Академический Документы

Профессиональный Документы

Культура Документы

Part 11 Metal Detector Manual PDF

Загружено:

Orlando MelipillanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Part 11 Metal Detector Manual PDF

Загружено:

Orlando MelipillanАвторское право:

Доступные форматы

MA3000

E R I E Z

M E T A L A R M

MA3000 SERIES

METAL

DETECTOR

Description of Installation and Operation

SERIAL NUMBER: 81447

CHECKED BY:

DATE:

DOCUMENT No: IOM-MA-3000

REVISION: A

ERIEZ MAGNETICS EUROPE LIMITED

BEDWAS HOUSE INDUSTRIAL ESTATE BEDWAS CAERPHILLY CF83 8YG

UNITED KINGDOM TEL. +44 (0) 2920 868501 FAX. +44 (0) 2920 851314

ERIEZ METALARM

PAGE 1

MA3000

Table of Contents

1.0

INTRODUCTION

2.0

INSTALLATION

2.1

Control Unit Mounting

2.2

Search coil Mounting

2.2.1 Underbelt TR Coil (Flat Pack)

2.2.2 TR10 Coil

2.2.3 Bridge Coil

2.2.4 U section belt conveyors or vibrator conveyors

2.2.5 Plate Coil

3.0

ELECTRICAL CONNECTIONS

3.1

Power Supply

3.2

Sensor Coil Connections

3.3

Control Relay Contacts

3.4

Fuse

4.0

OPERATING INSTRUCTIONS

4.1

Indicator Lights

4.2

Sensitivity Adjustment

4.3

Signal Level Indicator

4.4

Electronic Board Mounted Switches

5.0

ELECTRONIC CIRCUIT BOARD REPLACEMENT

6.0

WIRING TO THE CONVEYOR MOTOR CONTACTOR

7.0

AUXILIARY RELAY

7.1

Auxiliary Relay Wiring

8.0

EARTHING OF ASSOCIATED EQUIPMENT WHEN FREQUENCY INVERTER SPEED CONTROLS ARE

BEING USED

9.0

SUGGESTIONS FOR TROUBLE SHOOTING ENVIRONMENTAL INTERFERENCE

9.1

Movement of Metal

9.2

Intermittent Loops of metal surrounding the sensor

9.3

Excessive line voltage fluctuations

9.4

Proximity of severe RF radiation source

10.0

PARTS LIST

11.0

TECHNICAL DATA

ERIEZ METALARM

PAGE 2

MA3000

METALARM 3000 CE

1.0

INTRODUCTION

The METALARM (MA) 3000 Metal Detector, consists of a control unit, one or more sensor coils

dependent upon the application and optional accessories such as the sack dropper.

The optional QUARRYMASTER version of the control unit is constructed from stainless steel and is fitted

with an anti condensation heater & thermostat for frost protection. The thermostat is normally set to

+5C.

These instructions are concerned with the installation and operation of the control unit, sensor coils

and accessories.

Figure 1

ERIEZ METALARM

PAGE 3

MA3000

2.0

INSTALLATION

2.1

Control Unit Mounting

The MA3000 control unit is supplied with HDPE (high density polyurethane) mounting brackets for wall

mounting. Dimensions are shown in the diagram, Figure 1.

Ideally the control unit should be mounted within 3-5 metres of the sensor coil unit and no more than

20 metres.

The MA3000 control unit will normally be mounted by means of four M8 or 5/16 inch bolts utilizing the

four mounting holes.

Adequate clearance must be allowed below the control unit enclosure to allow for cable entry and

exit.

On no account must the HDPE mounting brackets be replaced, as these are provided to electrically

isolate the control unit from the metal conveyor framework. Similarly no metal work should be in

contact with the metal control unit case after mounting on the conveyor.

Failure to comply with the above mounting procedures will invalidate the 'CE' certificate covering

the EMC regulations.

2.2

Search Coil Mounting

The following instructions give details of how to install the various types of standard search coils

supplied as part of the Metalarm Metal Detector.

2.2.1

A)

Underbelt TR (Flatpack) Coil - Idler Conveyors (figure 2)

Locate a suitable position in the conveyor mid way between two idler sets where:

1. There will not be a return idler or cross piece beneath the search coil.

2. There is no join in the conveyor frame

3. Metal when detected can easily be removed from the conveyor belt

4. There is no moving metal in the vicinity

5. Where any metal base plate present can be removed or replaced by non metallic material.

6. Where any metal over-belt covers can be removed or replaced

B)

Place the search coil on the conveyor frame at the chosen position. There should be at least a

25mm (1 inch) gap between the underneath of the (fully loaded) conveyor belt and the top

of the search coil. If not cut out notches in the bottom of the search coil at all four corners so

as to lower the search coil within the conveyor frame.

C)

Brackets to hold the search coil to the conveyor frame (not supplied) should be fitted to the

coil to secure it to the conveyor stringers.

D)

The search coil should then be bolted to the conveyor frame so that the coil socket is on the

opposite side of the conveyor frame to any heavy duty cables.

E)

The idlers either side of the search coil should be checked to see that all nuts and bolts have

been tightened down. Ideally the idler frames should also be spot welded once at each of

the four corners to the conveyor frame.

ERIEZ METALARM

PAGE 4

MA3000

The cable to connect the search coil to the control unit should then be plugged into the

underneath of the search coil and run back to the control unit. The cable should be tied down so it

does not get damaged.

SENSOR COIL PLATES

CO-AX CABLE TO

METALARM CONTROL

UNIT

SIDE SUPPORT PLATES

SMALL ANGLE BRACKETS

(NOT SUPPLIED)

CONVEYOR STRINGER

Figure 2

2.2.2

TR10 Type Search Coil Idler Conveyors (figure 2A)

Follow the instructions as listed in section 2.2.1 points A-E for the coil location & installation.

This type of coil configuration is designed for transmit/receive mode operation only and both coils

are connected directly to the control unit. See section 3.2 (sensor coil connections) and figure 2A

below. Remember in both cases to make sure the cables are tied to the conveyor frame to prevent

them being damaged.

