Академический Документы

Профессиональный Документы

Культура Документы

V3i4 Ijertv3is041596

Загружено:

ANILОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

V3i4 Ijertv3is041596

Загружено:

ANILАвторское право:

Доступные форматы

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 4, April - 2014

Power Enhancement using Oxygen Enriched Air

for Multi Cylinder Diesel Engine

Sunit Jadhav1, S. N. Waghmare2, Suraj Dalvi3, Vinit Kamble4

1, 3,4

Student, Mechanical Engg Dept. Rajendra Mane College of Engg & Tech.,(Ambav),

Devrukh, Maharashtra, India.

2*

Assistant Professor, Mechanical Engg Dept. Rajendra Mane College of Engg & Tech., (Ambav),

Devrukh, Maharashtra, India.

Keywords-Power enhancement, oxygen enrichment, combustion,

ignition delay. Performance characteristics.

I.

INTRODUCTION

Todays conventional internal combustion engine uses

only air as it is necessary for combustion process. Air is

mixture of various gases which results in loss of heat energy

produced by combustion due to undesired combustion of

undesired gases. This results in loss of efficiency of that

particular internal combustion engine. Due to low cost of

diesel fuel diesel engine are more economical as compared

to the gasoline engines. Diesel engines are widely use in

field where both high power and high torque is required.

But diesel engines are suffers from inherent higher

particulate matter and nitride oxide emissions. Diesel

engines are measure contributors of air polluting exhaust

gasses such as particulate matter, carbon monoxide, oxides

of nitrogen and other harmful compounds. All polluting

exhaust gases form due to incomplete combustion of diesel

fuel.. To avoid pollution and heat loss it is necessary to have

complete combustion of fuel which can be accomplished by

availing extra oxygen for combustion. Diesel engine

manufacturers face major challenges to improve

performance characteristics of diesel engine by achieving

proper combustion of diesel fuel. To improve performance

and lower exhaust emission further one of the least

exploited variable has been oxygen concentration in

combustion air. Use of oxygen enriched air was compared

with different level of oxygen enrichment to evaluate

combustion parameters.

IJERTV3IS041596

II. LITRETURE REVIEW

To study the effect of oxygen enriched air on performance

characteristics of diesel engine. We referred research papers.

Mohammed Fahed [1], had used oxygen enriched

combustion (OEC) technology with high emission fuels.

The conclusions are oxygen enriched intake air should be

used to reduce the amount of stack gas CO emissions. Flue

gas reduction Energy efficiency, turndown ratio, flame

stability. Kuppusamy Rajkumar [2] investigates the effect of

using oxygen enriched air on Diesel engine exhaust

emission. And made conclusion that are Increasing the

oxygen content with the air leads to faster burn rates and the

ability to control Exhaust Emissions ,added oxygen in the

combustion air offers more potential for burning diesel.

Oxy-fuel combustion reduces the volume of flue gases and

reduces the effects of greenhouse effect also. Mattias

Nyberg [3] diagnoses the air intake system of an SI-engine.

System based on non-linear semi-physical model and use of

different residual generation method. And concluded that

increases performance of engine. Model based system

appropriate. Fredrik Norman [4] investigated the possibility

of high-temperature reduction of nitrogen oxides (NOx) in

oxy-fuel combustion. K.Rajkumar[5] have studied Added

oxygen in the combustion air leads to shorter ignition delays

and offers more potential for burning diesel. And different

parameters such as like Ignition delay, Combustion

duration, Heat release and Cylinder pressure was discussed.

