Академический Документы

Профессиональный Документы

Культура Документы

MEMS (Scaling)

Загружено:

Nasir AlfarajИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MEMS (Scaling)

Загружено:

Nasir AlfarajАвторское право:

Доступные форматы

Lecture

2:

Scaling

Eects

Ian

Foulds,

PhD

Assistant

Professor

of

Electrical

Engineering

King

Abdullah

University

of

Science

and

Technology

(KAUST)

KAUST - King Abdullah University of Science and Technology

Scaling

Laws

Scaling

laws

can

be

used

to

answer

the

quesGon

of

Why

go

small?

They

allow

us

to

determine

whether

physical

phenomena

will

scale

more

favorably

or

will

scale

poorly.

Because

the

natural

laws

scale

dierently

your

natural

intuiGon

will

fail

you

in

microsystems

design

and

you

need

to

develop

a

microscale-

intuiGon.

KAUST - King Abdullah University of Science and Technology

Scaling

Laws

Generally,

smaller

things

are

less

aected

by

volume

dependent

phenomena

such

as

mass

and

inerGa,

and

are

more

aected

by

surface

area

dependent

phenomena

such

as

contact

forces

or

heat

transfer.

FricGon

>

InerGa

Heat

DissipaGon

>

Heat

Storage

ElectrostaGc

Force

>

MagneGc

Force

KAUST - King Abdullah University of Science and Technology

Scaling

volume/surface

area

raGo

Example

1:

A

cube

of

material:

a

a

Surface Area for a cube = 6a2

Volume for a cube = a3

As we scale down, the value for volume will

decrease more rapidly than the value for surface

area. In other words, the volume/surface area

raGo will decrease.

KAUST - King Abdullah University of Science and Technology

Scaling

volume/surface

area

raGo

Assume

a

=

10

units

For

a

=

10:

S.A.

(surface

area)

V

(volume)

!

= 10"10" 6 = 600units2

= 10"10"10 = 1000units3

Therefore, the raGo

of

!

volume

V 1000 10

=

=

=

surface _ area S.A. 600 6

Assume

a

=

1

unit:

S.A.

(surface

area)

!

V

(volume)

= 1"1" 6 = 6units2

= 1"1"1 = 1units3

!

Therefore,

the

raGo

!

V

1

=

S.A. 6

KAUST - King Abdullah University of Science and Technology

Scaling

volume/surface

area

raGo

Assume

a

=

0.1

unit:

S.A.

(surface

area)

V

(volume)

!

Therefore, the raGo

!

= 0.1" 0.1" 6 = 0.06units2

= 0.1" 0.1" 0.1 = 0.001units3

V

1

=

S.A. 60

!

What

is

the

signicance

of

this?

V

a"a"a a

=

=

S.A. a " a " 6 6

" a#

Consider heat storage vs. heat dissipaGon.

!

heat storage is proporGonal to volume

!

heat dissipaGon is proporGonal to surface

area

V

#

S.A.

KAUST - King Abdullah University of Science and Technology

Scaling

volume/surface

area

raGo

-Given

three

cubes

of

dierent

sizes

a

=

10,

1

and

0.1,

with

all

other

properGes

the

same,

consider

the

rate

of

cooling.

-Assume

that

all

cubes

start

at

the

same

high

temperature,

and

are

allowed

to

cool

to

the

same

low

temperature.

-The

total

heat

contained

in

the

smallest

cube

is

1,000,000

Gmes

less

than

the

large

cube.

-The

total

surface

area

(heat

dissipaGon

area)

of

the

smallest

cube

is

only

10,000

Gmes

less

than

the

large

cube.

-Therefore,

there

is

100

Gmes

more

heat

dissipaGon,

per

unit

volume,

in

the

smallest

cube.

In

other

words,

it

will

cool

at

a

much

faster

rate,

even

though

all

other

condiGons

are

the

same

for

all

cubes.

KAUST - King Abdullah University of Science and Technology

Scaling

-

Stress

Example

2:

Stress

in

a

rod

connected

to

a

mass

experiencing

a

constant

acceleraGon.

How

is

the

stress

related

to

the

scale?

a

-

acceleraGon

r - radius

Mass

h

l

KAUST - King Abdullah University of Science and Technology

a - acceleraGon

SoluGon:

Step

1:

Derive

governing

equaGon.

