Академический Документы

Профессиональный Документы

Культура Документы

WPS Gmaw

Загружено:

asikurОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WPS Gmaw

Загружено:

asikurАвторское право:

Доступные форматы

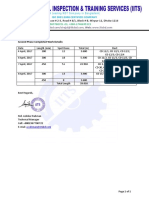

ISO 9OO1:2OO8 Certified Company

Head Office: flouse-2-3, Road-8/l, Block-8, Mirpur-L2, Dhaka-1216

Contact: M +88 0196770072L/+88 0174669531 88 0L96770O7221+88 01967700723

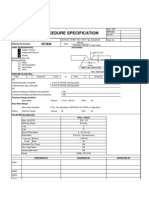

Welding Procedure Specification {WPSI

ASME 83L.3 & ASME Section lX

!niiovatinE safetg

BSRM

Company Narne

B5 RM -SAPCDS-AL-Vf F5.OZ

Welding Procedure Specification {WPSI No.

Supporting PQR No.

GMAW

Welding Process

3.i28iLufi

Date

00

Revision Na.

IITS

By

BsRM.SAPCDS-AL-PQR{z

Serni-Autometic

Types

All ASME Joints Design. Example for Joint Details

JOTNTS {QW-402}

7co

(tsci

7oo (tSDi

BASE METAL

PNo

NA

Group No"

2L

tqW - 4O3)

To

Base Metal Specification

AA 3105 M; Aluminium 3000 series

Base Metal Thickness

Actual Specimen

Range {mrn.}

Qualified

No.

2t

Group No.

10 mm

6 mrn to 20 mrn

NA

Fillet

None

Fitlet

All

Maxinnu!'n pass thickness < 3.4jmm

Other

(aw

Spec No" iSFA No)

AWS No. (Class)

5356

ER

23

F.No-

NA

A" No.

of Filler Metals

Filler Metal Product From

Filler Metal Form

1.6

Size

Esa

Weld

Groove

Thk.

Fillet

/ 2"4

blLin de/Llncal nl Hyu n da ilBoh ler

MIG Filler Wire ftoll

N/A

Supplirnental Filler Metal

Metal

Range

- 4t!41

5.1

+''

: -s -

t-L.g8 mrR rnax.

1i

tr^F

-/Jlnlimited

JT

Electrode Flux Class

lux Type

N/A

Flux Trade Name

N/A

CenssuRrabie Insert

rr /r

I\I/A

Other

NIA

Prepared by

Approved by

Revlewed by

'Ol

BSftM-PR-QC-02-01; REV. 00

Cl D(P. 1U1nA17

F*ge

3.

*f E

ISO 9OO1: 2OO8 Certified Cornpany

Head Office: Ilouse-2-3, Road-8/l, Block-B, Mirpur-Lz, Dhaka-L2l6

contact: M +8E 01967700721/+88 01746695315/+ 8E OA967700722t+88 01967700723

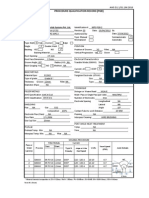

Weldins Procedure Specification (WPS)

HSRM

ASME Section

Di QW-48,L

inftsvating s*fetg

BSRM

Cornpany Narne

I

L4leiciing l:roceciure Specification tWPSi No.

sR

Supporting PQR No"

GMAW

Ht'elding Process

up

Position (s) of Fillet

All

Down

ffil

il

100

3000

(EW - 4O7}

N/A

N/A

Others

N/A

T-Limits

NIA

GAS

Preheat Ternp., Minimum

--

BSRM-5APCDS-AL-PQR-G2

Time Range

{qW - 406}

tnterpass Temp., Maximum

rulr

f 4

Semi-Autometic

Ternperature Range

All

(qw

- 4o8)

Percent Composition

Gas

C Maximurn

10o C Maximum

Shielding

Other

N/A

Trailling

Decrease > 1000 r

N/A

Preheat Maintenance

POST WELD HEAT TREATMENTS

Weiding Progression

PREHEAT

Types

POSTilON {qW - 40s}

Position {s} of Groove

t*

u 2w

-

Date

00

Eevision No.

