Академический Документы

Профессиональный Документы

Культура Документы

Risk Assessment - Lifting Operations

Загружено:

Jishad NalakathАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Risk Assessment - Lifting Operations

Загружено:

Jishad NalakathАвторское право:

Доступные форматы

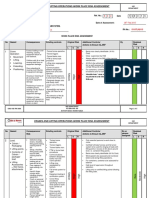

Form-104

Risk Assessment Form

Lifting Operations

Risk Assessment Title:

Risk Assessment

01

Revision:

Item

Rev. : 1

Hazard

Risk

Risk Rating

Who is at Risk

S

Necessary Control Measures

Action

By

Rating

Residual Risk

Rating

S

L

Rating

Plant

1

Personal risk of injury and / or ill health

Overturning,

Risk of Injury to the public

Supervisor

Operator

Labour- Public

Risk of damage to property and

equipment

2

Collision with

Structures or

mobile Plant

Personal risk of injury and / or ill health

Risk of Injury to the public

Supervisor

Operator

Labour - Public

Risk of damage to property and

equipment

Lack of

communication

Personal risk of injury and / or ill health

Risk of Injury to the public

Supervisor

Operator

-Labour

Risk of damage to property and

equipment

4

Unauthorized

Access

Personal risk of injury and / or ill health

Risk of Injury to the public

Supervisor

Operator

Labour -Public

Risk of damage to property and

equipment

5

Lifting near open

Trenching

Personal risk of injury and / or ill health

Risk of Injury to the public

HSE-001 Risk Assessment

Supervisor

Operator

Labour -Public

6

6

6

6

Only trained and authorised persons are permitted to operate the plant

Prior to setting up the operator and the designated banks man will assess

the ground conditions for stability to prevent subsidence.

The crane will be set up as close to the lift area as possible to avoid over

reaching.

The crane operator will not attempt to lift outside the specified crane

capacity

The load should always be Kept close to the ground

The crane operator should maintain a steady speed during the operation

Ground conditions : The crane company you have elected to use can give

you suitable words to the effect that the ground on which the cranes will

operate from are capable of supporting the weight of the cranes and load.

Crane outriggers will use ground mats and supporting grillages to provide

additional support.

Where possible an exclusion zone should be erected to segregate the

work area from other plant.

Setting up will be under the control of the banksman. The banksman

should ensure there is adequate space between the crane and any

structures and take into account the swing radius.

Before starting the crane operator shouldS carry out a trial run to ensure

there is adequate room.

All instructions to the excavator operator will be given by the banks man

(where possible this will be with the use of 2 way radios)

The crane operator will ensure that the plant is never left running or a load

suspended when he is not in attendance.

The operator will ensure the keys are removed and the cab doors locked

when he is on a break or at the end of his shift

Ensure suitable barriers are erected around the lift.

Ensure suitable warning signs are attached around the lift area.

Ensure a permit to lift is obtained. Ensure the load is fully braced before

lifting.

Supervi

sor

Operat

ors

Supervi

sor

Operat

ors

Supervi

sor

Operat

ors

Supervi

sor

Operat

ors

Supervi

sor

Operat

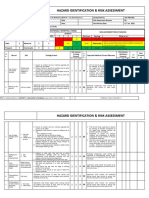

Form-104

Risk Assessment Form

Lifting Operations

Risk Assessment Title:

Risk Assessment

01

Revision:

Item

Rev. : 1

Hazard

Risk

Risk Rating

Who is at Risk

S

Necessary Control Measures

Action

By

Rating

Ensure all plant equipment remains at least 1 meter form the edge of the

open trenches.

Risk of damage to property and

equipment

Residual Risk

Rating

S

L

Rating

ors

Physical

1

Manual Handling

Manual Handling

Manual Handling

Manual Handling

Manual Handling

Manual Handling

Muscular / Skeletal Disorders

Slips, Trips and Falls

Crushing or Trapping

Stresses and Strains

Cuts and Abrasions

Personal Injury

Manual Handling

Public, Staff,

Labour

Labour

Labour

Labour

Labour

Labour

Over exertion

HSE-001 Risk Assessment

Labour

Ensure there is adequate information, instruction, training and supervision. Where

ever-possible use mechanical aids to reduce manual handling.

Ensure each lift is planned and assessed, avoid double handling of materials.

