Академический Документы

Профессиональный Документы

Культура Документы

V Notch Practical

Загружено:

AnushaBheenuckАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

V Notch Practical

Загружено:

AnushaBheenuckАвторское право:

Доступные форматы

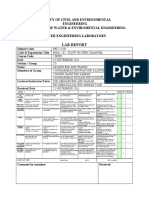

V-notch Practical Student ID: 1410441

Table of Contents

List of tables...............................................................................................................................2

Abstract......................................................................................................................................4

1.0. Introduction.....................................................................................................................5

2.0. AimsandObjectives.......................................................................................................5

2.1. Aim..............................................................................................................................5

2.2. Objectives....................................................................................................................5

3.0. LiteratureReview............................................................................................................6

4.0. Methodology...................................................................................................................8

4.1. Apparatus used............................................................................................................8

4.2. Procedure....................................................................................................................8

5.0. Limitations......................................................................................................................9

6.0. Results.............................................................................................................................9

7.0. AnalysisofResults.......................................................................................................10

8.0. Recommendationsonwhereresultscanbeusedinengineeringpractice....................12

9.0. HealthandSafety..........................................................................................................12

10.0. Disseminationofknowledge.....................................................................................12

11.0. Contributionofteammembers..................................................................................13

12.0. Conclusion.................................................................................................................13

13.0. References.................................................................................................................13

1|P a g e

V-notch Practical Student ID: 1410441

List of figures

Figure1.0...................................................................................................................................6

Figure2.0...................................................................................................................................6

Figure 3.0. Graph of discharge against H 5/2..........................................................................10

List of tables

Table1.0.Results.......................................................................................................................9

Table2.0.AnalysisofResults.................................................................................................10

Table3.0.ContributionofTeamMembersforExperiment....................................................13

2|P a g e

V-notch Practical Student ID: 1410441

Acknowledgement

WewouldliketothankthetwoLaboratoryTechnicians,Mr.SeeburnandMr.Bhuruthfortheir

preciousguidanceandexplanationinconductingtheexperiment.Theyshowedushowtousethe

apparatuseffectively.Wewouldalsoliketothankourlecturer,ProfessorRamjeawonwhoprovided

uswithusefulnoteswhichservedasareferenceforcarryingouttheexperiment.

Group Members: -BheenuckAnusha

-HalkhariBhagyasha

-RamdharryBhavish

-LuforDhandevi

Date of Practical:

Venturimeter:2ndOctober2015

Bernouilli:9thOctober2015

Rectangular Weir:16th October2015

V-Notch: 23rd October2015

Venue: FluidMechanicsLaboratory,UoM.

3|P a g e

V-notch Practical Student ID: 1410441

Abstract

Inthisexperiment,thecoefficientofdischargeforaV-notchweirwasfoundbyfollowinga

procedure.Toobtaintherequiredvalue,therelationshipbetweendischarge,Qandhead,H

wasconsideredwhichsuggeststhatthedischarge,QisdirectlyproportionaltoH5/2,thusthe

coefficientofdischargeremainingaconstantthroughoutthepractical.Thedischargeofthe

weir was calculated at different heights and a graph of Q against H5/2 was plotted whose

gradientgivesthevalueforthecoefficientofdischarge.

4|P a g e

V-notch Practical Student ID: 1410441

1.0. Introduction

AccordingtoR.KRajput(Fluidmechanicsandhydraulicsmachines,2008),anotchmaybedefined

asanopeningprovidedinthesideofatankorvesselsuchthattheliquidsurfaceinthetankisbelow

thetopedgeoftheopening.Anotchmayberegardedasanorificewiththewatersurfacebelowits

upperedge.Itisgenerallymadeofmetallicplate.Itisusedformeasuringtherateofflowofaliquid

throughasmallchanneloratank.

Aweirmaybedefinedasanyregularobstructioninanopenstreamoverwhichtheflowtakesplace.

It is made of masonry or concrete.The conditions of flow, in the case of a weir are practicallythe

same, as those of a rectangular notch.That is why; a notch is sometimes called as a weir and vice

versa.

Function of a V-notch:

Tocontroltheflowofthewateroutofthebasin.

How does it work?

