Академический Документы

Профессиональный Документы

Культура Документы

False Ceiling Work - (Gypsam)

Загружено:

virtechИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

False Ceiling Work - (Gypsam)

Загружено:

virtechАвторское право:

Доступные форматы

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 1 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

CONSTRUCTION WORK PROCEDURE

FOR

TYPICAL FALSE CEILING- PART 2 (GYPSUM BOARD) WORKS (UPPAL DEPOT)

IN HMRP

Document No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00.

Works at

Stations

Depots

Viaduct

Casting yard

Discipline

Civil

Mechanical

Electrical

Issue status

For review

For approval

Railways

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 3 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

INDEX

Clause

Clause Description

1.0

SCOPE OF WORK

2.0

TECHNICAL SPECIFICATION REFERENCES

3.0

OPERATING STRATEGY

4.0

SEQUENCE OF ACTIVITIES

5.0

CONSTRUCTION METHODOLOGY

6.0

QUALITY CONTROL & QUALITY ASSURANCE

6.1

INSPECTION PLAN (IP)

6.2

TEST PLAN (TP)

6.3

QUALITY FORMATS

7.0

8.0

ENVIRONMENT, HEALTH & SAFETY

7.01

ENVIRONMENTAL TEST

7.02

HEALTH

7.03

SAFETY

ATTACHEMENTS/ANNEXURES

Page No.

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 4 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

SCOPE OF WORK:

This Construction Work Procedure is applicable for execution of Typical False Ceiling WorkPart 2

(Gypsum Board) works as per approved drawing and technical specification, at Uppal Depot,

Hyderabad Metro Rail Project.

This work procedure includes the following:

a.

b.

c.

d.

e.

f.

g.

2

Surface/Area Cleaning

Marking of False Ceiling Level & Suspended Grid

Fixing of Wall Angles

Fixing of Suspension Wires/Rods

Installation of Main Channel and ss Tee

Level & Alignment Checking

Fixing of Mineral board

TECHNICAL SPECIFICATION REFERENCES:

2.1. CODES & SPECIFICATIONS:

IRS: Concrete Bridge Code

MORTH Specifications

BS EN 13964 Standard for Suspended Ceiling

BS 476 Part 20-23

Safety, Health & Environment (SHE) Manual document no.: L&TMRHL/OE/SATGE2A/D-8/2, Rev 1.

Safety, Health & Environment CONDITIONS Document no.: L&TMRHL/OE/STAGE2A/D-8/1, Rev 0.

2.2 DRAWINGS:

i)

S.No

1

2

3

4

MAIN WORK DRAWINGS:

Drawing NO.

Rev no

Note: Reference drawings are attached in Annexure - 1

Description

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 5 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

3.0

OPERATING STRATEGY:

3.1

ORGANISATION CHART

xxxxxxxxxx

SECTION INCHARGE/CONSTRUCTION MANAGER

xxxxxxxxxxxx

SITE ENGINEER

xxxxxxxxxxx

QA Engineer

XXXXX

Q/C ENGINEER

XXXXXXXX

SHE ENGINEER

Safety

Stewar

d

3.1.1 Roles & Responsibilities

3.1.1.1. Section Incharge/Construction Manager:

Organize & manage all resources and field activities to achieve an efficient and effective completion of the

contract, within the agreed time and cost, whilst paying due regard to safety and meeting Quality

requirements.

Over all responsible for co-ordinating and extracting the works from other agencies & department.

3.1.1.2. Site Engineer:

Responsible for arranging the required approved materials to site location for False ceiling works.

Responsible for co-ordination with service department and other agencies and ensuring the all fixing and

services fixer completed as per drawing.

Responsible for arranging working platform

Responsible for ensuring the False ceiling level & Grid properly

Responsible for ensuring the proper tools & tackles are readily available at site before starting of ceiling work.

Responsible for ensuring the line and level of ceiling and grid as per GFC drawing and shop drawing

Responsible for quality of finishing of false ceiling as per specification.

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 6 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

Interacts with the LTMRHL Representatives and generates RFIs for inspection activity as per Inspection plan.

To ensure that the relevant project specification, approved working procedure and approved shop drawings

are available in coordination with construction manager and QC engineer.

Ensures to implement all mandatory safety requirements within his work limits.

Ensure all works are carried out as per the working procedure.

Follows the Inspection plan, Test plans and submits records to LTMRHL for their reviews and approval through

EDMS.

Maintain all format and checklist

Responsible for implementation of safe work environment at work place.

Responsible for execution and maintain the good quality of work.

3.1.1.3. Quality Engineer- QC:

Check the quality of materials using for false ceiling work with MTC.

Identify material sources, and conduct material tests and ensure conformity with specifications & standards

Conduct Routine Tests on materials as per ITP and maintain records.

Identify, Calibrate and maintain Master List of Testing and Measuring Equipment

Responsible for submission of all reports related to quality matters

3.1.1.4. Quality Engineer-QA:

Responsible for cross checking of materials approvals at site before using it in works.

Responsible for regular inspection stage wise of tiling works

3.1.1.5. Safety Engineer

Identify potentially unsafe acts, areas and implement practice measures and educate staff & workmen.

Investigate unsafe occurrences and initiate corrective steps.

Discuss near miss accidents with staff and workmen

Involves in regular safety pep talks, periodical demonstrations of safe practices in work.

Helps to provide necessary safety materials as per work requirements.

Implement EHS system at site; supervise for the safety lapse before commencement of work.

Organize training programs for safety awareness.

Coordinates with site administration, first-aid centre, doctors & hospitals during emergency.

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 7 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

3.2 RESOURCE SOURCING:

3.2.1. WORKMEN:

S.No

Manpower

(other than in organization chart)

Nos. per

Day Shift

Nos For

Night Shift

Installer/Fitter

04

04

2

3

Helpers

Supervisor from agency

06

01

06

01

Total Manpower

11

Remarks

11

3.2.2 Materials

1

2

3

4

5

6

Gypsum Board

GI Channels/Angles Sections

Anchor Fastener

Self-Driven screws

Self-Adhesive jointing Tape

Gypsum Jointing Compound(POP Putty)

3.2.2.1. Gypsum board:

Gypsum boards are made with gypsum plaster materials and it shall conform to IS 2095.

Gypsum boards are approved make only. Ie. India gypsum or equivalent.

Board with 12.5 mm thick seamless board.

Mineral boards shall be stored in dry conditions and to expose to environmental

3.2.2 GI Channels/Angles Sections

GI Channels/sections shall be as per approved make and brand.

3.2.3. Anchor Fastener:

Anchor fastener shall be as per approved make and brand.