Ensure the route to be travelled is free from obstacles or hazards and has

adequate lighting.

Look at the individual and their capabilities (ensure they are capable of lifting or

moving the load). Assess the load for size, shape, weight, and stability before it is

moved. Never try to lift above your own capabilities.

Supervis

or &

Individual

s

Supervis

or &

Individual

s

Supervis

or &

Individual

s

1

3

When lifting the load carry out a test lift to ensure the load can be moved

comfortably, check for sharp edges (if required wear gloves to protect the hands).

Supervis

or &

Individual

s

When lifting the load carry out a test lift to ensure the load can be moved

comfortably, check for sharp edges (if required wear gloves to protect the hands).

Supervis

or &

Individual

s

6

6

If moving heavy or obscure loads use more than 1 person (one person should

give the lifting instruction). Ensure that the correct handling techniques are used

such as keeping the load close to the body, keep feet shoulder width apart, and

avoid twisting or stooping.

Avoid carrying heavy or obscure loads up or down stairs. Never carry heavy loads

up or down ladders.

Supervis

or &

Individual

s

Supervis

or &

Individual

3

3

Form-104

Risk Assessment Form

Lifting Operations

Risk Assessment Title:

Risk Assessment

01

Revision:

Item

Rev. : 1

Hazard

Risk

Risk Rating

Who is at Risk

S

Necessary Control Measures

Action

By

Rating

Residual Risk

Rating

S

L

Rating

Lifting

Failure of lifting equipment

1

Lifting

Lifting

Damage to lifting equipment

Lifting

Loss of load

Traffic

Public Access

HSE-001 Risk Assessment

Labour, Staff,

Public,

Operators

Labour,

Operators

Public,

Operators,

Labour

Public, Staff,

Labour

Ensure the correct type of lifting equipment is selected for the lift.

Ensure the load does not exceed the SWL of the equipment.

Do not lift outside of the cranes safe working radius

Ensure that all equipment certification is in date.

Inspect equipment before use to ensure it is free from damage.

Do not use makeshift or untested equipment.

Report any damage to your supervisor and take it out of use.

Only allow competent operatives to carry out lifting activities.

Rigger

Chargehand

Ensure only competent persons are permitted to carry out the lifting operations.

Ensure tag lines are used to control the load.

Place packing around sharp edges or corners to prevent damage.

Do not use hooks that are stretched or damaged.

Rigger

Chargehand

Ensure that an adequate barriers or hoardings are erected around the site to

prevent access.

Ensure that appropriate warning signs are on display (multi language if required)

Ensure all equipment is stored correctly when not in use.

Only use lifting equipment for what it is designed.

Do not leave nylon sling exposed to heat or sunlight.

Do not tie nylon or wire lifting equipment together to extend it.

Traffic Management

6

2

Rigger

Chargehand

CM,Sup

ervisor

and

3

1

3

2

Form-104

Risk Assessment Form

Lifting Operations

Risk Assessment Title:

Risk Assessment

01

Revision:

Item

Rev. : 1

Hazard

Risk

Risk Rating

Who is at Risk

S

Necessary Control Measures

Rating

warning of the dangers.

Restrict the access to construction traffic only.

Provide security to prevent unauthorised access.

Traffic

Plant & Vehicle Movement

Traffic

Trapping / Crushing

Traffic

Collision while reversing

Traffic

Collision at night

Traffic

Overturning

HSE-001 Risk Assessment

Public, Staff,

Labour

Public, Staff,

Labour

Public, Staff,

Labour

Public, Staff,

Labour

Public, Staff,

Labour

Action

By

Operati

ves

CM,Sup

ervisor

and

Operati

ves

Where appropriate implement a one way system to control vehicle movement,

where possible segregate walkways form vehicle movement.

Install designated parking areas.

Ensure that only trained and authorised persons are permitted to operate plant

and equipment.

Ensure that reversing vehicles are fitted with audible warning systems, where this

is not possible provide a banksman to direct the operator.

Provide High Viz Vests to the workforce so they are more visible to the operators

of plant.

CM,Sup

ervisor

and

Operati

ves

Ensure all reversing vehicles are controlled by a trained and competent

banks man.

Ensure routes are checked before reversing.

All mobile plant should be fitted with an audible reverse alarm.

Where practicable safety cones and plastic chain should be erected

around the reversing area.