Lets consider the example of a V-notch in a pond. When water gets into the pond, its height

increases,whenmorewatercomesdownthestream,thehigheritwillriseinthepondandthewater

willspillovertheV-notch.Therefore,byrecordingtheheightofthewaterinthepond,theamountof

water flowing out of the watershed can be measured and the flow rate can be calculated. In this

experimentapumpwasusedtovarytheflow,agaugewasusedtocalculatetheweirheadandthe

abovesituationwassimulated.

2.0. Aims and Objectives

2.1. Aim

Theexperimentiscarriedoutsoastoobservetherelationshipbetweentheheightofthewaterlevel

andthedischargeofthewaterflowinginthechannelandstudydischargeflowratesthroughanopen

channelusingaV-notchweir.

2.2. Objectives

Theobjectivesoftheexperimentwere:

(i) Tomaintainasteadyflowrateofwaterintheweir,

(ii) TotakemeasurementsoftheV-notchaccordingly.

5|P a g e

V-notch Practical Student ID: 1410441

3.0. Literature Review

RefertoFigure1.0.Atriangular(V-notch)

Let

1. theHeadofwaterabovetheapexofthenotchbeH

2. theanglebea

3. co-efficientofdischargebeCd

Considerahorizontalstripofwaterofthicknessdh,andatadepthhfromthewatersurfaceasshown

inFigure1.0.

Figure 1.0.

Figure 2.0.

(DiagramdrawnonAutoCad)

6|P a g e

V-notch Practical Student ID: 1410441

FromFigure2.0.,wehave

Tan = =

LN=(H-h)tan

Widthofstrip=LM=2LN=2(H-h)tan

Areaofthestrip=2(H-h)tan xdh

ApplyingBernoulliequation,

Totalenergyperunitmassatpoint1=totalenergyperunitmassatpoint2

v12 P1 v2 P

h1 2 2 h2

2g g 2g g

Equalsto0 Equalsto0

Thetheoreticalvelocityofwaterthroughthestrip= 2

Dischargethroughthestrip,

dQ=areaofstripxtheoreticalvelocity

Total discharge, over the whole notch, = tan

Thisequationisidealortheoreticaldischarged

For the actual discharge equation, the theoretical discharge must be multiplied by a coefficient of

dischargetoallowforenergylossesandthecontractionofthecross-sectionofthebottomendsides.

Q actual = Cd x Q theoretical

Q actual = Cd x tan

7|P a g e

V-notch Practical Student ID: 1410441

4.0. Methodology

4.1. Apparatus used

Stopwatch(0.01s)

Ruler(0.5cm)

Protractor(0.5o)

ChannelwithaV-notchattheend.

Hook-gauge(0.1cm)

Glasstubewithmeasuringtape(0.5cm)

Hook Gauge Glass tube giving water height with measuring tape alongside

4.2. Procedure

The discharge ofthe flowis regulated by using the benchsupply valve andtheexperiment

startedwiththehighestdischarge.

Usingasmallbeaker,thewaterlevelwasadjustedsothatthereflectionoftheV-notchweir

inthewaterlayjustonthesurface.

The flow wasallowedto be steady, thatis, remainat the same level;the Hook Gauge was

levelledsothatthepointedendjusttouchesthewatersurface(seeFigure6).Thereadingwas

noted.

Theriseofwaterintheglasstubewasnotedforaparticulartimeframe.

Thevalveinthetankwasthenopenedtoallowwatertogothroughtopreventoverflowofthe

tank.

Theaboveprocedureswererepeatedfor8differentdischarge.

ThedimensionsoftheV-notchweirweremeasuredusingtherulerandaprotractor.

8|P a g e

V-notch Practical Student ID: 1410441

5.0. Limitations

Thepumpsvibrationcausedthewatertomovealot;hencetheflowisnotkeptsteady.

The main source of error we encountered was the reaction time while we had to stop the

stopwatchandsimultaneouslynotethereadingofheightinthehopper.

