Академический Документы

Профессиональный Документы

Культура Документы

Hy-25xlt - Equivalencias Aprietes

Загружено:

Isidro Gomez GarciaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hy-25xlt - Equivalencias Aprietes

Загружено:

Isidro Gomez GarciaАвторское право:

Доступные форматы

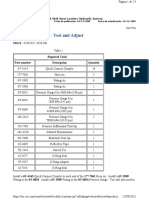

HYTORC

TOOL MODEL: HY-25XLT

PRESSURE/TORQUE CONVERSION CHART

Standard Torque Chart

PRESSURE IN

PSI

1500

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

3800

4000

4200

4400

4600

4800

5000

5200

5400

5600

5800

6000

6200

6400

6600

6800

7000

7200

7400

7600

7800

8000

8200

8400

8600

8800

9000

9200

9400

9600

9800

10000

* ISO DOCUMENT 9000

FT. LBS.

3960

4216

4728

5240

5752

6264

6776

7288

7800

8318

8836

9354

9872

10390

10898

11406

11914

12422

12930

13450

13970

14490

15010

15530

16040

16550

17060

17570

18080

18602

19124

19646

20168

20690

21214

21738

22262

22786

23310

23826

24342

24858

25374

25890

TORQUE IN

KGM

548

583

654

725

796

866

937

1008

1079

1150

1222

1294

1365

1437

1507

1577

1648

1718

1788

1860

1932

2004

2076

2148

2218

2289

2359

2430

2500

2573

2645

2717

2789

2861

2934

3006

3079

3151

3224

3295

3366

3438

3509

3581

NM

5368

5715

6409

7103

7797

8491

9186

9880

10574

11276

11978

12680

13382

14085

14773

15462

16151

16839

17528

18233

18938

19643

20348

21052

21744

22435

23127

23818

24509

25217

25924

26632

27340

28047

28758

29468

30178

30889

31599

32299

32998

33698

34397

35096

PRESSURE IN

BAR

104

110

124

138

152

165

179

193

207

220

234

248

262

276

290

303

317

331

345

358

372

386

400

414

427

441

455

468

482

496

510

524

538

552

565

579

593

607

620

634

648

662

676

690

REV. 09-93

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Your HYTORC TORQUE MACHINE is a power tool, and as with any power tool, certain safety precautions should be

observed to avoid accidents or personal injury. The following tips will assist you.

READ ALL INSTUCTIONS.

KEEP WORK AREA CLEAN AND WELL LIT.

CONSIDER WORK AREA ENVIRONMENT.

Electrical Pumps should never be used in an atmosphere which can be

considered potentially volatile. If there is any doubt, use an air pump. Also Note: metal to metal contact can cause sparks, precautions

should be taken.

AVOID PREMATURE TOOL STARTING. The Pump Remote Control is for the TOOL OPERATOR only.

STAY CLEAR DURING OPERATION. In most cases, the tool will allow hands free operation. If the tool must be held or steadied

during operation, use alternative means of securing the tool to the application

GUARD AGAINS ELECTRIC SHOCK. Ensure the pump is properly grounded and the proper voltage is being used.

STORE IDLE TOOLS. When not in use, tool sand accessories should be properly stored to avoid deterioration

USE RIGHT TOOL. Dont force small tools or attachments to do the job of a larger tool. Dont use a tool for purposes not intended.

PROPER SAFETY ATTIRE. When handling/operating hydraulic equipment use work gloves, hard hats, safety shoes and other

applicable clothing.

USE SAFETY GLASSES.

MOVING EQUIPMENT. Do not use hydraulic hoses, uni-swivels, pump power or remote cords as means of moving the equipment.

MAINTAIN TOOLS WITH CARE. For top performance, inspect tools, powerpack and accessories for visual damage frequently and

always prior to use. Always follow instruction for proper tool and pump maintenance. Refer to the Operations Maintenance Section for

further clarification

STAY ALERT. Watch what you are doing. Use Common sense. Do not use power equipment under the influence of any mood altering

substances.

PRIOR TO OPERATION

Ensure that all hydraulic connections are securely connected and there is no leakage

Verify that the Hydraulic hoses are not kinked or otherwise damaged.

Ensure the square drive and its retainer are fully and securely engaged.

Be certain that all connectors, elbows, fitting and swivels are not bent, loose or damaged.

PRIOR TO USE.

Check sockets for size, quality and flaws. (Do not use if questionable)

Cycle tool to ensure proper function.

Locate a solid, secure reaction point.