RECEIVER COIL

TRANSMITTER COIL

SMALL ANGLE BRACKETS

(NOT SUPPLIED)

SIDE SUPPORT PLATES

CENTRE SUPPORT PLATE

CONVEYOR STRINGER

Figure 2A

ERIEZ METALARM

PAGE 5

MA3000

2.2.3 Bridge Type Search Coil - Idler Conveyors (figure 2B)

A) Locate a suitable position in the conveyor mid way between two idler sets where:

1. There will not be a return idler or cross piece beneath the search coil.

2. There is not a join in the conveyor frame

3. Metal when detected can easily be removed from the conveyor belt

4. There is no moving metal in the vicinity

5. Where any metal base plate present can be removed or replaced by non metallic material.

6. Where any metal over-belt covers can be removed or replaced.

B)

Assemble the lower coil on the side supports & place on the conveyor frame at the chosen

position. There should be at least a 25mm (1 inch) gap between the underneath of the (fully

loaded) conveyor belt and the top of the search coil. If not cut out notches in the bottom of

the search coil at all four corners so as to lower the search coil within the conveyor frame.

C) Brackets to hold the search coil to the conveyor frame (not supplied) should be fitted to the coil

to secure it to the conveyor stringers.

D)

The search coil should be mounted on the conveyor frame so that the coil socket is on the

opposite side of the conveyor frame to any heavy duty cables.

E)

Fit top search coil section and bolt down

F)

The idlers either side of the search coil should be checked to see that all nuts and bolts have

been tightened down. Ideally the idler frames should also be spot welded once at each of the

four corners to the conveyor frame.

In the case of series connection, connect the lower coil using the short length of cable provided

using the unmarked socket on the top coil. The cable to connect the search coil to the control unit

should then be plugged into the socket marked CU on the top search coil and run back to the

control unit. See 3.2

In the case of transmit/receive mode operation; both coils are connected direct to the control unit.

See 3.2. Remember, in both cases make sure the cables are tied to the conveyor frame to prevent

them being damaged.

RECEIVER COIL

SMALL ANGLE BRACKETS

(NOT SUPPLIED)

SIDE SUPPORT PLATES

TRANSMITTER COIL

CONVEYOR STRINGER

Figure 2B

ERIEZ METALARM

PAGE 6

MA3000

2.2.4 U Section belt conveyors or vibrator conveyors - Search coils (figure 3/4)

A) Locate a suitable position in the conveyor where there is going to be no metal within 500mm of

the underneath of the search coil when it is mounted onto the conveyor. Simultaneously there

is no moving metal in close proximity to the search coil. In the case of vibrator conveyor the coil

is usually located midway between two of the vertical supports.

B)

To install a trough coil, it is necessary to cut out a length of the base and part of the side walls of

the conveyor. The dimensions of the required cut out can be found by measuring the recessed

area of the search coil.

COUNTERSINK FROM INNER

SURFACES OF TROUGH

DRILL MOUNTING HOLES

ALONG THIS PATH

REMOVE

TROUGH

SECTION VIEW

SECTION

FROM

CUT OUT LENGTH

RECESSED AREA

SENSOR COIL

CUT OUT HEIGHT

Figure 3

C) Draw a line 25mm from the edge of the cut out. Along this line drill M8 holes at 100mm (4 inches)

spacing or longer depending upon the weight and width of the search coil. Countersink the

holes from inside the conveyor.

D)

Locate the search coil into the cut out and clamp into position. Then using the trough as a

template spot mark through the holes from the inside of the trough directly onto the coil.

E)

Fix the search coil into position using countersunk M8 bolts x 40mm long, shakeproof washers,

and nuts.

ERIEZ METALARM

PAGE 7

MA3000

F)

The cable to connect the search coil to the control unit should then be plugged into the

underneath of the search coil and run back to the control unit. The cable should be tied down

so it does not get damaged.

UNDERSIDE VIEW

CO-AX CABLE TO

METALARM CONTROL

UNIT

M8 FIXINGS

Figure 4

ERIEZ METALARM

PAGE 8

MA3000

2.2.5

Plate Coil (figure 5)

Plate coils can either be mounted beneath a pre-prepared metal free section such as wood or

fiberglass, or providing the plate coil is an SF or SFC type directly onto the base of a metal sided

conveyor.

In the latter case if the base of the conveyor is metal this must be removed for the length of the coil

plus 3mm.

The search coil can be drilled into or through in any of the crossed areas shown below as long as it is

a minimum of 25mm away from the coil windings.

SECTION VIEW

SENSOR COIL

CONVEYOR STRINGER

CONVEYOR BELT

SENSOR COIL

DRILL

FRONT VIEW

COIL WINDINGS

Figure 5

ERIEZ METALARM

PAGE 9

MA3000

3.0

ELECTRICAL CONNECTIONS - (See Figure 6.)

The standard electrical connections are for power supply connections and for sensor coil

connections. Other cables may be added as necessary for control and monitoring functions.

Please note where armoured cables are being used, the armouring must be cut back at the gland

plate of the control unit such that it does not touch the Metal Detector Control Unit, as this will

compromise the electrical isolation of the Control Unit.

This also applies to electrical trunking.

230

OPTIONAL

FAULT

RELAY CONNECTION

TB2

TB1

TB3

10

11

12

N/C C N/O N/C C N/O N/C C N/O N/C C N/O

TB4

DETECT LIGHT

RESET SWITCH

DETECT RELAY

POWER LIGHT

MAINS POWER

DC PSU INPUT

EXT FAULT INPUT (+5VDC)

SENSOR COILS

SW4 POSITION

1: SINGLE COIL CONNECTION (TX)

2: SECOND COIL CONNECTION (RX)

AUXILIARY TERMINAL

Figure 6

3.1

Power Supply

The mains connection is made via the terminal block TB1 using 'E' for earth/ground connection,

either of the 'L' terminals for live 1/positive connection and either of the 'N' terminals for live 2/neutral

connection.

The spare 'L', N and 'E' terminals can be used for driving external controls or the bag dropper

accessory for example.

The Voltage Selector Switch should be set to 230VAC or 115VAC as required. This is located just

above the connector TB1.

DIN RAIL TERMINAL

BLOCK

(-)

2

3

OPTIONAL: If the system has been requested to operate

from a DC voltage, the input voltage must be within the

range 18-30VDC.

The input supply should be applied to the DIN rail terminal

block mounted in the bottom of the control unit at the

terminals listed below.

2 NEGATIVE SUPPLY (0V GREEN/YELLOW)

5 POSITIVE SUPPLY (FUSED TERMINAL)

ERIEZ METALARM

(+)

LINE

LOAD

NOTE The DIN rail terminals are not fitted in the standard

mains (AC) powered units.

PAGE 10

MA3000

3.2

Sensor Coil Connections

The sensor coil connection is made via the right hand 4 way terminal block TB4. When only one coil

is used, or a Bridge coil is being used with coils in series, connect to terminals 3 & 4.