S.Sranatha Reddy [6], have achieved reduction of smoke

through catalyst based oxygen enrichment technique which

proves to be an effective one as it utilizes air from the

ambient to produce oxygen-enriched air. The catalyst used

for the present study is zeolite. Mojtaba Moghad dam [7] in

their study, nitro methane (NM) and nitro ethane (NE) were

used as nitrogenated additives to improve brake specific fuel

consumption (BSFC), combustion performance and reduce

emission from diesel engine. A. Payakani [8] has taken

efforts to study performance andemission characteristics of

a diesel engine fuelled with biodieseland diesel fuel using

EGR. And prove that exhaust gas recirculation (EGR) is a

very effective technique to reduce NOx emissions from

adiesel engine. Azmi Osman [9] has said that,Air is replaced

with oxygen to maximize the combustion efficiency and to

enable broader range of fuels to be used. Water is injected

IJE

RT

Abstact-Today the diesel engine is the one of the most exciting

and promising technology in the world. The research efforts

directed towards improving the performance of CI engines.

Hence it is necessary to study performance parameters of the

engine. By increasing oxygen content with air leads to faster

burn rates and ability to burn more fuel at the same

stoichiometry. Added oxygen in combustion air leads to

shorter ignition delay and offers more potential of burning

diesel. Oxy-fuel combustion reduces the volume of fuel gases

and reduces the greenhouse effect also. This paper presents

how performance characteristics get improved by oxygen

enrichment.

www.ijert.org

1222

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 4, April - 2014

papered scribes some properties of synthetic oxygenates and

their influence on exhaust emissions from diesel engines.

According to the results of examinations, oxygenates are an

effective method for obtaining the reduction in the PM, CO

and HC emissions. A. I. Ramrez [18] explained fuel

injection and atomization processes are known to affect the

combustion and emission behavior in diesel engines. In this

study, characteristics from a six-hole, heavy duty,

Hydraulically-actuated,

Electronically-controlled

Unit

Injector (HEUI) have been investigated. Effects on cylinder

pressure, performance, and emissions information were

obtained. A. R.Patil [19], this Improvement of fuel

properties essential for suppression of pollutant and

optimization of engine performance. Now a days

oxygenated additives are widely considered for diesel fuel

also. During study of available material It is found that,

oxygenated are effective method for reducing PM, CO and

HC without significant increase in the NOx emission.

P.Sreenivasulu1 [20] tried to bring out the advantages of

additives to alcohol fuel on the performance of CI Engines.

The Additives such as n-butanol, hexanol, 1-octylamino3octyloxy-2propanol&N-octyl Nitra mine had been mixed

with theblends of diesel & ethyl alcohol and experiments

are carried out. The present research work is proposed to

carry out the experimental investigation on a ceramic hot

surface ignition engine by adding Ethyl nitrate,Butyl

nitrate,Diisi propyl ether and Dimethyl ether as additives to

ethanol/methanol as a fuel with an objective to find the best

one interms of performance, emission and combustion

parameters.

III. METHODOLOGY

IJE

RT

into the combustion chamber to enhance the combustion

heat absorption, gas expansion and to function as an energy

carrier. Engine secondary heat that will otherwise be wasted

to the environment is recovered and reused by the engine.

Engine theoretical efficiency and out emissions are

predicted to be improved. R. Senthilkumar [10] the

experiments were conducted by kriya bio additive in

different ratios with diesel. The quantity of bio additives

were increased gradually in the order of 1ml, 1.5ml, 2ml,

2.5, and 3ml respectively. Emission parameters such as HC,

smoke density, NOx, and CO2, characteristic were

determined for diesel and also for bio additive blends. Bio

additives mixed with diesel in different ratios by volume

based, it is noticed that the bio additive added diesel

enhances the cetane number and reduced the emission.

Stuart Nemser [11] made the objective for the research

that to NOx emissions by reducing the peak temperatures of

combustion. NOx emission reductions as high as 50% are

being achieved on diesel engines supplied with membrane

generated NEA. Results from some of these tests are

presented. C.D. Rakopoulos [12] presented two zone model

of a direct injection (DI) Diesel engine divides the cylinder

contents into anon-burning zone of air and another

homogeneous zone in which fuel is continuously supplied

from the injector and burned with entrained air from the air

zone. Duraid Maki [13]he has done study experiment on

multi cylinder, natural aspiration, four stroke, compression

ignition, and water cooled engine is tested under hydrogen

diesel different blends and at different operating conditions.