6.0. Results

DimensionsofHopper

L,Lengthofhopper=1.215m

W,Widthofhopper=0.901m

Cross-sectionalarea,A=1.095m2

Headofwateraboveweirwhenthereisnoflow, H 0 =0.038m

Angle=30

Hook Volume

Time/s

Gauge Waterin ofwater

Flow

reading, hopper/m

h/m t1/s t2/s <t>/s V/m

5.5 0.2685 0.0508 8.18 9.160 8.670 0.055626

5.0 0.2595 0.0508 10.30 10.53 10.415 0.055626

4.5 0.2275 0.0508 15.23 15.69 15.460 0.055626

4.0 0.22700 0.0508 15.43 15.92 15.675 0.055626

3.5 0.2255 0.0508 15.40 15.89 15.645 0.055626

3.0 0.22500 0.0508 15.80 16.00 15.900 0.055626

2.5 0.2247 0.0508 16.33 16.35 16.340 0.055626

2.0 0.22400 0.0508 16.44 16.39 16.415 0.055626

1.0 0.2175 0.0508 18.42 18.38 18.400 0.055626

Table 1.0. Results

9|P a g e

V-notch Practical Student ID: 1410441

7.0. Analysis of Results

Hook Gauge Water in Time/s Volume of Discharge, Q(actual)

Flow H(H - h) /m H5/2 / m5/2 water

reading, h/m hopper/m

t1 /s t2 /s <t>/s V/m x 10-3 m/s

5.5 0.2685 0.2305 0.02550805 0.0508 8.18 9.160 8.670 0.055626 6.41591696

5.0 0.2595 0.2215 0.02309055 0.0508 10.30 10.53 10.415 0.055626 5.34095055

4.5 0.2275 0.1895 0.01563231 0.0508 15.23 15.69 15.460 0.055626 3.59805951

4.0 0.22700 0.18900 0.01552939 0.0508 15.43 15.92 15.675 0.055626 3.54870813

3.5 0.2255 0.1875 0.01522310 0.0508 15.40 15.89 15.645 0.055626 3.55551294

3.0 0.22500 0.18700 0.01512182 0.0508 15.80 16.00 15.900 0.055626 3.49849057

2.5 0.2247 0.1867 0.01506124 0.0508 16.33 16.35 16.340 0.055626 3.40428397

2.0 0.22400 0.18600 0.01492047 0.0508 16.44 16.39 16.415 0.055626 3.38872982

1.0 0.2175 0.1795 0.01365090 0.0508 18.42 18.38 18.400 0.055626 3.02315217

Table 2.0. Analysis of Results

Graph of Discharge Q against H5/2

0.03

Discharge, Q , x10-3 / m3/s

0.025

0.02

0.015

0.01

0.005

0

0.0000 1.0000 2.0000 3.0000 4.0000 5.0000 6.0000 7.0000

H5/2 / m5/2

Figure 3.0. Graph of discharge against H 5/2

Fromtheoryweknowthat,Q= tan

Hence a graph of Q against H5/2 should produce a straight line with gradient tan

passingtheorigin.

Therefore, =

Fromthegraphweobtainedgradient=369.17x10-3,takingg=9.81ms-2and = 15

10|P a g e

V-notch Practical Student ID: 1410441

.

=

.

Cd = 0.583

. .

Percentageerror= .

100 =10.28%

The mean experimental value obtained for the coefficient of discharge is within 15 % of the

acceptablepercentageerror.Thetypicalvalueofcoefficientofdischargeis0.65(Douglas JF et al.,

2005).Therefore,ourresultiswithinthelimits.

Theorysuggestedthatthelineshouldpassthroughzerowhileinoursituationthiswasnotthecase.

TheQ-interceptwas0.0024x10-3m3/s.Thiserrormighthaveoccurredduetolossesinfrictionand

theconstantvibrationofthewaterduetothepump.

Thefollowingexperimentalerrorscouldhavecausedthedifferenceincoefficientofdischarge:

Vibrationandfrictionintheapparatusduetothepump

Errorinthemeasurementoftime(humanreactiontime).

Parallaxerrorwhenmeasuringtheincreaseinwaterlevelofthehopper.Also,thepositionof

thehopperandthedamageddivisionsofthescalealsomadeitdifficulttotakethereadings.

Hookgaugewasloose,withthedivisionsnotclearlyvisible.Thewaterlevelover the weir

wasnotconstantduringsomemeasurements

Andalsothetimeintervalrecordedwastooshort.