F

" =

A

(Tensile

Stress)

where

=

stress,

F

=

force,

A

=

area

Mass

h

l

F

=

ma

(Newtons

Second

Law)

!

where

m

=

mass,

a

=

acceleraGon

-assume

mass

of

rod

is

negligible.

!

total

mass

m = lwh!

Therefore,

total

force

acGng

on

rod

is:

r - radius

F = lwh! a

KAUST - King Abdullah University of Science and Technology

10

Scaling

-

Stress

a

-

acceleraGon

r - radius

Total cross-secGonal area of rod:

A = "r 2

Therefore, the governing equaGon is:

!

"=

Mass

lwh#a

$r 2

h

l

Step 2: IdenGfy all parameters related to length.

-these are: l, w, h, r

!

Step 3: Redene length related parameters.

l = L, w = dL, h = eL, r = fL

KAUST - King Abdullah University of Science and Technology

11

Scaling

-

Stress

a

-

acceleraGon

L # dL # eL # $ # a

"=

%f 2 L2

% de#a ( L3

"='

2 * 2

& $f ) L

" = CL

!

r - radius

Mass

h

l

KAUST - King Abdullah University of Science and Technology

12

Scaling Natural World

Land

^

[Madou]

KAUST - King Abdullah University of Science and Technology

Scaling - Resonant Frequency and Q

Factor

13

Example 3: How does scaling eect the

resonant frequency and Q factor of a

canGlever.

L

t

w

1

f0 =

2"

k

m

3EI

k= 3

L

KAUST - King Abdullah University of Science and Technology

14

Scaling - Resonant Frequency and

Q Factor

L

wt

I=

12

t

w

m = Lwt"

1

f0 =

2"

k

1

=

m 2"

3EI

1

=

3

mL

2"

Ewt

t

=

3

2

4mL

4 "L

E

#

KAUST - King Abdullah University of Science and Technology

Scaling - Resonant Frequency and

Q Factor

Take three canGlevers, one of each

meso, micro and nano scale:

C1 - 100 mm x 10 mm x 10 mm

C2 - 100 m x 10 m x 10 m

C3 - 100 nm x 10 nm x 10 nm

All 3 made of single crystal silicon E = 169 GPa, 2330 kg/m3.

C1 - f0 = 678 Hz

C2 - f0 = 678 kHz

C3 - f0 = 678 MHz

15

t

w

KAUST - King Abdullah University of Science and Technology

Scaling - Resonant Frequency and

Q Factor

Quality factor is the raGo of stored

energy, over lost energy:

m

Q = "0

b

16

L

t

w

Q factor as function of air pressure for

torsion mirror.

where b is the damping factor.

Heavily aected by the damping factor,

so many devices are vacuum packaged

to reduce damping.

A.K.Pandey, R.Pratap and F.S.Chau [2008]

KAUST - King Abdullah University of Science and Technology

Scaling - Resonant Frequency and

Q Factor

When canGlevers begin to reach

into the Nano scale they begin to

be in the size order as the mean

free path of air. As a result, the

Q-Factor becomes less sensiGve

to pressure.

Mo Li, H. X. Tang & M. L. Roukes [2007]

17

KAUST - King Abdullah University of Science and Technology

18

Scaling

-

Buoyancy

Example

4:

What

is

the

eect

of

scale,

on

the

buoyancy

force

fb

of

a

sphere,

submersed

in

a

liquid?

-

Note:

fb

=

(volume

displaced)

x

(density

of

uid)

x

g

-

Volume

of

a

sphere

V=

-Therefore:

!

-Therefore:

!

4 3

"r

3

4 3

fb = "r #g

3

fb =

4

" (aL )3 #g

3

fb = CL3 ,

where

C=

4 3

"a #g

3

fb $ L3

Drag

force

is

L2

.

What

aect

does

bubble

size

have

on

the

balance

between

buoyancy

and

drag

forces?

What

moves

faster

a

big

or

litle

bubble?

KAUST - King Abdullah University of Science and Technology

19

Reynolds

Number

The

dimensionless

Reynolds

number

Re

represents

raGo

of

inerGal

to

viscous

forces

(drag):

"vd

Re =

-

uid

density

v

-

uid

velocity

D

-

characterisGc

object

length

or

diameter

-

uid

viscosity

Flow regimes

Micro Fluidic Example:

v = 1mm/s

d = 100 m

air =/= 1 10-6 m2/s

water =/= 15 10-6 m2/s

Reair = 0.01

Rewater = 0.1

Re<<1: laminar ow, following smooth streamlines

MEMS regime Viscous forces dominate and inerGal forces can be neglected

Re < 2300: laminar ow

Re > 2300: turbulent ow, complex eddies

KAUST - King Abdullah University of Science and Technology

20

Laminar Flow and Diusion

" = 2Dx

where is the diusion Gme for a

distance x, and D is the diusion

constant.