The inner conductor is connected to terminal 'C' and the outer braiding to terminal

For applications where two coil windings are being used and there are two coil cables, i.e. separate

transmitter and receiver coils; the search coil with the coil socket marked RX should be connected

to TB4 1 and 2 and the search coil with coil socket marked TX should be connected to TB4 3 and 4.

Note:

Switch 4 should be moved to position 2, when in transmitter/receiver mode (TX/RX).

3.3

Control Relay Contacts

Connection to the output contacts of the control relay are made to terminal block (TB2) as

indicated in drawing Figure 6. Four sets of SPDT relay contacts are provided.

In the instance of the optional FAULT relay being fitted, then terminals 10, 11 & 12 of TB2 are used for

this signal. This leaves three sets of SPDT relay contacts for the DETECT signal on TB2 (terminals 1-9).

Note that the FAULT relay operates in a fail-safe mode so when power is applied to the control

unit, it will change state.

The contacts are rated for 5 amps resistive, for either low voltage DC application or for a maximum

of 250V ac application.

3.4

Fuse

Please note there is only one fuse on this Control Unit, located on the front panel and rated at

500mA (230VAC) or 1A (115VAC) A/S.

4.0

OPERATING INSTRUCTIONS - (See Figure 7.)

E E N N L L

Figure 7

Switch on the line power and the 'ON' lamp on the case door illuminates.

The red 'FAULT' light will be on if the sensor coil is not connected. When the sensor is properly

connected the light will extinguish.

ERIEZ METALARM

PAGE 11

MA3000

Note: The illuminated fault light will also cause the 'Detect' lamp to be on.

Rotate the SET ZERO control fully clockwise. If the right hand light illuminates, rotate the Set Zero

control anti-clockwise until this light extinguishes and the green light illuminates.

This adjustment compensates or zeros out any near by metal in the sensor coil detect area. If this

light cannot be illuminated there may be too much metal near the sensor coil. This can be

confirmed by positioning the sensor coil away from all surrounding metal and repeating the test.

After these adjustments, the detector may have operated illuminating the 'Detect' light and the

'Reset' lamp on the detector door. Pressing the 'Reset' lamp button will extinguish both lights.

The Relay switch controls the relay function. In the OFF position only the 'Detect light and door

'Reset' lamp operate when metal is present in the sensing area.

In the ON position, the 4 pole DPDT relay, the 'Detect' light and the door 'Reset' lamp operate when

metal is present in the sensing area.

In the LATCH position, the relay and above indicators operate but after the metal is removed, the

relay and the indicators remain on until either the door 'Reset' button is pressed or the 'Relay' switch

is turned to the ON or OFF position.

The 'Sensitivity' control is a gain adjustment control to adjust for the detection of the desired size of

material or to allow for smaller pieces of material to be ignored.

4.1

Indicator Lights

SET ZERO

When the Metalarm is operating and correctly set, the green light of these three lights is the only one

illuminated.

If a piece of metal passing across the Sense coil is large enough it will cause the green light to go

out and the right hand red light to come on while the metal is within the detect range of the Sense

coil.

DETECT

This red light illuminates whenever metal is within the detect range of the Metalarm.

COIL FAULT

This red light illuminates if the sensor is either open circuit, not connected or short circuited.

This light also causes the Detect light to illuminate to prevent operation of the Metalarm until the coil

fault is rectified.

Normally, the Metalarm control unit should not require any major re-adjustments after performing

the adjustments during installation. After switching the control unit on, the green 'Set Zero' light

should illuminate immediately without the need to turn the 'Set Zero' control. Proper operation may

be verified by depressing the 'Test' button, which is mounted on the electronic circuit board

beneath the front panel.

Certain extremely large objects may produce an overload signal causing the unit to indicate

continuously even after the object has passed clear of the sensor coil. Depress the 'Reset' button to

cancel the indication.

NOTE:

Although the control unit will adequately zero out stationary masses of background metal, it will

respond to moving metal near the sensor coil. When mounting the sensor coil, consideration should

not be limited to only large objects such as fork lift trucks, but should be extended to smaller objects

such as maintenance workers carrying metal tools and equipment in the vicinity.

Although the metal detector system is suppressed against both airborne and power supply

interference, some false alarms may nevertheless occur occasionally. Such triggering is usually due

to transient effects, which are both infrequent and unpredictable.

Metallic framework encircling the search coil can act as a "shorted turn". It may be necessary to

insert insulating sections to prevent comparatively small masses of metal generating inordinately

large background signals.

ERIEZ METALARM

PAGE 12

MA3000

4.2

Sensitivity Adjustment

The 'Sensitivity' controls permit sensitivity adjustments for detecting or rejecting the desired size of

objects. Rotate the 'Sensitivity' control clockwise to increase the Metalarm sensitivity or counterclockwise to decrease the sensitivity.

A coarse sensitivity adjustment (VR1) may be performed by means of the sensitivity adjustment

control on the control unit printed circuit board (see figure 8). Extreme care must be used in

performing the coarse sensitivity adjustment. Consult the factory prior to making any coarse

sensitivity adjustments.

NOTE:

Take particular care, as with the mains supply connected parts of the printed circuit board will be

carrying high voltages. Therefore DO NOT touch anything other than the coarse sensitivity control

you are adjusting.

Rotating the coarse sensitivity adjustment control in the clockwise direction may reduce the

sensitivity of the control unit. Rotate this control one section at a time, checking each time to

determine whether the gain has been reduced sufficiently.

After each coarse sensitivity adjustment, it may be necessary to rezero the internal lights using the

'Set Zero' control and depress the reset button on the enclosure door.

4.3

Signal Level Indicator

This consists of a row of ten LEDs, which light in sequence from left to right, as the detected signal

level increases when metal approaches the sensor. Normally none or perhaps the first 1 or 2 LEDs

on the left side may be flicking ON and OFF and the last LED on the right side will be constantly ON.

Upon detection of metal each LED starting from the left will individually illuminate until the last two

LEDs on the right hand side are ON. This will mean that metal has been detected and the LEDs will

then revert back to the normal position (stated previously). However, if the Metalarm is suffering

from 'false alarms' which are of a fairly regular nature, then this indicator should be examined, since

it may show more than the first one or two indicators flickering ON and OFF indicating the presence

of some interference which is either mains or airborne. Rotating VR10 clockwise may reduce the

effects of this. The signal level should now move to the left until only 1 or 2 indicators are on. Care

should be taken to not rotate this control further than necessary, since it does reduce the sensitivity

of the unit.