IITS

By

M -5APe DS-AL-W P5-02

(es) i Mixture

Argon |

99%

Backing

Other

Electrical Clraracteristics tqW - 409)

Weld Passes

ftoot

* {-.!

f-lut

Frocess

Filler Metal

Filler Metal

Amps

Volts

Travel Speed

Wire feed

Classification

Diarneter

(Range)

{Range}

IPM

speed ilPM)

5356

rD

rara

LI\ JJ*}L,

1.2 rnm

1s-25

2-8

50-80

.t 1 *-*

I.a ! rll ll

ULE.I.

r{lA

-I-5-Lb

10

&'o

rn

GMAW

Pass

n--rd55

ER

u wIAVV

^rIlrU

DCEP

7G1"05

N/A

y.v-Ltu

rr /

AA

4 AA

rul

N/A

frn

:,U.$U

Filling

GMAW

ER

5356

L.2 mm

DCEP

100-140

N/A

NIA

15-29

2-8

50-80

Capping

GMA\frI

ER

5356

L.2 rnnr

DCEP

100-L50

N/A

N1A

L4-29

2-8

50-80

Heat lnput

Pulsing Current

Pulse MIG

Tungsten Electrode Type & Size

2%Thorieated; 1.6 rnrn X L75 mm to 2.4 mm X 775 mno

Mode of Metal Transfer for GMAW

/ FCAW

Other

TECHNIQUE

String on Weave

size

cleanins

of back gouging

,

lnitial and lnteroass

Method

Contact tube to work

GMAW

NIA

.distance

'

:_

: Droplet sizes

: I - 12 rnm

: Brushing / Glindpg {Gr!!4lng_d:trAgal9-b.ushes

: Diamond Grinder

'

ilfiuitiple or Single Pass tPer Side)

Multiple or Single Electrode

flectnode

must be suitable fer Al qnly.

N/A

Multiple or As Required

Single

Spacing

Peening

N/A

None

Others

Backing gas shall remain until Znd pass {Hotpass} completed

Manual / Automatic

Serni-Autometic

Use +f Therrnal

1.5 KJlSec"

tqW - 410)

bead

Oi"ifice, Nozzle or gas cup

(Max) ;

Process

' _U{

Appr+l,eC by

BSRM-PR-QC-0L-42; REV. 00

Page 2 af 7

Вам также может понравиться

- WPS 6G CS Pipe CorrectДокумент4 страницыWPS 6G CS Pipe CorrectAla ReguiiОценок пока нет

- CE ProblemДокумент5 страницCE ProblemJho FОценок пока нет

- Everything You Need to Know About Stainless Steel Welding Procedure SpecificationДокумент6 страницEverything You Need to Know About Stainless Steel Welding Procedure SpecificationDanem HalasОценок пока нет

- ASME IX Sample WPS GTAW SMAWДокумент1 страницаASME IX Sample WPS GTAW SMAWDeepak ShrivastavОценок пока нет

- WPS GTAW Stainless SteelДокумент2 страницыWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WPS MigДокумент3 страницыWPS MigAJOJOY00960% (5)

- WPS GTAW Stainless SteelДокумент4 страницыWPS GTAW Stainless SteelAnand NarayananОценок пока нет

- Loading Unloading Temperature Welding ProgressionДокумент5 страницLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- Moment Influence Line LabsheetДокумент12 страницMoment Influence Line LabsheetZAXОценок пока нет

- Welding Procedure Specification: Page 1 of 1Документ2 страницыWelding Procedure Specification: Page 1 of 1Harshad100% (1)

- WPS TITLEДокумент2 страницыWPS TITLERichard Periyanayagam86% (14)

- RT Film IntepretationДокумент44 страницыRT Film Intepretationawong_911374100% (3)

- Wps For Aluminium WeldingДокумент8 страницWps For Aluminium Weldingvishal bailur50% (2)

- Welding Procedure Specification For Storage Tank & Piping SystemДокумент3 страницыWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadОценок пока нет

- Super Duplex Stainless SteelДокумент1 страницаSuper Duplex Stainless SteelUma Shankar100% (1)

- Ownership and Governance of State Owned Enterprises A Compendium of National Practices 2021Документ104 страницыOwnership and Governance of State Owned Enterprises A Compendium of National Practices 2021Ary Surya PurnamaОценок пока нет