Anchor fastener shall comply with manufacturer test certificates.

3.2.6. POP Putty:

Plaster of Paris materials shall be used for joint finishing.

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 8 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

3.2.3

EQUIPMENTS:

Sl.No.

Machinery

Nos. per Day

Remarks

Hammer

As per site requirement

For fixing of wall anles

Drilling Machine

As per site requirement

For drilling hole

Screwdriver

One per Installer

For fixing Main runners & cross tee

Line Dori/Pion wire

As per site requirement

For checking alignment

Tile Cutter/Knife/hacksaw

As per site requirement

Measuring Tape

7

8

Spirit Level

Auto Level

One per installer /As per

site requirement

As per site requirement

One number

For boards/angles cutting as per site

requirement

For dimension checks.( Calibrated one

only)

For grid level cross checking.

For levels providing and checking

4.0 Prerequisites for Block masonry

Gypsum Board and other fixing accessories materials shall be only approved brand.

Before starting of installation of Suspended grid system all services works (such as MEP/Intra

vendors such as Samsung for AFC, Thales for Communication and signaling and OTIS for Lifts

and elevators) shall be completed.

RFI for False Ceiling works (Gypsum Board) shall be raised after clearances from inter

departments such as MEP/Intra vendors such as Samsung for AFC, Thales for Communication

and signaling and OTIS for Lifts and elevators. And the record shall be attached with RFI for

inspection.

5.0 WORK SEQUENCE:

5.01. Surface/Area cleaning

5.02. Marking of False Ceiling Level & Grid

5.03. Fixing of Wall Angles/Perimeter Channel

5.04. Fixing of Suspension Angle

5.05. Installation of Intermediate Channel

5.06. Fixing of Ceiling section Channel

5.06. Leveling and Alignment of Grid

5.07. Fixing of Gypsum Board

5.08. Jointing and Finishing

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 9 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

6.

CONSTRUCTION METHODOLOGY:

6. 01 Surface/Area Cleaning:

Above the false ceiling area/location shall be free from any loose constructional materials.

Before starting of False ceiling activity, all the services (Electrical/MEP/Interface) works above false

ceiling shall be completed and clearance obtained from concerned department.

6.02. Marking of False Ceiling Level and Grid:

The reference level from main survey pillars shall be transferred and marked on all sides of walls

surface.

The marked reference level shall be as per approved GFC drawing or Shop Drawing.

False ceiling grid shall be marked on roof level with lime powder/chalk powder/red oxide powder as

per approved shop drawing or as per grid pattern layout.

Check and ensure the false ceiling level and grid pattern location as per GFC drawing before offering

inspection to LTMRHL by in-house QA/Checking engineers.

The false ceiling level & grid shall be obtained inspection from LTMRHL before starting of wall angle

fixing and grid works.

6.03.

Draw the reference line (50/100 mm) below the false ceiling level around the entire room.it will act as

a reference line for fixing wall angle/perimeter channel.

The wall angle shall be fixed as per approved shop drawing or GFC drawing level.

The wall angle shall start from one end of wall and move to other end.

Wall angles)/Perimeter Channel (GI Perimeter shall be fixed with nails/screws/fasteners with ravel plug

(if required) at every 450 mm c/c

The wall angle/Perimeter Channel make and product shall be approved one only.

6.04.

Fixing of Suspension Rod/Angle:

As per grid centerline (pattern/layout/shop drawing) suspension rods/wire/Angle shall be fixed.

Drill and fix anchor fastener (6 mm dia) at 1200 c/c as per grid pattern or layout.

Fix or tie the pre straightened GI rod/wire along with anchor fastener at 1200 c/c

Suspension rod/wire shall be fixed/hanged from all the anchor fasteners and left as it is.

6.05.

Fixing of Wall Angle/Perimeter Channel:

Installation of GI Intermediate Channels and GI Ceiling Section :

Before installation of intermediate channels, tie the guide line (dori/piano wire) in both directions from

the reference level of below wall angle.

Position and fix one end of intermediate channel on resting wall angle/perimeter channel and screw

with self-driven screw and further fix the intermediate main channel to the next support suspended

from ceiling and screw with supporting GI strip.

As explained above all the intermediate channels shall be fixed to suspended support angle from

ceiling as per grid pattern at 1200 c/c.

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 10 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

Intermediate channel shall be attached with another intermediate channel by overlapping minimum

100 mm and fix with self-driven screws.

Continue the installation of intermediate channel and form a grid one side.

After completion of intermediate channel installation (leveled and secured with suspension

rod/wires/angle, the GI ceiling section shall be installed and fixed with suspended straps.

GI ceiling section shall be provided across the intermediate channel at intervals not more than 450mm

centers at the bottom and the same fixed by GI connection clips at the intersection points. The same

procedure shall be continued till grid fixing completed whole area.

Additional GI channel grid shall be made along with main channel grid for light fixtures/AC

diffusers/door openings in ceiling etc., wherever required as per drawing.

6.06.

Leveling and Alignment of Grid :

After completion of installation of intermediate channel and ceiling sections, the grid pattern level

and alignment shall be cross checked and ensured as per approved GFC or shop drawing. The same

shall be inspected and obtained clearance from LTMRHL before proceeding fixing of gypsum board.

6.07.

Fixing of Gypsum Boards:

Once the false ceiling grid patren alignment and level obtained clearance from LTMRHL board shall

be installed.

Start the installation of boards in a staggered joint manner and fix with self-drive screws along with

ceiling sections. While installing the boards, the edges shall not be damaged. The extra care shall be

taken in handling of panels.

Damaged boards shall not be used.

The provision for light fixtures shall be left as it is as per shop drawing.

6.08.

Jointing and Finishing:

Upon completion of board fixing with GI frame, the joints are treatred with approved

jointing compound (POP Putty).

The open joints and damages are pre filled with the compound (POP Putty).

Joints are taped with self-adhesive tape at jointing portion.

Then the joint compound is applied in two layers for a width of 75 mm each to either side

of the joint.

After drying the joint compound is sanded smooth to receive paint.

7. QUALITY CONTROL & QUALITY ASSURANCE:

7.01.

Inspection Plan:

7.02. Test Plan:

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 11 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

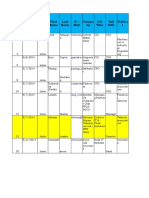

7.1. Inspection Plan for Typical false ceiling with Gypsum board works at Uppal depot area:

Check

Sl.