The setting for this control can be measured with a voltmeter between test points TP0 and TP19. The

default value is 180mV.

ERIEZ METALARM

PAGE 13

MA3000

4.4

Electronic Board - Mounted switches - (See Figure 8.)

SW1

Figure 8

For the position of the switches, which control additional optional features, refer to figure 8 above.

SW1

Selection of voltage - 115V or 230V 50Hz or 60Hz AC

SW2

(1) Brown - This prevents the metal detector being reset when metal is still in the field of the

search coil - Can only be used when the conveyor belt stops immediately after metal is

detected - to ensure all metal has been removed before the conveyor belt can be

restarted.

(2) Red -Fail Safe Operation. - This powers up the 'Detect' relay immediately power is

connected to the control unit rather than when metal is detected. When metal is detected

therefore the 'Detect' relay drops out. Similarly if power to the unit fails the relay also drops

out - creating a fail safe mode.

All controls on SW2 are off in the 'up' position and 'on' when in the down position.

SW4

This separates the TX and RX coil connections when switched to position 2 and is used when

separate search coils are used for transmitting and receiving, such as to create an even

search field or where magnetic ores are being processed.

SW5

Test button.

SW6

This, when switched 'on', i.e. in the up position, reduces the integrator speed. This facility is

used where belt speeds are slow, such as in the Wood Industry and where noise levels are

high.

5.0

ELECTRONIC CIRCUIT BOARD REPLACEMENT

Normally, access to the electronics is not required but if the circuit board requires replacement, the

following procedures must be used.

Turn off the mains supply to the control unit and disconnect all terminal blocks connected to the

base of circuit board by pulling downwards.

Undo the three panel fixing clips by turning a 1/4 turn anti-clockwise.

Undo the five screws holding the two mounting brackets and remove.

Undo the five pillars and three mounting screws. Remove the circuit board and inspect the

enclosure. Remove any foreign material such as loose pieces of metal filings or wire cutting etc.

Install the new circuit board in the reverse procedure of above. Refer to section 4 for testing and

operation.

ERIEZ METALARM

PAGE 14

MA3000

6.0

WIRING TO THE CONVEYOR MOTOR CONTACTOR

To stop the conveyor drive motor when metal is detected, connect the Metalarm normally-closed

relay contacts (terminals C and N/C on (TB2)) in series with the conveyor motor contactor, KM1, as in

Figure 9.

After removing the metal, if the system is wired as shown in Fig 9, the conveyor will not restart until

the Metalarm control unit is reset AND the conveyor motor start switch is depressed.

230

TB2

TB1

1

STOP

N/C

START

N/O N/C

KM1

10

N/O N/C

11

12

N/O

SAFETY STOP

KM1

L1

L2

L3

KM1

Figure 9

Note: If the metal detector is operated in fail-safe mode, then the wire connected to pin 1 of TB2

should be moved to pin 3, as the relay will change polarity when power is applied to the control

unit.

ERIEZ METALARM

PAGE 15

MA3000

7.0

AUXILIARY RELAY

An auxiliary relay is necessary between the Metalarm Control Unit and the motor starter when the

motor wiring system is a fully three-phase delta with no star-point and uses a motor starter with a

415V coil.

The 415 volt motor starter coil exceeds the maximum voltage rating of the Metalarm output

contacts, which are rated at 250V ac maximum.

An auxiliary relay or small contactor is required for the 415V ac contacts.

An auxiliary relay is also necessary when the plant switchgear is generating electrical interference or

brushes are arcing, or when other electrical noise is being created.

This interference will propagate through the air and may also travel along the conductors in close

proximity to the noise sources. When this occurs, interference will be fed into the Metalarm Control

Unit along the interconnecting wires, and will cause false triggering.

An auxiliary relay in a separate enclosure, external to the Metalarm and separate from the main

switchgear cabinet, will normally isolate the offending interference.

7.1

Auxiliary Relay Wiring

230

TB2

TB1

1

N/C

N/O N/C

10

N/O N/C

11

12

N/O

RL1

RL1

Auxiliary Relay Wiring Diagram

Note: If the metal detector is operated in fail-safe mode, then the wire connected to pin 1 of TB2

should be moved to pin 3, as the relay will change polarity when power is applied to the control

unit.

ERIEZ METALARM

PAGE 16

MA3000

8.0

EARTHING OF ASSOCIATED PLANT WHEN FREQUENCY INVERTER SPEED CONTROLS ARE BEING

USED.

Please note that when frequency inverter speed controls are being used in the vicinity of the metal

detector all earth connections must be run independently back to a single star point as shown

below:-

In addition, if filters are being used they should be mounted and connected as shown below:-

INSTALLATION RECOMMENDATIONS FOR CONNECTING

RFI FILTERS TO HIGH FREQUENCY INVERTER DRIVES

Because of the complex circuit design used in these filters an Earth Leakage Current of 8 to 80mA

may be observed. It is possible that nuisance tripping of extremely sensitive type of ELCBs may

occur so this figure should be considered when choosing such a device.

It is important to provide well defined paths for the high frequency currents involved so, by far the

best results are achieved when both filter and inverter are mounted securely on the same

conducting, earthed backplate and not on rails etc.

Supply Cable

The supply cable should be a stranded conductor and not a solid conductor type to achieve

proper connection inside the terminal block, also cable lengths inside the wiring cabinet should be

kept to a minimum i.e. cable entry to filter and filter to inverter. This will reduce the effect of

radiated emissions back into the input cables.

ERIEZ METALARM

PAGE 17

MA3000

Motor Cable

Since the cable between the inverter and motor is a major source of radiated and conducted

interference, it should be a screened type and as short as possible with the screen and safety earth

core connected directly to the bonded earth post at one end and to the motor earth at the other.

Never connect only one end of the screen to earth as this can be detrimental. (Pig tail effect). It is

strongly recommended that the conducting cores (not the earth or screen) are threaded through,

or, if possible, wound around an output cable filter choke as shown.

Earthing

The point here is to clearly define the paths through which high frequency earth currents flow, and

thereby minimise their harmful effect on other nearby, sensitive devices. All earthing leads, including

filter earth, inverter earth and screened cable earths, should be as short as possible and securely

fastened to the bonded backboard earth post - poor connections and loops of cable will act as

aerials and pick up stray radiated emissions.