- WPS, PQR & WPQ - Duplex 2205Документ20 страницWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- Preliminary WPS for 12.7mm SMAW WeldingДокумент3 страницыPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- PQR SAW ProcessДокумент1 страницаPQR SAW Processdevendrasingh202133% (3)

- WPS For Structure Mild Steel Fillet Weld PDFДокумент2 страницыWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniОценок пока нет

- GTAW Welding Procedure SpecificationДокумент3 страницыGTAW Welding Procedure SpecificationVimin Prakash100% (1)

- WELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111Документ15 страницWELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111surya1960Оценок пока нет

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeДокумент6 страницWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberОценок пока нет

- Gauss MeterДокумент2 страницыGauss MeterasikurОценок пока нет

- PQRДокумент2 страницыPQRalokbdasОценок пока нет

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Документ6 страницMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajОценок пока нет

- Equipment For Tank InspectionДокумент1 страницаEquipment For Tank InspectionasikurОценок пока нет

- Equipment For Tank InspectionДокумент1 страницаEquipment For Tank InspectionasikurОценок пока нет

- Equipment For Tank InspectionДокумент1 страницаEquipment For Tank InspectionasikurОценок пока нет

- WPS 316 LДокумент4 страницыWPS 316 Llaz_k100% (2)

- Welding Procedure Specification For 24'' PipeДокумент2 страницыWelding Procedure Specification For 24'' Pipeenels77100% (1)

- WELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928Документ2 страницыWELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928duyanhОценок пока нет

- Welder Id SampleДокумент1 страницаWelder Id Sampledevendrasingh202157% (7)

- Welder Performance Qualification-Interactive Form QW-484AДокумент1 страницаWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- According To ASME IX: Welding Procedure Specification (W.P.S)Документ4 страницыAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehОценок пока нет

- WPS For Smaw06-001 (Pipe 6G CS)Документ10 страницWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- Wps p91 - BhelДокумент2 страницыWps p91 - BhelAshish Gupta100% (4)

- Welding Procedure SpecificationДокумент3 страницыWelding Procedure SpecificationAhmed saber100% (2)

- Smaw Wps FinalДокумент3 страницыSmaw Wps FinalsheikmoinОценок пока нет

- Page No: 01: SA 240 GR 304 SA 240 GR 304Документ5 страницPage No: 01: SA 240 GR 304 SA 240 GR 304jobertОценок пока нет

- WPS PQR A36.20Документ5 страницWPS PQR A36.20gchaves504100% (2)

- PQR Gmaw3gДокумент4 страницыPQR Gmaw3gdevendrasingh2021100% (3)

- Professional Builder - Agosto 2014Документ32 страницыProfessional Builder - Agosto 2014ValОценок пока нет

- Proposed WPSДокумент2 страницыProposed WPSChisom Ikengwu100% (2)

- Electrode Baking ProcedureДокумент3 страницыElectrode Baking ProcedureAkhilesh Kumar90% (10)

- WPS & PQRДокумент46 страницWPS & PQRJohn Candidate CIns88% (8)

- SS312 Type310Документ4 страницыSS312 Type310Vimin PrakashОценок пока нет

- Wps SawДокумент2 страницыWps Sawdevendrasingh2021100% (6)

- WPS Sitelca S002Документ2 страницыWPS Sitelca S002Jose Antonio GomezОценок пока нет

- 7 Tools for Continuous ImprovementДокумент202 страницы7 Tools for Continuous Improvementvivekanand bhartiОценок пока нет

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Документ5 страницWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Painting ProcedureДокумент62 страницыPainting Procedureasikur100% (3)

- 03 WPS PQR For FCAWДокумент3 страницы03 WPS PQR For FCAWBrijesh Yadav100% (1)

- Clad PQRДокумент5 страницClad PQRRinshadОценок пока нет

- WPS Sa 335 P91 PipeДокумент3 страницыWPS Sa 335 P91 Pipecsankarananth50% (2)

- Aws d1.1 WPS, PQR & WQTДокумент4 страницыAws d1.1 WPS, PQR & WQTWeld Bro SandeepОценок пока нет