Suggestionstoimprovethepractical:

Thetimebeingmeasuredshouldbeenoughlargetocompensateforhumanreactiontime.So,

thelargestpossible-heightofwatershouldbetimedfor.Inaddition,morereadingsforthe

timetakenforeachsetupshouldberecordedandameancalculated.

Foreachsetofreadings,theflowratemustbemeasuredseveraltimesandameanshouldbe

calculatedtominimiseerrors.

Theexperimentshouldbecarriedoutwithanon-defectivehookgauge.

11|P a g e

V-notch Practical Student ID: 1410441

WemustletthewaterwellstabilisebeforetakingthewaterPressureheadreadings.

Thechannelinnerwallscanbecoatedwithcarboncoatingsoastoreducefrictionand

energylosses.

8.0. Recommendations on where results can be used in engineering practice

Broad-crested weirscan beobservedin damspillwayswhere thebroadedgeisbeneaththe

watersurfaceacrosstheentirestream.

In rivers, so that the water utility company can easily measure the flow and other required

parametersfortheriver.

9.0. Health and Safety

Directcontactwiththewaterusedintheexperimentwasavoidedsinceitwasnothygienic.

Anyspillageofwaternearthepowersupplywaswipedtoavoidelectrocution.

10.0. Dissemination of knowledge

Gaugingtheflowinnaturalstreamscanneverbeprecisebecausethechannelisusuallyirregularand

soistherelationshipbetweenstageandflowrate.Naturalstreamchannelsarealsosubjecttochange

byerosionordeposition.Morereliableestimatescanbeobtainedwhentheflowispassedthrougha

section where these problems have been reduced. This could be simply smoothing the bottom and

sides of the channel, or perhaps lining it with masonry or concrete, or installing a purpose-built

structure.Thereisawidevarietyofsuchdevices,mostlysuitableforaparticularapplication.Hence,

aV-notch is usedto calculatethe flow ofthe water.The above situationhas been simulatedin the

laboratorywherethepumpwasusedto varytheflow,theV-notch wasplaced attheendofalong

rectangular metallic passage where the water falling from the V-notch was collected and the time

taken to collect it was measured. From these measurements, the flow was calculated using the

formula; Volume collected/ time taken. The theoretical flow calculated will not be the same as the

actualflowobtainedfromthisexperiment;thisiswhereacoefficientofdischargeisapplied.Itadjusts

thedifferenceswhichoccurduetofrictionlosses.

12|P a g e

V-notch Practical Student ID: 1410441

11.0. Contribution of team members

Team Member Contribution during experiment

Halkhari Collectionofwater+Timingcollectionofwater

Bhagyasha

Bheenuck Recordingthevalues+Measuringvolume+Monitoring

Anusha steadyflow

LuforDhandevi Recordingthevalues+Measuringvolume+Monitoring

steadyflow

Ramdharry Measuringvolume+Collectionofwater+emptyingthe

Bhavish measuringtank

Table 3.0. Contribution of Team Members for Experiment

12.0. Conclusion

Asperthecalculations,theexperimentproducedavalueofcoefficientofdischargeof0.583

withadegreeofuncertaintyof10.28%.Hence,theresultscanbeconsideredassatisfactory

andreliable.Toconclude,theaimsandobjectivesofthispracticalhavebeenachieved

successfully.

13.0. References

1. DouglasJF,GasiorekJM,SwaffieldJA,JackLB(2005).Fluid Mechanics, Fifth edition,Pearson

PublicationLimited,England.

2. https://www.scribd.com/doc/39520118/Flow-Over-Weirs[accessedon24.11.15]

13|P a g e

Вам также может понравиться

- LAB REPORT - Discharge Over WeirsДокумент9 страницLAB REPORT - Discharge Over WeirsLuli LolОценок пока нет

- V-Notch ExperimentДокумент5 страницV-Notch ExperimentKheshav Jhundoo100% (2)

- Fluid Mechanics Lab Experiment 2Документ8 страницFluid Mechanics Lab Experiment 2SSShakeelОценок пока нет

- Final Experiment HydraulicsДокумент12 страницFinal Experiment HydraulicsKevin OngjuncoОценок пока нет

- Lab7-Phelton Turbine Experiment-UpdatedДокумент7 страницLab7-Phelton Turbine Experiment-Updatedtomtoms92Оценок пока нет