A molecule can diuse 1 m a million

Gmes faster than 1 mm

Lb et al. 2004

KAUST - King Abdullah University of Science and Technology

21

Surface

Tension

Liquids

want

to

minimize

surface

energy.

Scales

linearly

with

decreasing

size

so

it

becomes

very

strong

in

microsystems.

Can

damage/sGck

down

structures

during

release.

Can

be

used

for

assembly.

Syms group, !

Imperial College!

Bright group, Univ. of Colorado!

KAUST - King Abdullah University of Science and Technology

SGcGon

MEMS

tend

to

be

quite

at

and

smooth,

which

combined

with

the

increased

signicance

of

surface

area

forces

can

lead

to

what

is

commonly

called

sGcGon.

SGcGon

-

occurs

when

a

microstructure

gets

stuck

to

the

substrate

due

to

surface

adhesion

forces

being

greater

than

the

mechanical

restoring

force

of

the

micro-structure.

There are a number of forces involved in sGcGon.

Capillary forces

Van der Waals Force

Non-bond related intermolecular forces

Hydrogen bonding

AtracGve interacGon of a hydrogen atom with an electronegaGve

atom

ElectrostaGc atracGon

22

KAUST - King Abdullah University of Science and Technology

SGcGon

During

drying

a{er

release,

surface

tension

can

cause

parts

to

deform.

The

parts

can

then

become

permanently

stuck

to

the

surface

of

the

substrate

due

to

sGcGon.

23

KAUST - King Abdullah University of Science and Technology

SGcGon

For

in-use

sGcGon

various

surface

treatments

have

been

developed

to

reduce

the

occurrence

of

sGcGon.

Self

Assembled

Monolayers

(SAMs),

uorocarbon

coaGngs(teon)

and

diamond

like

carbon

coaGngs.

SoluGons

to

post

release

sGcGon

exist

in

the

forms

of

vapor

phase

etching

or

more

commonly

criGcal

point

drying.

Vapor

Phase

Etching

Etching

of

the

sacricial

layer

using

dry

gas

phase

etchants.

Our

nanofabricaGon

facility

will

be

equipped

with

a

vapor

phase

HF

for

etching

oxide,

as

well

as

a

XeF2

etcher

for

vapor

phase

etching

of

silicon.

CriGcal point drying

release soluGon is displaced by supercriGcal CO2, which transiGons

directly to gas and does not show surface tension eects.

24

KAUST - King Abdullah University of Science and Technology

25

Nano

Scaling

Beyond

the

microscale

many

properGes

of

materials

begin

to

change

once

the

nano

regime

is

reached.

Cataloguing

and

nding

ways

to

exploit

these

new

properGes

is

a

new

and

hot

area

of

research.

Youngs Modulus of Nitride CanGlevers

MelGng point of Gold NanoparGcles

Buat et al. 1975

Gavan et al. 2009

KAUST - King Abdullah University of Science and Technology

Conclusion

26

Вам также может понравиться

- John W. Mitchell, James E. Braun - Principles of Heating, Ventilation, and Air Conditioning in Buildings 1st Edition (2012, Wiley) - Libgen - LiДокумент627 страницJohn W. Mitchell, James E. Braun - Principles of Heating, Ventilation, and Air Conditioning in Buildings 1st Edition (2012, Wiley) - Libgen - LiabhijeetОценок пока нет

- Investigation of MotionsДокумент17 страницInvestigation of MotionsIzi MuhОценок пока нет

- The Effect of Pitch Radius of Gyration On Sailing Yacht PerformanceДокумент10 страницThe Effect of Pitch Radius of Gyration On Sailing Yacht PerformanceMerlin4SCОценок пока нет

- V-Notch ExperimentДокумент5 страницV-Notch ExperimentKheshav Jhundoo100% (2)

- 22 Metallic Glasses, Dr. T. HufnagelДокумент30 страниц22 Metallic Glasses, Dr. T. HufnagelSam AkinaОценок пока нет