Check by

Description of sub-activity

by

Documentation

QCP QHP

No

L&T C

LTMRHL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Fixing of temporary level marks on walls as per

False Ceiling level(FCL)

Surface/Area cleaning above ceiling level

Fixing of Level for wall angle/Perimeter channel as

per FCL

Marking of Grid patterns on slab bottom

Receipt of Gypsum board and Grid GI channels

and accessories

Stacking of Materials(Gypsum board & channels)

Interface Checklist

(MEP/AFC/Telecom/Signaling/Lifts/

PSS/Track/OETS)

Fixing of wall angle/perimeter Channel

Fixing of suspended angle /rod with anchor

fastener

Installation of Intermediate channel

Supporting of suspended angle /wires to

intermediate channel

Installation of ceiling section along with

Intermediate Channel with suspended strap

Leveling & Aligning of Grid

Fixing of Gypsum Boards

Fixing of tape in joints

Providing openings/cutout provisions for light

fittings, grills etc

Finishing of joints with POP Putty

Housekeeping check list

Format No

Remarks

RFI, L F book, list of

TBMs

LTMRHL/CMP011F01(Rev 01)

LTMRHL/AF3(Rev01

List of RFIs through

EDMS

RFI, Checklist

LTMRHL/CMP011F01(Rev 01)

Invoices and MTCs

Checklist Points

W

W

W

R

R

R

Checklist

L&TC/B&F/TF95

LTMRHL/CMP011F01(Rev 0)

L&TC/B&F/TF 83

HMRP-31-A-rev 00

List of RFIs

through EDMS

along with

interface

clearance

checklist.

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 12 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

19

20

21

22

Pep talk report

Equipment fitness report

Weekly environment inspection

Electrical safety check list

QCP

QHP

W

R

EDMS

QC

Quality Control Point

Quality Hold Point

Witness

Review

Enterprise Data Management System

Quality Control

R

R

R

R

W

W

W

W

MTC

TBM

RFI

BBS

LF

PCC

Manufacturer Test Certificate

Temporary Bench Mark

Request for Inspection

Bar Bending Schedule

Level Field Book

Profile correction concrete

HMRP-12-A-Rev 00

HMRP-15-B Rev 00

HMRP-28-A3 Rev00

HMRP-09-A2 Rev00

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 13 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

7.2. Test Plan for Gypsuml Board for False Ceiling Works at Uppal depot area:

Mineral Fiber Board Tiles for Materials approval and routine tests during permanent works

S.No.

TEST TYPE

CODE OF PRACTICE

FREQUENCY OF TESTING

1

Dimension

2

Thickness

As per manufacturer

MTC to be reviewed for every batch/lot as

3

Edge details

spec and with relevant per manufacturer spec and with relevant

4

Thermal Conductivity

codes

codes

5

Thermal resistance

6

GI Channels/Sections

7

POP Putty

Other tests

S.No.

TEST TYPE

1

Calibration of Total station

2

Calibration of auto level

3

Environment monitoring

4

5

Illumination monitoring

Noise levels monitoring

CODE OF PRACTICE

A.P State

Pollution Board

BOCW act

BOCW act

SPECIFICATION REQUIREMENT

Gypsum Board shall conform to IS 2045 and

also manufacturer specifications.

FREQUENCY OF TESTING

Once per 6 months

Once per 6 months

SPECIFICATION REQUIREMENT

<2mm+2ppm for distance and <1 for angle

<2mm per Km

Once per 6 months (air and ground water)

As per APPB norms comparing to base line reading

Once per week

Once per week

>33 lux (using calibrated lux meter)

<63 dB (using calibrated decibel meter)

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 14 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

8.

ENVIRONMENT, HEALTH & SAFETY:

8.1. ENVIRONMENTAL:

Vehicle / machinery and equipment operation, maintenance and refuelling shall be carried out in such a

fashion that spillage of fuels and lubricants does not contaminate the ground.

Excavation shall not be carried out from the bund of the water bodies, No debris disposal near any water body.

Shall ensure that no trees / branches to be fell by labourer for fuel, warmth during winter. Enough provision of

fuel to be ensured.

General refuse shall be stored in enclosed bins or units and it should to be separated from construction and

chemical wastes.

8.2. HEALTH:

Section In-charge / Engineer shall ensure all workers are screened before engaging them for duties.

In-charge shall ensure availability of first aider with first aid kit.

Shed / shelter shall be provided for workers for weather protection along with drinking water.

8.3. SAFETY:

Flagman shall be provided at all exit points of the trucks / tippers.

Warning Sign Boards like Men at Work, Deep Excavation, Go Slow etc shall be displayed at work area.

The speed of vehicles plying in the work area shall be restricted to 15kmph maximum.

Levelling staff shall be made of wood.

If night work is to be carried out the area shall be sufficiently provided with lighting.

It shall be ensured that the safety belts were worn, tied and anchored properly while working at heights.

All working platforms shall be tied at the both ends firmly.

The electrical connections for vibrators / lighting shall be given by qualified / experienced P&M personnel

through ELCB only.

Sign Boards/warning signs shall be displayed at prominent locations near to work places.

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 15 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

REFERENCE :

L&T METRO RAIL HYDERABAD Ltd.

SAF 30

SITE EMERGENCY CONTACT LIST

Name of the Contractor: L&T ECCD B&F IC

Contract No. ---

The following persons have been appointed to be our representatives on site for all site safety emergencies.

Name of

Representative

RAJESH B KONDLE(RBK)

Position

A G CHANDRA SEKHAR

S K JHA

Dr. KARUNAKAR

P CHAITHANYA

Project Manager

Signature

Home

Tel.

-

Mobile No.

PM

7799699880

CM

9963027004

PROJECT HEAD

K. SRINIVAS REDDY

K. SRINIVAS

Office

Tel.

-

ACM

9849949767

9912855721

EHSM

9666097111

DOCTOR

9985738741

886998920

IR

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 16 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

LARSEN & TOUBRO LIMITED ECC DIVISION B & F IC

CONTINGENCY PLAN FOR HYDERABAD METRO RAIL PROJECT

Ambulance vehicle Number;

(Stationed at Uppal Depot)

LARSEN & TOUBRO CONSTRUCTION

Quality Assurance Plan

BUILDINGS & FACTORIES INDEPENDENT

No: HM-LE-NDPNDP-M0301-DOC-MS-QMS-00-104 Rev 00

COMPANY

Page 17 of 17

HYDERABAD METRO RAIL PROJECT

Construction work procedure for Typical False Ceiling Part 2-(Gypsum Board) works (UPPAL DEPOT) in

HMRP

LIST OF HOSPITALS IN HYDERABAD (NEARBY WORK PLACE)

Sl Name of the

No

Hospital

1

CARE

HOSPITALS

2

MEDICITI

HOSPITALS

Hospital Location

Contact No:

Exhibition Grounds Road, Nampally, Hyderabad - 500

004

5-9-22, Secretariat Road, Hyderabad - 500 063

+9140 30417777, 30417488

+9140 23231111

YASHODA

HOSPITALS

Nalgonda X Roads, Malakpet, Hyderabad - 500 036

+9140 24555555

IMAGE

HOSPITALS

Madhapur, Hyderabad - 500 081

+9140 23116666, 23116000

APOLLO

HOSPITAL

Jubilee Hills, Hyderabad - 500 033

+9140 23607777, 23607760

JAGDAMBA

HOSPITAL

#1-1-380/3, Gandhi Nagar, Hyderabad - 500 080

+9140 27613419, 27613420

IMAGE

HOSPITALS

903/F12 & 13, Ameerpet, Hyderabad 500 016

+9140 23750000

SWAPNA

NURSING HOME

6-3-1111/19, Nishanth Bagh, Begum pet

Hyderabad 500016

+9140 23402417, 23405019

4-1-1227, King Koti

Road, Hyderabad,

Andhra Pradesh, India

10

GLOBAL

Lakdi-kaHOSPITALS

Pul,

Hyderabad

Andhra Pradesh, India

11 JAYABHUSHAN

Santosh Nagar

HOSPITALS

Colony,

Mehdipatnam,

Hyderabad

12

KAMINENI

: Cross

Road, L B Nagar , Hyderabad- 500068 , Andhra

HOSPITALS

Pradesh

9

KAMINENI

HOSPITALS

9.

ATTACHEMENTS/ ANNEXURES:

1. Annexure 1 Risk Assessment

2. Annexure 2 Incident Flow

+9140 66924444

+9140 23244444

+9140 66563334

+9140 39879999

RISK ASSESSMENT/ SUMMARY SHEET

CONTRACTOR NAME: L&T CONSTRUCTION

RISK ASSESSMENT FOR: FALSE CEILING WORKS

Originator Name (Print): K. SRINIVAS

Contract:

Signature:

Date: 15.10.2013

KEY:

RISK RANKING:

Task/Element

L = Likelihood

S = Severity

L = Low priority to be implemented when

resources allow.

Population at

Potential Hazards

Risk

M = Medium priority to be scheduled as

soon as practicable.

Risk

Control Measures/ FollowRating

up Checklist

L S R

Falling of material, hitting,

slip & fall

Employee &

Workmen

Fall of material & people

Employee &

Workmen

Marking of False Ceiling Level & Grid

Fall of material & people

Employee &

Workmen

Fixing of Wall Angles & Suspension Rods

Fall of Material &

workmen

Cut Injuries, Electrocution

Employee &

Workmen

Installation of Main Runner /

Mineral Board

Trips & Falls

Unbalancing / toppling

while board fixing

Fitter, Helper,

Supervisors.

Height Work

Surface Preparation / Cleaning

Ref: HMRP-12-A Rev 00

Ref: HMRP-15-A Rev 00

Ref: HMRP-14-I Rev 00

Ref: HMRP-09-A13 Rev00

Ref: HMRP-12-A Rev 00

Ref: HMRP 31A Rev 00

Ref: HMRP-14-I Rev 00

Ref: HMRP-12-A Rev 00

Ref: HMRP 31A Rev 00

Ref: HMRP-14-I Rev 00

Ref: HMRP-12-A Rev 00

Ref: HMRP 31A Rev 00

Ref: HMRP-14-I Rev 00

HMRP-09-C 1 Rev 00

Ref: HMRP-12-A Rev 00

Ref: HMRP-31-A Rev 00

Ref: HMRP-09-A13 Rev00

R = Risk (Likelihood x

Severity)

H = High priority to be acted

on immediately.

Revised Rating

L

R

L

2

L

2

L

2

L

CONTRACTOR NAME: L&T CONSTRUCTION

RISK ASSESSMENT FOR: FALSE CEILING WORKS

Originator Name (Print): K. SRINIVAS

Contract:

Signature:

Date: 15.10.2013

KEY:

L = Likelihood

RISK RANKING:

Task/Element

L = Low priority to be

implemented when resources

allow.

Population

Risk Rating

Potential Hazards

at Risk

S = Severity

R = Risk (Likelihood x Severity)

M = Medium priority to be scheduled as

soon as practicable.

H = High priority to be acted on

immediately.

Revised Rating

L

S

R

Control Measures

R

1.

Height Works

Falling of material,

hitting, slip & fall

Employee &

Workmen

Only experience person shall be allowed erect the Mobile

Scaffolding

2. Access & egress shall be kept clean.

3. Brakes shall be applied before workmen allowing workmen

on to the mobile scaffolds.

4. Shifting of materials shall be carried out under the

supervision of a responsible person.

5. Manual handling shall be avoided as far as possible.

6. No loose material shall be stored on working platform.

7. Only standard/approved fittings shall be used in scaffolding

assembly

8. All scaffolding shall be provided with edge protection and

platform consisting of top rail & mid rail.

9. Life line shall be tied if workmen extend work beyond

working platform

10. Competent person shall inspect scaffolding periodically &

after adverse weather conditions.

1.

Surface

Preparation /

Cleaning

Marking of

False Ceiling

Level & Grid

Improper shifting of

Materials

Entanglement

Cut Injuries,

Electrocution

Employee &

Workmen

Proper handling shall be ensured without dropping the

containers on the ground.

Safety goggles/ Face shield / visor shall be used during

cutting and grinding activity.

2.

1. Only experience person shall be allowed to work on

mobile Scaffolding

2. Full body harness shall be worn by all workmen on

elevated work platforms.

3. Access & egress shall be kept clean.

4. Brakes shall be applied before allowing workmen on

to the mobile scaffolds.

5. Workmen shall not be allowed to overreach locations

outside from scaffolds.

Fixing of Wall

Angles &

Suspension

Rods

Falling of material/

Cut Injuries,

Electrocution

Helpers/

khalasis /

Public.

1. Proper arrangement shall be made for stacking the

materials.

2. All the sharp ends / protruding members shall be

protected with covers.

3. Scaffolding / Staging shall be erected for working on

height, Certified Inspector shall check periodically for

worthiness.

4. Proper working platform shall be maintained for

height work, with safe access and egress.

5. Safety harness shall be used when working above 1.8

meter height.

6. Proper walkways shall be provided on the fixed rebars.

7. Only proper hand tools shall be used for bolting the

rods.

8. Sharp metal wires shall be folded.

9. Tool box meeting shall be conducted before execution

of the reinforcement. Hazard associated &

precautionary measures shall be explained to the

work.