Logistic

s

Manage

r

Banksm

an

Driver

Residual Risk

Rating

S

L

Rating

Ensure adequate access lighting is installed and maintained on main

road ways.

Ensure all vehicle and plant lights are in good working order and used

at night.

Restrict vehicle movement at night

Unloading should be carried out in well lit and restricted areas.

Logistic

s

Manage

r/

Supervi

sor

Banksm

an

Ensure vehicles stay on the designated access roads and do not take

shortcuts over the sandy areas.

If unloading materials using a forklift ensure the ground is level.

Supervi

sor

Form-104

Risk Assessment Form

Lifting Operations

Risk Assessment Title:

Risk Assessment

01

Revision:

Item

Rev. : 1

Hazard

Risk

Risk Rating

Who is at Risk

S

Necessary Control Measures

Rating

Ensure roads are maintained and free from potholes.

Traffic

Contact with people or pedestrians

Public, Staff,

Labour

Action

By

Ensure adequate pedestrian accesses are installed that give pedestrian

right of way. Where possible post a flagman to control vehicle and

pedestrian movement.

Construct speed humps in areas where pedestrians need to cross.

Implement designated pedestrian routes with barriers to segregate the

pedestrians from vehicle movement.

Ensure operatives are equipped with High Visibility Vests so they can be

easily seen by the drivers.

Residual Risk

Rating

S

L

Rating

Banksm

an

Logistic

s

Manage

r/

Supervi

sor

Banksm

an

2

3

Welfare

1

Lack of welfare and

medical facilities

Food / drinking water contamination

Lack of welfare and

medical facilities

Human waste contamination of

temporary facilities and site

Lack of welfare and

medical facilities

Lack of welfare and

medical facilities

Escalation of minor injuries due to

lack of treatment infection risk

Lack of welfare and

medical facilities

Ill health due to lack of recognition of

medical conditions

Lack of welfare and

medical facilities

HSE-001 Risk Assessment

Disease and ill health due to lack of

washing facilities

Preventable fatalities due to lack of

first aid skills and equipment

General site

workers

General site staff

Site visitors

General site

workers

General site staff

Site visitors

General site

workers

General site staff

Site visitors

General site

workers

General site staff

Site visitors

General site

workers

General site staff

Site visitors

General site

workers

General site staff

Site visitors

Site welfare facilities shall be established in line with the requirements set out in

FAST SWP 01 Site Establishment. Sufficient toilets, washing facilities, drying

facilities and mess facilities shall be installed in line with manpower levels. As

manpower levels change, welfare facilities shall be reviewed and altered

accordingly. Mess and welfare facilities shall be installed in a safe area where

there is no risk from moving vehicles or other site hazards

Temporary chemical toilets may be utilized in the early stages of a project,

however, these shall not be permitted in the long term. Full flushing WCs shall

be installed

Medical facilities shall be established in line with the requirements set out in

FAST SWP 001 Site establishment. Sufficient first aiders and / or a site nurse

shall be appointed for the project

CM

CM

CM

Nurse

Vehicle to be on site to transport any medical emergency to the nearest

hospital for further checks and treatment

CM

All prolonged medical illnesses reported must be sent to the nearest

hospital for further checks and treatment.

CM

Nurse

Where local regulations require a different standard to that set out in the FAST

SWP 001, the higher standard shall be implemented

PM

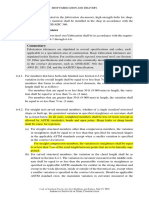

Form-104

Risk Assessment Form

Lifting Operations

Risk Assessment Title:

Risk Assessment

01

Revision:

Item

Hazard

Risk

Risk Rating

Who is at Risk

S

Prepared By:

A - Architect

PM Project Manager

CM Construction Manager

LM Logistics Manager

PLM Plant Manager

HSEM HSE Manager

PS Project Supervisor

SC Subcontractor

Project:

Assessment Carried out by:

Assessment Date:

Risk Assessment Number:

HSE-001 Risk Assessment

Rev. : 1

Severity (S)

1

2

3

4

5

Minor Injury

Major Single Injury

Major Multiple Injuries

Single Death

Multiple Deaths

Frequency (F)

1

2

3

4

5

Improbable

Possible

Occasional

Frequent

Regular

Action

By

Necessary Control Measures

Rating

Risk Rating (RR)

R=SxF

Unacceptability Limits

More than 5 is unacceptable re-assess task

and preventative actions.