- Unit Operations of Chemical Engineering - McCabe and Smith PDFДокумент1 154 страницыUnit Operations of Chemical Engineering - McCabe and Smith PDFRuel Arila Jr.91% (67)

- MSMPR Crystallization ModelДокумент12 страницMSMPR Crystallization ModelAbou Tebba SamОценок пока нет

- The Geiger-Mueller Tube, Nuclear Electronics, and Counting StatisticsДокумент4 страницыThe Geiger-Mueller Tube, Nuclear Electronics, and Counting StatisticsWalimatul FitriyahОценок пока нет

- Reza Taghipour, Professor Torgeir MoanДокумент16 страницReza Taghipour, Professor Torgeir MoansegomezpОценок пока нет

- DownloadfileДокумент22 страницыDownloadfilePvsksk SravanОценок пока нет

- Foundatin of Engeneering 2Документ16 страницFoundatin of Engeneering 2sunshaniОценок пока нет

- CharginganddischargingДокумент19 страницCharginganddischargingac0471007Оценок пока нет

- Accurate Computation of Wave Loads On A Bottom Fixed Circular CylinderДокумент4 страницыAccurate Computation of Wave Loads On A Bottom Fixed Circular CylinderTrần Văn CườngОценок пока нет

- Combined Flux Compression and Plasma Opening Switch On The Saturn Pulsed Power GeneratorДокумент4 страницыCombined Flux Compression and Plasma Opening Switch On The Saturn Pulsed Power GeneratorAnonymous b2k9ABe7eОценок пока нет

- Lab 202 - Numerical Verification of Guass's LawДокумент4 страницыLab 202 - Numerical Verification of Guass's LawSamuel Chandru VasudevanОценок пока нет

- Kendriya VidyalayaДокумент21 страницаKendriya Vidyalayahamdanharish7Оценок пока нет

- Numerical Simulation For Droplets Formation Due To Breaking WaveДокумент22 страницыNumerical Simulation For Droplets Formation Due To Breaking WaveTung DangОценок пока нет

- E1 03 PDFДокумент8 страницE1 03 PDFreza515heiОценок пока нет

- Villa L Pando 2011Документ9 страницVilla L Pando 2011Isa JanabaiОценок пока нет

- Slip Flow McVeighДокумент8 страницSlip Flow McVeighTubaguts1234Оценок пока нет

- Keynote Lecture: Technology of Pile Dynamic Testing: E. HoleymanДокумент21 страницаKeynote Lecture: Technology of Pile Dynamic Testing: E. Holeymanhasantha fonsekaОценок пока нет

- A Safe and Effective Modification of Thomson's Jumping Ring ExperimentДокумент11 страницA Safe and Effective Modification of Thomson's Jumping Ring ExperimentJames YoungОценок пока нет

- Reed S Volume 4 Naval Architecture For MДокумент398 страницReed S Volume 4 Naval Architecture For MKarina PingarilhoОценок пока нет

- Park - Optimal Hatch Filter With An Adaptive Smoothing Window WidthДокумент20 страницPark - Optimal Hatch Filter With An Adaptive Smoothing Window Widthmlytvyn1Оценок пока нет

- Jmse 02 00477 PDFДокумент16 страницJmse 02 00477 PDFCristian BasoaltoОценок пока нет

- Cambridge International AS and A Level Physics (9702) : Practical Booklet 7Документ8 страницCambridge International AS and A Level Physics (9702) : Practical Booklet 7BoedisantosoОценок пока нет

- Cse Physics Lab ManualДокумент83 страницыCse Physics Lab Manualbalajichakilam2012100% (1)

- 2013 Iepc PolkДокумент24 страницы2013 Iepc PolkmgОценок пока нет

- Calculation of Slowly Varying Drift ForcesДокумент4 страницыCalculation of Slowly Varying Drift Forcesmohdsolihat1Оценок пока нет

- Scaling Laws in Miniaturization: Lectures On MEMS and Microsystems Design and ManufactureДокумент22 страницыScaling Laws in Miniaturization: Lectures On MEMS and Microsystems Design and ManufactureDharshan Kofi100% (1)

- Thermodynamics: P K Nag Exercise Problems - SolvedДокумент10 страницThermodynamics: P K Nag Exercise Problems - Solvedhirenpatel_universalОценок пока нет