Separation

Keep the separation of the input and output cables as great as possible to prevent feedback. Input

and motor output cables should never be run together in the same trunking or conduit.

Control Cables

The control cables to the inverter or any other equipment in the vicinity are obviously highly

susceptible to radiated emissions in the same way and should also never be run along side motor

output cables.

Multiple Inverters

Where more than one inverter is used, for effective suppression, it is preferable that a separate filter

should be used for each inverter.

ERIEZ METALARM

PAGE 18

MA3000

9.0

SUGGESTIONS FOR TROUBLE SHOOTING ENVIRONMENTAL INTERFERENCE

The Metalarm Control Unit generates a high frequency alternating field within and near the sensor

coil. While the field is strongest on the sensor coil face or in the throat of the sensor coil, it is inherent

in the sensor coil design that a certain amount of the field exists outside of the sensor coil. Certain

environmental conditions may sometimes affect this alternating field causing false and erratic

signals.

If after installation the unit does not work properly, check for compliance with the following hook-up

and installation details before proceeding to the specific causes of interference.

All cable connections should be tight on the terminal blocks in the control unit. Any sensor coil lead

splice should be soldered and taped.

The power source cables should be isolated from varying inductive loads and should be run in a

separate conduit.

The control unit should have a good electrical ground connection.

In certain locations more than one problem may exist and the problems may be interrelated.

Observing the installation site and the operation of the metal detector for repeating symptoms is

very helpful in isolating the causes of the problems.

Correlating malfunctioning occurrences is invaluable for environmental interference trouble

shooting. Observe whether interference occurs at certain specific times and in conjunction with

specific activity.

Observe whether interference occurs when operated by certain personnel or only after physical

change of the environment.

Use the following to help diagnose problems and problem sources and to implement corrective

measures.

Basically environmental interference may be classified into four types, as described below:

9.1

Movement of Metal

Large masses of metal such as shaker screens, metal deflection plates, vehicles etc. may affect

metal detector operation even when at a considerable distance from the sensor coil.

Other smaller masses of moving metal when sufficiently close to the search unit may also cause false

trips.

Interference may exist outside of the room or building and be hidden from operators view, such as

vehicular traffic in an alley next to the building wall or a chain conveyor below or above the floor, or

moving metal objects in an adjacent room.

Corrective Measures

Secure moving metal objects or remove them altogether if possible, or replace with a non

metallic material. Re-route vehicular traffic.

Place a metal shield securely fastened and stationary between the sensor and the source of

interference. Place a shield as close to moving object as possible. The size of the shield will

depend on the size of the moving object.

Install the metal detector in another location free from interference sources.

9.2

Intermittent loops of metal surrounding the sensor (Shorted Turns)

A source of interference, which is difficult to recognise, is that of the shorted turn. A shorted turn is

formed by metal pieces forming a complete path in an orientation around or near the sensor.

If this is intermittent, as in the case of two pieces of conduit occasionally touching together, the

detector will trip each time the conduits make or break connections. The intermittence may be

caused by physical deflection or vibration of equipment, and by expansion or contraction of metal

due to temperature changes.

ERIEZ METALARM

PAGE 19

MA3000

The effect of the 'shorted turn' is that of a secondary 'coil' or 'turn' coupled to the metal detector

sensor coil. The varying load of this secondary 'coil' when it makes or breaks is reflected to the sensor

coil tripping the control unit.

The following metal objects may be part of or form a 'shorted turn' by themselves: metal framework,

pipes, conduit, flexible conduit, guard railing, metal catwalks, conveyor rolls, etc.

To determine the existence of a 'shorted turn: switch the metal detector off and disconnect the

sensor lead at the terminal block. This will disconnect the sensor from the control instrument and

there will be no metal detection.

Now, turn the control instrument on again and set gain control to maximum. Run operation under

normal conditions and observe the signal level indicator. If the indicator is stable at this time, it is

most likely that the sensor is picking up a shorted turn. However, the problem may also be a break

on the sensor cable.

Check for breaks at this time and replace the cable if necessary.

If the cable is in good condition search for a 'shorted turn' as described in the following paragraph. If

the level indicator is not stable at this time, the problem is likely to be due to excessive line voltage

fluctuation.

To isolate and correct the 'shorted turn' problem, reconnect the sensor coil and turn off all

surrounding equipment in order to eliminate any vibration.

The level indicator should settle down at this time or at least reduce the number of false trips.

Proceed by tapping on all metal objects, starting near the sensor coil and working out from there, in

order to find where the break point is located. It is suggested that one person watch the level

indicator on the control unit in order to observe any movement while another person is tapping on

metal objects around and near the sensor coil.

In some cases, this may be several feet from the sensor coil. Sudden level indication movement

when a metal object is tapped will indicate the intermittent connection. It may be possible to fix the

problem by insulating or permanently securing this metal to metal connection. For example, in the

case of broken weld, re-weld or in the case of a loose pipe or conduit, re-secure the holders.

9.3

Excessive Line Voltage Fluctuations

Electrical interference may be in the form of line voltage 'spikes' caused on-off varying inductive

loads of electrical equipment on the same power line as the metal detector, or other power lines in

close proximity to the supply line for the metal detector.

Corrective Measures

Use another power line, (without the varying inductive loads) for the metal detector.

Disconnect electrical equipment causing the large inductive loads.

Connect interfering electrical equipment to another power source.

Re-route the power line to the metal detector.

Install a constant voltage transformer (120 va. minimum) between metal detector and power

source.

9.4

Proximity of Severe RF Radiation Sources

Electrical or electronic interference can be radiated into the sensor coil or introduced into the metal

detector from other energy emitting devices such as arcing motors, arc welders, and arcing relay

points.

Corrective Measures

Remove or replace equipment causing interference.

Operate welding equipment only at times when metal detector is not required to operate.

Call the factory service department if unable to arrive at a satisfactory solution. Telephone: + 44 (0)

2920 868501 email: eriez@eriezeurope.co.uk

ERIEZ METALARM

PAGE 20

MA3000

10.0

MA3000 CE Case Assembly Parts List

1/2

10

9

3/8

5

4/8

Ref No

01

02

03

04

05

06

07

08

09

10

Description

Case fully fitted

Enclosure 400x300x150 (SS or painted steel)

Indicator Assembly (POWER).

Momentary Illuminated Switch Assembly (DETECT/RESET).