A hydrogen induction set up is built in the lab with all of the

acquitting sensors and measuring instruments. Experimental

tests are done to investigate engine thermal performance and

exhaust emission constituents under those blends

circumstances. The optimum operating conditions and

optimum parameters for those blends are found. Sagar Kadu

[14] determine performance of a four stroke, single cylinder

C.I. engine by preheated neat Karanja oil and performance

parameters considered for comparing are brake specific fuel

consumption, thermal efficiency, brake power, Nox

emission of the engine. And concluded that, at higher speed

there is no significant difference in BSFC when the engine

is operated with preheated and unheated vegetable oil fuels.

Engine power increases with speed to a maximum value at

an engine speed of 3500 rpm. Vipul Jain [15] used Exhaust

Gas Recirculation (EGR) System means to use the Exhaust

Gas coming from Exhaust Manifold to Inlet Manifold in

order to reduce the Emission of NOX, which is particularly

very harmful. Using Exhaust Gas Recirculation (EGR)

Technique in engines, the emissions are very much

controlled. This method is very reliable in terms of fuel

consumption. Meisam Ghadikolaei [16] investigated the

effect of cylinder air pressure and fuel injection pressure on

combustion characteristics of direct injection (DI) diesel

engine .The tests have been performed in a constant

combustion chamber with single-hole pintle nozzle which

the conditions were similar to real DI engine conditions.

Alagu [17] presented the article of literature study of the

effect of different fuel additives on performance and

emission characteristics of CI Engine fuelled with additives

of oxygenated and metallo-organic compounds. The

IJERTV3IS041596

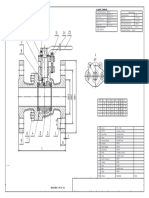

Fig.1 Block diagram setup

Oxygen Cylinder: The oxygen cylinder of 7 cubic meter

capacity is used for the present work. Oxygen stored at the

pressure of 150psi.

Distributor pipe: The distributor pipe having four drilled

hole from which oxygen is passed to flow meters. It is

placed in between oxygen cylinder and flow meters. The

suction flow rate of oxygen in diesel engine is up to 80-90

lit per min. Therefore to attain this requirement 4 flow

meters are used in series. The pipe of 50 mm diameter and

260 mm length is sealed by both ends and at one end inlet

valve is drilled through which oxygen is passed from

oxygen cylinder.

Flow Meter: Flow meter is device used to measure volume

flow of gas. The principle of lifting of mass by density of

gas is used in a working of flow meter. In the flow meter

pressurized gas from reservoir is injected in a vertical

capillary tube having ball of unit mass enclosed in it. The

capillary tube is having increasing scale from bottom to top

that is 0-25 litre/min. There are four flow meters are used to

www.ijert.org

1223

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 4, April - 2014

IV. EXPERIMENTAL WORK

The various experiments are conducted on four cylinder

four stroke diesel engine test rig. Whose specifications are

as follows :

Make

Bhp

Speed

No. Of Cylinders

Compression Ratio

Bore

Stroke

Type Of Ignition

Hindustan Motors

10hp

4500 To 5000 Rpm

Four

17:1

0.073m

0.09m

Compression Ignition

Method Of Loading

Hydraulic Dynamometer

Method Of Starting

Method Of Cooling

Starter Motor

Water

Test engine used in the experiments is a multi cylinder fourstroke, naturally aspirated, constant speed compression

ignition engine. Calorimeter was connected at the exhaust

manifold of engine to measure the exhaust gas temperature.

Oxygen concentration of intake air was increased by

injecting pure oxygen from compress cylinder to the mixing

chamber. Mixing chamber is connected before air box of

diesel engine test rig. To ensure the effective oxygen

enrichment, the pure oxygen was injected directly through

mixing chamber and intake air oxygen concentration was

measured properly using gas flow meters.

