu100% (2)

- Axial Force and Unaxial BendingДокумент4 страницыAxial Force and Unaxial BendingYunitan TeguhОценок пока нет

- Catalog Series RTC Aventics en 6912350Документ150 страницCatalog Series RTC Aventics en 6912350Omar Jasid LaraОценок пока нет

- Metric ConductorsДокумент1 страницаMetric ConductorsABELWALIDОценок пока нет

- Counter Shank BoltДокумент4 страницыCounter Shank BoltEndika AlfanОценок пока нет

- 13.-En NT Bolts UtilcellДокумент3 страницы13.-En NT Bolts Utilcellnu.arabiaОценок пока нет

- Revisedkho Beam7'Документ1 страницаRevisedkho Beam7'neophymenОценок пока нет

- RCDДокумент7 страницRCDRodel John AberiaОценок пока нет

- Dimensionamento Roscas Stub-AcmeДокумент13 страницDimensionamento Roscas Stub-AcmeVítor CarvalhoОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Samsung Galaxy S23 Series (Galaxy S23, S23 Plus and S23 Ultra) User Guide for Beginners and SeniorsОт EverandSamsung Galaxy S23 Series (Galaxy S23, S23 Plus and S23 Ultra) User Guide for Beginners and SeniorsРейтинг: 1 из 5 звезд1/5 (1)

- Disston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderОт EverandDisston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderОценок пока нет

- British Commercial Computer Digest: Pergamon Computer Data SeriesОт EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesОценок пока нет

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosОт EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosОценок пока нет

- HdfcLogs 20 June 23Документ10 страницHdfcLogs 20 June 23Asif RazaОценок пока нет

- Bolting Galvanised SteelДокумент10 страницBolting Galvanised SteelAsif RazaОценок пока нет

- Escape Plan PDFДокумент2 страницыEscape Plan PDFAsif RazaОценок пока нет

- En 14399-4Документ24 страницыEn 14399-4Asif RazaОценок пока нет

- Bolting Galvanised SteelДокумент10 страницBolting Galvanised SteelAsif RazaОценок пока нет

- Mechanical Properties of Metric FastenersДокумент2 страницыMechanical Properties of Metric FastenersAsif RazaОценок пока нет

- Mechanical Properties of Metric FastenersДокумент2 страницыMechanical Properties of Metric FastenersAsif RazaОценок пока нет

- Filing FilesДокумент56 страницFiling FilesAsif RazaОценок пока нет

- HCLДокумент7 страницHCLAsif RazaОценок пока нет

- ASTM E18-05 AP Note Rockwell Hardness and Rockwell Superficical HardnessДокумент4 страницыASTM E18-05 AP Note Rockwell Hardness and Rockwell Superficical HardnessAsif RazaОценок пока нет

- Bottom Nut's Tack Welding On Straigth Anchor Bolt 141106Документ2 страницыBottom Nut's Tack Welding On Straigth Anchor Bolt 141106Asif RazaОценок пока нет

- Department:-Galvanising Date:-23/11/14: Item No. Cat No / Size Project Pieces Unit WT Total WTДокумент7 страницDepartment:-Galvanising Date:-23/11/14: Item No. Cat No / Size Project Pieces Unit WT Total WTAsif RazaОценок пока нет