Be sure the reaction arm retaining clamp is fully engaged.

Be sure the hydraulic hoses are free of the reaction point.

Pressurize the system momentarily; if the tool tends to ride up or to creep, stop and re-adjust the reaction arm to a more solid and

secure position.

NOTE: Remain clear of the reaction arm during operation and never put body parts between reaction arm and reaction surfaces.

ALWAYS USE QUALITY ACCESSORIES. Always use top quality impact sockets in good condition which are the correct size and

fully engage the nut. Hidden flaws, however, remain a possibility which could cause breakage, so stay clear of sockets during operation

DO NOR USE other equipment to enhance performance (Hammer on Socket/Tool)

NOTE: Hytorc Pumps are designed to operate Hytorc Tools only. Damage may occur to the pump or the product that is being operated

due to misuse.

SAVE THESE INSTRUCTIONS FOR FUTURE USE!

Вам также может понравиться

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsОт EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsРейтинг: 5 из 5 звезд5/5 (5)

- Small Block Chevrolet: Stock and High-Performance RebuildsОт EverandSmall Block Chevrolet: Stock and High-Performance RebuildsРейтинг: 4 из 5 звезд4/5 (6)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideОт EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Diesel Engine Care and Repair: A Captain's Quick GuideОт EverandDiesel Engine Care and Repair: A Captain's Quick GuideРейтинг: 5 из 5 звезд5/5 (1)

- K3VДокумент15 страницK3VJacques Van Niekerk100% (14)

- 9y02113768 PDFДокумент662 страницы9y02113768 PDFJoseph Boulanger100% (8)

- Westco Hydraulic Tubing Tongs 5500 ManualДокумент37 страницWestco Hydraulic Tubing Tongs 5500 ManualLucas Lewis0% (3)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- Operation & Maintenance ManualДокумент60 страницOperation & Maintenance ManualDeepak Kumar Raut92% (12)

- Refill Brand Guidelines 2Документ23 страницыRefill Brand Guidelines 2Catalin MihailescuОценок пока нет

- WREN Hydraulic Torque Wrench Manual - LOWДокумент20 страницWREN Hydraulic Torque Wrench Manual - LOWMohd ZaidОценок пока нет

- Engine 3066 - Disassembly and Assembly (Supplemental Information)Документ125 страницEngine 3066 - Disassembly and Assembly (Supplemental Information)Miguel Leguizamón98% (44)

- K3V K5V eДокумент15 страницK3V K5V evyvy83Оценок пока нет

- Periodic Maintenance: J45-70XN (A276)Документ87 страницPeriodic Maintenance: J45-70XN (A276)Baciu Nicolae100% (1)

- Procedure For The Inspection, Repair, and Component Replacement On The Frames of CertainДокумент217 страницProcedure For The Inspection, Repair, and Component Replacement On The Frames of Certainfoca88100% (1)

- CAT Antes de Usar TH460BДокумент4 страницыCAT Antes de Usar TH460Bmiguel0% (1)

- Offer LetterДокумент8 страницOffer LetterMadhavi Latha100% (3)

- SK714,815-5 #01876-00902 - Webm005501 - U0502Документ270 страницSK714,815-5 #01876-00902 - Webm005501 - U0502Camilo Maulen Balladares75% (4)

- Analog and Digital Electronics (Ade) Lab Manual by Prof. Kavya M. P. (SGBIT, BELAGAVI)Документ74 страницыAnalog and Digital Electronics (Ade) Lab Manual by Prof. Kavya M. P. (SGBIT, BELAGAVI)Veena B Mindolli71% (7)

- MXT Manual PDFДокумент36 страницMXT Manual PDFhüseyin100% (1)

- Stringing EquipmentДокумент90 страницStringing EquipmentMuhammad Vicky100% (1)

- Avanti ManualДокумент36 страницAvanti ManualCristian D TabordaОценок пока нет

- Xlt/Mxt/Mxt-Sa Series: Operational and Spare Parts ManualДокумент40 страницXlt/Mxt/Mxt-Sa Series: Operational and Spare Parts ManualAbdullah AnsariОценок пока нет

- RT Usersguide PDFДокумент36 страницRT Usersguide PDFRoy RamosОценок пока нет

- Hydrostatic System - Test and AdjustДокумент23 страницыHydrostatic System - Test and AdjustSanchez Gamarra AndyОценок пока нет

- XLCT Series: Operational and Spare Parts ManualДокумент36 страницXLCT Series: Operational and Spare Parts ManualArthamigas EngineeringОценок пока нет