- Theory VenturiДокумент7 страницTheory VenturiMahendranath RamakrishnanОценок пока нет

- 5 Calibration of Triangular NotchДокумент8 страниц5 Calibration of Triangular Notchkanavan monОценок пока нет

- Open Channel LabДокумент27 страницOpen Channel Labஅருண்ராஜ் கிருஷ்ணன்சாமிОценок пока нет

- Lab Report 2Документ16 страницLab Report 2Limmy Yingran0% (1)

- Lab - #5. - Hydraulic JumpДокумент6 страницLab - #5. - Hydraulic JumpCarlos J. SantacruzОценок пока нет

- Venturimeter ExperimentДокумент9 страницVenturimeter ExperimentcoutohahaОценок пока нет

- Swinburne University of Technology: School of Engineering (Sarawak Campus)Документ19 страницSwinburne University of Technology: School of Engineering (Sarawak Campus)Mahfuzah MustaphaОценок пока нет

- Pelton Wheel TurbineДокумент8 страницPelton Wheel TurbineSiew LynОценок пока нет

- University of Mauritius: Faculty of Engineering Mechanical & Production Engineering DepartmentДокумент17 страницUniversity of Mauritius: Faculty of Engineering Mechanical & Production Engineering Departmenthansley100% (1)

- Hydraulic Laboratory Civil Engineering Department Sultan Azlan Shah PolytechnicДокумент12 страницHydraulic Laboratory Civil Engineering Department Sultan Azlan Shah PolytechnicSyafiq Roslan75% (4)

- Venturi Meter Experiment ProceduresДокумент2 страницыVenturi Meter Experiment ProceduresAnonymous mRBbdopMKf100% (1)

- EXP 5 - Study of Hydraulic Jump in A Rectangular ChannelДокумент9 страницEXP 5 - Study of Hydraulic Jump in A Rectangular Channelsiva ramОценок пока нет

- Impact of JetДокумент5 страницImpact of Jetميسرة33% (3)

- Hydraulic Jump LabДокумент24 страницыHydraulic Jump Labbwu333Оценок пока нет

- Centre of Hidrostatic PressureДокумент16 страницCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Experiment 4 - Broad Crested WeirДокумент3 страницыExperiment 4 - Broad Crested Weirbomtozor50% (2)

- Orifice and Free Jet Flow: University of NebraskaДокумент8 страницOrifice and Free Jet Flow: University of NebraskaJemuel Flores100% (1)

- Lab Soil-Hydrometer TestДокумент6 страницLab Soil-Hydrometer TestSyed Zulfaizzuan AljufriОценок пока нет

- Flow Over WeirsДокумент12 страницFlow Over WeirsItemogeng Bernatt Babe100% (1)

- Impact of A Water JetДокумент5 страницImpact of A Water JetAnirban SardarОценок пока нет

- Venturimeter 28Документ10 страницVenturimeter 28Agyeman EmmanuelОценок пока нет

- CE 2020 - Fluid Mechanics LaboratoryДокумент67 страницCE 2020 - Fluid Mechanics LaboratoryMd.Tarequl IslamОценок пока нет

- Impact of JetДокумент7 страницImpact of JetHeng Xiu KohОценок пока нет

- Report Hydraulic JumpsДокумент11 страницReport Hydraulic JumpsMayLeongОценок пока нет

- Flow in Open ChannelДокумент24 страницыFlow in Open ChannelSue IlaОценок пока нет

- Material LaboratoryДокумент14 страницMaterial LaboratoryAnonymous tLXKwTОценок пока нет

- Orifice and Free Jet Flow Experiment: Updated 8/9/06Документ3 страницыOrifice and Free Jet Flow Experiment: Updated 8/9/06shaneshaneshaneshaneОценок пока нет

- Additional Flow Over Crump WeirДокумент8 страницAdditional Flow Over Crump WeirnaeemОценок пока нет

- Lab-2: Flow Over A Weir Objectives: Water Resources Engineering Jagadish Torlapati, PHD Spring 2017Документ4 страницыLab-2: Flow Over A Weir Objectives: Water Resources Engineering Jagadish Torlapati, PHD Spring 2017Katy PerryОценок пока нет

- Energy Losses in Pipes: Experiment # 4Документ4 страницыEnergy Losses in Pipes: Experiment # 4محمد جوادОценок пока нет