S = 0 is deemed to be the limit of practicability

of control measures.

Very High

15-25

S

5

4

3

2

1

5

25

20

15

10

5

High

8-12

4

20

16

12

8

4

Residual Risk

Rating

S

L

Rating

Medium

4-6

3

15

12

9

6

3

2

10

8

6

4

2

Low

1-3

1

5

4

3

2

1

Вам также может понравиться

- Risk Assesment 16 - Pre - Assembly and Erection ofДокумент7 страницRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriОценок пока нет

- Risk Assessment For Crane Operations (Oml-Hse-Ra-3003) - Atlas Engom Civil Camp MoveДокумент3 страницыRisk Assessment For Crane Operations (Oml-Hse-Ra-3003) - Atlas Engom Civil Camp MoveNorman Ainomugisha71% (14)

- 002 Working at Height Risk AssessmentДокумент4 страницы002 Working at Height Risk Assessmentgangadharan000100% (14)

- Forklift Risk AssessmentДокумент6 страницForklift Risk AssessmentMoayed Altaweel76% (29)

- Heavy Lifting Risk AssessmentsДокумент9 страницHeavy Lifting Risk AssessmentsSayed Darwish100% (6)

- Risk Assessment - Lifting OperationsДокумент3 страницыRisk Assessment - Lifting Operationsdnmule100% (1)

- Working at Height Risk AssessmentДокумент2 страницыWorking at Height Risk Assessmentvismay83% (6)

- Hyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectДокумент4 страницыHyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectYounis Khan100% (1)

- Working at Height Risk AssessmentДокумент9 страницWorking at Height Risk AssessmentNebosh Diploma Assignment80% (5)

- Risk Assessment Work at HeightДокумент3 страницыRisk Assessment Work at HeightSathi sh0% (1)

- Risk assessment for excavation worksДокумент3 страницыRisk assessment for excavation worksYaser A. Al-Bustanji72% (18)

- Risk Assessment Lifting OperationsДокумент5 страницRisk Assessment Lifting OperationsHưng Hoàng Duy100% (1)

- RA 024 Risk Assessment - Precast Concrete WorksДокумент14 страницRA 024 Risk Assessment - Precast Concrete Worksthomson75% (8)

- Risk Assessment for 10 Villa Construction ProjectДокумент5 страницRisk Assessment for 10 Villa Construction ProjectFrancis Enriquez Tan100% (3)

- HEALTH & SAFETY RISK ASSESSMENTДокумент52 страницыHEALTH & SAFETY RISK ASSESSMENTmujahid113794% (36)

- Excavation Risk Assessment SheetДокумент3 страницыExcavation Risk Assessment SheetMuhammad Ibrahim93% (45)

- Project:: Fujairah F3 Independent Power Project (IPP) Electrical Special Facility (ESF) - 400KV SWITCHING STATIONДокумент20 страницProject:: Fujairah F3 Independent Power Project (IPP) Electrical Special Facility (ESF) - 400KV SWITCHING STATIONghaleb alhourani100% (1)

- Welding and Radiography Risk AssessmentДокумент11 страницWelding and Radiography Risk AssessmentAldrin75% (8)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEДокумент12 страницRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- Risk Assessment of Scaffolding Works - Rev. 1Документ20 страницRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- Working at Height Risk AssessmentДокумент7 страницWorking at Height Risk AssessmentAshish100% (3)

- Risk Assessment For Hot WorkДокумент4 страницыRisk Assessment For Hot WorkLu Min Han91% (46)

- Risk Assessment WarehouseДокумент12 страницRisk Assessment WarehouseGul Muhammad Khan100% (3)

- Risk Assessment For Installation of Drainage PipesДокумент17 страницRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- 1326370398-HS6-54 Use of MEWP Risk AssessmentДокумент2 страницы1326370398-HS6-54 Use of MEWP Risk AssessmentJohn David Hoyos Marmolejo83% (6)

- 6-Steel Work Risk Assessment ReportДокумент7 страниц6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- Risk Assessment ConstructionДокумент70 страницRisk Assessment ConstructionArun Celestin93% (42)

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingДокумент7 страницHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- Forklift Risk AssessmentДокумент5 страницForklift Risk AssessmentPajserchina100% (4)