IJERTV3IS041596

Fig.2 experimental setup

V. RESULT & DISCUSSION

Oxygen enrichment in intake air leads to more efficient

fuel consumption. By increasing oxygen concentration in

intake air the heat that is released from combustion reaction,

is also increased. By assuming heat transfer from

combustion, the same for all oxygen concentration levels,

the rate of fuel consumption is reduced along with

increasing oxygen concentration in intake air. We can

determine the per cent of fuel consumption with respect to

the initial state in which pure air with 21% oxygen by

volume had been used. By increasing the amount of oxygen

from 21% to 28%, variation of fuel consumption rate in

different loads can be seen. The practical fuel consumption

achieved for different oxygen concentration levels is

compared to theoretical calculations. We have obtained

different results for different oxygen concentration.

IJE

RT

maintain the flow. By using four flow meters, we can

measure flow up to 100 litre/min.

Collector pipe: The collector pipe is placed in between

flow meters and mixing chamber. The measured oxygen

from flow meters outlet is collected in collector pipe. Then

it is send to the mixing chamber. The collector pipe having

four drilled hole from which oxygen is collected from flow

meters.

Mixing chamber: - The main purpose of mixing chamber is

to mix oxygen in to sucked air. The diameter of original

suction pipe of engine is 37mm, so for mixing chamber 37

mm diameter is selected. .The pipe of M.S. of diameter

37mm and length 150 mm is selected. For oxygen mixing

one jet is penetrated into this pipe. So when air is sucked by

engine, additional required oxygen will be provided by jet

and the mixture will suck by engine. The one end of pipe is

connected to engine and another end is open to atmosphere,

so when there is no suction in engine then there are chances

of oxygen loss due to back pressure. To prevent this loss

non return valve is used at the open side of suction pipe.

The non-return valve of flap type is used. Whole assembly

is bolted at opening of air box with help of 4 nut bolts of

M12.

Engine: The four cylinder four stroke diesel engine test rig

is used for experimental work. The oxygen from mixing

chamber is then sending to suction of engine.

Fig.3 load versus brake specific fuel consumption (BSFC)

The graph shows the variation of brake specific fuel

consumption (BSFC) versus load for oxygen enrichment in

intake air. Red line shows variation of brake specific fuel

consumption with respect to load with normal suction air.

Blue dotted line shows variation brake specific fuel

consumption with respect to loads with oxygen enriched

suction air. The BSFC decreases as in oxygen concentration.

At higher loads, BSFC tends to increase a little. Oxygen

enrichment decreases the BSFC at all loads.

www.ijert.org

1224

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 4, April - 2014

Fig.3 load versus Air-Fuel ratio

Fig.4 load versus brake thermal efficiency

Graph shows the variation of brake thermal efficiency

versus loads. Red line shows variation of brake thermal

efficiency with respect to load with normal suction air. Blue

dotted line shows variation brake thermal efficiency with

respect to loads with oxygen enriched suction air. By

increasing oxygen concentration, the brake thermal

efficiency is increased at all loads. Increase in oxygen

concentration leads to efficient combustion and hence

efficiency increases.

The graph shows variation of air fuel ratio versus different

loads. Red line shows variation of air fuel ratio with respect

to load with normal suction air. Blue dotted line shows

variation air fuel ratio with respect to loads with oxygen

enriched suction air. In case of oxygen enriched air, for a

load, mixture of air and fuel becomes lean i.e lean mixture

is required for same power output as compared to power

output in case of without oxygen enrichment. Hence air-fuel

ratio increases with increase in oxygen concentration for

different loads.

VI. CONCLUSION & FUTURE SCOPE

IJE

RT

There are different methods for the enrichment of the

oxygen such as air separation membrane, using the pressure

adsorption theory (PSA) with the help of the zeolite, with

the help of the different additives such as karanja oil, etc.

But among all these methods the enrichment of the oxygen

with the help of the separate oxygen cylinder is the most

convenient method. With help of this method we will get

the enrichment in the oxygen level. And because of this

there is complete combustion will be occur which may

enhance the power.