- Procedure For Managing MSDS and LabelsДокумент6 страницProcedure For Managing MSDS and LabelsasikurОценок пока нет

- Gtaw WPQДокумент3 страницыGtaw WPQMuhammadShabbirОценок пока нет

- PQRДокумент2 страницыPQRSreenivas Kamachi Chettiar100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDДокумент5 страницWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedОценок пока нет

- Welding Procedure Specification For 24'' PipeДокумент2 страницыWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Toshiba Brazing Procedure SpecificationДокумент3 страницыToshiba Brazing Procedure Specificationsheikmoin100% (1)

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELДокумент4 страницыWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidОценок пока нет

- Wps Gmaw SawДокумент2 страницыWps Gmaw Sawupedro26Оценок пока нет

- Aws D1.1 - WPS - Smaw-Fcaw PDFДокумент1 страницаAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityОценок пока нет

- Fcaw 16 THKДокумент5 страницFcaw 16 THKparesh2387Оценок пока нет

- Welder Identification Card: Reference Code: ASME SEC IX Company Name - TESCOДокумент4 страницыWelder Identification Card: Reference Code: ASME SEC IX Company Name - TESCOibrahim100% (2)

- PT Kuwera Karya Me: PanduДокумент2 страницыPT Kuwera Karya Me: PanduGalang Pratama PutraОценок пока нет

- Des QC 8505 Ab 08Документ3 страницыDes QC 8505 Ab 08Touseef RafiqueОценок пока нет

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Документ1 страницаQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Оценок пока нет

- ASME Boiler and Pressure Vessel Code Welding Procedure SpecificationДокумент3 страницыASME Boiler and Pressure Vessel Code Welding Procedure SpecificationArupendranarayan ThakurОценок пока нет

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Документ1 страницаQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Оценок пока нет

- IITS SAFERAD PROCEDUREДокумент34 страницыIITS SAFERAD PROCEDUREasikurОценок пока нет

- RT RequestДокумент1 страницаRT RequestasikurОценок пока нет

- Industrial Inspection & Training Services (Iits) : Sensetivity: Din/Iso Pac DesignationДокумент1 страницаIndustrial Inspection & Training Services (Iits) : Sensetivity: Din/Iso Pac DesignationasikurОценок пока нет

- Notice - Late Return PenaltiesДокумент1 страницаNotice - Late Return PenaltiesasikurОценок пока нет

- 2nd Phase Work DetailsДокумент1 страница2nd Phase Work DetailsasikurОценок пока нет

- Car RentДокумент1 страницаCar RentasikurОценок пока нет

- Material dispatch details for WMSL projectДокумент1 страницаMaterial dispatch details for WMSL projectasikurОценок пока нет

- Material dispatch details for WMSL projectДокумент1 страницаMaterial dispatch details for WMSL projectasikurОценок пока нет

- WQTДокумент2 страницыWQTasikurОценок пока нет

- La Ko Sure Unsa NiДокумент3 страницыLa Ko Sure Unsa NiJeromeОценок пока нет

- Ii (Dustrial Inspecti I (A I-Eading NDT CornpanyДокумент2 страницыIi (Dustrial Inspecti I (A I-Eading NDT CornpanyasikurОценок пока нет

- SS ProcurementДокумент5 страницSS ProcurementasikurОценок пока нет

- DownfileДокумент3 страницыDownfileasikurОценок пока нет

- 003 IITS UT Procedure Rev. BДокумент21 страница003 IITS UT Procedure Rev. BasikurОценок пока нет

- Curriculam Vitae: Present & Mailing AddressДокумент5 страницCurriculam Vitae: Present & Mailing AddressasikurОценок пока нет

- Manage Community Harmony Chevron Facilities BibiyanaДокумент7 страницManage Community Harmony Chevron Facilities BibiyanaasikurОценок пока нет

- Azad Boiler PDFДокумент3 страницыAzad Boiler PDFasikurОценок пока нет

- 1 Ridoy CVДокумент4 страницы1 Ridoy CVasikurОценок пока нет

- MSDS (Material Safety Data Sheet) APPROVAL FORMДокумент1 страницаMSDS (Material Safety Data Sheet) APPROVAL FORMasikurОценок пока нет