Front Door Wiring Loom

Insulated Mounting Kit

Cable Gland PG11 Brass Filament bulb MBC

Label

Door Key

Qty

1

1

1

1

1

1

As req'd

2

1

1

SEARCH COIL CABLES

Cable Search Coil - 1m

Cable Search Coil - 3m

Cable Search Coil - 5m

Cable Search Coil - 10m

Cable Search Coil - 20m

ERIEZ METALARM

1

1

1

1

1

PAGE 21

MA3000

MA3000 CE Electronic Assembly Parts List

21

24

25/27

22

23

29

28

25/26

31

30

33

Ref No

**

21

22

23

24

25

26

27

28

29

30

31

32

33

Description

Electronic Unit Complete

PTL147A Printed Circuit Board

Front Panel MA3000 CE

Push Latch Arrow 2001

Bargraph Module with plug

Control knob

Plain cap for control knob

Pointer cap for control knob

Relay 4PCO

Fuse T500mA/1A 20mm

Plug 4 way

Plug 6 way

Plug 9 way

Plug 12 way

32

Qty

1

1

1

3

1

3

1

2

1

1

1

1

1

1

** Electronic unit comprises - printed circuit board, bargraph module, front panel etc. all mounted on

back plate

ERIEZ METALARM

PAGE 22

MA3000

11.0

TECHNICAL DATA

POWER SUPPLY

115 230VAC VIA SELECTOR SWITCH 50/60Hz

(24VDC VERSION AVAILABLE ON REQUEST 2A STARTUP CURRENT CAPACITY REQUIRED)

POWER

11W

FUSE

1A 500mA (115/230)

RELAY

4PCO VOLT FREE

250V/5A MAXIMUM RATING

TEMPERATURE

0 TO +50C

MATERIALS

CONTROL UNIT: POWDER COATED STEEL OR STAINLESS STEEL

SENSOR COIL: HDPE (HIGH DENSITY POLYETHYLENE)

SENSOR CABLE

RG58/URM76 50 OHM CO-AXIAL CABLE

IP RATING

IP66 (NEMA 4X)

ERIEZ METALARM

PAGE 23

Вам также может понравиться

- Part 11 Metal Detector ManualДокумент24 страницыPart 11 Metal Detector ManualWilliams Rojas Quispe100% (2)

- Metal Detectors MA 3000Документ4 страницыMetal Detectors MA 3000estramilsolution100% (1)

- Code C On Extec Jaw CrusherДокумент6 страницCode C On Extec Jaw CrusherAdal Vera100% (1)

- E7 Hydraulic Diagram-ESДокумент2 страницыE7 Hydraulic Diagram-ESCésar A. Chacón100% (1)

- DIAGRAMA ELECTRICO MX T MK 19 - 100635EKPegon Maxtrak 1000Документ14 страницDIAGRAMA ELECTRICO MX T MK 19 - 100635EKPegon Maxtrak 1000Itza Lozada100% (2)

- Terex Finlay I-110 Impact Crusher PDFДокумент4 страницыTerex Finlay I-110 Impact Crusher PDFeaglego00Оценок пока нет

- How To - Understanding Clutches REV3Документ154 страницыHow To - Understanding Clutches REV3Erdenebileg SangidorjОценок пока нет

- Manual Powertrak 750Документ7 страницManual Powertrak 750JG Ramirez MОценок пока нет

- Triturador de Entulho Rubble-Master-Rm60Документ12 страницTriturador de Entulho Rubble-Master-Rm60João Santiago0% (1)

- Cone Crushers: C-1540 C-1540RS C-1550Документ8 страницCone Crushers: C-1540 C-1540RS C-1550brajesh123Оценок пока нет

- Set Up Guide Qi430 (1440)Документ35 страницSet Up Guide Qi430 (1440)Mf Lui100% (2)

- En 01.251 - RM 70go! 2.0 Short Manual Help v2Документ63 страницыEn 01.251 - RM 70go! 2.0 Short Manual Help v2andrew stablesОценок пока нет

- Premiertrak 400 r400 Crushing Brochure en 2014Документ1 страницаPremiertrak 400 r400 Crushing Brochure en 2014anon_728840059Оценок пока нет

- Catalog Transformatoare Cofi2011Документ7 страницCatalog Transformatoare Cofi2011PodaruОценок пока нет

- Presentation Slide showQJ341 QJ241..ppsxДокумент120 страницPresentation Slide showQJ341 QJ241..ppsxdaniel100% (1)

- Start Up / Tracking Manual Model: S190/S130/S80: Mccloskey International LTDДокумент11 страницStart Up / Tracking Manual Model: S190/S130/S80: Mccloskey International LTDWilson BarajasОценок пока нет

- Fault Code 800101 Emergency Stop Fault 2017Документ14 страницFault Code 800101 Emergency Stop Fault 2017Justice Machiwana50% (2)

- J-1175 Dual Power Jaw Crusher: SpecificationДокумент8 страницJ-1175 Dual Power Jaw Crusher: SpecificationAndrey L'vovОценок пока нет

- 14 Wet SandvikДокумент14 страниц14 Wet SandvikdanielОценок пока нет

- Trakpactor 320sr Crushing Brochure en 2014Документ1 страницаTrakpactor 320sr Crushing Brochure en 2014Claudiu Ionut RusuОценок пока нет

- Iampm Hpto12wДокумент19 страницIampm Hpto12wvitoОценок пока нет

- QJ340Документ11 страницQJ340defiunikasungti100% (2)

- Chieftain 2200 3 DeckДокумент1 страницаChieftain 2200 3 DeckSrinivas NandikantiОценок пока нет

- Powerscreen Commander 1400 2 Deck Tech Spec Rev5!01!02-2013Документ10 страницPowerscreen Commander 1400 2 Deck Tech Spec Rev5!01!02-2013macross086Оценок пока нет

- Pegson Crusher Bearing Product Luoyang JCB Bearing Technology CompanyДокумент1 страницаPegson Crusher Bearing Product Luoyang JCB Bearing Technology CompanyJusto Ernesto Gutierrez Schweitzer100% (1)

- 3.20 Premium Metal Detector TestingДокумент20 страниц3.20 Premium Metal Detector Testingdaniel100% (1)

- Extec C12 - Sandvik QJ341 Parts List PDFДокумент4 страницыExtec C12 - Sandvik QJ341 Parts List PDFghitaОценок пока нет

- Powerscreen 1300 Maxtrak Tech Spec Rev 5-01-01-2013Документ12 страницPowerscreen 1300 Maxtrak Tech Spec Rev 5-01-01-2013baoyingОценок пока нет