Fig.5 load versus specific fuel consumption (SFC)

Graph shows variation of specific fuel consumption versus

different loads. Red line shows variation of specific fuel

consumption with respect to load with normal suction air.

Blue dotted line shows variation specific fuel consumption

with respect to loads with oxygen enriched suction air.

Enrichment of oxygen leads to efficient combustion. As

combustion is proper power output for same mass of fuel is

increases. Therefore for fixed power output mass of fuel

decreases with enrichment of oxygen. Therefore specific

fuel consumption decreases with increase in oxygen

concentration in suction air.

IJERTV3IS041596

Oxygen enriched combustion technology influences in

increasing the cylinder pressure. This may be attributed to

the reduction of the ignition delay period which means early

starting of combustion and the availability of longer reaction

duration result in a more completion of the combustion

process due to the excess of oxygen and the higher gas

temperature. The use of oxygen enrichment on diesel engine

under different loading conditions was studied to discuss

various parameters like brake specific fuel consumption,

specific fuel consumption, brake thermal efficiency, air fuel

ratio.

By increasing oxygen concentration in intake air the heat

that is released from combustion reaction, is also increased.

The rate of fuel consumption is reduced along with

increasing oxygen concentration in intake air. By increasing

the load, rate of fuel consumption is gradually reduced.

Brake thermal efficiency increases at all loads with increase

in oxygen concentration. Brake specific fuel consumption is

decreased by oxygen enrichment, at all loads. Increase in

oxygen concentration leads to increase in the air-fuel ratio.

The present work can be extended by following

modification. (1)The test for emissions can be conducted to

www.ijert.org

1225

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 4, April - 2014

indicate the reduction in particulate matters, hydrocarbon,

etc.

(2) The exhaust gas emissions recirculation can be adopted

to reduce NOx emission of engine. (3) The turbocharger can

be used to improve power of engine. (4) The limitation of

scuderi engine can be eliminated by adopting the method of

present work.

REFERENCES

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

Mohammed Fahed Mohammed Alsayed.Oxygen Enriched

Combustion of High Emission Fuels, An-Najah National University

Faculty of Graduate Studies, 2008.

Kuppusamy Rajkumar and Palanisamy Govindarajan. Impact of

Oxygen Enriched Air Intake on the Exhaust ofa Single Cylinder

Diesel Engine, American Journal of Environmental Sciences, 7 (2):

136-140, 2011.

Mattias Nyberg and Lars Nielsen. Model Based Diagnosis for the

Air Intake System of the SI-Engine, Vehicular Systems, ISY,

Linkoping University,1998.

Fredrik Normann ,Klas Andersson, Bo Leckner, Filip

Johnsson.High-temperature reduction of nitrogen oxides in oxy-fuel

combustion, Department of Energy and Environment, Chamers

University of Technology, SE-412 96 Gteborg, Sweden,2008.

K.Rajkumar and P. Govindarajan. Experimental Investigation of

Oxygen Enriched air intake on CombustionParameters of a Single

Cylinder DieselEngine, International Journal of Engineering Science

and Technology, Vol. 2(8), 2010, 3621-3627.

S. Sreenath Reddy , K.L.N. Murthy, M. Harinathreddy, P.Nageshwara

Reddy. Reduction of smoke emission from diesel engine using

catalyst based oxygen enrichment, International Journal of

Mechanical and Industrial Engineering (IJMIE), ISSN No. 22316477, Vol-3, Iss-1, 2013.

Mojtaba Saei Moghaddam, Mohammad Mataei Moghaddam,

Sina Aghili, Ali Absalan and Ali Najafi. Performance and Exhaust

Emission Characteristics of aCI Engine Fueled with DieselNitrogenatedAdditives,International Journal of Chemical

Engineering and Applications, Vol. 3, No. 5, October 2012.