- Lab 2 Mini FLow ChannelДокумент16 страницLab 2 Mini FLow ChannelIr Fik TОценок пока нет

- Hydraulics Lab AnalysisДокумент45 страницHydraulics Lab AnalysisjosephОценок пока нет

- Pipe FrictionДокумент4 страницыPipe FrictionShubham ChauhanОценок пока нет

- Pelton Turbine LabДокумент12 страницPelton Turbine LablufimanОценок пока нет

- Mechanics of Fluids Lab Impact of A JetДокумент10 страницMechanics of Fluids Lab Impact of A JetpatrickNX942088% (17)

- Broad Crested Weir Exp. ManualДокумент5 страницBroad Crested Weir Exp. Manualsonalsinghal171181Оценок пока нет

- 1 Rectangular NotchДокумент4 страницы1 Rectangular NotchAshlin Augusty80% (5)

- Duhok Polytechnic University Technical College of Engineering Petrochemical Department Transport Phenomena Fourth Year-2018-2019Документ10 страницDuhok Polytechnic University Technical College of Engineering Petrochemical Department Transport Phenomena Fourth Year-2018-2019Bryar XalilОценок пока нет

- Hydraulics JumpДокумент10 страницHydraulics JumpIkhwan Z.100% (2)

- FULL REPORT Flow Over WeirДокумент18 страницFULL REPORT Flow Over WeirShahrul Ikram0% (1)

- Fluid Mechanics Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, UttarakhandДокумент29 страницFluid Mechanics Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, Uttarakhandvihangam yoga chandauli100% (1)

- V NotchДокумент2 страницыV NotchUstaziyatul AlamОценок пока нет

- Bioproduct Facility Design Lab: Faculty of Engineering Technology Department of Chemical Engineering TechnologyДокумент18 страницBioproduct Facility Design Lab: Faculty of Engineering Technology Department of Chemical Engineering TechnologyAswini Purushothanan0% (1)

- LAB SHEET For Pelton Wheel 21 Sept 2011Документ3 страницыLAB SHEET For Pelton Wheel 21 Sept 2011Mohd FazliОценок пока нет

- Rectagular WeirДокумент19 страницRectagular WeirJeffОценок пока нет

- InstrruДокумент27 страницInstrrumagnifcoОценок пока нет

- Physical Chemistry Final ReportsДокумент13 страницPhysical Chemistry Final ReportsRheanneОценок пока нет

- EXPT No. 2 Bernoullis EuationДокумент12 страницEXPT No. 2 Bernoullis EuationLowEnd GamerОценок пока нет

- Lab Session 03 UptadeДокумент7 страницLab Session 03 UptadeAbdullah SahirОценок пока нет

- Hydraulics PBL Group 5 - 061021Документ12 страницHydraulics PBL Group 5 - 061021CE 19 Kaushlendra KumarОценок пока нет

- 003Документ13 страниц003NSBMRОценок пока нет

- Department of Mechanical and Industrial TechnologyДокумент20 страницDepartment of Mechanical and Industrial TechnologyMPHILWENHLE JELEОценок пока нет

- Exp1 - Fluid Friction New DMCFДокумент6 страницExp1 - Fluid Friction New DMCFSri Haaran RameshОценок пока нет

- Laporan Praktikum Mekflud SisiДокумент9 страницLaporan Praktikum Mekflud SisiKia FajarОценок пока нет

- Visual Inspection of TimberДокумент1 страницаVisual Inspection of TimberAnushaBheenuckОценок пока нет

- Fluids Past Papers PDFДокумент65 страницFluids Past Papers PDFAnushaBheenuckОценок пока нет

- Experiment Shearing ForcesДокумент17 страницExperiment Shearing ForcesAnushaBheenuck73% (11)

- Beam Reaction Experiment Group 2Документ22 страницыBeam Reaction Experiment Group 2AnushaBheenuck100% (1)

- Fill in The Table by Determining The Functions of The Following ItemsДокумент6 страницFill in The Table by Determining The Functions of The Following ItemsJessabel CandidatoОценок пока нет

- Staff Code Subject Code Subject Data FromДокумент36 страницStaff Code Subject Code Subject Data FromPooja PathakОценок пока нет