- Transmision Trituradora TesabДокумент4 страницыTransmision Trituradora Tesabjorge alfonsoОценок пока нет

- Chieftain 1600 PartsДокумент79 страницChieftain 1600 PartsGiuro Kralev100% (2)

- JMG Systems LTDДокумент34 страницыJMG Systems LTDWassiem Sayoun100% (1)

- 1000 SR 07 Can Mk9pdfДокумент9 страниц1000 SR 07 Can Mk9pdfMarcelo Araoz ValdezОценок пока нет

- Terex Finlay J-1160Документ4 страницыTerex Finlay J-1160eaglego00Оценок пока нет

- Manual Issue 2 NewДокумент96 страницManual Issue 2 NewSport Diet Music SDMОценок пока нет

- 623CT Sales Specification NewДокумент19 страниц623CT Sales Specification NewDaniel Alejandro Navarro Jara100% (1)

- 428 Trakpactor - pdf428335614 PDFДокумент8 страниц428 Trakpactor - pdf428335614 PDFusuario29000100% (1)

- RM-250 Cat ELEC DIAGДокумент2 страницыRM-250 Cat ELEC DIAGluis eduardo corzo enriquezОценок пока нет

- XA750S Operations Manual Rev 1.0 (En)Документ292 страницыXA750S Operations Manual Rev 1.0 (En)PrekelОценок пока нет

- Fault Code 800102 Dog Lead Stop Request Stop Fault 2017Документ12 страницFault Code 800102 Dog Lead Stop Request Stop Fault 2017Justice MachiwanaОценок пока нет

- QJ341 HydraulicДокумент48 страницQJ341 HydraulicJustice Machiwana100% (3)

- BROCHURE PEGSON 4242SR - TerexPegson+SpecsДокумент9 страницBROCHURE PEGSON 4242SR - TerexPegson+SpecsGoran Erakovic100% (1)

- 1012TSДокумент87 страниц1012TSסטניסלב טלשבסקיОценок пока нет

- QH M-PRO S Operations Manual 04-07Документ46 страницQH M-PRO S Operations Manual 04-07jesus silva100% (2)

- Chieftain 1700 - 1700S Illustrated Parts Catalog Rev 9Документ341 страницаChieftain 1700 - 1700S Illustrated Parts Catalog Rev 9andras100% (5)

- 693+ Supertrak: SpecificationДокумент4 страницы693+ Supertrak: Specificationjiv2011100% (1)

- Powerscreen Metrotrak HA Techical Specification Rev 8 01 01 2017Документ12 страницPowerscreen Metrotrak HA Techical Specification Rev 8 01 01 2017Konrad MatuszkiewiczОценок пока нет

- Manual de Operacion Extec C13Документ31 страницаManual de Operacion Extec C13Harold Marcano100% (1)

- Terex Magnum 140 EspecificacionesДокумент11 страницTerex Magnum 140 EspecificacionesVictor José De La RosaОценок пока нет

- Premiertrak 1100x650 Parts ENGДокумент276 страницPremiertrak 1100x650 Parts ENGarttv44100% (1)

- Manual Maxtrak1300 PDFДокумент418 страницManual Maxtrak1300 PDFjulioОценок пока нет

- New 4 Bearing Screenbox Assembly'sДокумент33 страницыNew 4 Bearing Screenbox Assembly'sJorge GalarceОценок пока нет

- Sandvik QH Blue FaultsДокумент12 страницSandvik QH Blue FaultsJuan GuzmánОценок пока нет

- Product Link / Machine: Product Link PL631 and PL641 PLE601, PLE631 and PLE641Документ2 страницыProduct Link / Machine: Product Link PL631 and PL641 PLE601, PLE631 and PLE641Daniel Pacheco LLantoyОценок пока нет

- Techspec QA140Документ2 страницыTechspec QA140Dyego GarciaОценок пока нет

- QhBlueFaultCodes PDFДокумент1 страницаQhBlueFaultCodes PDFJuan GuzmánОценок пока нет

- The Extec C-12: Features and Benefits BookДокумент21 страницаThe Extec C-12: Features and Benefits BookReyna CoaquiraОценок пока нет

- Installation WordДокумент19 страницInstallation WordmsanchezОценок пока нет

- Metal DetectorДокумент25 страницMetal DetectoraugustoОценок пока нет

- Anti Climb DevicesДокумент8 страницAnti Climb DevicesBijaya Kumar MohantyОценок пока нет

- Instruction Manual: TCR - FM TypeДокумент19 страницInstruction Manual: TCR - FM TypeHien Nguyen VanОценок пока нет

- Ts4065 Parts Rev4Документ30 страницTs4065 Parts Rev4Orlando MelipillanОценок пока нет

- C2.2 Parts BookДокумент263 страницыC2.2 Parts BookOrlando Melipillan100% (5)

- Acoples PDFДокумент1 страницаAcoples PDFOrlando MelipillanОценок пока нет

- Ch2100x Rev 8 Parts Manual New Side Conveyors Design AddedsmallДокумент230 страницCh2100x Rev 8 Parts Manual New Side Conveyors Design AddedsmallOrlando Melipillan80% (5)

- TS4065 McCloskeyДокумент61 страницаTS4065 McCloskeyOrlando Melipillan100% (1)

- Strickland Parts ManualДокумент27 страницStrickland Parts ManualOrlando Melipillan100% (1)

- Liner SelectionДокумент68 страницLiner SelectionOrlando MelipillanОценок пока нет

- Jaw Crusher BrochureДокумент2 страницыJaw Crusher BrochureAnthony FuОценок пока нет

- Jaw Crusher BrochureДокумент2 страницыJaw Crusher BrochureAnthony FuОценок пока нет

- Trio 44x32 Twin FMW Operating ManualДокумент33 страницыTrio 44x32 Twin FMW Operating ManualOrlando Melipillan100% (2)

- C38Документ1 страницаC38Orlando MelipillanОценок пока нет

- Irri-Loc Ball and Socket Couplings: Female X Shank (Includes EPDM Gasket) Female X Male NPT (Includes EPDM Gasket)Документ1 страницаIrri-Loc Ball and Socket Couplings: Female X Shank (Includes EPDM Gasket) Female X Male NPT (Includes EPDM Gasket)Orlando MelipillanОценок пока нет

- Jaw Crusher BrochureДокумент2 страницыJaw Crusher BrochureAnthony FuОценок пока нет

- Lam 090713 Din Rail Engl Fin WebДокумент8 страницLam 090713 Din Rail Engl Fin WebOrlando MelipillanОценок пока нет