A. Paykani, A. Akbarzadeh and M. T. ShervaniTabar.

Experimental Investigation of the Effect of Exhaust Gas

Recirculation on Performance andEmissionsCharacteristics of a

Diesel Engin Fueled with Biodiesel, IACSITInternational Journal

Engineering and Technology, Vol.3, No.3, June 2011.

Azmi Osman. Feasibility Study of a Novel Combustion Cycle

IJERTV3IS041596

IJE

RT

[1]

Involving Oxygen and Water, SAE International,2009.

[10] R.Senthilkumar and S.Sivaprakasam. Performance Combustion and

Emission Characteristics on DI Diesel Engine using BioAdditive,

International Journal of Engineering and Technology, Volume No. 1,

January, 2013.

[11] Stuart Nemser and Donald Stookey Joyce Nelson. Diesel Engine Nox

Reduction Via Nitrogen Enriched Air,American Filtration and

Separation Society,September 30, 2003.

[12] C.D. Rakopoulos, D.C. Rakopoulos, E.G. Giakoumis, D.C. Kyritsis.

Validation and sensitivity analysis of a two zone Dieselengine model

for combustion and emissions prediction, Energy Conversion and

Management 45 14711495 (2004).

[13] Duraid F. Maki, P. Prabhakaran. An Experimental Investigation on

Performance and Emissions of a Multi Cylinder Diesel Engine

Fueled with Hydrogen-Diesel Blends,World Renewable Energy

Congress,2011.

[14] Sagar Pramodrao Kadu, Rajendra H. Sarda. Experimental

Investigations on the Use of Preheated Neat Karanja Oil as Fuel in a

Compression Ignition Engine, World Academy of Science,

Engineering and Technology,Vol:48 2010-12-24.

[15] Vipul Jain, Dipesh Singh Parihar, Vaibhav Jain and Irfan H Mulla.

Performance of Exhaust Gas Recirculation (EGR) System on Diesel

Engine,International Journal of Engineering Research and

Applications (IJERA), Vol. 3, Issue 4, Jul-Aug 2013, pp.1287-1297.

[16] Meisam Ahmadi Ghadikolaei. Effect of Cylinder Air Pressure and

FuelInjection Pressure on Combustion Characteristics of Direct

Injection (DI) DieselEngine Fueled with Diesel and Gasoline,

International Journal of Application or Innovation in Engineering &

Management (IJAIEM),Volume 3, Issue 1, January 2014.

[17] Alagu Sundara Pandian A and Paullinga Prakash R. A Study On

Effect Of Oxygenated And Metallo-Organic Fuel Additive On The

Performance And Emission Characteristics Of Diesel Engine,

International journal of research and technology,vol.3,No.1,2014.

[18] A. I. Ramrez, S. Som, T. P. Rutter, D.E. Longma2, S. K.

Aggarwal.Investigation of the Effects of Rate of Injection on

Combustion Phasing and Emission Characteristics: Experimental and

Numerical Study, April 2224, 2012.

[19] A. R. Patil, S. G. Taji. Effect of Oxygenated Fuel Additive on Diesel

Engine Performance and Emission: A Review, IOSR Journal of

Mechanical and Civil Engineering IOSR-JMCE).

[20] P.Sreenivasulu, B. Durga Prasad, G. Naga MalleswarRao, S.Sudhakar

Babu. Importance And Role Of Additives For Estimating

Performance And Emissions In C.I Engines Using Alcohol As A

Fuels- A Study,International Journal of Innovative Research in

Science, Engineering and Technology, Vol. 2, Issue 8, August 2013.

www.ijert.org

1226

Вам также может понравиться

- ME GATE 2016 Set 22Документ33 страницыME GATE 2016 Set 22Devaraj DevuОценок пока нет

- Prototype: Build Review Refine & IterateДокумент7 страницPrototype: Build Review Refine & IterateANILОценок пока нет

- VVNBVNДокумент5 страницVVNBVNANILОценок пока нет

- Patent Filing ProcedureДокумент34 страницыPatent Filing ProcedureANILОценок пока нет