10. All the working personnel shall wear Mandatory PPE.

11. All cable used to be routed thru RCCB.

12. All cables used to be double insulated, with plug tops

& routed above height.

13. Insulation of the joints to be provided sufficiently &

with a knot to provide stability

14. Housekeeping activity shall be carried out before &

after the work.

15. Illumination shall be minimum 100 lux maintained

during night time for all the activities.

16. Proper access shall be maintained for ingress / egress

( Ladder / Cross-over)

1.

2.

3.

Installation of

Main Runner /

Mineral Board

Fall of materials / trips

Unbalancing / toppling

while board fixing

Employee &

Workmen

4.

2

M

5.

6.

7.

8.

Approach stair case / ladder are kept safe & free from

material stacking.

Working platform shall be provided for height work.

Edge protection like guard rails shall be provided for

platforms

Life Line & Full Body Harness shall be used while working

above 6 Feet height.

Materials shall not be dropped from height should be

lowered using ropes.

All cable used to be routed thru RCCB.

All cables used to be double insulated, with plug tops &

routed above height.

Insulation of the joints to be provided sufficiently & with a

knot to provide stability

RISK MATRIX

PROBABILITY

SEVERITY

1

4

5

L

M

M

M

M

H

H

H

H

H

IDENTIFICATION OF ENVIRONMENTAL ASPECTS AND IT'S IMPACTS

Debris / Scrap

Installation of ceiling

components

1

IMPACT

AIR

WATER

Dust due to

the mixing /

Pollution

Contamination Due to

flowing to nearby

drains

Air pollution

due to

emissions

from diesel

engines

LAND

Spillage & Contamination

RATINGS

OTHER

DURATION

ASPECT

PROBABILITY

ACTIVITY

SEVERITY

S.No.

FALSE CEILING WORKS

SCALE

NAME OF THE OPERATION :

Noise level of that area

may increase

Disturbance to local

community

3

Note:

SCALES:

RATINGS

1

SCALE OF

IMPACT

Localized

SEVERITY OF

IMPACT

very low

PROBABILITY OF

OCCURANCE

Rare

Department

Low

Once a year

Factory

Moderate

Once a month

City

High

Once a week

Very high

Intermittently/

when activity goes

on

Global

DURATION

OF IMPACT

LAST

Momentary

Lasts for a

day

Lasts for a

month

As long as

aspect

continues

Permanent

Total= Scale x Severity x Probability x Duration

Total rating if >150 or any Legal Compliance is observed then Operation

Control Procedure required.

INCIDENT COMMUNICATION FLOW CHART

MINOR INCIDENTS

(Such as Near miss, First-Aid, Property damage, Traffic zone

incidents etc.)

STEPS

L&T Construction

LTMRHL

Receive SMS

(by EHS Department)

Receive e-mail

(by EHS Department)

Inform

By SMS Immediately

Identify, Register and send

e-mail (register in .exl)

Complete correction

Investigate

1

2

Propose Corrective Action

MAJOR INCIDENTS

(such as Dangerous Occurrences, LTI, Fatal, Working zone incidents)

STEPS

1

2

L&T Construction

LTMRHL

Inform

By SMS Immediately

Identify, Register and send email (register in .exl)

Receive SMS

(by EHS Department)

Receive e-mail

(by EHS Department)

Complete Correction

Within 24 hrs., prepare report in

the prescribed format

Send report by Email within 24

hrs. of incidence

Receive a written report in a

prescribed format

(by EHS Department)

Implement Corrective

Action

Inform to all personnel,

Statutory authorities as per

Clause 14.2 of SHE Contract

conditions

Record and Update

Register

Send copies by e-mail

Receive a copy of the said

communication

Investigate and report

Attend and receive an

Investigation report

Inform By e-mail

(by EHS Department)

Receive updated register

every Saturday by e-mail

(by EHS Department)

Discuss in

weekly review meeting

Discuss in

weekly review meeting

LTMRHL EHS TEAM

1. K.P.SREEHARI7702555383

2. Prakash Rahamatkar- 7702222693

3. Bhaskar Kunadharaju- 9866299599

(by EHS Department)

Propose Corrective Action

10

Implement Corrective Action

Circulate the incident report to

all Interested Parties through

EDMS

Discuss in

weekly review meeting

11

12

Discuss in

weekly review meeting

Format No: LTMRHL/CMP 011 F01 (Rev.01)

REQUEST FOR INSPECTION

PROJECT

CLIENT

INDEPENDENT ENGINEER

CONCESSIONNAIRE

CONTRACTOR

: Hyderabad Metro Rail

: Hyderabad Metro Rail Limited

: Louis Berger Consulting Pvt. Ltd

: L&T Metro Rail (Hyderabad) Limited

: L&T Construction

B&F IC

Infra IC

EDMS submission No:

RFI No :

Date:

Date:

Discipline: CIVIL / MECHANICAL / ELECTRICAL / RAILWAYS

Activity:

ITEM LOCATION

Corridor No:

Stage No:.

Area name:

Drawing Number:

Quality Hold Point

Quality Control Point

Details of item :

Reduced From:

level

To:

Requested by:

Quantity:

Inspected by:

Name

Name

Date

Date

Time

Time

Signature:

Signature:

Details of inspection :

1. Inspection completed, the contractor may proceed with the works.

Yes

No

2. Remedial works required as below but further inspection not required.

Yes

No

3. Remedial works required as below and re-inspection is required.

Yes

No

Remarks by LTMRHL:

FOR L&T

Distribution :

FOR LTMRHL / LBC

Original to Contractor ; Duplicate to LTMRHL

Format No. L&TC/B&F/TF 95, Rev 01

INTERFACE CLEARANCE FOR

BLOCK WORK

/ PLASTERING /

FLOORING

PAINTING

: Hyderabad Metro Rail

Project

: Hyderabad Metro Rail Limited

Client

: Louis Berger Consulting Pvt. Ltd

Concessionaire

: L&T Metro Rail (Hyderabad) Limited

Independent Engineer

: L&T Construction

Contractor

B&F IC

Corridor No.:

Platform level

Location / Grid

Number / Room

Station/Building Name :

Concourse level

Cleared for next

Interface Contractor stage of construction

(Yes/No)

L&T C' MEP

AUTOMATIC FARE

COLLECTION

COMMUNICATION

LIFTS

ESCALATORS

SIGNALLING

POWER SUPPLY &

SCADA

TRACTION

TRACK WORK

Stage No.:

Street level

Remarks

Date

Name

Signature

CHECKLIST FOR TILES FIXING WORKS

PROJECT

CLIENT

INDEPENDENT ENGINEER

CONCESSIONNAIRE

CONTRACTOR

: Hyderabad Metro Rail

: Hyderabad Metro Rail Limited

: Louis Berger Consulting Pvt. Ltd

: L&T Metro Rail (Hyderabad) Limited

: L&T Construction

B&F IC

Infra IC

Format No. L&TC/B&F/TF 83

Structre/Building:

Floor Level:

Location/Room:

Type of Fixing :

Flooring Tile

Skirting Tile

Dado Tile

Date:

Tiles :- Vitrified/Ceramic/Glazed Tiles

Description

Pre-Checks

Sl.No.