- Chapter 4: Palm Oil and Oleochemical Industries.: Presented By: Lovelyna Eva Nur Aniqah Siti MaryamДокумент15 страницChapter 4: Palm Oil and Oleochemical Industries.: Presented By: Lovelyna Eva Nur Aniqah Siti MaryamdaabgchiОценок пока нет

- Reservoir Rock PropertiesДокумент148 страницReservoir Rock Propertiesiscribdusername100% (7)

- 7 Stages of NafsДокумент7 страниц7 Stages of NafsLilyОценок пока нет

- Acc05 SCG116Документ42 страницыAcc05 SCG116Hilal HazaaОценок пока нет

- TamasДокумент180 страницTamaslike 2Оценок пока нет

- MPI Report 009 Sub Structure B668Документ1 страницаMPI Report 009 Sub Structure B668John DolanОценок пока нет

- Q3 Module 15Документ33 страницыQ3 Module 15jovielyn kathley manaloОценок пока нет

- 33 SriSriTadepalliShastryGaru 1Документ4 страницы33 SriSriTadepalliShastryGaru 1Kiran GopalanОценок пока нет

- 02K inДокумент1 страница02K inAbbode HoraniОценок пока нет

- Anish Pandey ResumeДокумент4 страницыAnish Pandey ResumeAnubhav ChaturvediОценок пока нет

- Gastritis: Department of Gastroenterology General Hospital of Ningxia Medical University Si Cen MDДокумент82 страницыGastritis: Department of Gastroenterology General Hospital of Ningxia Medical University Si Cen MDAvi Themessy100% (1)

- Sander Protein SkimmersДокумент18 страницSander Protein Skimmerslleimicojon100% (1)

- Website Catalog MOTORS v2 PDFДокумент8 страницWebsite Catalog MOTORS v2 PDFИгорь КернякевичОценок пока нет

- Pahlavi PoemДокумент9 страницPahlavi PoemBatsuren BarangasОценок пока нет

- Infineon IRFZ44N DataSheet v01 - 01 ENДокумент9 страницInfineon IRFZ44N DataSheet v01 - 01 ENIkram RidhoОценок пока нет

- 300 20Документ3 страницы300 20Christian JohnsonОценок пока нет

- EASL 2021 Version 4 NewДокумент691 страницаEASL 2021 Version 4 NewGupse Köroğlu AdalıОценок пока нет

- Samsung Bd-p4600 SMДокумент101 страницаSamsung Bd-p4600 SMIonel CociasОценок пока нет

- The Seventh House in AstrologyДокумент6 страницThe Seventh House in Astrologytratak100% (1)

- Pigging Training Course Mod 7 Rev 1Документ26 страницPigging Training Course Mod 7 Rev 1Suparerk Sirivedin100% (1)

- Wind Load CompututationsДокумент31 страницаWind Load Compututationskim suarezОценок пока нет

- Chemistry - JEE Main 2024 January - Detailed Analysis by MathonGoДокумент3 страницыChemistry - JEE Main 2024 January - Detailed Analysis by MathonGoGulam Naziruddin Makandar (NuTHeaD94)Оценок пока нет

- BFE II ScenariosДокумент25 страницBFE II Scenarioselmitxel100% (1)

- DA-42 Performance Calculator v2.3.1Документ23 страницыDA-42 Performance Calculator v2.3.1DodgeHemi1Оценок пока нет

- Mohd Mopti Bin Yassin V Lembaga Kemajuan Perusahaan Pertanian Negeri Pahang (LKPP) Corp SDN BHD & AnorДокумент12 страницMohd Mopti Bin Yassin V Lembaga Kemajuan Perusahaan Pertanian Negeri Pahang (LKPP) Corp SDN BHD & AnorA random humanОценок пока нет

- Ruger MKIIДокумент1 страницаRuger MKIIMike Pape100% (1)

- A General Strategy For The Synthesis of Reduced Graphene Oxide-Based CompositesДокумент8 страницA General Strategy For The Synthesis of Reduced Graphene Oxide-Based CompositesCristian Gonzáles OlórteguiОценок пока нет

- Eurolite Led TMH 7 PDFДокумент2 страницыEurolite Led TMH 7 PDFSarahОценок пока нет