- Gas Turbine Performance CalculationДокумент7 страницGas Turbine Performance CalculationAtiqur RahmanОценок пока нет

- LRP Manual Rev. 2-0-2Документ32 страницыLRP Manual Rev. 2-0-2Sha'ban Hussaini100% (2)

- Hyster s16 Ac PDFДокумент317 страницHyster s16 Ac PDFRenato Portela100% (3)

- MXT 20Документ2 страницыMXT 20jast111Оценок пока нет

- Stealth 2Документ2 страницыStealth 2Miguel GamboaОценок пока нет

- Av 5Документ2 страницыAv 5Jádson Silva RiosОценок пока нет

- Stealth 8Документ2 страницыStealth 8Guillermo Manuel SchödlОценок пока нет

- MXT Manual 100710Документ40 страницMXT Manual 100710Amilcar BolagОценок пока нет

- High Lift Hydraulic Transmission Jacks "AF25082" "AF50080" "AF100080"Документ6 страницHigh Lift Hydraulic Transmission Jacks "AF25082" "AF50080" "AF100080"Alain DefoeОценок пока нет

- Manual Controlador EC25N2Документ199 страницManual Controlador EC25N2Claudio Galvez RojasОценок пока нет

- Handbook of HYTOPS15000rev10-09Документ182 страницыHandbook of HYTOPS15000rev10-09ChusnadiОценок пока нет

- !!!WARNING!!!: Thd-Series S11Sr280 Thru S27Sr1020 Double Acting Scotch Yoke Actuators With Hydraulic Manual OverrideДокумент2 страницы!!!WARNING!!!: Thd-Series S11Sr280 Thru S27Sr1020 Double Acting Scotch Yoke Actuators With Hydraulic Manual Overrideorlando montielОценок пока нет

- Versa Series: Operational and Spare Parts ManualДокумент28 страницVersa Series: Operational and Spare Parts ManualJennibabes AlgosoОценок пока нет

- Before Operation: Operation and Maintenance Manual ExcerptДокумент4 страницыBefore Operation: Operation and Maintenance Manual ExcerptFabian Ariza ArizaОценок пока нет

- Wi040 IngДокумент5 страницWi040 Ingjeremytoh89Оценок пока нет

- EDGE ManualДокумент28 страницEDGE ManualMussardОценок пока нет

- Tool Model: Stealth 2 With Hex Link: Pressure in Pressure in PSI Ft. Lbs. KGM NM BAR Torque inДокумент1 страницаTool Model: Stealth 2 With Hex Link: Pressure in Pressure in PSI Ft. Lbs. KGM NM BAR Torque inLimberg Carrasco EstevaОценок пока нет

- Esl IntensifierДокумент44 страницыEsl IntensifierdguyОценок пока нет

- Belt Filter PressДокумент5 страницBelt Filter PressMaku RajkumarОценок пока нет

- Bomba de Engrenagem Hidraulica - h155Документ49 страницBomba de Engrenagem Hidraulica - h155leonardoОценок пока нет

- MXT XLT Series: Operational and Spare Parts ManualДокумент40 страницMXT XLT Series: Operational and Spare Parts ManualCristian de IsusiОценок пока нет

- Hyster 330YДокумент20 страницHyster 330Yjimmetuiro100% (1)

- Before Operation: Operation and Maintenance Manual ExcerptДокумент4 страницыBefore Operation: Operation and Maintenance Manual ExcerptHernan Sanchez100% (1)

- Before Operation: Operation and Maintenance Manual ExcerptДокумент4 страницыBefore Operation: Operation and Maintenance Manual ExcerptAnthony PozoОценок пока нет

- Avanti Series: Operational and Spare Parts ManualДокумент32 страницыAvanti Series: Operational and Spare Parts ManualCruzCarrizalesОценок пока нет

- PressureGuard Self-Contained Hydraulic Emergency Shutdown Systems (2017)Документ6 страницPressureGuard Self-Contained Hydraulic Emergency Shutdown Systems (2017)Kader BenОценок пока нет

- XLCT Series: Operational and Spare Parts ManualДокумент24 страницыXLCT Series: Operational and Spare Parts Manualcrni rokoОценок пока нет

- Service and Maintenance Manual: Models 400S 460SJДокумент662 страницыService and Maintenance Manual: Models 400S 460SJPedro LeonОценок пока нет

- Parts Manual Bandeja M8Документ27 страницParts Manual Bandeja M8pabloОценок пока нет