A

1

Date

Inspected By

L&T

LTMRHL

Using approved brand, shade and manufacturers of

tiles

1.1

Brand

1.2

Shade

1.3

Manufacturer

Surface preparation and cleaning the base slab area

Soaking of Tiles( If applicable- minimum 2 hours)

Mixing the cement mortar ration as specification

Spreading the bed mortar with CM ----- to average

thickness of _______mm and maintaining perfect level

as per FFL

Application of Cement slurry paste like consistencey at

the rate of 3 kgs/sqm

Tile to be placed on mortar one after another by gently

tapping it with wooden mallet.

Maintaining the joints as thin as possible and in

straight line( With Spacer or without spacer Paper

Joint) - Spacer thickness

Cleaning of Tile joints

10

Grouting Approved Materials

10.1 Make

10.2 Shade/Colour

11

Curing - minimum 3 days after grouting completion

For L&T C

For LTMRHL

Remarks

Weekly Environmental Inspection Checklist

HMRP-28 A3 Rev 00

_______________________________________________________________________________________

Project

: Hyderabad Metro Rail

Client

: Hyderabad Metro Rail Limited

Independent Engineer

: Louis Berger Consulting Pvt.Ltd

Concessionaire

: L&T Metro Rail Hyderabad Limited

Contractor

: L&T Construction

B&F IC

Infra IC

________________________________________________________________________________________

A) SUMMARY SHEET

1.

Major issues of non-conformity in the past week are:

Issue

2.

Reason

(i)

Air (Specify)

(ii)

Water (Specify)

(iii)

Noise (Specify)

(iv)

Waste (Specify)

(v)

Storage (Specify)

(vi)

Housekeeping (Specify)

(vii)

Roads (Specify)

Over the last week have been able to implement environmental management requirements as per

contract

Yes

if not yes reasons are

No

(i)

(ii)

3.

Following issues have not been resolved for more than past two weeks

(i)

(ii)

4.

Support/Clarification from L&TMRHL and/or its representative required in the following:

(i)

(ii)

5.

Complaints received in the past week.

(i)

From

(ii)

Public

(iii)

Client

(iv)

Statutory Agency

Action Taken

Reasons for Delay

Auditor:

Project Manager

Contract Number:

Contractor

Environmental Manager

Project Manager

Document No.:

Вам также может понравиться

- PP - 100 Service ManualДокумент8 страницPP - 100 Service ManualBob Bob100% (1)

- Project: Mars Factory Extension Project at Jafza: Consultant Client ContractorДокумент9 страницProject: Mars Factory Extension Project at Jafza: Consultant Client ContractorAzhar Shaikh100% (1)

- Method Statement For Kitchen Counter Work For Crest-21 (Ggl/Gem/Ssb)Документ7 страницMethod Statement For Kitchen Counter Work For Crest-21 (Ggl/Gem/Ssb)mayank dixit50% (2)

- MEP ChecklistДокумент8 страницMEP ChecklistvirtechОценок пока нет

- PD Cen-Tr 15589-2014 PDFДокумент16 страницPD Cen-Tr 15589-2014 PDFvirtechОценок пока нет

- Method Statement For RCC WorksДокумент10 страницMethod Statement For RCC WorksSagar AliasjackeyОценок пока нет

- Work Method Statement - TEXTURE PAINTДокумент3 страницыWork Method Statement - TEXTURE PAINTSathish Gowda0% (1)

- Method Statement For CuttingДокумент5 страницMethod Statement For Cuttingmarcke0% (1)

- ML-KW-MST-002 R1 Floor, Wall Tile InstallationДокумент8 страницML-KW-MST-002 R1 Floor, Wall Tile InstallationprithivirajОценок пока нет

- Method Statement For Installation of Suspended CeilingsДокумент7 страницMethod Statement For Installation of Suspended Ceilingsadeniyi abiola67% (3)

- JLL Quality Test Reports & Checklists - CivilДокумент55 страницJLL Quality Test Reports & Checklists - CivilN.PrabhuОценок пока нет

- Department of Civil Engineering, VVIET, MysoreДокумент60 страницDepartment of Civil Engineering, VVIET, Mysoredinesh_sshiva91% (11)

- Method Statement For Installation of Wooden Flooring PDFДокумент18 страницMethod Statement For Installation of Wooden Flooring PDFChris EnyinnayaОценок пока нет

- American National Standard For EvaluatingДокумент31 страницаAmerican National Standard For EvaluatingvirtechОценок пока нет

- The Sociology of Urban Public Spaces PDFДокумент10 страницThe Sociology of Urban Public Spaces PDFMeriç DemirОценок пока нет

- Campbell, IPPUC: The Untold Secret of CuritibaДокумент26 страницCampbell, IPPUC: The Untold Secret of CuritibaNicola HumanОценок пока нет

- Method Statement For Loose Furniture Fixing: Sandvik PVT LTD, Dapodi, PuneДокумент2 страницыMethod Statement For Loose Furniture Fixing: Sandvik PVT LTD, Dapodi, PuneParasОценок пока нет

- Estimate Road SafetyДокумент44 страницыEstimate Road SafetyBilal Ahmed BarbhuiyaОценок пока нет

- Method Statement For Granite FrameДокумент7 страницMethod Statement For Granite FrameMonali Varpe100% (1)

- Method Statement For Exterrnal PlasteringДокумент7 страницMethod Statement For Exterrnal PlasteringSagar ParabОценок пока нет

- Wall and Floor Tiles Method Statment PDFДокумент4 страницыWall and Floor Tiles Method Statment PDFAli SaifОценок пока нет

- Tata Projects Limited, Hyderabad: ClientДокумент7 страницTata Projects Limited, Hyderabad: ClientBibhuti Bhusana BisoyiОценок пока нет

- Work Method Statement - POP PUNNINGДокумент3 страницыWork Method Statement - POP PUNNINGSathish Gowda100% (1)

- PCC & RCC Work MSДокумент19 страницPCC & RCC Work MSjonesОценок пока нет

- METHOD STATEMENT - Internal Plaster WorkДокумент7 страницMETHOD STATEMENT - Internal Plaster WorkThink itОценок пока нет