- Season Classification Chart 2017: Alleppey Munnar Coorg Binsar Kanatal Shimla Kanha JaipurДокумент2 страницыSeason Classification Chart 2017: Alleppey Munnar Coorg Binsar Kanatal Shimla Kanha JaipurANILОценок пока нет

- VVNBVNДокумент1 страницаVVNBVNANILОценок пока нет

- WordlistДокумент1 страницаWordlistANILОценок пока нет

- Word ListДокумент1 страницаWord ListANILОценок пока нет

- L9 Nominal Taguchi 1Документ38 страницL9 Nominal Taguchi 1ANILОценок пока нет

- MCДокумент4 страницыMCViral PatelОценок пока нет

- OceaneeringДокумент1 страницаOceaneeringANILОценок пока нет

- My Statement of PurposeДокумент1 страницаMy Statement of PurposeANILОценок пока нет

- What Is Your Actual Pump Flow Rate?: Norman F. Perkins, P.E. Philip S. StacyДокумент10 страницWhat Is Your Actual Pump Flow Rate?: Norman F. Perkins, P.E. Philip S. StacyANILОценок пока нет

- GRE Essay TipsДокумент1 страницаGRE Essay TipsANILОценок пока нет

- Ghalib... (In Hindi)Документ36 страницGhalib... (In Hindi)api-19771339Оценок пока нет

- Courses Welingkaronline Org Newlogin Subjectlist PortionДокумент1 страницаCourses Welingkaronline Org Newlogin Subjectlist PortionANILОценок пока нет

- Malleable Cast Iron Heat TreatmentДокумент1 страницаMalleable Cast Iron Heat TreatmentANILОценок пока нет

- Name: Nilesh Ashok Wagh Mobile No.: +91 7588930595/7020322853 Technical AchievementsДокумент2 страницыName: Nilesh Ashok Wagh Mobile No.: +91 7588930595/7020322853 Technical AchievementsANILОценок пока нет

- PV Elite Heat Exchanger CalculationsДокумент99 страницPV Elite Heat Exchanger CalculationscbousmuОценок пока нет

- Cryogenic RefrigerationДокумент7 страницCryogenic RefrigerationANILОценок пока нет

- ASM E B16.34 Valve Body W All Thickness ASM E B16.10 Api 6D Design & M AnufacturingДокумент1 страницаASM E B16.34 Valve Body W All Thickness ASM E B16.10 Api 6D Design & M AnufacturingANILОценок пока нет

- 34 NCMCДокумент5 страниц34 NCMCANILОценок пока нет

- VW CS 0412 PDFДокумент4 страницыVW CS 0412 PDFANILОценок пока нет

- Body Language For InterviewДокумент5 страницBody Language For InterviewANILОценок пока нет

- BS en 1092Документ21 страницаBS en 1092Pranay Kharbe100% (5)

- Eflv 005Документ1 страницаEflv 005ANILОценок пока нет

- Refrigeration and Airconditioning by S K Mondal T&Q .0001Документ133 страницыRefrigeration and Airconditioning by S K Mondal T&Q .0001ANILОценок пока нет

- Eflv 005Документ1 страницаEflv 005ANILОценок пока нет

- Club Mahindra Goa Varca Beach FactSheetДокумент2 страницыClub Mahindra Goa Varca Beach FactSheetshrinidhik@gmailcomОценок пока нет

- GD & T Stack Up Analysis PDFДокумент12 страницGD & T Stack Up Analysis PDFANILОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Chem 2 Alkane PropertiesДокумент9 страницChem 2 Alkane PropertiesPatricia Theresa Ira IlustreОценок пока нет

- Fuel ManagementДокумент27 страницFuel Managementpprasad_g9358100% (1)

- 81 Solid Waste Management - VcsДокумент78 страниц81 Solid Waste Management - VcsakashОценок пока нет

- Rice Husk Based Energy GenerationДокумент25 страницRice Husk Based Energy GenerationTU_MTECH_ENV11Оценок пока нет