- Electrical Risk AssessmentДокумент6 страницElectrical Risk AssessmentRaul Moyo100% (2)

- 2.risk Assessment of Working at HeightДокумент7 страниц2.risk Assessment of Working at HeightRisal Sinu50% (2)

- Dar Al Hijra Painting Risk AssessmentДокумент5 страницDar Al Hijra Painting Risk Assessmentmakdel68% (22)

- Risk Assessment For General ActivitiesДокумент25 страницRisk Assessment For General Activitiesabou bakar67% (3)

- Building System Risk AssessmentДокумент42 страницыBuilding System Risk Assessmentمحمد عمر حسين100% (4)

- ConfinedSpace RiskAssessmentДокумент9 страницConfinedSpace RiskAssessmentrashid zaman100% (4)

- Excavation Risk Assessment KTPS - 8 PAGESДокумент7 страницExcavation Risk Assessment KTPS - 8 PAGESrajalingam100% (1)

- GHI Warehouse Risk Assessment SummaryДокумент5 страницGHI Warehouse Risk Assessment SummaryYounis Khan50% (2)

- Risk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONДокумент6 страницRisk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONnsadnanОценок пока нет

- 4.2 - Risk Assessment Project - SAMPLEДокумент3 страницы4.2 - Risk Assessment Project - SAMPLEDhana Sekar71% (21)

- Electrical Department Risk Assessment FormДокумент4 страницыElectrical Department Risk Assessment FormTheRedHarimau75% (4)

- Site Activities Risk AssessmentДокумент50 страницSite Activities Risk Assessmentjamie542393% (41)

- Forklift Truck Risk AssessmentДокумент2 страницыForklift Truck Risk AssessmentAshis Das100% (1)

- 125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتДокумент3 страницы125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتeng_hma75% (4)

- Consolidated International Contractor Risk AssessmentДокумент45 страницConsolidated International Contractor Risk Assessmentkumar100% (1)

- Hazard Identification Risk Assessment and Risk ControlДокумент7 страницHazard Identification Risk Assessment and Risk ControlChowKC03100% (17)

- RISK ASSES-105-Erection of Steel Structure BuildinДокумент4 страницыRISK ASSES-105-Erection of Steel Structure BuildinRochdi Bahiri75% (8)

- Risk Assesment Tie-In (Mechanical)Документ5 страницRisk Assesment Tie-In (Mechanical)Galih SukmaОценок пока нет

- Mustafa Adnan - Risk Assessment Project PDFДокумент2 страницыMustafa Adnan - Risk Assessment Project PDFMustafaAdnanОценок пока нет

- Portable Power Tools - Risk Assessment2Документ3 страницыPortable Power Tools - Risk Assessment2Basit Nawaz100% (1)

- Generic Risk AssessmentДокумент8 страницGeneric Risk Assessmentmorgojoyo100% (3)

- Risk Assessment For Temporary ServicesДокумент15 страницRisk Assessment For Temporary Servicesfaizan khan100% (2)

- Risk Assessment Sheet - PaintingДокумент5 страницRisk Assessment Sheet - PaintingYash Sharma89% (9)

- Risk AssessmentДокумент10 страницRisk AssessmentKyaw Kyaw Aung89% (9)

- 7 Hand Held Power ToolsДокумент4 страницы7 Hand Held Power ToolsGilmar MonteiroОценок пока нет

- Risk Assessment For Electrical Equipment InstalationДокумент15 страницRisk Assessment For Electrical Equipment Instalationmanikandan100% (2)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsДокумент6 страницRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Truck Driver SOPДокумент3 страницыTruck Driver SOPAldi Rinaldi Rahmat60% (5)

- Construction Site Management Training Pack Part 2Документ41 страницаConstruction Site Management Training Pack Part 2Jaka Sembung GolokОценок пока нет

- DRIVING - HEAVY EQUIPMENT SAFETYДокумент9 страницDRIVING - HEAVY EQUIPMENT SAFETYVidyesh Viswanathan NairОценок пока нет

- Bulldozer Operator SOPДокумент3 страницыBulldozer Operator SOPJacksmith ThadiusОценок пока нет

- Bolts Nuts Similar SupplierДокумент3 страницыBolts Nuts Similar SupplierJishad NalakathОценок пока нет