- Work Method Statement - GYPSUM FALSE CEILINGДокумент3 страницыWork Method Statement - GYPSUM FALSE CEILINGSathish GowdaОценок пока нет

- Method Statement FALSE CEILING-1Документ7 страницMethod Statement FALSE CEILING-1beshnu garanaikОценок пока нет

- Checklist For Design & Drawing of Compound Wall and Main GateДокумент2 страницыChecklist For Design & Drawing of Compound Wall and Main GateRupesh KhandekarОценок пока нет

- Method Statement Structural Excavation BackfillingДокумент16 страницMethod Statement Structural Excavation Backfillingthelast_aienОценок пока нет

- Tiling WorksДокумент21 страницаTiling WorksGhayas JawedОценок пока нет

- Shuttering Deshuttering PDFДокумент27 страницShuttering Deshuttering PDFSyed Viqar AhmedОценок пока нет

- Method Statement For Anti Termite TreatmentДокумент7 страницMethod Statement For Anti Termite TreatmentSagar Aliasjackey100% (2)

- Final Qty. & Upto Rar-18 Qty. Compare 02.01.22.Документ128 страницFinal Qty. & Upto Rar-18 Qty. Compare 02.01.22.Iqbal ShaikОценок пока нет

- Water Proofing and DPC checklist-Rev-R6Документ1 страницаWater Proofing and DPC checklist-Rev-R6Guna SekaranОценок пока нет

- Standard Specs - Masonry WorkДокумент7 страницStandard Specs - Masonry Worknirmal sutharОценок пока нет

- AAC Block Masonary - Method StatementДокумент2 страницыAAC Block Masonary - Method StatementdawoodnagnurОценок пока нет

- METHOD STATEMENT Gypsum Board Ceiling Gypsum Partitions Ceiling TilesДокумент10 страницMETHOD STATEMENT Gypsum Board Ceiling Gypsum Partitions Ceiling TilesHARISH ROHANОценок пока нет

- Method Statement For Civil WorksДокумент16 страницMethod Statement For Civil WorksRICHARD FUNUEОценок пока нет

- Work Method Statement Tiling: Organisation DetailsДокумент7 страницWork Method Statement Tiling: Organisation DetailsKamagara Roland AndrewОценок пока нет

- Method Statement For False Ceiling WorkДокумент5 страницMethod Statement For False Ceiling Worktrija_mrОценок пока нет

- 11 MS For RC Retaining WallДокумент25 страниц11 MS For RC Retaining WallIlyas Khan100% (3)

- Water Proofing WorksДокумент8 страницWater Proofing Worksukali_csОценок пока нет

- Tiling - Check ListДокумент2 страницыTiling - Check ListYash Sharma100% (1)

- WATERPROOFДокумент1 страницаWATERPROOFKarthick NatrajanОценок пока нет

- Inspection & Test Plan (Itp) : Gypsum Board False CeilingДокумент1 страницаInspection & Test Plan (Itp) : Gypsum Board False CeilingLOPA THANDARОценок пока нет

- Sunken FillingДокумент3 страницыSunken FillingASHOKKUMARОценок пока нет

- TREMIX FLOORING (For Car Park and Drive Way) : Method StatementДокумент12 страницTREMIX FLOORING (For Car Park and Drive Way) : Method Statementmukesh sharma100% (1)

- Method Statement For Construction of An Additional Column To Support The Existing Ground)Документ7 страницMethod Statement For Construction of An Additional Column To Support The Existing Ground)Akash Yadav100% (1)

- Risk AssessmentДокумент3 страницыRisk AssessmentAkinbami Olorunnifemi100% (1)

- Method Statement of Waterproofing (Wet Area & Brick Bat Coba)Документ4 страницыMethod Statement of Waterproofing (Wet Area & Brick Bat Coba)Salman Shah100% (1)

- Ra 02 - Anti-Termite TreatmentДокумент4 страницыRa 02 - Anti-Termite TreatmentHafiz M WaqasОценок пока нет

- Demountable Partition Installation - Method StatementДокумент8 страницDemountable Partition Installation - Method StatementÖmer Faruk TaşdemirОценок пока нет

- Construction Method StatementДокумент24 страницыConstruction Method StatementMichael KaziОценок пока нет

- Method Statement For Finishing WorkspdfДокумент7 страницMethod Statement For Finishing Workspdfmohamed nabilОценок пока нет

- Check List For Inspection of Road WorksДокумент6 страницCheck List For Inspection of Road WorksPranjeet ChakravartyОценок пока нет

- Project: Preliminary Cost Sheet - INTERIOR FITOUT WORK-Budgetary CostingДокумент3 страницыProject: Preliminary Cost Sheet - INTERIOR FITOUT WORK-Budgetary CostingDeepa Junnarkar DegwekarОценок пока нет

- IASLC-MS-006 - Raft Concrete WorksДокумент6 страницIASLC-MS-006 - Raft Concrete WorksJoe PsОценок пока нет

- Method Statement For Wall PuttyДокумент5 страницMethod Statement For Wall PuttySagar ParabОценок пока нет

- 9.Ms-METHOD STATEMENT FOR TILING, SKIRTING, TOILET DADO & KITCHEN PLATFORM WORKДокумент15 страниц9.Ms-METHOD STATEMENT FOR TILING, SKIRTING, TOILET DADO & KITCHEN PLATFORM WORKShenbagaraja Pandian100% (2)

- Work Method Statement - LACQUERED GLASS PANELINGДокумент2 страницыWork Method Statement - LACQUERED GLASS PANELINGSathish GowdaОценок пока нет

- 7 BOQ For Furnishing Work Bahadurganj BranchДокумент1 страница7 BOQ For Furnishing Work Bahadurganj BranchRashedОценок пока нет

- 5.method Statement Shuttering and Form WorkДокумент4 страницы5.method Statement Shuttering and Form Workشاز إياس100% (1)

- Methodology Fo Tapecrete WaterproofДокумент3 страницыMethodology Fo Tapecrete Waterproofbeshnu garanaikОценок пока нет

- Quotation (Revised)Документ9 страницQuotation (Revised)Asif AlamОценок пока нет

- Water Proofing Toilets WorksДокумент63 страницыWater Proofing Toilets WorksGhaffar Laghari100% (1)

- WP056P Rev0Документ12 страницWP056P Rev0Mohamed Reda HusseinОценок пока нет

- 30-04-2018 JV BMS Specs PDFДокумент98 страниц30-04-2018 JV BMS Specs PDFvirtechОценок пока нет