- PPI CorpBroДокумент0 страницPPI CorpBroOrlando MelipillanОценок пока нет

- 3710 Installation and Operation Manual of Hydro Power PlantДокумент106 страниц3710 Installation and Operation Manual of Hydro Power Plantjuliuspates@yahooОценок пока нет

- AC Current TransducerДокумент5 страницAC Current TransducerOrlando MelipillanОценок пока нет

- LambdaДокумент1 страницаLambdaOrlando MelipillanОценок пока нет

- Ppi FLCДокумент16 страницPpi FLCOrlando MelipillanОценок пока нет

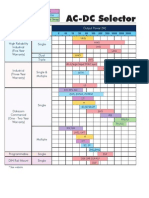

- AC-DC Selector: Output Power (W)Документ3 страницыAC-DC Selector: Output Power (W)Orlando MelipillanОценок пока нет

- Data Acquisition Modules/ Distributed IO Modules: User ManualДокумент75 страницData Acquisition Modules/ Distributed IO Modules: User ManualOrlando MelipillanОценок пока нет

- Engineering Data To Design A Conveyor Pulley, Shaft & BearingДокумент0 страницEngineering Data To Design A Conveyor Pulley, Shaft & BearingOrlando MelipillanОценок пока нет

- Autómato Mitsubishi fx1sДокумент80 страницAutómato Mitsubishi fx1sMicael FigueiraОценок пока нет

- PPI ProfileДокумент0 страницPPI ProfileOrlando MelipillanОценок пока нет

- PPI TermsДокумент0 страницPPI TermsOrlando MelipillanОценок пока нет

- Pulley CatalogДокумент32 страницыPulley CatalogOrlando MelipillanОценок пока нет

- Idler EngrDimДокумент64 страницыIdler EngrDimOrlando MelipillanОценок пока нет

- Lagging WebДокумент0 страницLagging WebOrlando MelipillanОценок пока нет

- Designing For EfficiencyДокумент6 страницDesigning For EfficiencyOrlando MelipillanОценок пока нет

- The Fabulous Four September 2013Документ14 страницThe Fabulous Four September 2013Julián Castro-CifuentesОценок пока нет

- Davey Water PumpДокумент8 страницDavey Water PumpMohamedAbdel-Rahman0% (1)

- tp3908202 940 1995 Wiring Diagrams Section 3 39Документ215 страницtp3908202 940 1995 Wiring Diagrams Section 3 39vanapeer83% (6)

- Contain CeДокумент4 страницыContain CenageshОценок пока нет

- PCB Surface Finishes Presentation by MultekДокумент54 страницыPCB Surface Finishes Presentation by Multeksmtdrkd100% (1)

- Cc1110 Cc2510 Basic Software Examples OverviewДокумент9 страницCc1110 Cc2510 Basic Software Examples Overviewalongdayx3Оценок пока нет

- Samsung Galaxy S4 Press Release Final EngДокумент5 страницSamsung Galaxy S4 Press Release Final EngdewjiblogОценок пока нет

- User Manual Flash Machine T1511M enДокумент18 страницUser Manual Flash Machine T1511M enMarius StefanОценок пока нет

- Digital Clock Using MSP430 - AllДокумент3 страницыDigital Clock Using MSP430 - AllAhmad Ali MirОценок пока нет

- Cmos Check Sum ErrorДокумент3 страницыCmos Check Sum Erroryogeshdhuri22Оценок пока нет

- Uninterruptible Power Supply UPS: Protect 5.31/xxx-480-220-120 10 kVA - 120 kVAДокумент61 страницаUninterruptible Power Supply UPS: Protect 5.31/xxx-480-220-120 10 kVA - 120 kVAMIGUEL ALVARO BLASCO MARTINEZОценок пока нет

- Date: Reg - No: PVP Siddhartha Institute of Technology, Kanuru Department of Mechanical Enginnering Subject: Cad/Cam Objective QuestionsДокумент2 страницыDate: Reg - No: PVP Siddhartha Institute of Technology, Kanuru Department of Mechanical Enginnering Subject: Cad/Cam Objective QuestionsRajyalakshmi M67% (3)

- MPD 810HДокумент5 страницMPD 810Hdan22yОценок пока нет

- MD Rakibul Islam Rakib - Lab Report 2Документ4 страницыMD Rakibul Islam Rakib - Lab Report 2A H MОценок пока нет

- Maestro XS Reference Manual Version 2.0 PDFДокумент130 страницMaestro XS Reference Manual Version 2.0 PDFRenato García Espinosa50% (2)

- Katalog Gree 2018 RacДокумент51 страницаKatalog Gree 2018 RacDitzsu tzsuDiОценок пока нет

- BELIMO LM24 ActuadorДокумент2 страницыBELIMO LM24 ActuadordcarunchioОценок пока нет

- Assembly-Level Service Guide Counter 53132AДокумент252 страницыAssembly-Level Service Guide Counter 53132AJhonSebastianGarcia100% (1)

- Fuji Semiconductor RB104 de DatasheetДокумент1 страницаFuji Semiconductor RB104 de DatasheetGheorghe DanielОценок пока нет

- Interfacing 8251 With 8086 PDFДокумент10 страницInterfacing 8251 With 8086 PDFMurthyОценок пока нет

- Reimagining IndiaДокумент4 страницыReimagining IndiaKushal BathijaОценок пока нет

- Rbs3206 Integration and Testing Course Pa2Документ48 страницRbs3206 Integration and Testing Course Pa2forwirelessОценок пока нет

- Expt 5.1Документ6 страницExpt 5.1Joel Catapang0% (1)

- Pioneer DV 300 KДокумент69 страницPioneer DV 300 KsvnnvsОценок пока нет

- Ovn MainДокумент54 страницыOvn MainAvenir BajraktariОценок пока нет

- Catalogo Numatics Serie l2Документ15 страницCatalogo Numatics Serie l2adrianaОценок пока нет

- Akai P42l6a-T1 (SM)Документ49 страницAkai P42l6a-T1 (SM)ricardoОценок пока нет

- IEO Syllabus Third Year-Electronics and Communications EngineeringДокумент2 страницыIEO Syllabus Third Year-Electronics and Communications EngineeringAkhil AaronОценок пока нет

- Schedule TrainningДокумент43 страницыSchedule TrainningdarkbertОценок пока нет

- B737 3 ATA 27 L3 eДокумент296 страницB737 3 ATA 27 L3 eAnonymous afPplXbc100% (2)