- Aess Aisc 1Документ6 страницAess Aisc 1Jishad NalakathОценок пока нет

- m3-Cjv-ckl-ecifo-Via-000001 - CKL Piling Works Viaduct 6.1 - Line 6 Rev. AaДокумент7 страницm3-Cjv-ckl-ecifo-Via-000001 - CKL Piling Works Viaduct 6.1 - Line 6 Rev. AaJishad NalakathОценок пока нет

- A325 PDFДокумент8 страницA325 PDFGHULAM NABIОценок пока нет

- 6.4. Fabrication Tolerances: CommentaryДокумент1 страница6.4. Fabrication Tolerances: CommentaryJishad NalakathОценок пока нет

- Form 071 HIAB Boom Truck Safety ChecklistДокумент2 страницыForm 071 HIAB Boom Truck Safety ChecklistJishad Nalakath100% (3)

- Thermal Design of Precast WallsДокумент56 страницThermal Design of Precast WallsJishad NalakathОценок пока нет

- Heat-Treated Steel Structural Bolts, 150 Ksi Minimum Tensile StrengthДокумент7 страницHeat-Treated Steel Structural Bolts, 150 Ksi Minimum Tensile StrengthJishad NalakathОценок пока нет

- Tower Crane Safety ChecklistДокумент2 страницыTower Crane Safety ChecklistJishad Nalakath100% (3)

- Erection ToleranceДокумент1 страницаErection ToleranceJishad NalakathОценок пока нет

- Pci Manual For The Design Hollow Core SlabsДокумент141 страницаPci Manual For The Design Hollow Core Slabsmedodo100% (4)

- TolerancesenwaДокумент11 страницTolerancesenwaKatarina MeyersdorfОценок пока нет

- Form-068-Mobile Crane Daily Safety ChecklistДокумент1 страницаForm-068-Mobile Crane Daily Safety ChecklistJishad Nalakath67% (3)

- Form-062-Pre Start Daily Lifting ChecklistДокумент1 страницаForm-062-Pre Start Daily Lifting ChecklistJishad NalakathОценок пока нет

- AMANA Specs-ASHPHALTIC CONCRETE WORKSДокумент25 страницAMANA Specs-ASHPHALTIC CONCRETE WORKSJishad NalakathОценок пока нет

- Form-091-Truck Inspection ChecklistДокумент3 страницыForm-091-Truck Inspection ChecklistJishad Nalakath83% (6)

- Sapmle Checklist PrepouringДокумент2 страницыSapmle Checklist PrepouringJishad NalakathОценок пока нет

- Form-067-Weekly Crane Inspection ChecklistДокумент2 страницыForm-067-Weekly Crane Inspection ChecklistJishad NalakathОценок пока нет

- Designers Guide To EN 1993 2 Steel Bridges 2007 PDFДокумент334 страницыDesigners Guide To EN 1993 2 Steel Bridges 2007 PDFserkanozen80Оценок пока нет

- MPI Painting ManualДокумент28 страницMPI Painting ManualJishad NalakathОценок пока нет

- Ansi Ssfi Sc100 05 05Документ47 страницAnsi Ssfi Sc100 05 05Tehman Alam100% (1)

- Fig. C-7.5. Exterior Column Plumbness Tolerances Normal To Building ExteriorДокумент1 страницаFig. C-7.5. Exterior Column Plumbness Tolerances Normal To Building ExteriorJishad NalakathОценок пока нет

- 2014 ANSI Z60.1 Revision HighlightsДокумент8 страниц2014 ANSI Z60.1 Revision HighlightsJishad NalakathОценок пока нет

- AESS Finish PDFДокумент32 страницыAESS Finish PDFkeerthivasan_mrvОценок пока нет

- Aess Aisc 1Документ6 страницAess Aisc 1Jishad NalakathОценок пока нет

- Designers' Guide To EN 1994-1-1 Composite Steel and ConcreteДокумент235 страницDesigners' Guide To EN 1994-1-1 Composite Steel and ConcreteLuis Sequeira100% (5)

- Licensed by Information Handling ServicesДокумент24 страницыLicensed by Information Handling ServicesJishad NalakathОценок пока нет

- Aci209r 92 PDFДокумент47 страницAci209r 92 PDFJishad NalakathОценок пока нет

- Spa Multiple PrincipalДокумент2 страницыSpa Multiple PrincipalGn67% (3)