- 03-Kim Spitler Delahoussaye 02 Pt1Документ3 страницы03-Kim Spitler Delahoussaye 02 Pt1virtechОценок пока нет

- Carrier E20s HAP50 ManualДокумент1 страницаCarrier E20s HAP50 ManualvirtechОценок пока нет

- 7-0 Causes and Effects of Fires and ExplosionsДокумент21 страница7-0 Causes and Effects of Fires and ExplosionsvirtechОценок пока нет

- ARB CPR Complying With USP 797Документ7 страницARB CPR Complying With USP 797virtechОценок пока нет

- M 334 ContentДокумент62 страницыM 334 ContentvirtechОценок пока нет

- IC-8 Chilled Water SequenceДокумент4 страницыIC-8 Chilled Water Sequencevirtech0% (1)

- Room Pressure For Critical EnvironmentsДокумент6 страницRoom Pressure For Critical Environmentsvirtech100% (1)

- Ecology UnitДокумент14 страницEcology UnitvirtechОценок пока нет

- Internal Gas Piping Design and Installation GuidelinesДокумент27 страницInternal Gas Piping Design and Installation Guidelinesvirtech67% (3)

- Refer To Service Building Requirements LayoutДокумент1 страницаRefer To Service Building Requirements LayoutvirtechОценок пока нет

- Frru004 Mom4Документ2 страницыFrru004 Mom4virtechОценок пока нет

- VLC Install GuideДокумент34 страницыVLC Install GuidevirtechОценок пока нет

- Standard PDI G102Документ8 страницStandard PDI G102virtechОценок пока нет

- TR 082Документ59 страницTR 082virtechОценок пока нет

- Fundamentals of Water System Design: Errata To, I-P Edition (2000) January 5, 2016Документ3 страницыFundamentals of Water System Design: Errata To, I-P Edition (2000) January 5, 2016virtechОценок пока нет

- FMDS0307Документ45 страницFMDS0307Story LoveОценок пока нет

- M 575 ContentДокумент27 страницM 575 ContentvirtechОценок пока нет

- Keeping Your Control Valves: in Good HealthДокумент8 страницKeeping Your Control Valves: in Good HealthvirtechОценок пока нет

- Evaluasi Kinerja Bus Kota Yang Trayeknya Berhimpitan Dengan Batik Solo Trans (Studi Kasus: Koridor 1 Kartasura - Palur)Документ13 страницEvaluasi Kinerja Bus Kota Yang Trayeknya Berhimpitan Dengan Batik Solo Trans (Studi Kasus: Koridor 1 Kartasura - Palur)Agus TriyonoОценок пока нет

- Cio NCRДокумент16 страницCio NCRVirender RawatОценок пока нет

- 2023年1-4月模考盒子David考官雅思口语素材 Part 1Документ27 страниц2023年1-4月模考盒子David考官雅思口语素材 Part 1Limin DingОценок пока нет

- Comprehensive Traffic & Transportation Plan For Bengaluru Chapter 8 - Transport IntegrationДокумент7 страницComprehensive Traffic & Transportation Plan For Bengaluru Chapter 8 - Transport IntegrationManu BkОценок пока нет

- BRT LagosДокумент20 страницBRT LagosJorge Cuervo Erthisa100% (1)

- Malolos Clark Railway Project - Framework Financing Agreement 1 PDFДокумент22 страницыMalolos Clark Railway Project - Framework Financing Agreement 1 PDFDeniell Joyce MarquezОценок пока нет

- Gta 3 CheatsДокумент5 страницGta 3 CheatsHarsheel ShahОценок пока нет

- Ap20105 Acm 34 s3 Iom Final TestДокумент6 страницAp20105 Acm 34 s3 Iom Final TestRajdip SilОценок пока нет

- Time Sheet 325201989076Документ4 страницыTime Sheet 325201989076Daffyboy MandyОценок пока нет

- Post Graduate Programme in Metro & Rail Technology (PGPMRT) : With Guaranteed PlacementДокумент2 страницыPost Graduate Programme in Metro & Rail Technology (PGPMRT) : With Guaranteed PlacementjeelaniОценок пока нет

- WDFWFДокумент4 страницыWDFWFDilan WarnakulasooriyaОценок пока нет

- METRO1Документ12 страницMETRO1Bhagyashri KulkarniОценок пока нет

- LA Metro - 444Документ5 страницLA Metro - 444cartographica100% (5)

- (Metro System and Engineering) - Subhadip BhattacharyaДокумент8 страниц(Metro System and Engineering) - Subhadip BhattacharyaUtpal MandalОценок пока нет

- Part 5, Rail Transit CapacityДокумент134 страницыPart 5, Rail Transit CapacityJonor AtaatОценок пока нет

- Presentation On Underground Metro: Prepared By-Yusuf RampurawalaДокумент71 страницаPresentation On Underground Metro: Prepared By-Yusuf RampurawalaYusuf RampОценок пока нет

- Malaysia Rail Industry A Snapshot PDFДокумент25 страницMalaysia Rail Industry A Snapshot PDFMarketing BОценок пока нет

- Combinations 1 2 3 4 5Документ2 страницыCombinations 1 2 3 4 5Tanmoy DasОценок пока нет

- 10th NASCENT Moot Court Competition, 2020 - Moot PropositionДокумент5 страниц10th NASCENT Moot Court Competition, 2020 - Moot PropositionGaurav NarvarОценок пока нет

- Sky Bus PDFДокумент59 страницSky Bus PDFSesha ReddyОценок пока нет

- WhitePaper Rolling Stock-2014Документ18 страницWhitePaper Rolling Stock-2014haftommmmОценок пока нет

- Sumador BCDДокумент1 страницаSumador BCDJessica RojasОценок пока нет

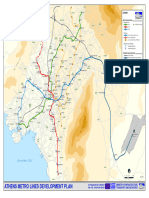

- AM Athens Metro Map Apr14 enДокумент1 страницаAM Athens Metro Map Apr14 enwuxezisakumugokiОценок пока нет

- Clementi MRT Station To West Coast Plaza, SingaporeДокумент1 страницаClementi MRT Station To West Coast Plaza, SingaporeAnnice KhooОценок пока нет

- Study On MetroДокумент8 страницStudy On MetroRanajit SamantaОценок пока нет

- ListДокумент8 страницListMovin MenezesОценок пока нет

- Gujarat Metro Rail Recruitment 2021: 31 Maintainer, JE, Assistant Section Engineer, & Other PostsДокумент5 страницGujarat Metro Rail Recruitment 2021: 31 Maintainer, JE, Assistant Section Engineer, & Other PostsRajesh K KumarОценок пока нет