- Castro, Domingo, Ofina Written ReportДокумент3 страницыCastro, Domingo, Ofina Written ReportMarc CastroОценок пока нет

- Energy Loss of A High Charge Bunched Electron Beam in Plasma: Simulations, Scaling, and Accelerating WakefieldsДокумент11 страницEnergy Loss of A High Charge Bunched Electron Beam in Plasma: Simulations, Scaling, and Accelerating WakefieldsParticle Beam Physics LabОценок пока нет

- Heaving Body Draft InfluenceДокумент8 страницHeaving Body Draft InfluenceDomenico CoiroОценок пока нет

- Taj Mar 2015Документ10 страницTaj Mar 2015JonasMeyer-OhleОценок пока нет

- Direct Thrust Measurements of An EM Drive and Evaluation of Possible Side-EffectsДокумент10 страницDirect Thrust Measurements of An EM Drive and Evaluation of Possible Side-EffectsTimothy GonzalezОценок пока нет

- Lab 3 - CIVL 3720Документ16 страницLab 3 - CIVL 3720Jun KangОценок пока нет

- Resonancia SubsincronaДокумент16 страницResonancia SubsincronaSheyla Elizabeth Santamaria RoqueОценок пока нет

- Development of Turbulence Models For Shear Flows BДокумент28 страницDevelopment of Turbulence Models For Shear Flows BHelen ChoiОценок пока нет

- Numerical Study of Gas-Solid Flow in A Cyclone Separator: B. Wang, D. L. Xu, G. X. Xiao, K. W. Chu and A. B. YUДокумент6 страницNumerical Study of Gas-Solid Flow in A Cyclone Separator: B. Wang, D. L. Xu, G. X. Xiao, K. W. Chu and A. B. YUAzharuddin Ehtesham FarooquiОценок пока нет

- Experiment No. 6 To Determine The Time Constant of An RC Circuit. 6.1 ObjectivesДокумент5 страницExperiment No. 6 To Determine The Time Constant of An RC Circuit. 6.1 Objectivesf wОценок пока нет

- Hot Wire SynjetДокумент8 страницHot Wire SynjetDaniel SilvaОценок пока нет

- Cold Atom ThesisДокумент5 страницCold Atom ThesisBuyCheapPapersMiramar100% (2)

- Physics Project FileДокумент17 страницPhysics Project FileKunal SagarОценок пока нет

- Cavity Meas ByrdДокумент15 страницCavity Meas ByrdGoji SabaОценок пока нет

- Reeds NaДокумент398 страницReeds Nanisar ahmedОценок пока нет

- Time Domain Simulation of Jack-Up Dynamics Witli The Extremes of A Gaussian ProcessДокумент5 страницTime Domain Simulation of Jack-Up Dynamics Witli The Extremes of A Gaussian ProcessMoe LattОценок пока нет

- Units and Conversion Factors: E.J. Roschke Propulsion Division Jet Propulsion LaboratoryДокумент30 страницUnits and Conversion Factors: E.J. Roschke Propulsion Division Jet Propulsion LaboratoryanaazizОценок пока нет

- Haynes Shockly Experiment LabДокумент7 страницHaynes Shockly Experiment LabweetardОценок пока нет

- Barov 2002 0505Документ10 страницBarov 2002 0505Particle Beam Physics LabОценок пока нет

- Outline: Energy Transport: Radiative Equilibrium and ConvectionДокумент27 страницOutline: Energy Transport: Radiative Equilibrium and ConvectionAndie AcostaОценок пока нет

- Factors For One Sided Tolerance Limits and Variables Sampling PlansДокумент25 страницFactors For One Sided Tolerance Limits and Variables Sampling PlansMartin FauteuxОценок пока нет

- State-Space Realization of The Wave-Radiation Force Within FastДокумент14 страницState-Space Realization of The Wave-Radiation Force Within FastjamilОценок пока нет

- Underwater Floating Buoyant Based Ocean Wave Power Generation PlantДокумент12 страницUnderwater Floating Buoyant Based Ocean Wave Power Generation Plantkshitu gargОценок пока нет

- Hooke's LawДокумент5 страницHooke's LawVikash Kumar SinghОценок пока нет

- UBC Liquefaction Prediction ProjectДокумент11 страницUBC Liquefaction Prediction ProjectpkОценок пока нет