- RUJUKANДокумент3 страницыRUJUKANSufiaSyah ExertionОценок пока нет

- Liberty Healthcare Draft ReportДокумент43 страницыLiberty Healthcare Draft ReportStatesman JournalОценок пока нет

- Pulse Oximeter Perfusion Index InfoДокумент1 страницаPulse Oximeter Perfusion Index InfopavoneОценок пока нет

- Transport System Question and AnswersДокумент12 страницTransport System Question and Answerskumara guruparanОценок пока нет

- Unprotected ResumeДокумент2 страницыUnprotected Resumeapi-337529555Оценок пока нет

- What%2 Bis%2 B DissociationДокумент2 страницыWhat%2 Bis%2 B DissociationGeorgiana PrisoschiОценок пока нет

- Brigada Eskwela Forms 1 and 3Документ4 страницыBrigada Eskwela Forms 1 and 3Mar Sebastian100% (1)

- People V Veneracion Case DigestДокумент3 страницыPeople V Veneracion Case DigestraykarloBОценок пока нет

- Chemical Engineering Science: Ishara Dedunu Kamalanathan, Peter James MartinДокумент11 страницChemical Engineering Science: Ishara Dedunu Kamalanathan, Peter James MartinarulrajasiОценок пока нет

- Mech-Design and Fabrication of Motorized Screw Jack For A Four WheelerДокумент26 страницMech-Design and Fabrication of Motorized Screw Jack For A Four WheelerkumarsandiОценок пока нет

- SVM-7600 Series Bedside Monitor Advanced Monitoring and ReviewДокумент4 страницыSVM-7600 Series Bedside Monitor Advanced Monitoring and ReviewCathy Palongpong TumaraoОценок пока нет

- Birth InjuriesДокумент24 страницыBirth InjuriesGayathri R100% (1)

- PID Symptoms, Causes, Diagnosis and TreatmentДокумент13 страницPID Symptoms, Causes, Diagnosis and TreatmentAnandila MaulinaОценок пока нет

- 12.1 Guided ReadingДокумент2 страницы12.1 Guided ReadingGrant HasletonОценок пока нет

- Rule 59 To 65 Case Digest As of September 5 2014Документ143 страницыRule 59 To 65 Case Digest As of September 5 2014Kristian CaumeranОценок пока нет

- Adaptor Retea, HH-CM01, OmronДокумент8 страницAdaptor Retea, HH-CM01, OmronpaspargiliusОценок пока нет

- Nitrile Oxides A Key Intermediate in Organic SynthesisДокумент12 страницNitrile Oxides A Key Intermediate in Organic Synthesispopescu vasilicaОценок пока нет

- 13 Stoiprobs 1Документ2 страницы13 Stoiprobs 1Sabila IzzatiОценок пока нет

- Categorical Data Analysis Selected Solutions by AgrestiДокумент30 страницCategorical Data Analysis Selected Solutions by AgrestiNeil Bot67% (3)

- Blockchain SystemДокумент12 страницBlockchain Systemkhairina100% (1)

- uPVC Windows Indian StandardДокумент61 страницаuPVC Windows Indian StandardRamachandra Budihal71% (7)

- First Aid Basics and Vital Signs EssentialsДокумент18 страницFirst Aid Basics and Vital Signs EssentialsJoyce Anne Tuala YabutОценок пока нет

- Oncology Doctors Contact Details ListДокумент28 страницOncology Doctors Contact Details Listpurnima4uonly100% (2)

- 241 PGTRB Psychology Study Material PDFДокумент10 страниц241 PGTRB Psychology Study Material PDFPradeep Kumar100% (2)

- Jl. Ampera Raya No. 9 menuДокумент17 страницJl. Ampera Raya No. 9 menuNina ShafienaОценок пока нет

- Digital biometric ruler for eye measurementsДокумент2 страницыDigital biometric ruler for eye measurementsFrancisco GomezОценок пока нет

- Tridacna Giant ClamДокумент15 страницTridacna Giant ClamBechah Kak MaОценок пока нет

- Pulkit PPT Steam Turbine3Документ42 страницыPulkit PPT Steam Turbine3Abhishek KumarОценок пока нет

- Institute for Biodiversity Research EstablishedДокумент7 страницInstitute for Biodiversity Research Establishedshami mohammedОценок пока нет