- Steam System Basics: Watertube BoilersДокумент4 страницыSteam System Basics: Watertube BoilersNaОценок пока нет

- M.tech Syllabus, KUKДокумент23 страницыM.tech Syllabus, KUKAnonymous sfkedkymОценок пока нет

- Flame Retardant PolyesterДокумент14 страницFlame Retardant PolyesterSENTHIL KUMAR100% (2)

- Introduction To Fire Dynamics For Structural Engineers: by DR Guillermo ReinДокумент103 страницыIntroduction To Fire Dynamics For Structural Engineers: by DR Guillermo ReinPamela Hancock80% (5)

- GAS QUALITY Methane Number Calculation 2012-04-04Документ4 страницыGAS QUALITY Methane Number Calculation 2012-04-04Gabriel BerrioОценок пока нет

- Firefly Pellet Solutions en 3.0Документ9 страницFirefly Pellet Solutions en 3.0Anghel DumitriuОценок пока нет

- Diesel Engien 325 CCДокумент7 страницDiesel Engien 325 CCSachinОценок пока нет

- CHP 1-3 PDFДокумент94 страницыCHP 1-3 PDFvsudarsanОценок пока нет

- Typical Flare PackageДокумент5 страницTypical Flare PackageRahmat RiskiОценок пока нет

- How Hovercrafts WorkДокумент10 страницHow Hovercrafts WorkHarish VermaОценок пока нет

- Boiller Types Sabic PDFДокумент40 страницBoiller Types Sabic PDFMuhammad Hamza NaveedОценок пока нет

- IT38G Fuel SitemaДокумент24 страницыIT38G Fuel Sitemavitor santosОценок пока нет

- Design and Fabrication of Hydro Tech Water Fuel Saver Kit: Kolbe Joy, Jithin Raj, Ijas K, Adarsh Babu, Rajamani.BДокумент6 страницDesign and Fabrication of Hydro Tech Water Fuel Saver Kit: Kolbe Joy, Jithin Raj, Ijas K, Adarsh Babu, Rajamani.BgonekatОценок пока нет

- 8 3 Types of Reactions 4th EdДокумент21 страница8 3 Types of Reactions 4th EdDaffa FachrurОценок пока нет

- Wartsila Training Material - PouloДокумент1 085 страницWartsila Training Material - PouloMoji LarkiОценок пока нет

- DeHaan, John D., Icove, David J., Kirk's Fire Investigation, 7a Ed. 2013, John Wiley & Sons. Inc., BerkeleyДокумент800 страницDeHaan, John D., Icove, David J., Kirk's Fire Investigation, 7a Ed. 2013, John Wiley & Sons. Inc., BerkeleyPaulina100% (3)

- ECOFLAM Product Range 2018 ENG PDFДокумент28 страницECOFLAM Product Range 2018 ENG PDFramaОценок пока нет

- Novarossi Rex 57 Carburetor Setting and TIPSДокумент3 страницыNovarossi Rex 57 Carburetor Setting and TIPSchainman_Оценок пока нет

- 8 Appleton ATX Hazardous Locations Guide EnglishДокумент59 страниц8 Appleton ATX Hazardous Locations Guide Englishamirhosseine00Оценок пока нет

- Ongc Project ReportДокумент16 страницOngc Project ReportChitraParialОценок пока нет

- Reliable Blocked Flue Wall Detection For EnhancedДокумент4 страницыReliable Blocked Flue Wall Detection For EnhancedDebashis DashОценок пока нет

- Gas TurbineДокумент6 страницGas TurbineShashank SrivastavaОценок пока нет

- Wartsila o e W 50df TRДокумент16 страницWartsila o e W 50df TRNoel MejiaОценок пока нет

- Cap Defense 2019Документ59 страницCap Defense 2019Pransis Mason100% (1)

- GEA Imaforni Bakery Ovens Brochure - tcm11 77238Документ24 страницыGEA Imaforni Bakery Ovens Brochure - tcm11 77238Carlos NeyОценок пока нет