- Cswip QДокумент6 страницCswip QasikurОценок пока нет

- Cswip QДокумент6 страницCswip QasikurОценок пока нет

- CA-Endevor Quick EditДокумент31 страницаCA-Endevor Quick Editmariela mmascelloniОценок пока нет

- Asian Studies For Filipinos The Philippines in The Asian CenturyДокумент15 страницAsian Studies For Filipinos The Philippines in The Asian CenturyGlaizza QuintonОценок пока нет

- 1651 EE-ES-2019-1015-R0 Load Flow PQ Capability (ENG)Документ62 страницы1651 EE-ES-2019-1015-R0 Load Flow PQ Capability (ENG)Alfonso GonzálezОценок пока нет

- Marketing Budget: Expenses Q1 Q2 Q3 Q4 Totals Budget %Документ20 страницMarketing Budget: Expenses Q1 Q2 Q3 Q4 Totals Budget %Miaow MiaowОценок пока нет

- Sample Interview Questions for Motivation, Communication, TeamsДокумент6 страницSample Interview Questions for Motivation, Communication, TeamsSahibzada Muhammad MubeenОценок пока нет

- Canna DispensariesДокумент35 страницCanna DispensariesWaf Etano100% (1)

- The Daily Tar Heel For September 18, 2012Документ8 страницThe Daily Tar Heel For September 18, 2012The Daily Tar HeelОценок пока нет

- Clustering Social Network GraphsДокумент12 страницClustering Social Network GraphsRáhùl SréédhãrОценок пока нет

- Filler SlabДокумент4 страницыFiller Slabthusiyanthanp100% (1)

- War, Rivalry An State Building in Latin AmericaДокумент16 страницWar, Rivalry An State Building in Latin AmericaPablo Andrés Garrido GonzálezОценок пока нет

- Anatomy 090819Документ30 страницAnatomy 090819Vaishnavi GourabathiniОценок пока нет

- Food Science, Technology & Nutitions - Woodhead - FoodДокумент64 страницыFood Science, Technology & Nutitions - Woodhead - FoodEduardo EstradaОценок пока нет

- Kanavos Pharmaceutical Distribution Chain 2007 PDFДокумент121 страницаKanavos Pharmaceutical Distribution Chain 2007 PDFJoao N Da SilvaОценок пока нет

- AD 251 - Equivalent Uniform Moment Factor, M (Italic)Документ1 страницаAD 251 - Equivalent Uniform Moment Factor, M (Italic)symon ellimacОценок пока нет

- STS Syllabus 2020Документ27 страницSTS Syllabus 2020AndreaDimaculangan100% (1)

- Videocon ProjectДокумент54 страницыVideocon ProjectDeepak AryaОценок пока нет

- OsmanabadДокумент5 страницOsmanabadKirankumar MutnaliОценок пока нет

- The Case of Ataraxia and Apraxia in The Development of Skeptic THДокумент11 страницThe Case of Ataraxia and Apraxia in The Development of Skeptic THeweОценок пока нет

- Echt Er Nacht 2014Документ8 страницEcht Er Nacht 2014JamesОценок пока нет

- Youre The Inspiration CRDДокумент3 страницыYoure The Inspiration CRDjonjammyОценок пока нет

- Beyond VaR OfficialДокумент76 страницBeyond VaR OfficialmaleckicoaОценок пока нет

- Rock Type Identification Flow Chart: Sedimentary SedimentaryДокумент8 страницRock Type Identification Flow Chart: Sedimentary Sedimentarymeletiou stamatiosОценок пока нет

- Rock Laboratory PricelistДокумент1 страницаRock Laboratory PricelistHerbakti Dimas PerdanaОценок пока нет

- Expt 1 Yarn Formation (Sherley Trash Analyser)Документ7 страницExpt 1 Yarn Formation (Sherley Trash Analyser)Yashdeep Sharma0% (1)

- 03 Seatwork 1 ProjectManagement SenisRachelДокумент2 страницы03 Seatwork 1 ProjectManagement SenisRachelRachel SenisОценок пока нет