- Sebu7709-05 BДокумент4 страницыSebu7709-05 BJaime SuaОценок пока нет

- Before Operation: Operation and Maintenance Manual ExcerptДокумент4 страницыBefore Operation: Operation and Maintenance Manual Excerptgeorgejr8950% (2)

- Hand PumpДокумент8 страницHand Pumppaulnunez9389Оценок пока нет

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationОт EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationОценок пока нет

- R R O S A: Model Rf-It Model Ce-It Insulator TestersДокумент2 страницыR R O S A: Model Rf-It Model Ce-It Insulator Testersvictor raul sandoval martinezОценок пока нет

- QuickTransit SSLI Release Notes 1.1Документ12 страницQuickTransit SSLI Release Notes 1.1subhrajitm47Оценок пока нет

- Product DetailsДокумент215 страницProduct DetailsEric MagnayeОценок пока нет

- Application For Type Aircraft Training: Farsco Training Center IR.147.12Документ1 страницаApplication For Type Aircraft Training: Farsco Training Center IR.147.12benyamin karimiОценок пока нет

- Sharp AR-C172M ServiceM EN PDFДокумент308 страницSharp AR-C172M ServiceM EN PDFpiaggio_nrgОценок пока нет

- HSE - Made Gde PanduДокумент3 страницыHSE - Made Gde Pandurezki_WSОценок пока нет

- Amendment Notes For June 2021Документ32 страницыAmendment Notes For June 2021arohi gupta0% (2)

- Agricultural Extension System in Sudan FinalДокумент52 страницыAgricultural Extension System in Sudan FinalMohamed Saad AliОценок пока нет

- XJ600SJ 1997Документ65 страницXJ600SJ 1997astracatОценок пока нет

- OIG ReportДокумент43 страницыOIG ReportRohan M100% (1)

- Project DescriptionДокумент5 страницProject DescriptionM ShahidОценок пока нет

- Packages: Khidmatul A'WaamДокумент4 страницыPackages: Khidmatul A'WaamAltaaf IzmaheroОценок пока нет

- Needs Assessment Form Company Name: HRMO Address: Sta. Barbara Agoo, La UnionДокумент2 страницыNeeds Assessment Form Company Name: HRMO Address: Sta. Barbara Agoo, La UnionAlvin LaroyaОценок пока нет

- Divisional Sec. Contact Details 2019-03-01-UpdateДокумент14 страницDivisional Sec. Contact Details 2019-03-01-Updatedotr9317Оценок пока нет

- 14.symmetrix Toolings LLPДокумент1 страница14.symmetrix Toolings LLPAditiОценок пока нет

- Design Calculation of Braking System (Landcruiser) : AbstractДокумент4 страницыDesign Calculation of Braking System (Landcruiser) : AbstractDr. Aung Ko LattОценок пока нет

- Sop ECUДокумент5 страницSop ECUSumaira CheemaОценок пока нет

- ProEXR ManualДокумент44 страницыProEXR ManualSabine BОценок пока нет

- KACE SeДокумент63 страницыKACE SeAbdul RahimОценок пока нет

- Theory and Practice AssignmentДокумент12 страницTheory and Practice AssignmentMelikteОценок пока нет

- ALLOY 7150-T7751 PLATE AND 7150-T77511 EXTRUSIONS: Alcoa Mill ProductsДокумент4 страницыALLOY 7150-T7751 PLATE AND 7150-T77511 EXTRUSIONS: Alcoa Mill Productshitesh_tilalaОценок пока нет

- Nil Queries Sheet: S. No. ProcessДокумент24 страницыNil Queries Sheet: S. No. ProcessTarun BhardwajОценок пока нет

- M6 FORMATIVE3 VHDL Behavioral Programming 1Документ14 страницM6 FORMATIVE3 VHDL Behavioral Programming 1Allen Ray LedesmaОценок пока нет

- SERVA 4-Axle Coiled Tubing Unit - Electric Over HydraulicДокумент25 страницSERVA 4-Axle Coiled Tubing Unit - Electric Over HydraulicWilliamОценок пока нет

- Cambridge International Advanced Subsidiary and Advanced LevelДокумент4 страницыCambridge International Advanced Subsidiary and Advanced Leveljunk filesОценок пока нет

- Group 5 Transforming Banana Stem Waste To Eco Tote Bag.Документ4 страницыGroup 5 Transforming Banana Stem Waste To Eco Tote Bag.Gabriel Abram JopiaОценок пока нет