- Exp 6, Determination of Impact Against A Flat, Curve and Semispherical SurfaceДокумент6 страницExp 6, Determination of Impact Against A Flat, Curve and Semispherical SurfaceWasi Uddin MahmudОценок пока нет

- Technical Note: Nasa TM D eДокумент43 страницыTechnical Note: Nasa TM D eSenad SmakaОценок пока нет

- Numerical Study of Water Mitigation Effects On Blast Wave: K. C. Hung O. Y. ChongДокумент7 страницNumerical Study of Water Mitigation Effects On Blast Wave: K. C. Hung O. Y. ChongezedinОценок пока нет

- Fedsm2017 69175Документ10 страницFedsm2017 69175datam38Оценок пока нет

- Numerical Simulation of Cavity Flow Induced Noise: by LES and FW-H Acoustic AnalogyДокумент6 страницNumerical Simulation of Cavity Flow Induced Noise: by LES and FW-H Acoustic AnalogyprotonozОценок пока нет

- Air Flow Test of Filter'sДокумент2 страницыAir Flow Test of Filter'sArun GuptaОценок пока нет

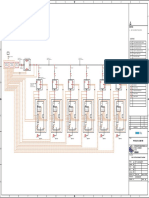

- Fuel System Schematic DiagramДокумент1 страницаFuel System Schematic DiagramAbhilash100% (1)

- Von Karman FlowДокумент5 страницVon Karman FlowAhmed LamineОценок пока нет

- HDPE Pipes Fittings PDFДокумент56 страницHDPE Pipes Fittings PDFInthees RagavanОценок пока нет

- Jkl-m L型无电软水阀系列-2023.5.9 EngДокумент35 страницJkl-m L型无电软水阀系列-2023.5.9 Engbig lasagnaОценок пока нет

- Design and Optimization of The Methanolto-Olefin Process Part IДокумент12 страницDesign and Optimization of The Methanolto-Olefin Process Part IForcus onОценок пока нет

- Module 3 - Basic Components of AFSS2Документ103 страницыModule 3 - Basic Components of AFSS2Justin EvangelistaОценок пока нет

- ConsolidationДокумент17 страницConsolidationthak49100% (1)

- AcousticsДокумент5 страницAcousticsarchi042Оценок пока нет

- DBS Bookletpagewithoutprice - WhatsappДокумент76 страницDBS Bookletpagewithoutprice - WhatsappShaik MunawarОценок пока нет

- Heat Transfer 2013 2014 PDFДокумент4 страницыHeat Transfer 2013 2014 PDFrajkumar rОценок пока нет

- Air Cooled Condenser ACC PDFДокумент3 страницыAir Cooled Condenser ACC PDFHoney TiwariОценок пока нет

- Making Them Work: Primary-Secondary Chilled Water SystemsДокумент9 страницMaking Them Work: Primary-Secondary Chilled Water Systemspsn_kylmОценок пока нет

- Shear Strength of SoilДокумент7 страницShear Strength of SoilRenz PagcaliwaganОценок пока нет

- Steam HammeringДокумент5 страницSteam HammeringMuhammad JunaidОценок пока нет

- 2nd-Fahu-02 SPCДокумент1 страница2nd-Fahu-02 SPCMohammad IsmailОценок пока нет

- XCPC CilindrosДокумент3 страницыXCPC CilindrosAngel ArteagaОценок пока нет

- Incomp Comp CombustionДокумент3 страницыIncomp Comp CombustionAbby SevillaОценок пока нет

- Tomas de Fondo 2Документ2 страницыTomas de Fondo 2alfredoОценок пока нет

- SHEET1 - Pipe Friction - 2023-2024Документ2 страницыSHEET1 - Pipe Friction - 2023-2024pyoussef109Оценок пока нет

- Pressurized Fluid Extractions: Factors Affecting An Extraction ProcessДокумент21 страницаPressurized Fluid Extractions: Factors Affecting An Extraction ProcessVRUSHABHОценок пока нет

- OF TO: Oxidation Acetaldehyde Acetic Acid In1 A Sparger ReactorДокумент8 страницOF TO: Oxidation Acetaldehyde Acetic Acid In1 A Sparger Reactorarpit gargОценок пока нет

- EATONДокумент24 страницыEATONAli Tavakoli NiaОценок пока нет

- Module 5 WearДокумент23 страницыModule 5 WearrohanОценок пока нет

- IOSДокумент3 страницыIOSEsteban Constantino Cruz100% (1)